What is a Chocolate Coating Machine?

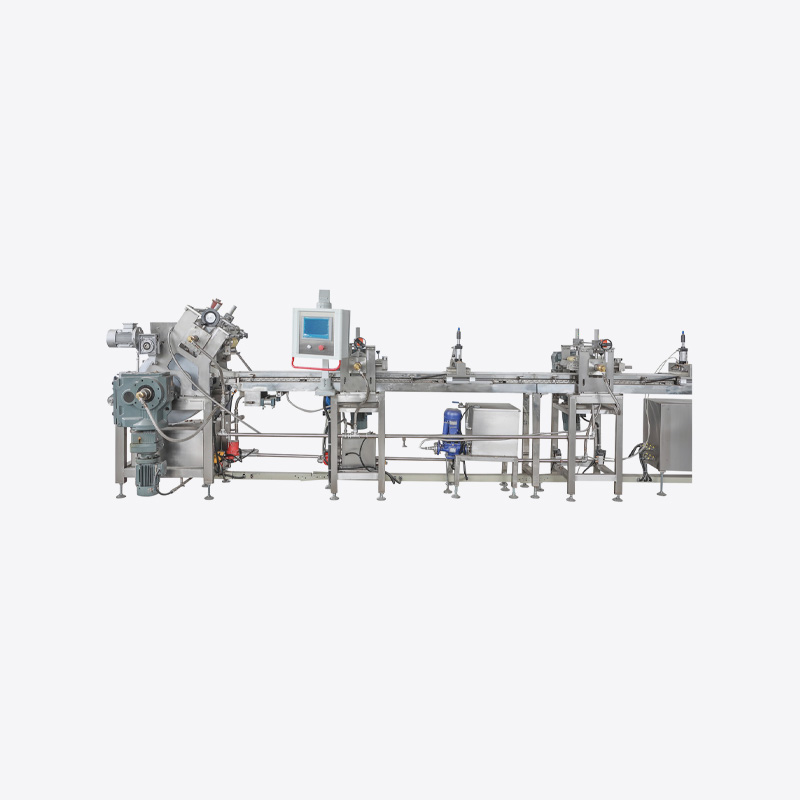

A chocolate coating machine is a specialized piece of equipment used in the confectionery industry to cover products such as candies, biscuits, snacks, and nuts with a smooth and consistent layer of chocolate. These machines play a crucial role in streamlining the chocolate coating process, offering a high degree of precision and efficiency that is difficult to achieve manually.

The process involves melting chocolate and applying it evenly onto the surface of the products. Chocolate coating machines ensure uniform thickness, smooth finishes, and consistent texture, which are essential for producing high-quality chocolate-coated goods. Whether for small-scale artisanal production or large-scale commercial operations, chocolate coating machines are designed to optimize production speed, reduce labor costs, and ensure product consistency.

Benefits of Using Chocolate Coating Machines

There are numerous benefits to using chocolate coating machines in production:

Consistency and Quality: One of the primary advantages of using a chocolate coating machine is the consistent and high-quality coating it provides. Automated machines ensure that each product is uniformly coated, with precise control over the thickness of the chocolate layer. This leads to fewer defects and more aesthetically pleasing products.

Increased Efficiency: By automating the chocolate coating process, manufacturers can significantly increase production speed and output. Machines can coat large quantities of products in a short amount of time, reducing the need for manual labor and cutting down on production time.

Cost-Effectiveness: While chocolate coating machines may require a higher initial investment, they save money in the long run by reducing labor costs and improving production efficiency. The ability to produce large volumes of consistently coated products also results in a higher return on investment (ROI).

Reduced Waste: Automated chocolate coating machines allow for better control over the amount of chocolate used, minimizing waste and ensuring that every bit of chocolate is utilized. This helps to reduce material costs and improve sustainability.

Customization and Flexibility: Many modern chocolate coating machines allow manufacturers to customize the coating process. They can adjust parameters such as the thickness of the coating, the speed of the conveyor, and the temperature of the chocolate to meet specific product requirements.

How Does a Chocolate Coating Machine Work?

