What is a Candy Bar Line?

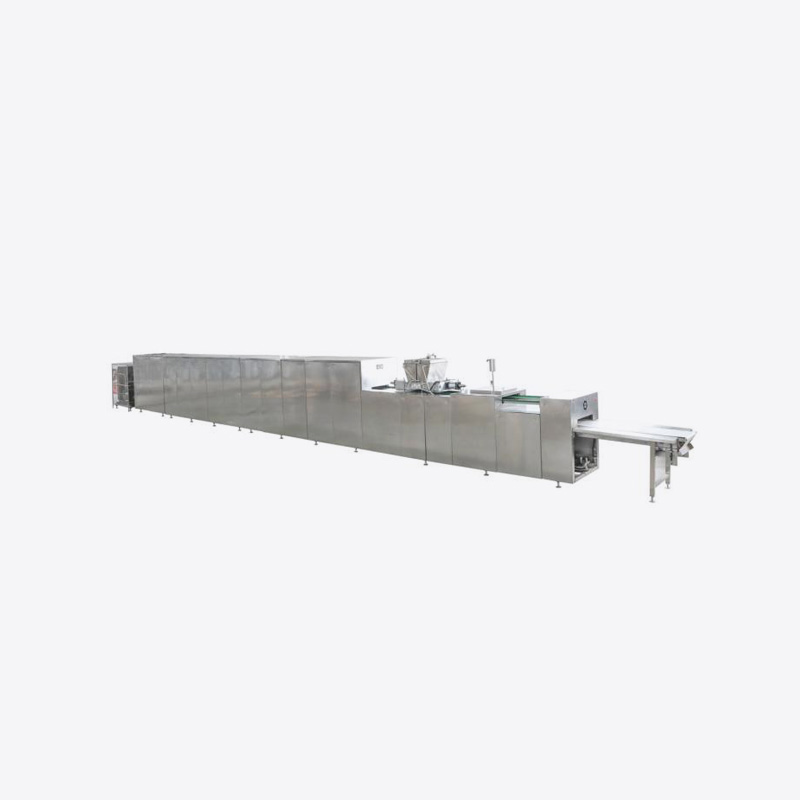

A Candy Bar Production Line refers to an integrated system used for the mass production of candy bars. It is a series of interconnected machines and processes designed to take raw ingredients, transform them into finished candy bars, and package them for distribution. The production line automates the manufacturing process to ensure consistency, speed, and efficiency in candy bar production, making it possible to produce large quantities at a time.

A candy bar production line is capable of handling various types of candy bars, from traditional chocolate bars to specialty formulations such as protein bars or sugar-free options. The line is typically modular and adaptable, enabling manufacturers to customize the system to produce different kinds of candy products.

Key Components Involved in the Production Process

A candy bar production line involves multiple stages, each requiring specific components to ensure the smooth transformation of raw ingredients into a finished product. Below are the key components typically found in a candy bar production line:

1. Ingredient Preparation

Mixers: The first step involves mixing raw ingredients such as sugar, cocoa, milk, and other flavoring agents. Mixers ensure uniform distribution of ingredients and prepare the dough or base mixture for the candy bar.

Ingredient Feed Systems: These systems are used to transport the ingredients from storage to the mixers or other stages of the production process, ensuring a continuous flow of raw materials.

2. Cooking and Tempering

Cookers: In this phase, the mixture is cooked to the desired temperature and consistency. Cookers typically have temperature controls and timers to ensure that the candy base is cooked evenly, without burning or overcooking the mixture.

Tempering Machines: These are used for chocolate-based candy bars. The process of tempering ensures that chocolate is heated and cooled to the correct temperature, allowing it to solidify with a smooth texture and glossy finish.

