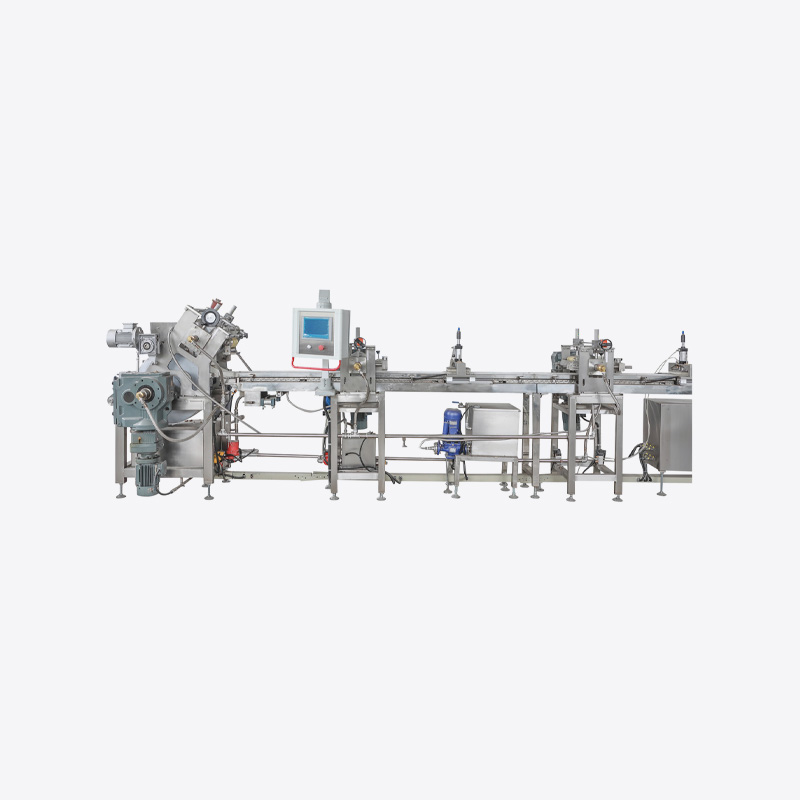

How Chocolate Chips Machines Shape Efficient and Consistent Production

In a chocolate production facility, machines are not just equipment; they set the rhythm of operations, influence product quality, and affect the daily workflow of operators. Among these, chocolate chips machines are particularly critical. They directly determine how well chocolate flows, how chips are formed, and how the line adapts to recipe variations. While purchasing decisions often start with technical specs and budgets, experienced operators and plant managers know that the real impact emerges from day-to-day operation, maintenance practices, and the flexibility of the line.

Choosing the right machine involves more than checking dimensions or throughput. The factory's workflow, ingredient behavior, operator interaction, and maintenance schedule all play roles. Observing real conditions, involving staff in decisions, and planning for variations often results in smoother operation, less waste, and more consistent chocolate chips than what initial specifications alone can promise.

Understanding the Importance of Consistency

Chocolate chips may seem simple, but their uniformity affects every step downstream—packaging, quality control, storage, and customer perception. Even minor deviations in size or shape can create issues.

Ingredient behavior

Chocolate reacts to humidity, temperature, and slight changes in formulation. High humidity, for example, can make chocolate sticky, causing chips to clump together. Machines with adjustable temperature control and feed mechanisms help operators maintain consistent output even in fluctuating conditions.

Operator adjustments

Experienced staff quickly learn how to fine-tune feed rates, cutting speeds, and blade angles. On humid days, they might reduce speed slightly; on colder days, they might adjust feed pressure. These small interventions prevent waste and ensure the chips remain uniform.

Monitoring real-time output

Operators usually inspect chocolate immediately after forming and again after cooling. Observations include shape, size, and surface finish. These quick checks allow small corrections before any batch leaves the forming section, preventing quality issues downstream.

Human oversight is essential

Automation assists but does not replace judgment. Operators notice subtle changes that sensors cannot detect, such as slight stickiness or irregular thickness, and make corrections that preserve product quality.

Optimizing Workflow for Efficiency

A chocolate chips machine alone cannot guarantee efficiency; it is the integration with the entire production line that matters.

Reducing unnecessary handling

In many factories, raw chocolate is transported manually between mixers, tempering machines, and the forming machine. Each manual transfer introduces delays and opportunities for inconsistency. Aligning machines to allow direct transfer reduces downtime and helps maintain flow.

