The food manufacturing industry is experiencing a surge in demand for efficient, high-quality production systems, with energy bar lines emerging as a cornerstone for meeting consumer needs. As health-conscious trends drive the popularity of nutrient-dense snacks, these automated lines are revolutionizing how manufacturers balance speed, consistency, and product versatility. Their integration into modern facilities highlights the sector’s shift toward scalable and hygienic processing solutions.

Precision Engineering for Consistent Output

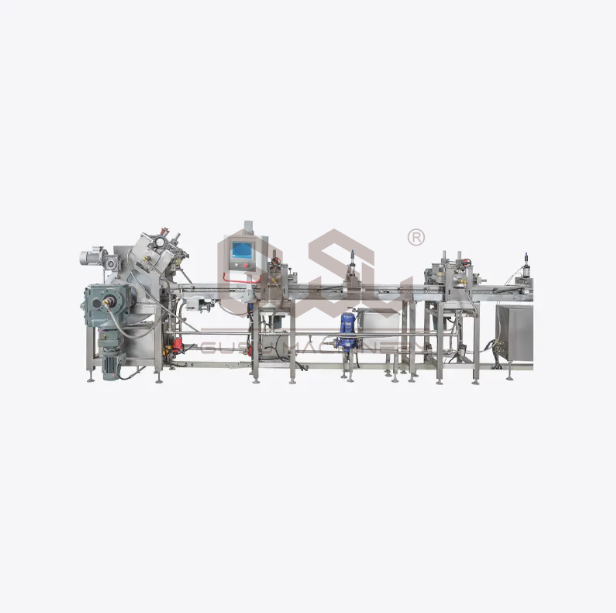

Modern energy bar production relies on advanced engineering to ensure uniformity in texture, weight, and ingredient distribution. Automated mixing, shaping, and packaging modules minimize human intervention, reducing contamination risks while maintaining strict adherence to food safety protocols. Innovations such as adjustable molding mechanisms and real-time quality monitoring enable manufacturers to swiftly adapt to varying recipes, catering to diverse dietary preferences without compromising throughput.

Meeting Evolving Consumer Demands

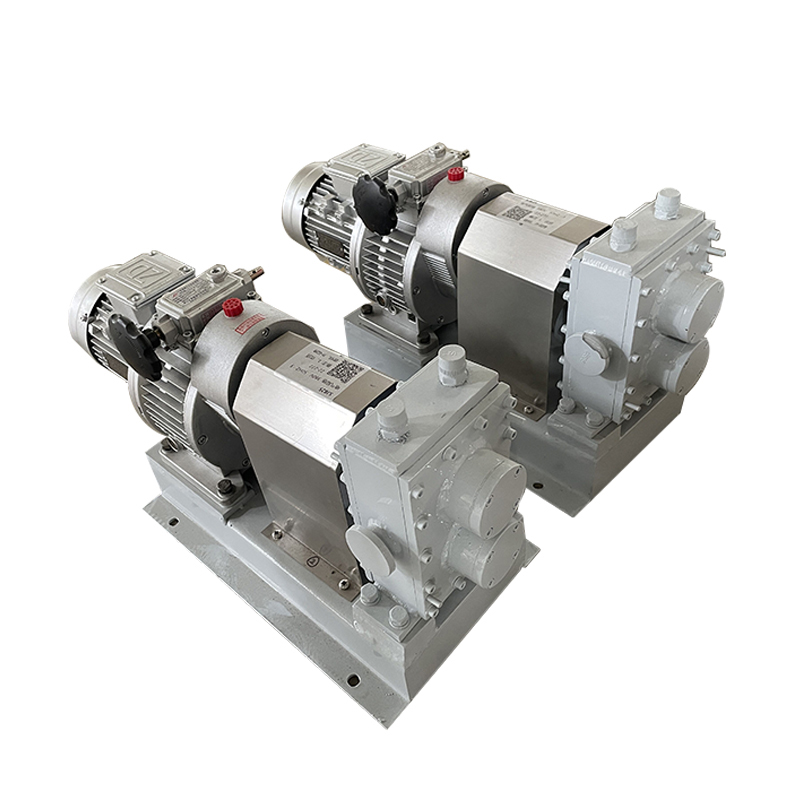

Today’s consumers prioritize transparency and sustainability, prompting manufacturers to refine production processes. Energy bar lines now incorporate features like clean-in-place systems and energy-efficient motors to align with eco-friendly practices. Additionally, modular designs allow facilities to integrate organic or plant-based ingredient handling seamlessly, supporting brands aiming to capitalize on niche markets. This adaptability ensures manufacturers remain competitive in a rapidly changing landscape.

Enhancing Operational Flexibility

The ability to produce multiple product formats—such as chewy, crunchy, or layered bars—on a single line is reshaping production strategies. Quick-change tooling and programmable controls enable manufacturers to switch between recipes with minimal downtime, optimizing resource utilization. Such flexibility is particularly valuable for companies managing seasonal launches or limited-edition products, ensuring agility in responding to market trends.

Sustainability in Focus

As environmental regulations tighten, energy bar line manufacturers are prioritizing resource efficiency. Innovations include reduced water consumption during cleaning cycles and recyclable packaging integration within production workflows. By minimizing waste and energy use, these advancements not lower operational costs but also align with global sustainability goals, appealing to eco-conscious stakeholders across the supply chain.

The Rise of Smart Manufacturing

Integration of IoT-enabled sensors and data analytics is transforming energy bar production into a predictive and preventive process. Real-time monitoring of equipment performance helps identify potential issues before they disrupt operations, while data-driven insights optimize ingredient usage and reduce overproduction. This shift toward smart factories enhances traceability, allowing brands to assure consumers of product quality and ethical sourcing.

Future Prospects

Looking ahead, the convergence of automation and artificial intelligence is expected to further elevate energy bar production. Technologies like machine learning for recipe optimization and robotics for precision handling could redefine efficiency benchmarks. Moreover, as plant-based and functional ingredients gain traction, production lines capable of processing novel raw materials will become indispensable. For manufacturers, investing in adaptable, future-ready systems will be key to sustaining growth in a dynamic market.

By combining technological innovation with sustainability-driven design, modern energy bar lines are setting new benchmarks for the food industry—empowering brands to deliver quality, variety, and accountability in every product.

English

English Español

Español