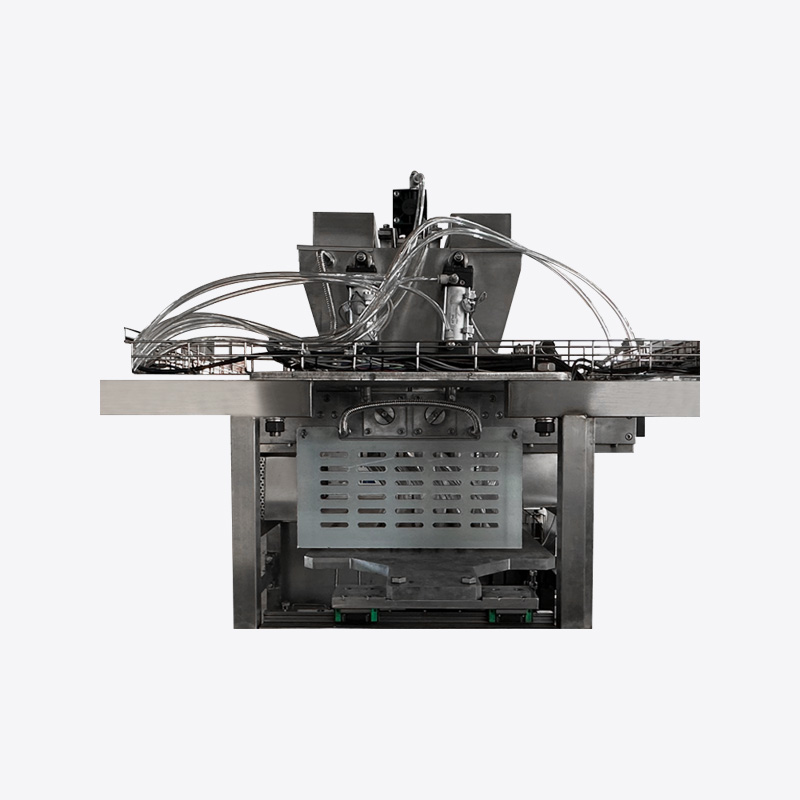

3. Forming and Molding

Forming Machines: Once the mixture is cooked, it is transferred to forming machines that shape it into the desired size and shape of the candy bar. These machines can handle a variety of shapes and sizes depending on the candy bar type.

Molds: In some cases, molds are used to create a specific shape or design. These molds are an essential part of the process, ensuring that each candy bar is uniform in size and appearance.

4. Cooling and Solidifying

Cooling Tunnels: After the candy bars are formed, they need to be cooled to harden. Cooling tunnels or cooling racks are used to regulate the temperature and allow the candy bars to solidify. This step is particularly important for chocolate bars, as proper cooling ensures a crisp and shiny finish.

Air Circulation Systems: These systems help control the airflow and temperature in cooling tunnels, providing an even and efficient cooling process.

5. Coating and Enrobing

Enrobers: For candy bars that are coated with chocolate or other coatings, enrobers are used. These machines coat the bars with a uniform layer of chocolate or any other coating, ensuring that the candy bars maintain a smooth, even surface.

Coating Pans: In some candy bar lines, especially those producing nut or caramel-coated bars, coating pans are used to coat individual bars with powdered ingredients or syrup before they are packaged.

6. Cutting and Shaping

Cutting Machines: After cooling and coating, candy bars are cut into their final size. Cutting machines are used to slice the cooled candy mass into individual bars or smaller bite-sized pieces.

Shaping Machines: For candy bars that require intricate shapes, shaping machines can be used to add designs, embossing, or other decorations to the surface of the bar.

7. Packaging

Wrapping Machines: After the candy bars are formed, cooled, and cut, they are wrapped for sale. Wrapping machines automatically wrap the bars in foil, plastic, or paper, providing protection and branding for the product.

Packing Machines: These machines collect the wrapped candy bars and pack them into cartons or boxes for storage and distribution. Automated packing systems can handle high volumes of candy bars and ensure that they are safely and securely packed.

8. Quality Control and Inspection

Vision Systems and Sensors: Throughout the production line, vision systems and sensors are used for real-time quality control. These systems can check for defects in shape, size, weight, or packaging. They help ensure that only high-quality candy bars make it to the packaging stage.

Metal Detectors: Metal detectors are often installed to check for metal contaminants in the candy bars, ensuring food safety and compliance with regulations.

9. Conveyor Systems

Conveyor Belts: Conveyor systems transport the candy bars from one stage of production to the next, providing an efficient flow of materials through the production line. These belts are designed to handle the weight and size of the candy bars while minimizing damage during transport.