The Chocolate Coating Process

The operation of a chocolate coating machine typically involves several key stages. While the exact configuration and components of the machine can vary, most machines follow a similar process. Here is a general overview of how a chocolate coating machine works:

1. Chocolate Preparation

Before coating any products, the chocolate must first be prepared. This step involves melting the chocolate to the right consistency and temperature. Chocolate coating machines often include dedicated melting tanks or heating units designed to melt and maintain the chocolate at an ideal temperature.

Melting: The chocolate is typically broken down into smaller pieces or chips, and then melted in a controlled environment. This ensures the chocolate achieves the right texture—smooth, glossy, and flowable.

Temperature Control: The temperature of the melted chocolate is closely monitored to ensure it does not overheat or become too thick, which can negatively impact the coating process.

2. The Coating Mechanism

Once the chocolate has been prepared, it is applied to the product through one of several coating techniques. The choice of technique depends on the type of chocolate coating machine being used and the shape or size of the product. Below are some common coating methods:

Dipping: In dipping machines, products such as nuts, biscuits, or candies are submerged into a pool of melted chocolate. The machine ensures that the product is completely covered by the chocolate, achieving a uniform coating.

Enrobing: In enrobing machines, a conveyor belt moves the product through a "chocolate curtain" or stream, where chocolate is poured or sprayed over the surface of the product. The product is continuously moved under this chocolate stream to ensure an even coat.

Spraying: For delicate or irregularly shaped items, such as fruit or specialty candies, a chocolate spraying machine might be used. The machine releases a fine mist of melted chocolate over the product, ensuring an even and delicate coating.

Drum Coating: In drum coating machines, products are placed inside a rotating drum where they are coated with chocolate. The rotation of the drum ensures that the product is evenly covered with chocolate as it moves through the system.

3. Cooling and Solidifying

Once the chocolate has been applied to the product, the next critical step is cooling and solidifying the coating. After coating, products typically move through a cooling tunnel where they are subjected to cool air or chilled environments. The cooling process ensures that the chocolate sets and hardens, giving it a smooth and glossy finish.

Cooling Tunnel: Cooling tunnels are specifically designed to regulate the temperature around the product, gradually cooling the chocolate layer. This process prevents the chocolate from becoming too thick or losing its shine.

Hardening: The cooling stage also ensures that the chocolate solidifies without cracking, which is crucial for the appearance and integrity of the finished product.

4. Finishing Touches

After the chocolate coating has solidified, the product may undergo additional finishing processes. These can include:

Polishing: Some chocolate-coated products are polished to give them a shiny, glossy finish. This is typically done by adding a thin layer of edible glaze or by passing the products through a polishing machine.

Decorating: In some cases, manufacturers may choose to add decorative elements, such as sprinkles, crushed nuts, or other coatings, to enhance the visual appeal and texture of the final product. These additional steps can be incorporated into the chocolate coating machine setup or done in a separate step.

Key Components of a Chocolate Coating Machine

To understand how chocolate coating machines work, it's essential to be familiar with their key components. While designs can vary, most chocolate coating machines share common elements that help facilitate the coating process:

Chocolate Melting Tank: This component ensures that the chocolate is melted and maintained at the right temperature. It also helps to maintain a consistent flow of liquid chocolate, which is essential for a smooth coating.

Conveyor Belt: The conveyor belt transports products through the coating process. The belt moves the product under the chocolate stream or dipping station and carries it through the cooling tunnel and finishing stages.

Chocolate Pump/Distribution System: This component is responsible for pumping the melted chocolate into the coating area. It ensures an even and controlled flow of chocolate, preventing both excess and insufficient coating.

Cooling Tunnel: A vital part of the machine, the cooling tunnel is where the chocolate-coated products cool and solidify. This step is essential for achieving a firm, glossy finish.

Coating Drum (Optional): In drum coating machines, the rotating drum is a critical component that ensures products are evenly coated as they tumble through the chocolate.

Factors Affecting the Chocolate Coating Process

Several factors can impact the outcome of the chocolate coating process. By controlling these variables, manufacturers can ensure a uniform and high-quality chocolate coating:

Chocolate Quality: The quality of the chocolate used directly impacts the final product. High-quality chocolate with a smooth texture and proper consistency is essential for achieving a glossy, smooth finish.