Layout planning

Placement relative to conveyors, cooling tunnels, and packaging equipment significantly affects efficiency. Smooth material flow minimizes operator travel and prevents bottlenecks.

Integration with upstream and downstream equipment

Chocolate must arrive at the forming machine at the right temperature and viscosity. Machines that align well with melting, tempering, or coating stations maintain uniform chip formation and minimize variations.

Operator feedback

Staff often notice small but important interruptions, such as a partially clogged feed chute or uneven flow from a hopper. Acting on these observations prevents repeated stoppages and improves overall throughput.

Reducing Waste and Maximizing Yield

Minimizing scrap and maximizing usable chocolate are key objectives.

Consistent forming

Uneven feeding or misaligned blades can create broken or irregular chips. Machines with adjustable cutting mechanisms help operators produce chips of uniform size, reducing waste.

Environmental control

Temperature and humidity directly affect chocolate behavior. Machines that maintain steady conditions reduce sticking, cracking, or over-hardening.

Adjustments during production

Minor tweaks to speed, blade angles, or feed intervals can prevent problems from escalating. Operators often rely on their experience to make these micro-adjustments, improving yield without stopping the line.

Easily replaceable parts

Blades, belts, and other wear components should be simple to swap. Fast maintenance reduces downtime and prevents production inconsistencies.

Team expertise

Experienced staff can anticipate seasonal or recipe-based changes. Adjustments for higher humidity in summer or thicker chocolate batches in winter are examples of proactive problem solving.

Maintenance Practices that Protect Performance

Routine maintenance is essential to sustain output and quality.

Daily cleaning

Chocolate can accumulate in hoppers, feeding systems, and cutting components. Cleaning prevents sticking, contamination, and unexpected stoppages.

Scheduled inspections

Bearings, belts, blades, and other moving parts require regular checks. Identifying wear early prevents more serious failures.

Operator involvement

Trained staff who understand machine behavior can spot deviations early, reducing emergency downtime.

Lubrication and replacement

Following the manufacturer's guidance for lubricants and replacing worn parts ensures smooth operation and consistent chip formation.

Documentation

Recording maintenance activities, cleaning, and minor adjustments allows the team to track recurring issues and identify areas for improvement.

Supporting Flexibility and Product Development

Factories need machines that accommodate new products and variations.

Adjustable feed and cutting

Machines that allow changes in chip size, shape, or feed speed make recipe trials possible without halting the main line.

Planning for seasonal demand

Flexible machines help adjust quickly to seasonal variations in product demand without causing delays or downtime.

Trial production

Small batches allow operators to test new ingredients or recipes safely, adjusting machine settings as necessary before full-scale production.

Supplier collaboration

Technical support, spare parts, and guidance help implement product changes with minimal disruption.

Operational Efficiency Beyond the Machine

Efficiency involves the wider system, not just the equipment.

Workflow alignment

Operators and materials should move logically through the factory. Efficient routing reduces fatigue and errors.

Ergonomics

Machines with accessible controls, cleanable surfaces, and intuitive operation reduce operator strain and improve morale.

Energy and resource management

Machines that use electricity, water, and compressed air efficiently contribute to lower operational costs.

Expansion planning

Modular design and spare capacity allow incremental growth, helping factories scale without major reconstruction.

Data-driven improvement

Recording production metrics like downtime, waste, and output helps managers make informed operational adjustments.

Real-Life Observations from Factory Floors

From daily experience:

- Humidity and temperature: Chips stick more in humid conditions. Operators adjust feed and temperature to keep flow smooth.

- High-volume runs: Monitoring the cutting mechanism prevents broken or irregular chips.

- Recipe variations: Adjusting belt speed or blade timing reduces scrap for new flavors or coatings.

- Operator insights: Small bottlenecks, misaligned hoppers, or access issues can be resolved before affecting production.

These observations illustrate that real efficiency comes from combining machine capability with human judgment.

Chocolate chips machines influence efficiency, consistency, and flexibility far beyond what specifications suggest. Their effect is most visible in how smoothly the line operates, how predictable output becomes, and how confident operators feel managing daily variations.

Factories that involve operators, monitor ingredient behavior, and plan for flexibility achieve more consistent chocolate chips, lower waste, and predictable production. Over time, this approach supports new product development, line expansion, and sustainable operation. Choosing a machine is not merely an equipment decision—it is a long-term investment in workflow stability and production quality.

English

English Español

Español