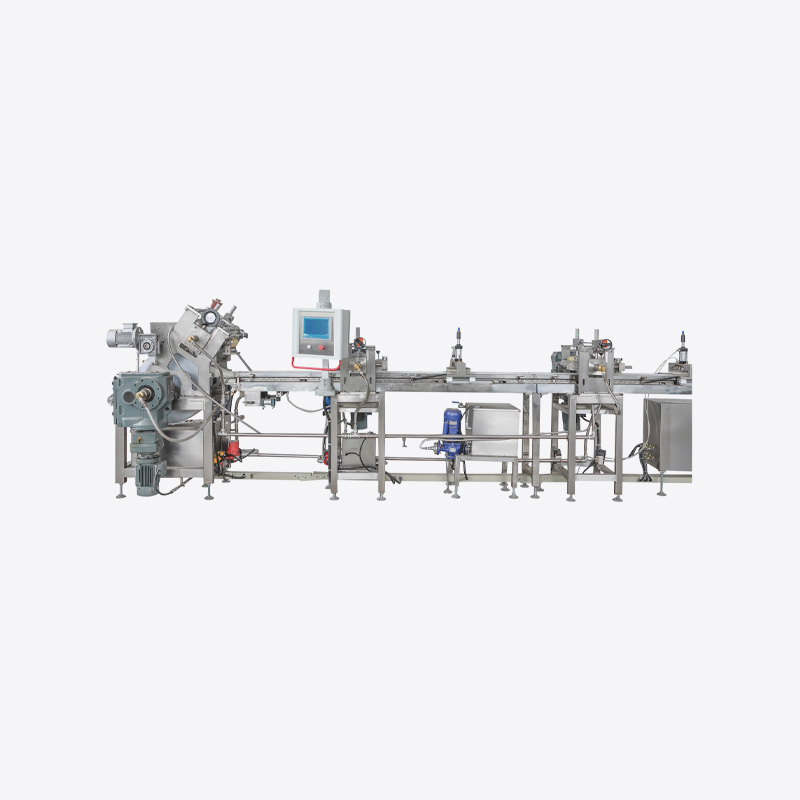

10. Control Systems and Automation

PLC (Programmable Logic Controllers): The entire candy bar production line is typically controlled by PLCs that manage the various stages of production. These systems allow operators to monitor and adjust settings in real time, ensuring optimal performance.

HMI (Human-Machine Interface): HMIs allow operators to interact with the control system, view production data, and make necessary adjustments to the line.

| Stage | Key Components | Function |

|---|---|---|

| Ingredient Preparation | Mixers, Ingredient Feed Systems | Mix and prepare raw ingredients, ensuring uniform distribution. |

| Cooking and Tempering | Cookers, Tempering Machines | Cook ingredients to the desired consistency and ensure proper tempering of chocolate. |

| Forming and Molding | Forming Machines, Molds | Shape the candy mixture into bars and create specific designs or sizes. |

| Cooling and Solidifying | Cooling Tunnels, Air Circulation Systems | Cool the candy bars to harden and achieve the desired texture and finish. |

| Coating and Enrobing | Enrobers, Coating Pans | Coat candy bars with chocolate or other coatings for a smooth surface. |

| Cutting and Shaping | Cutting Machines, Shaping Machines | Cut and shape the candy bars into individual pieces. |

| Packaging | Wrapping Machines, Packing Machines | Wrap the candy bars and pack them into cartons for distribution. |

| Quality Control and Inspection | Vision Systems, Sensors, Metal Detectors | Monitor product quality and ensure food safety by detecting defects or contaminants. |

| Conveyor Systems | Conveyor Belts | Transport candy bars through various production stages efficiently. |

| Control Systems and Automation | PLCs, HMIs | Control and automate the production line, ensuring smooth operations. |

What Are the Key Stages of a Candy Bar Line?

A Candy Bar Production Line is a complex system that includes various stages designed to efficiently process raw ingredients into finished candy bars. Each stage in the production process is crucial for achieving the desired texture, taste, and appearance while ensuring quality and safety.

1. Ingredient Preparation

The candy production process begins with preparing the raw ingredients. This stage involves sourcing and accurately measuring ingredients like sugar, cocoa, milk powder, and flavorings. The quality and consistency of the final product depend heavily on how well these ingredients are mixed.