Temperature Control: The temperature of the chocolate, as well as the environment around the product, plays a significant role in the coating process. Too high or too low a temperature can result in a poor coating or compromised texture.

Speed of the Machine: The speed of the conveyor belt or coating process can also influence the thickness of the chocolate layer. Faster speeds may result in thinner coatings, while slower speeds may result in thicker coatings.

Product Type: Different products require different coating methods. For example, delicate items such as nuts may need to be coated using a gentler process (such as spraying) to avoid damage.

Why Chocolate Coating Machines Are Important in the Confectionery Industry

1. Ensuring Consistency and Quality

One of the most significant challenges in the production of chocolate-coated products is achieving consistency. In manual coating processes, variations in temperature, chocolate application, and product handling can result in uneven coatings, which impact the product’s quality, appearance, and taste. Chocolate coating machines address this issue by automating the process, ensuring that each product receives a consistent, smooth, and uniform layer of chocolate.

Uniform Coating: These machines are designed to deliver precise amounts of chocolate to products, which helps achieve a uniform coating. Whether using dipping, enrobing, or spraying methods, the machines ensure that each product is coated evenly, preventing over-coating or under-coating.

High-Quality Finish: Chocolate coating machines help maintain the glossy finish that is a hallmark of high-quality chocolate products. Automated processes also minimize defects, such as chocolate streaks, smudges, or air pockets, which can affect the product’s appearance and texture.

Consistency in Taste and Texture: By maintaining a consistent coating, these machines ensure that the chocolate layer is of the desired thickness. This consistency is crucial in delivering a product with the right taste, texture, and mouthfeel, which consumers expect from premium chocolate brands.

2. Increased Production Efficiency

Chocolate coating machines significantly improve the speed of production, enabling confectionery manufacturers to scale up their operations without sacrificing quality. The automation of the chocolate coating process speeds up production, making it possible to coat hundreds or even thousands of products per hour, far surpassing what can be achieved manually.

Time-Saving: The manual coating process can be slow and labor-intensive, requiring skilled workers to dip or pour chocolate over each individual item. With chocolate coating machines, the entire process is streamlined and faster, allowing manufacturers to meet high production demands in less time.

High Output: For large-scale manufacturers, efficiency is crucial. Chocolate coating machines enable continuous operation, reducing downtime between batches and maximizing output. This results in higher throughput and better utilization of resources.

Less Labor-Intensive: The need for manual labor is significantly reduced with chocolate coating machines. This not only reduces labor costs but also minimizes human error. The automation ensures that the products are consistently coated, allowing workers to focus on other tasks in the production process.

3. Cost Savings and Profitability

While investing in chocolate coating machines requires an initial capital expenditure, the long-term benefits outweigh the costs. These machines help businesses cut down on labor costs, reduce chocolate wastage, and increase production volume, all of which contribute to enhanced profitability.

Labor Cost Reduction: By reducing the need for manual labor, chocolate coating machines lower operational costs. Fewer workers are required to perform repetitive tasks, which helps save on wages and benefits.

Minimized Waste: Chocolate coating machines are designed to apply chocolate precisely, reducing wastage. Excess chocolate can be collected and reused, ensuring that the material is utilized efficiently and minimizing product losses during production.

Higher Return on Investment (ROI): The ability to produce larger quantities of high-quality products in a shorter amount of time improves the overall efficiency of the production line. This leads to increased sales and higher returns on investment, making the machines a worthwhile investment in the long run.

4. Meeting Consumer Demand for Variety and Customization

The confectionery industry is driven by ever-changing consumer preferences. As more consumers look for variety in their chocolate products, manufacturers need to adapt to new trends and offer a range of chocolate-coated products. Chocolate coating machines allow businesses to experiment with different types of coatings and flavors, helping them stay ahead of market trends and satisfy consumer demand.

Variety of Coatings: Chocolate coating machines can be easily adjusted to accommodate different types of coatings, such as milk chocolate, dark chocolate, white chocolate, and even specialty coatings like flavored chocolates or chocolate with inclusions (nuts, fruits, etc.). This flexibility enables manufacturers to offer a broader range of products, catering to a wide audience.

