In the chocolate production industry, achieving consistent quality and operational efficiency requires both advanced equipment and skilled personnel. The chocolate coating machine plays a pivotal role in ensuring products meet high standards, but its performance ultimately depends on operator expertise.

This guide presents a structured training framework to equip your team with the knowledge and skills needed to operate chocolate coating machines efficiently, minimize waste, and maintain optimal production quality.

The Importance of Effective Training

Investing in comprehensive staff training yields significant benefits:

- Enhanced productivitythrough optimized machine operation

- Improved product consistencywith uniform coating applications

- Reduced material wastefrom proper chocolate viscosity control

- Increased equipment longevitythrough correct handling and maintenance

- Strengthened safety compliancewith standardized operating procedures

Key Machine Components and Functions

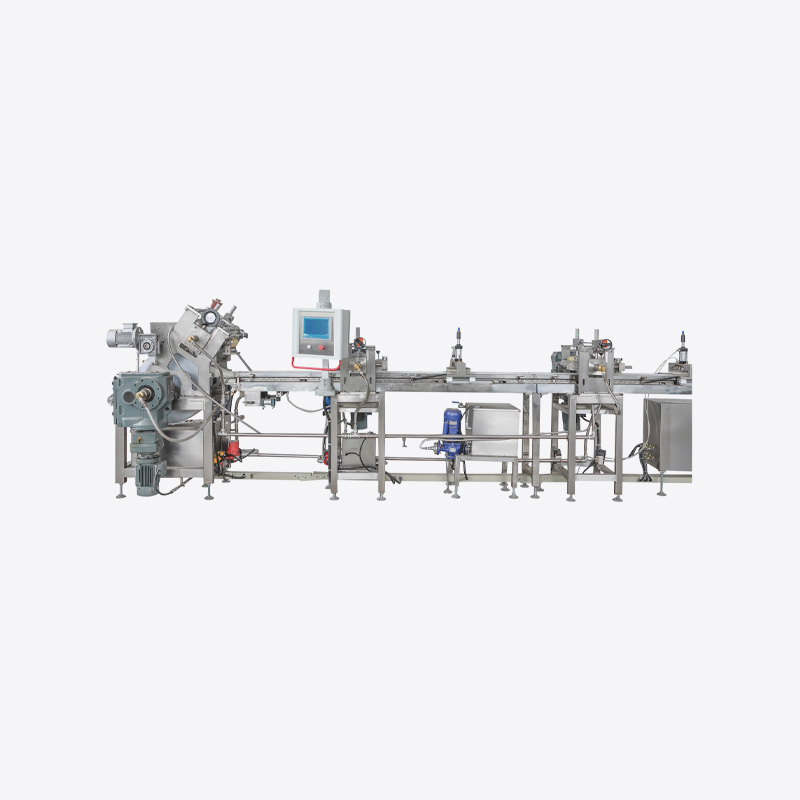

A thorough understanding of the chocolate coating machine's structure is essential before operational training begins. The main components include:

|

Component |

Primary Function |

|

Coating drum |

Ensures even distribution of chocolate |

|

Heating system |

Maintains optimal chocolate temperature |

|

Cooling section |

Rapidly solidifies coated products |

|

Spray mechanism |

Applies chocolate with precision |

|

Automatic feed system |

Regulates product input flow |

|

Discharge controls |

Manages output of finished items |

Operators who understand these components can better monitor performance and identify potential issues.

Structured Training Program

A phased training approach ensures systematic skill development:

|

Training Phase |

Key Objectives |

Training Methods |

|

1. Machine Fundamentals |

- Component identification |

- Instructor-led demonstrations |

|

2. Operational Training |

- Temperature control |

- Hands-on practice |

|

3. Coating Optimization |

- Layer thickness control |

- Sample production batches |

|

4. Maintenance Procedures |

- Daily cleaning |

- Disassembly/reassembly practice |

|

5. Advanced Troubleshooting |

- Error code interpretation |

- Scenario simulations |

Best Practices for Optimal Performance

To maximize machine efficiency, operators should:

- Maintain precise temperature controlto ensure proper chocolate viscosity

- Calibrate feed ratesto prevent overloading and ensure consistent coating

- Conduct regular equipment inspectionsto identify wear or alignment issues

- Implement strict hygiene protocolsto meet food safety standards

- Document operational parametersfor repeatable quality results

Sustaining Operational Excellence

To maintain high performance levels:

- Schedule quarterly refresher training sessions

- Implement a tiered certification program for skill validation

- Establish a mentorship system for knowledge transfer

- Analyze production data to identify training opportunities

- Encourage cross-training between production lines

By combining technical knowledge with hands-on practice and continuous skill development, manufacturers can fully leverage their chocolate coating machines to achieve superior production outcomes.

At Gusumachinery, we combine precision-engineered chocolate coating machines with comprehensive training solutions to help manufacturers achieve peak production performance. Our expertise ensures your team masters every operational aspect, from basic functions to advanced troubleshooting, for maximum efficiency and product quality. Let us help you transform your chocolate coating operations - because exceptional equipment deserves exceptional operation.

English

English Español

Español