Mixing: Large mixers blend the ingredients to ensure uniformity. The raw materials are combined to form a consistent base mixture that will later be shaped and processed.

Weighing and Conveying: Precise weighing systems ensure that each ingredient is added in the correct proportions. Conveyors transport ingredients to the next stages in the production line.

2. Cooking and Tempering

Once the ingredients are properly mixed, the mixture is heated and cooked to the desired consistency.

Cooking: The mixture is heated in large cooking vessels, typically called cookers, to achieve the correct texture. The temperature and cooking time must be precisely controlled to prevent burning or overcooking the ingredients.

Tempering: For candy bars that include chocolate coatings, tempering is a critical step. Tempering involves heating and cooling the chocolate to specific temperatures to ensure it solidifies with the right glossy finish and smooth texture.

3. Forming and Molding

After the mixture has been prepared and cooked, it is transferred to forming machines that shape it into bars. This is the stage where the candy bar takes its final form.

Forming Machines: These machines shape the mixture into the desired size and shape of the candy bar. Some lines may produce various shapes and sizes based on consumer preferences and packaging requirements.

Molds: In some cases, molds are used to create specific designs, such as embossing or logos on the candy bar surface. Molding is also important for creating bars with different textures, like those with nuts or fruit inclusions.

4. Cooling and Solidifying

After the candy bars are shaped, they need to be cooled to set and solidify.

Cooling Tunnels: The candy bars move through cooling tunnels where air is circulated to cool the product evenly. This ensures the bars harden correctly and retain their shape.

Air Circulation Systems: These systems ensure that the temperature is consistent throughout the cooling process, preventing defects like cracking or improper solidification.

5. Coating and Enrobing

For candy bars that have chocolate coatings or other types of enrobing, this step is essential for finishing the product with a smooth and glossy outer layer.

Enrobers: An enrober is a machine that coats the candy bars with chocolate or any other desired coating. The bars are dipped or passed through a continuous stream of melted chocolate to ensure an even coating.

Coating Pans: In some cases, candy bars might be coated with a powdered substance or syrup before being wrapped. These coatings add flavor and texture to the final product.

6. Cutting and Shaping

Once the candy bars are cooled and coated, they are cut to the desired size and shape.

Cutting Machines: These machines slice the candy mixture into individual bars or bite-sized pieces. The cutting process must be precise to ensure that each bar is the correct size and shape.

Shaping Machines: Some candy bars may need to undergo further shaping, like adding details or designs to the surface of the bar. This can be done using specialized shaping machines or rollers.

7. Packaging

Packaging is the final stage in the candy bar production line, where the product is wrapped and prepared for distribution.

Wrapping Machines: The wrapped candy bars are sealed in protective packaging, such as foil or plastic, to ensure freshness and preserve the product during transportation.

Packing Machines: Once the bars are wrapped, they are grouped and packed into larger boxes or cartons for shipment. This step often involves automated packing systems that quickly and efficiently handle large quantities.

8. Quality Control and Inspection

Throughout the entire production process, quality control is maintained to ensure that the candy bars meet the required standards.

Vision Systems and Sensors: These systems are used to inspect the candy bars for defects, such as size inconsistencies or missing coatings. They also check for any contaminants or foreign objects.

Metal Detectors: To ensure food safety, metal detectors are often used to scan for metallic contaminants that could be harmful to consumers.

9. Conveyor Systems

Conveyor systems are used to transport the candy bars through each stage of the production process, from ingredient preparation to packaging.

Conveyor Belts: These belts ensure that the candy bars move smoothly and consistently between different parts of the production line. They also help prevent damage to the product during transportation between stages.

10. Control Systems and Automation

The entire production line is typically controlled by an integrated system of automation.

PLC (Programmable Logic Controllers): PLCs control the machines and processes within the candy bar production line. They ensure that each machine performs its task at the right time and in the right sequence.

HMI (Human-Machine Interface): Operators can use HMIs to monitor and control the production line, making adjustments if necessary to maintain optimal performance.

What Steps Are Involved in a Candy Bar Line?