Customization: Today's consumers are increasingly seeking personalized or artisanal products. Chocolate coating machines allow manufacturers to introduce customizable coatings, including unique textures, shapes, and decorative finishes. Whether it's adding a glossy sheen, sprinkling toppings, or creating textured patterns, the machines provide the flexibility to create a wide variety of chocolate-coated products.

Speed to Market: With the ability to quickly adapt to new product types and trends, chocolate coating machines help businesses bring new products to market faster. This is essential in a competitive market where consumer preferences are constantly evolving.

5. Enhancing Hygiene and Food Safety Standards

Food safety and hygiene are critical concerns in the food manufacturing industry, particularly when it comes to confectionery products. Chocolate coating machines are designed with sanitation in mind, ensuring that the coating process meets strict hygiene standards and reduces the risk of contamination.

Automated Hygiene: Chocolate coating machines minimize human contact with the product, reducing the chances of contamination during the coating process. Automated cleaning systems also ensure that the machines remain sanitized and ready for the next batch, without the need for extensive manual cleaning.

Food Safety Compliance: Many chocolate coating machines are designed to comply with food safety regulations, ensuring that the chocolate is processed in a controlled, hygienic environment. This is especially important when producing products for large-scale distribution, where meeting food safety standards is essential.

6. Reducing Environmental Impact

With growing concerns over environmental sustainability, manufacturers are increasingly looking for ways to reduce their environmental footprint. Chocolate coating machines are helping to address these concerns by optimizing the use of resources and reducing waste.

Efficient Chocolate Usage: By applying chocolate more efficiently, these machines minimize excess waste. Excess chocolate can often be collected and reused, which reduces the need for additional chocolate and helps lower overall production costs.

Energy-Efficient Designs: Many modern chocolate coating machines are designed with energy efficiency in mind, utilizing less power to operate while maintaining high output levels. This helps manufacturers reduce their energy consumption, lower operating costs, and minimize their environmental impact.

Types of Chocolate Coating Machines: Which Type of Chocolate Coating Machine is Right for You?

1. Chocolate Enrobing Machines

Best For: Mass production of chocolate-coated products like bars, biscuits, and snack foods.

How They Work:

Chocolate enrobing machines are one of the most widely used types in the confectionery industry. The process involves a conveyor belt that moves the products through a curtain of liquid chocolate. As the products travel along the conveyor, they are coated evenly with a thin layer of chocolate. The enrobing process ensures uniform coverage and can be adjusted for thickness.

Advantages:

High Efficiency: Perfect for high-volume production with minimal human labor.

Consistency: Guarantees an even coat on all products.

Versatility: Can be used for a wide variety of chocolate-coated products.

Considerations:

Enrobing machines require a steady supply of chocolate and are best suited for larger operations that need to coat a large number of products at once. If you're dealing with irregularly shaped or delicate items, this machine may not be ideal.

2. Chocolate Dipping Machines

Best For: Smaller batch production and items like candies, nuts, or truffles.

How They Work:

In chocolate dipping machines, products are individually dipped into a pool of melted chocolate. The machine ensures that the product is fully coated, and it may be followed by a quick cooling process to harden the chocolate layer. Some dipping machines are manual, while others can be automated to handle larger batches.

Advantages:

Ideal for Smaller Batches: Best for artisans or businesses producing small quantities.

Customization: Offers more control over the chocolate thickness and coating style.

Suitable for Delicate Products: Dipping allows for a gentler coating, which is ideal for fragile items like nuts or fruits.

Considerations:

Although perfect for smaller, more delicate items, dipping machines may not be as efficient for large-scale, high-volume production. Additionally, they may require more hands-on labor compared to fully automated enrobing machines.

3. Chocolate Spraying Machines

Best For: Delicate, irregularly shaped items or products that require a fine, even coating.

How They Work:

Chocolate spraying machines work by spraying a fine mist of melted chocolate onto products, providing a thin and even coating. These machines use compressed air to spray the chocolate, ensuring that every corner of the product is covered. They are commonly used for products like fruit, nuts, or small candies where an even but delicate coating is desired.

