1. Understanding the Role of Temperature in Chocolate Coating

Temperature control is one of the most critical factors in chocolate coating operations. The texture, gloss, and mouthfeel of chocolate are all influenced by how well it is tempered and maintained during production. When chocolate is overheated, it can lose its crystalline structure, resulting in a dull finish or grainy texture. On the other hand, chocolate that cools too quickly may not adhere properly to the product being coated, leading to uneven coverage.

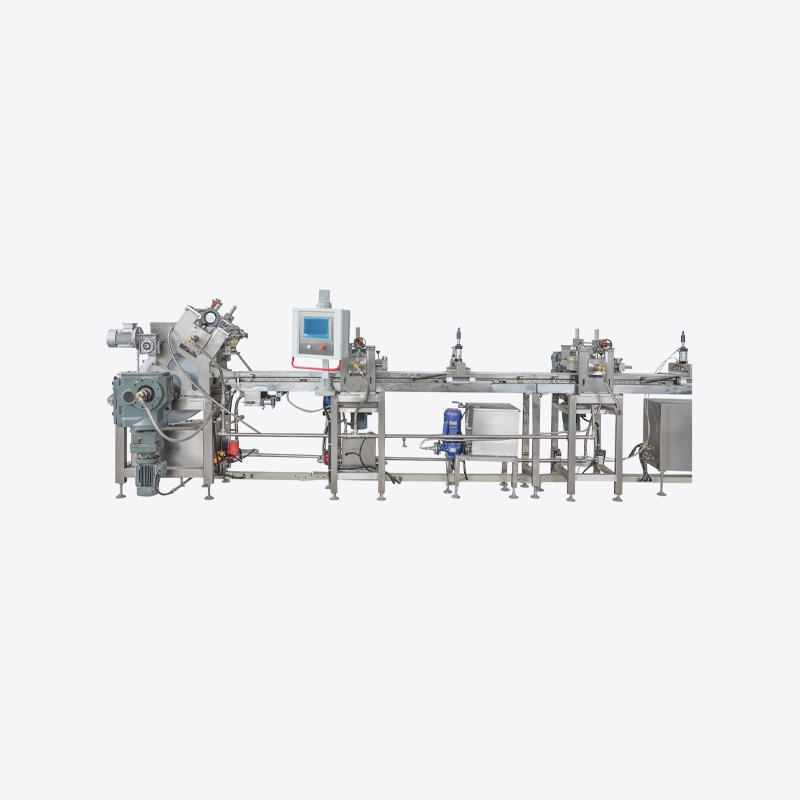

This is where modern chocolate coating machines come in. Many of them feature integrated systems that automatically regulate temperature throughout the coating process. These systems ensure that chocolate maintains the right fluidity and consistency, enabling uniform coating and professional-quality results.

2. Can Chocolate Coating Machines Automatically Control Temperature?

Yes, many advanced chocolate coating machines are equipped with automatic temperature control systems. These machines use digital sensors and thermostatic regulators to continuously monitor and adjust the chocolate’s temperature. By maintaining an optimal range—typically between 30°C and 34°C—the machine ensures that the chocolate remains in its tempered state throughout production.

Automatic temperature control provides several advantages. It minimizes human error, reduces waste, and maintains consistent product quality. This technology is particularly valuable in commercial environments where large-scale production demands both precision and efficiency.