The production of candy bars is a multi-stage process that involves several steps to ensure high-quality, consistent products. Each step is crucial for transforming raw ingredients into a finished candy bar that meets consumer expectations.

1. Ingredient Preparation

The process begins with preparing the raw ingredients that will make up the candy bar. This stage is critical as the quality and ratio of ingredients directly affect the final product.

Weighing and Measuring: Ingredients such as sugar, chocolate, milk powder, and flavoring agents are carefully weighed and measured according to the recipe.

Mixing: The ingredients are then fed into large mixing machines, where they are blended to create a uniform mixture. This is an essential step to ensure that all the ingredients are evenly distributed throughout the final candy bar.

2. Cooking and Tempering

Once the ingredients are mixed, they need to be cooked and tempered to achieve the desired texture and consistency.

Cooking: The mixture is transferred to cooking machines, where it is heated under controlled temperatures. This helps break down the ingredients, allowing them to bond together and create the desired consistency. The cooking time and temperature must be precise to prevent overcooking or undercooking.

Tempering (For Chocolate Coating): If the candy bar includes a chocolate coating, tempering is necessary. The chocolate is heated and then cooled in a controlled process, ensuring it hardens with a smooth, glossy finish.

3. Forming and Shaping

At this stage, the candy mixture is shaped into the form of bars or other desired shapes, which can vary depending on the product specifications.

Forming Machines: After cooking, the mixture is transferred to forming machines, where it is shaped into candy bars. The machines use molds or rollers to press and shape the mixture into uniform pieces.

Shaping: Some candy bars may require further shaping, such as flattening or rounding. This ensures the candy bars fit into packaging and meet size requirements.

4. Cooling and Solidifying

Once the candy bars are formed, they need to be cooled to set their shape and achieve the right texture.

Cooling Tunnels: The shaped candy bars pass through cooling tunnels, where they are subjected to controlled temperatures that help solidify the mixture. This step ensures that the bars hold their shape and texture.

Airflow Systems: Airflow systems inside the cooling tunnels maintain a consistent and even cooling process, preventing issues like cracking or uneven texture.

5. Coating and Enrobing

Many candy bars require a coating of chocolate, caramel, or other ingredients. This stage gives the candy bars their final appearance and enhances flavor.

Enrobing Machines: Candy bars are passed through enrobers, which coat them with chocolate or another desired material. The enrobing process ensures an even coating over the candy bars, giving them a smooth, glossy finish.

Coating Pans: In some production lines, coating pans are used to add a layer of syrup or powder to the candy bars. This is common for bars that require additional texture or flavor.

6. Cutting and Shaping

After coating and cooling, the candy bars are cut to the desired size and shape.

Cutting Machines: Cutting machines slice the candy bars into standard sizes. This step is essential for ensuring that the final products are uniform in size, which is crucial for packaging and branding purposes.

Shaping: Some candy bars, especially those with unique designs or shapes, may undergo additional shaping at this stage to ensure they match the required specifications.

7. Packaging

Once the candy bars are shaped, cooled, and cut, they are ready for packaging. This step protects the product and prepares it for shipment.

Wrapping Machines: Candy bars are wrapped in protective materials, such as foil or plastic, to keep them fresh and safe during transportation. Wrapping machines are highly automated and ensure that each bar is sealed properly.

Packing Machines: After wrapping, the candy bars are grouped and packed into larger cartons or boxes for easier distribution. Automated packing systems streamline this process, reducing manual labor and ensuring the product is packed efficiently.

8. Quality Control and Inspection

Quality control is critical at each stage of production to ensure that the candy bars meet industry standards and consumer expectations.

Visual Inspection: During various stages of production, candy bars are visually inspected to identify any defects such as shape irregularities, inconsistencies in coating, or foreign objects.

Metal Detectors: To ensure food safety, metal detectors are used to scan for any potential contaminants in the candy bars. This is a standard safety measure to protect consumers from harmful materials.

Weight and Size Checking: Machines are often used to check the weight and size of each candy bar, ensuring they meet the product specifications and uniformity requirements.

9. Conveyor Systems

Conveyor belts are an integral part of the candy bar production line, ensuring smooth movement from one stage to the next.