Advantages:

Precision: Spraying creates a light, uniform coating.

Minimal Waste: The fine mist ensures that chocolate is used efficiently, reducing waste.

Perfect for Irregular Shapes: Unlike dipping or enrobing, spraying can effectively coat products with complex shapes or surfaces.

Considerations:

This method may not be suitable for large batches of standard-sized products due to its slower speed. Also, some machines may require a higher level of technical operation and setup.

4. Drum Coating Machines

Best For: Coating irregular products like nuts, dried fruits, and snack mixes.

How They Work:

Drum coating machines feature a rotating drum that moves the product as it’s coated with chocolate. The drum ensures that the products tumble while the chocolate is applied, allowing for a more thorough and even coating. This method is often used for coating bulkier products that need to be thoroughly coated on all sides.

Advantages:

Ideal for Bulk Coating: Perfect for items like nuts, seeds, and dried fruits, where a complete and even coating is necessary.

Consistent Coverage: The rotating drum ensures that the chocolate is evenly distributed.

Suitable for Large Quantities: Can handle larger batches of smaller items, making it efficient for high-output production.

Considerations:

While great for bulkier items, drum coating machines may not be suitable for delicate products due to the tumbling action. Also, they are generally slower than enrobing or dipping machines.

5. Small-Scale Chocolate Coating Machines

Best For: Artisanal producers or businesses with low to medium production volumes.

How They Work:

These machines are designed for small-scale chocolate coating operations. They are often tabletop units, smaller in size, and can handle small batches of products. Small-scale machines may include dipping systems or miniature enrobers, designed to give artisan chocolatiers the flexibility to create handcrafted chocolate products.

Advantages:

Flexible and Compact: Ideal for small operations or businesses that don’t need large machines.

Lower Cost: Smaller machines are less expensive, making them more accessible for small businesses.

Handcrafted Appeal: Provides a more artisanal and personalized touch for specialty chocolate products.

Considerations:

These machines are not suitable for mass production and may struggle with high-volume output. They also require more manual intervention and attention during the coating process.

6. Coating & Decorating Machines

Best For: Producing chocolate-coated products with additional toppings, designs, or textures.

How They Work:

Some coating machines can be combined with decorative processes, allowing manufacturers to add toppings like crushed nuts, sprinkles, or even colored patterns onto the chocolate coating. These machines may be equipped with additional features such as sprinkling stations or mechanisms to apply a shiny glaze or sugar coating.

Advantages:

Adds Variety: Perfect for introducing new textures and flavors to chocolate-coated products.

Customization: Offers the ability to create visually unique products, making them stand out in the market.

Efficient Decorating: Combining coating and decoration into one process reduces the need for additional steps or equipment.

Considerations:

These machines can be more complex, requiring specialized components for decoration. They may also have higher maintenance needs compared to standard chocolate coating machines.

Choosing the Right Chocolate Coating Machine for Your Business

When selecting a chocolate coating machine, it's important to consider several factors:

Production Scale: For large-scale operations, enrobing machines or drum coating machines are ideal. Smaller producers may prefer dipping machines or small-scale coating equipment.

Product Type: Consider the shape and delicacy of your products. Spraying machines are best for delicate items, while drum coating machines are perfect for bulkier, irregular items.

Customization Needs: If you need to add decorative elements or varied coatings, look for machines that offer customization features.

Budget and Space: Larger, more automated machines require a significant investment and more floor space. Smaller machines may offer more flexibility for businesses with limited space and lower budgets.

