Chocolate enrobing is a critical process in confectionery production, where candies, biscuits, or other treats are coated evenly with chocolate. Traditionally, enrobing was done manually, which is time-consuming and labor-intensive. With the introduction of chocolate enrobers, manufacturers have seen a significant shift in how efficiently chocolate products are produced. But the key question remains: Can a chocolate enrober improve production efficiency? The answer is a definitive yes, and here’s why.

1. Understanding Chocolate Enrobers

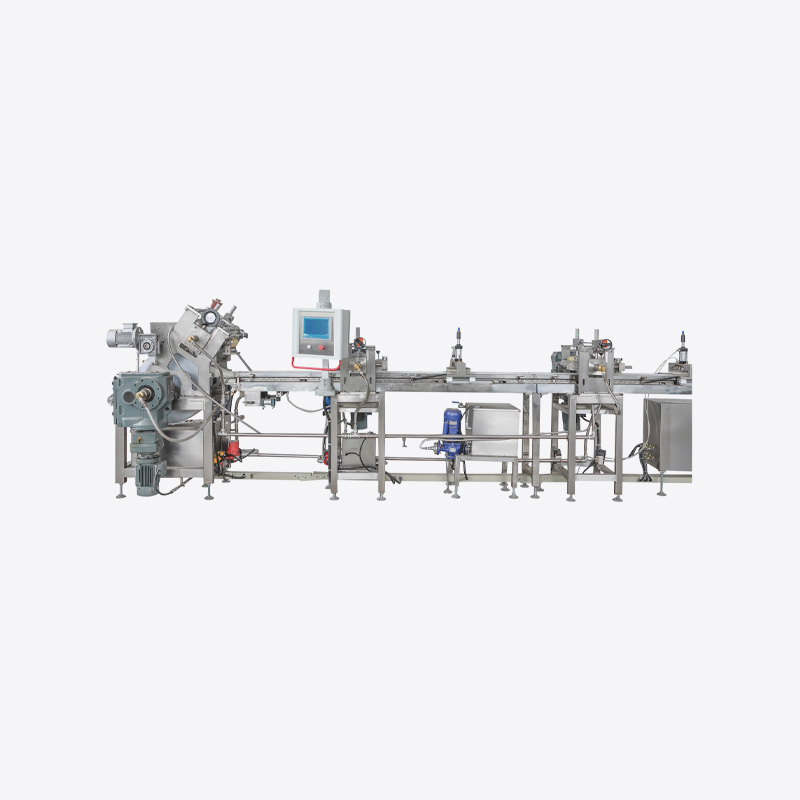

A chocolate enrober is a machine designed to coat products uniformly with liquid chocolate. The enrobing process typically involves:

Conveying: Products move along a conveyor belt under the chocolate curtain.

Coating: Liquid chocolate flows over the items, covering all surfaces.

Excess Removal: A vibrating or scraping system removes excess chocolate to ensure uniform thickness.

Cooling: Products are passed through a cooling tunnel to solidify the chocolate layer.

Chocolate enrobers are available in various sizes and types, from small tabletop models for artisanal production to large industrial machines capable of handling thousands of units per hour.

2. Faster Production Compared to Manual Methods

Manual chocolate coating requires workers to dip each piece individually. This method:

Takes significantly more time per product.

Results in inconsistent coating thickness.

Requires more labor, increasing production costs.

In contrast, a chocolate enrober:

Handles multiple items simultaneously on a conveyor.

Ensures consistent chocolate coverage.

Reduces the time required per batch.

By automating the enrobing process, manufacturers can produce higher quantities in less time, directly improving efficiency.

3. Consistent Quality Reduces Waste

Production efficiency is not just about speed—it also includes minimizing waste. Chocolate enrobers offer:

Uniform coating: Reduces the likelihood of uneven or defective products.

Precise chocolate usage: Excess chocolate is collected and reused, minimizing material waste.

Less rework: Consistent results mean fewer products need to be redone or discarded.

Reducing waste translates to cost savings and higher overall productivity, which is a key aspect of efficiency.

4. Labor Savings

Labor efficiency is another significant factor:

Manual coating requires skilled workers for prolonged periods.

Chocolate enrobers allow one operator to oversee the entire process, freeing other workers for different tasks.

Automation reduces human error and physical strain on workers, contributing to smoother production operations.

Overall, fewer workers can manage larger production volumes without compromising quality.

5. Versatility Enhances Efficiency

Modern chocolate enrobers are highly versatile, capable of handling:

Chocolates with fillings, nuts, or biscuits.

Different chocolate types: dark, milk, white, or flavored chocolate.

Custom-sized products or irregular shapes.

This versatility means a single machine can produce multiple product types without extensive downtime for cleaning or setup, further improving efficiency.

6. Integration with Other Production Lines

Chocolate enrobers can be integrated with other machines, such as:

Cooling tunnels to solidify the coating quickly.

Depositors that place fillings or centers before enrobing.

Packaging lines for automated wrapping after enrobing.

Integration reduces manual handling between stages, shortens production cycles, and optimizes workflow, all of which contribute to overall efficiency.

7. Reduced Maintenance and Downtime

High-quality chocolate enrobers are designed for continuous operation:

Stainless steel construction and modular design simplify cleaning.

Automated chocolate flow and temperature control prevent clogging.

Easy maintenance procedures reduce downtime between production batches.

Less downtime ensures the production line keeps moving efficiently, improving throughput.

8. Cost Efficiency

While chocolate enrobers represent an initial investment, they often save costs in the long term through:

Reduced labor costs.

Less chocolate waste.

Higher production capacity.

Faster production cycles.

For medium to large-scale operations, these savings can quickly offset the purchase cost, making the enrober both a productivity and cost-efficiency solution.

9. Ideal Applications

Chocolate enrobers are suitable for a variety of confectionery products, including:

Chocolate-covered biscuits and wafers.

Truffles and bonbons.

Candy bars and coated nuts.

Seasonal treats like chocolate eggs or holiday figures.

In all these applications, enrobers streamline production, enhance consistency, and reduce manual labor.

Can a chocolate enrober improve production efficiency? The answer is absolutely yes. By automating the coating process, ensuring consistent product quality, reducing waste, and saving labor, chocolate enrobers significantly enhance overall productivity in confectionery production.

Whether for artisanal chocolatiers or large industrial operations, incorporating a chocolate enrober allows businesses to produce higher volumes, maintain consistent quality, and optimize costs. In a competitive market where both speed and quality matter, chocolate enrobers are an essential investment for efficiency and growth.

English

English Español

Español