Transporting the Product: Conveyor systems transport the candy bars through each stage of the production line. They ensure that the candy bars move efficiently between machines, from ingredient preparation all the way to packaging.

10. Control Systems and Automation

The entire production line is controlled by automated systems to ensure smooth, efficient, and precise operations.

PLC (Programmable Logic Controllers): PLCs are used to control the machines on the production line. They ensure that each stage of the process runs in sync and that any adjustments are made automatically to maintain efficiency.

HMI (Human-Machine Interface): Operators use HMIs to monitor and control the line. These systems provide real-time data and allow operators to make adjustments when necessary to ensure optimal performance.

What Are the Different Types of Candy Bar Lines?

Candy bar production lines are not all the same. Depending on the type of candy bar being produced and the specific needs of the manufacturer, there are different types of production lines, each designed for particular processes, efficiency levels, and product varieties.

1. Standard Candy Bar Lines

Standard candy bar lines are designed for mass production of traditional candy bars, such as chocolate bars, nougat bars, and caramel-filled bars. These lines typically involve simple, efficient processes to create a consistent product. These lines are widely used by manufacturers producing high volumes of popular candy bars.

Key Features:

High-speed production with minimal downtime.

Primarily designed for large-scale manufacturing of conventional candy bars.

Includes basic processes like mixing, cooking, forming, and cutting.

Focus on efficiency and product uniformity.

Best for: High-volume production of traditional candy bars, where the focus is on speed and consistency.

2. Customized Candy Bar Lines

Customized production lines are designed for manufacturers who want to create candy bars with unique features, such as different fillings, textures, or coatings. These lines allow for greater flexibility and customization, enabling manufacturers to experiment with new recipes, ingredients, and flavors.

Key Features:

Flexibility to accommodate various ingredients, fillings, and coatings (e.g., nuts, caramel, fruit).

Ability to change the shape, size, and texture of the candy bars.

Capability for small batch production with frequent recipe changes.

Can handle diverse products like protein bars, energy bars, or dietary-specific candy bars.

Best for: Brands that offer specialty candy bars with unique flavor profiles or ingredients (e.g., gluten-free, vegan, low-sugar options).

3. Modular Candy Bar Lines

Modular candy bar lines offer flexibility in terms of production capacity and product variety. The modular design allows manufacturers to easily add or remove components to match production demands or product specifications. These lines are ideal for businesses looking for scalability or the ability to adjust their production capacity based on demand.

Key Features:

Composed of separate, interchangeable modules (e.g., mixers, ovens, enrobers, and wrapping machines).

Flexibility to adjust production speed or change products quickly.

Easy to upgrade and expand with additional modules for higher capacity or different product types.

Efficient for testing new products or seasonal variations.

Best for: Manufacturers who need to adjust their production line to accommodate different candy bar types, flavors, or seasonal variations.

4. High-Capacity Automated Candy Bar Lines

These production lines are designed for companies that need to produce large quantities of candy bars quickly and efficiently. High-capacity automated lines incorporate advanced robotics and automated systems to handle everything from ingredient mixing to packaging, without requiring constant human supervision.

Key Features:

Fully automated systems with minimal manual intervention.

High-speed production, designed for mass-market candy bars.

Use of robotics and advanced sensors for quality control and efficiency.

Continuous operation with minimal downtime and maximum throughput.

Best for: Large manufacturers with high-volume demands looking to automate their production process and increase overall efficiency.

5. Small-Scale or Batch Candy Bar Lines

Small-scale or batch candy bar lines are designed for smaller production runs or artisanal candy bar manufacturers. These lines allow for greater control over the production process and can be used to create premium, limited-edition, or specialty candy bars in smaller quantities.

Key Features:

Smaller-scale operations for more control over the production process.

Ideal for premium, artisanal, or handmade candy bars.

Flexibility to experiment with ingredients, flavors, and sizes.

Less automation compared to larger lines, often requiring more manual labor.

Best for: Small businesses, craft candy makers, or companies focused on niche markets that require more customization in the production process.

6. Energy and Protein Bar Production Lines

While not always classified as traditional candy bars, energy and protein bars share many production processes with candy bar lines. These lines are specialized for creating candy-like bars that cater to health-conscious consumers. They often feature ingredients like protein, nuts, and oats, and are designed for high nutritional value.