Summary of Chocolate Coating Machines

| Type of Machine | Best For | Advantages | Considerations |

|---|---|---|---|

| Enrobing Machines | High-volume products like bars and biscuits | High efficiency, consistency, versatility | Best for large-scale operations, less suited for delicate items |

| Dipping Machines | Small batch production (candies, nuts) | Customization, ideal for delicate products | Slower, less efficient for large-scale production |

| Spraying Machines | Irregularly shaped products | Precision, minimal waste, ideal for delicate items | Slower, not ideal for high-volume production |

| Drum Coating Machines | Bulk items like nuts and dried fruits | Even coverage, suitable for high output | Not ideal for delicate items, slower than other methods |

| Small-Scale Machines | Artisanal or low-volume production | Compact, flexible, lower cost | Not suitable for high-volume production |

| Coating & Decorating Machines | Products needing decoration (sprinkles, glaze) | Adds variety, efficient decorating process | Higher maintenance, more complex design |

Maintaining and Cleaning Chocolate Coating Machines

Why Maintenance and Cleaning Matter

Hygiene and Food Safety

Chocolate is a food product, and maintaining a clean machine is crucial for preventing contamination. Any leftover chocolate, sugar, or other ingredients can become breeding grounds for bacteria and mold, posing a risk to both the product and the consumers. Regular cleaning ensures that your machine meets the necessary food safety standards and produces hygienic, safe chocolate-coated products.

Prevention of Clogs and Downtime

Chocolate coating machines often rely on precise fluid systems to pump chocolate evenly. If chocolate or other residues are left to harden in pipes, nozzles, or other parts of the machine, it can cause blockages. These blockages can slow down production, leading to costly downtime and requiring more extensive maintenance. Regular cleaning prevents clogs and ensures smooth operation.

Extended Equipment Lifespan

Over time, the buildup of chocolate and other materials can lead to the wear and tear of machine parts. If not cleaned and maintained properly, these parts may degrade more quickly, reducing the machine's lifespan. Proper care extends the life of the equipment, saving you money on repairs or replacements in the long run.

Consistent Product Quality

Chocolate coating machines are designed to deliver precise amounts of chocolate with uniform coverage. If the machine is dirty or has chocolate residue left from previous batches, the coating may become uneven or affect the consistency of the chocolate. Regular cleaning ensures that the machine functions at its best, producing consistently high-quality products.

How to Clean and Maintain Chocolate Coating Machines

1. Daily Cleaning Routine

End of the Day Cleanup:

At the end of each production shift, it's essential to clean the machine thoroughly. This involves wiping down surfaces, removing excess chocolate from the conveyor belts, and ensuring that chocolate is cleared from all parts that come into contact with the product.

Remove Residues:

Chocolate residues can easily build up in areas like the chocolate pool, pumps, and nozzles. Use warm water and food-safe detergents to remove the buildup. For machines with a heated chocolate tank, allow the chocolate to cool before removing it to prevent burns or injury.

Clean Conveyor Belts:

Conveyor belts are exposed to chocolate, which can get sticky. Clean the belts to prevent chocolate buildup that can affect their movement and the even distribution of chocolate. A soft cloth or sponge with warm water and mild detergent works well for this task.

2. Weekly Maintenance Tasks

Disassemble and Inspect:

Once a week, or after a particularly heavy production run, disassemble parts of the machine to inspect for wear, damage, or leftover chocolate. Key parts to check include the chocolate tank, pumps, nozzles, and conveyor belt mechanisms.

Lubricate Moving Parts:

Moving parts such as gears, belts, and motors need to be lubricated to reduce friction and prevent premature wear. Be sure to use a food-grade lubricant designed for use in food production equipment.

Check for Wear and Tear:

Regularly check rubber seals, gaskets, and other critical parts for signs of wear. Replace these components promptly to prevent leaks or breakdowns during operation.

3. Monthly or Periodic Maintenance

Deep Clean:

Every month, a deep cleaning session should be carried out. This involves fully disassembling parts of the machine to clean internal components like the pumps and the chocolate reservoir. A deep clean ensures that no chocolate or other ingredients remain inside the machine, reducing the risk of contamination or clogged pipes.

Calibrate and Test the Machine:

Calibration is essential to ensure that the machine is applying chocolate at the correct thickness and consistency. This should be done periodically to maintain product quality and precision in coating. Testing the machine after cleaning is crucial to ensure that it is functioning optimally.

Inspect Electrical Components:

Electrical parts of the machine, such as motors and wiring, should be inspected monthly to ensure they are working properly. Look for signs of corrosion or damage that could lead to electrical failures. Always disconnect power before working on electrical components.