How Automatic Temperature Control Works

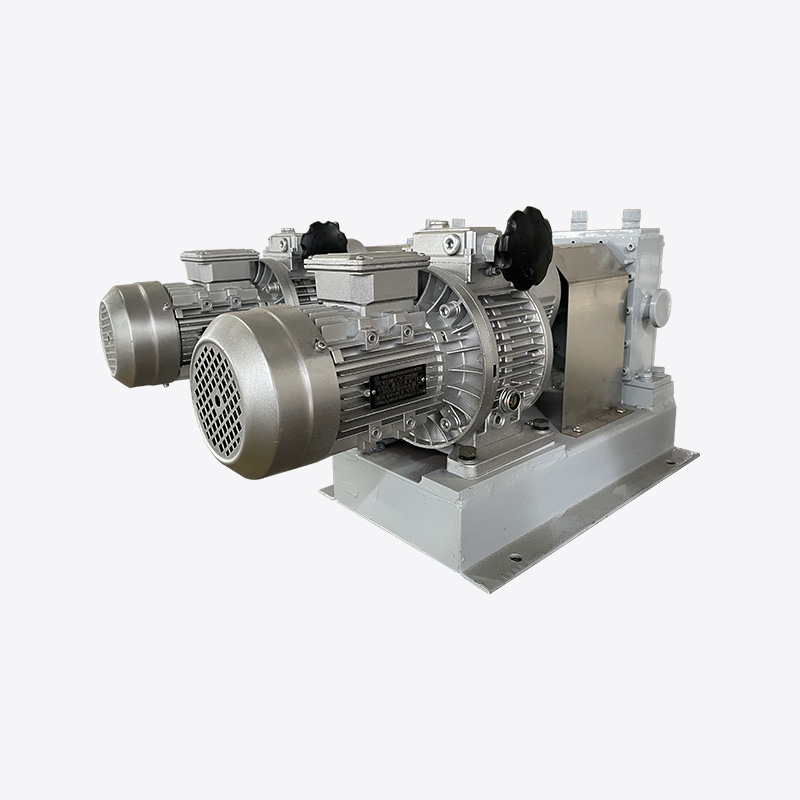

The system relies on a combination of heating elements, temperature probes, and control software. The heating elements warm the chocolate mixture, while sensors measure the exact temperature in real time. When the temperature deviates from the set value, the system automatically increases or decreases heat output to restore balance. Some models also include a cooling mechanism that uses circulating air or water to prevent overheating.

3. Key Benefits of Automatic Temperature Control

Automatic temperature control systems in chocolate coating machines offer multiple advantages, both for industrial and artisanal applications:

- Ensures consistent coating thickness and shine

- Prevents chocolate burning or crystallization

- Reduces manual monitoring and labor costs

- Improves overall energy efficiency

- Enhances the lifespan of the machine by maintaining stable operating conditions

4. Types of Chocolate Coating Machines with Temperature Control

Different models of chocolate coating machines offer various temperature control capabilities depending on their design and intended use. Below is a comparison of common machine types:

| Machine Type | Temperature Control Feature | Common Application |

| Manual Coating Machine | Basic thermostat; manual adjustment | Small-scale artisan production |

| Semi-Automatic Coating Machine | Digital temperature control with monitoring display | Medium-scale confectionery production |

| Fully Automatic Coating Machine | Integrated smart control with sensors and adaptive heating | Large-scale industrial production |

5. Common Challenges and Solutions in Temperature Management

Even with automatic systems, temperature management can face challenges. Environmental temperature changes, inconsistent chocolate batches, or poor insulation can affect stability. To maintain efficiency, operators should:

- Regularly calibrate sensors and thermostats

- Ensure proper ventilation to prevent overheating

- Use high-quality chocolate with uniform melting characteristics

- Clean heating elements to prevent residue buildup

Following these practices ensures the machine maintains accurate temperature readings and provides consistent coating performance over time.

6. Maintenance Tips for Temperature-Controlled Chocolate Coating Machines

Proper maintenance extends the life of your chocolate coating machine and helps retain temperature accuracy. Below are key maintenance recommendations:

- Clean all components after each use to remove residual chocolate and prevent buildup.

- Inspect wiring and sensors regularly for wear or corrosion.

- Avoid exposure to excessive moisture to protect the heating system.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Schedule periodic professional servicing to ensure calibration accuracy.

7. Conclusion: Consistent Quality Through Smart Temperature Control

To sum up, the ability of a chocolate coating machine to automatically control temperature plays a pivotal role in the final product’s quality. From glossy coatings to even textures, precision heating ensures that chocolate maintains the perfect viscosity and adhesion properties. Investing in a machine with intelligent temperature control not only boosts production efficiency but also delivers superior results in every batch. Whether for artisanal chocolatiers or large-scale manufacturers, this technology ensures consistent performance and professional-quality coatings every time.

English

English Español

Español