Key Features:

Ability to handle ingredients such as protein powders, fibers, and organic materials.

Capability for low-sugar or sugar-free formulations.

Often features a more complex forming and molding process to achieve the right texture.

Specialized coating systems for added flavor or texture (e.g., chocolate or yogurt coatings).

Best for: Manufacturers focused on health-conscious products, protein bars, and functional snack bars.

7. Coated or Enrobed Candy Bar Lines

These production lines specialize in candy bars that require a coating, typically chocolate, caramel, or other types of enrobing. This category includes the majority of traditional chocolate bars but also extends to candy bars with unique coatings, such as yogurt-covered bars or sugar-free chocolate enrobed bars.

Key Features:

Includes enrobers and coating systems designed to apply smooth, even layers of coating.

Specific machines for applying chocolate, caramel, or other coatings to the bars.

Coating can be used to add flavor, texture, and visual appeal.

High-level precision in applying coatings to avoid any inconsistencies.

Best for: Manufacturers producing chocolate-covered candy bars, fruit-coated bars, or yogurt-covered bars.

8. Flexible and High-Speed Candy Bar Lines

Some production lines are built specifically to meet both high-speed and flexibility requirements. These lines are designed to adapt quickly to changing market demands or seasonal variations, allowing manufacturers to change product types without significant downtime.

Key Features:

High-speed machines capable of handling large volumes quickly.

Flexibility to switch between products without substantial downtime or reconfiguration.

Suitable for fast-growing businesses or those with frequent product line changes.

Best for: Growing manufacturers or companies that need to quickly adapt to changing market demands or introduce new products.

| Type of Candy Bar Line | Key Features | Best For |

|---|---|---|

| Standard Candy Bar Lines | - High-speed production with minimal downtime. - Simple processes for traditional candy bars. - Focus on efficiency and product consistency. |

High-volume production of conventional candy bars (e.g., chocolate, nougat, caramel bars). |

| Customized Candy Bar Lines | - Flexibility to accommodate various ingredients and coatings. - Ability to change shape, size, and texture. - Small batch production capabilities. |

Specialty candy bars with unique flavors, dietary-specific formulations, and custom designs. |

| Modular Candy Bar Lines | - Interchangeable modules for flexibility. - Easy to upgrade and expand. - Can handle different products and seasonal variations. |

Manufacturers requiring scalability or ability to change production based on demand. |

| High-Capacity Automated Candy Bar Lines | - Fully automated systems with minimal manual intervention. - High-speed production for mass-market bars. - Use of robotics and advanced sensors. |

Large manufacturers seeking to automate production for high-volume, consistent output. |

| Small-Scale or Batch Candy Bar Lines | - Smaller-scale, manual processes. - Ideal for artisanal or premium products. - Greater control over customization. |

Small businesses or premium product manufacturers requiring flexibility and customization. |

| Energy and Protein Bar Production Lines | - Ability to handle ingredients like protein powders, oats, and organic materials. - Specialized for low-sugar or sugar-free formulations. |

Manufacturers producing energy bars, protein bars, or health-conscious snack bars. |

| Coated or Enrobed Candy Bar Lines | - Focus on applying smooth, even coatings (e.g., chocolate, caramel, yogurt). - Machines specialized for coating and enrobing candy bars. |

Manufacturers of chocolate-covered, caramel-covered, or yogurt-coated candy bars. |

| Flexible and High-Speed Candy Bar Lines | - High-speed production. - Ability to switch between products with minimal downtime. - Suitable for fast-growing businesses with changing demands. |

Growing manufacturers needing to adapt quickly to changing market demands or introduce new products. |

What Are the Benefits of an Automated Candy Bar Line?

An automated candy bar production line uses advanced machinery and technology to streamline the entire manufacturing process, from ingredient preparation to packaging. The integration of automation has significantly transformed candy production, providing numerous advantages that are key to meeting the increasing demand for candy products.

1. Increased Production Speed

One of the most significant benefits of an automated candy bar line is its ability to significantly increase production speed. Automation allows for continuous, uninterrupted operation, leading to higher throughput and the ability to produce large quantities of candy bars in less time.