4. Troubleshooting Common Issues

Despite regular maintenance, some common issues may arise with chocolate coating machines. Below are a few troubleshooting tips to help address these challenges:

Chocolate Not Flowing Properly:

If the chocolate isn't flowing evenly or is thickening, it may be a sign that the temperature isn’t being maintained correctly, or that the machine's nozzles or pumps are clogged. Clean the machine thoroughly and ensure the chocolate is melted to the correct consistency.

Uneven Coating:

If the chocolate coating isn't consistent, check the coating system for blockages. Sometimes, chocolate residues can clog the nozzle or spraying mechanism, leading to uneven coverage. Clean and inspect the system to ensure the chocolate is being applied evenly.

Sluggish Conveyor Belt:

If the conveyor belt is moving slowly or unevenly, it could be due to a buildup of chocolate or dust. Clean the belt and lubricate the motor to ensure smooth movement.

Excessive Chocolate Build-Up:

In some cases, you may notice excessive chocolate build-up on parts of the machine. This could be due to improper settings or temperature issues. Adjust the settings to achieve the optimal flow of chocolate, and make sure all parts are regularly cleaned to prevent accumulation.

Best Practices for Maintaining and Cleaning Chocolate Coating Machines

Use Food-Safe Cleaning Products:

Always use food-safe detergents and cleaning solutions when cleaning chocolate coating machines. Non-food-safe products could contaminate the chocolate and compromise product quality.

Keep a Cleaning Schedule:

Create a cleaning schedule that outlines when each task should be performed, whether it’s daily, weekly, or monthly. A consistent routine ensures that the machine stays in top condition.

Train Operators:

Ensure that all operators are trained on how to properly clean and maintain the machine. This includes understanding the different parts of the machine, the correct cleaning techniques, and how to spot issues early.

Document Maintenance Activities:

Keep a log of all maintenance and cleaning activities performed. This will help you track the machine's condition over time and can be useful for troubleshooting or ensuring compliance with food safety regulations.

Chocolate Coating Machines in the Global Market: Trends and Demand

1. Rising Demand for Chocolate-Coated Products

The global demand for chocolate-coated products, including candies, biscuits, snacks, and desserts, has been steadily increasing. This surge in demand is attributed to several factors:

Consumer Preferences: Chocolate remains one of the most popular flavors in the confectionery industry, and consumers are increasingly seeking variety in chocolate-coated products. As a result, manufacturers are introducing new combinations of chocolate, such as dark chocolate, milk chocolate, white chocolate, and specialty flavors like caramel and hazelnut.

Health-Conscious Choices: The growing trend of health-conscious consumers has influenced the development of products that incorporate healthier chocolate alternatives, such as low-sugar or organic chocolate. This shift has prompted manufacturers to adapt their production processes, including the use of chocolate coating machines that can handle different formulations and types of chocolate.

Premium Products: Consumers are also willing to pay a premium for high-quality, artisanal, and custom-made chocolate products. As demand for premium chocolate increases, the need for specialized chocolate coating machines that deliver consistent quality and precision becomes more crucial.

2. Technological Advancements in Chocolate Coating Machines

As the chocolate coating industry evolves, so too do the machines that produce these sweet treats. Manufacturers are increasingly seeking machines that offer higher efficiency, better product quality, and greater customization. Key technological advancements include:

Automation and Smart Technologies: The integration of automation and IoT (Internet of Things) technologies has significantly enhanced the capabilities of chocolate coating machines. These technologies allow for real-time monitoring and control of the production process, ensuring that each product is coated uniformly and at optimal temperatures. Automation also reduces the need for manual labor, cutting production costs and increasing throughput.

Energy-Efficient Machines: As sustainability becomes a major concern in manufacturing, energy-efficient machines have gained popularity. Chocolate coating machines that consume less energy while maintaining high performance help reduce operating costs and improve the environmental footprint of food production facilities.

Multi-Function Machines: Manufacturers are now looking for more versatile machines that can handle multiple types of coatings and production requirements. Multi-function chocolate coating machines allow businesses to produce a variety of chocolate-coated products with minimal downtime, making them a valuable investment for manufacturers looking to diversify their product lines.

Improved Cleaning and Maintenance Features: Machines with easier-to-clean designs and self-cleaning functions have gained attention due to the need for maintaining high hygiene standards. Automated cleaning systems ensure that the machines are ready for the next batch without requiring extensive manual labor, minimizing downtime and enhancing food safety.

3. Growing Popularity of Artisanal and Small-Scale Production

While large-scale manufacturing dominates the chocolate coating market, there is a growing trend towards artisanal and small-batch production. Many consumers today seek unique, handcrafted products, and chocolatiers are meeting this demand by offering premium, small-batch chocolate-coated products. The following factors are driving this shift:

Personalization and Customization: Consumers increasingly desire personalized chocolate products, whether it’s custom chocolate bars, chocolates with unique toppings, or special seasonal flavors. Small-scale chocolate coating machines, which offer greater flexibility and control over the coating process, have become more popular among boutique chocolate makers.

Sustainability and Ethical Practices: As consumers become more environmentally conscious, they are turning to companies that prioritize sustainability. Artisanal chocolate makers often emphasize ethical sourcing, environmentally friendly packaging, and small-batch production, which aligns with the growing demand for sustainable products. Chocolate coating machines tailored for small-scale production help these businesses meet the needs of their niche markets while maintaining quality and minimizing waste.

4. Expansion in Emerging Markets

The chocolate industry is also seeing strong growth in emerging markets, particularly in regions such as Asia, Latin America, and Africa. Rising disposable incomes, urbanization, and changing consumer preferences are contributing to the increased demand for chocolate products. As these markets expand, the demand for chocolate coating machines is expected to grow as well.

Rising Middle-Class Population: In countries with rapidly growing middle-class populations, such as China and India, there is an increasing appetite for Western-style products, including chocolate confectionery. This trend is driving investment in food manufacturing equipment, including chocolate coating machines, to meet the growing demand for chocolate-coated treats.

Local Manufacturers Adapting to Trends: As local manufacturers in emerging markets recognize the potential of chocolate-coated products, they are investing in the latest chocolate coating technology to stay competitive. These manufacturers are now focusing on improving product quality and production efficiency to cater to the tastes and preferences of consumers in these regions.

5. Factors Influencing the Demand for Chocolate Coating Machines

Several factors influence the growing demand for chocolate coating machines in the global market:

Consumer Trends: As discussed, the demand for premium, personalized, and healthier chocolate products is rising. Chocolate coating machines that offer flexibility, precision, and customization are in high demand to support these changing consumer preferences.

Increased Focus on Automation: As labor costs rise, manufacturers are turning to automation to reduce reliance on manual labor. Chocolate coating machines that incorporate advanced automation and monitoring features can help manufacturers improve efficiency, reduce errors, and enhance consistency.

Cost-Effectiveness: As chocolate manufacturers strive to maintain competitive prices, they seek machines that offer high efficiency and low operational costs. The ability to produce high-quality chocolate-coated products with minimal energy consumption and reduced waste is a key selling point for chocolate coating machines in the global market.

Environmental Concerns: The growing emphasis on sustainability in food manufacturing has led to an increase in the demand for energy-efficient and eco-friendly machines. Chocolate coating machines that consume less energy, reduce waste, and require fewer cleaning agents are becoming increasingly popular in the market.

The global market for chocolate coating machines is growing rapidly due to the rising demand for chocolate-coated products, technological advancements, and changing consumer preferences. As the confectionery industry continues to evolve, manufacturers are seeking more efficient, versatile, and sustainable chocolate coating machines to meet the needs of a diverse and dynamic market.

If you are looking to invest in high-quality chocolate coating machinery that meets the demands of today’s confectionery industry, look no further than Gusu Food Processing Machinery Suzhou Co., Ltd. Our advanced chocolate coating machines are designed to provide consistent quality, increased efficiency, and flexibility, making them ideal for both large-scale and artisanal production. Whether you are looking to enhance your existing production line or expand into new markets, our machines can help you meet the challenges of the ever-evolving global chocolate market.

English

English Español

Español