Faster Processing: Automated machines can perform tasks such as mixing, cooking, cooling, and packaging much quicker than manual labor.

High-Speed Machines: With advanced robotics and automated systems, candy bars are produced and packaged at faster rates, reducing cycle times and maximizing production output.

2. Consistent Product Quality

Maintaining a consistent quality in every batch is essential for building consumer trust and brand loyalty. Automated candy bar lines are designed to maintain high levels of precision and consistency, reducing the chances of human error.

Uniformity: Automation ensures that every candy bar is made to the same size, weight, and appearance, leading to fewer defects and more uniform products.

Precise Control: With automated systems, manufacturers can adjust parameters like temperature, cooking time, and ingredient quantities with great accuracy, ensuring the desired product quality every time.

3. Reduced Labor Costs

Automating the production line reduces the reliance on manual labor, which in turn helps lower labor costs. Automation takes over repetitive, time-consuming tasks, such as mixing, molding, and packaging, allowing workers to focus on higher-level tasks, such as quality control or machine maintenance.

Lower Labor Expenses: With fewer workers required to operate the machinery, manufacturers can allocate their resources more efficiently.

Reduced Labor-related Errors: Automation reduces human errors that could lead to product defects or inconsistencies, further lowering the need for corrective labor.

4. Improved Safety and Reduced Risk

Automation helps reduce the risks associated with manual handling of machinery and raw ingredients, enhancing the overall safety of the production process.

Minimized Human Contact: Automated systems can handle hazardous processes, such as high-temperature cooking or heavy lifting, minimizing human exposure to potentially dangerous tasks.

Safety Features: Modern automated lines come equipped with safety mechanisms like emergency stops, sensors, and protective covers to safeguard workers and ensure compliance with safety regulations.

5. Higher Production Flexibility

An automated candy bar production line offers the flexibility to switch between different products, sizes, and flavors with minimal downtime. This is crucial for manufacturers who want to cater to changing market demands or seasonal trends.

Quick Changeovers: Many automated systems are designed for rapid product changeovers, making it easy to switch between various candy bar types without having to reconfigure the entire production line.

Customization Capabilities: The flexibility to customize candy bars by incorporating different fillings, coatings, and packaging styles is enhanced by automation, allowing manufacturers to cater to niche markets or customer preferences.

6. Enhanced Efficiency and Lower Waste

Automation in candy bar production helps optimize every step of the process, ensuring that raw materials are used more efficiently and reducing overall waste.

Material Optimization: Automated systems can more accurately measure and mix ingredients, minimizing excess or leftover materials. This precision helps reduce raw material waste.

Reduced Product Waste: Automated cutting and forming machines ensure that candy bars are consistently sized, reducing the amount of scrap material generated during production.

7. Real-Time Monitoring and Data Collection

Automated candy bar lines typically include integrated systems that allow for real-time monitoring of the production process. This helps operators track various performance metrics and quality indicators, ensuring the process runs smoothly.

Data-Driven Insights: Real-time data collection provides valuable insights into production efficiency, energy usage, and machine performance, allowing for better decision-making and process improvements.

Predictive Maintenance: By tracking the performance of machinery, automated systems can predict when a piece of equipment needs maintenance, preventing unexpected breakdowns and reducing downtime.

8. Scalability and Growth Potential

Automated production lines are designed with scalability in mind, allowing manufacturers to easily expand their production capacity as demand increases. Scaling up operations on an automated line is relatively simple, requiring only minimal adjustments to the existing setup.

Capacity Expansion: As market demand grows, manufacturers can add more machines or expand existing systems to handle higher production volumes without major disruptions.

Future-Proofing: Automation provides the foundation for incorporating newer technologies, such as artificial intelligence and machine learning, to further optimize production as industry needs evolve.

9. Cost-Effective Long-Term Investment

While the initial investment in automated machinery may be high, the long-term savings outweigh the costs. The increase in production speed, quality consistency, and labor savings makes automation a cost-effective solution for candy manufacturers.

Return on Investment (ROI): The combination of reduced labor costs, minimized waste, and increased production speed ensures a quicker ROI for automated production lines.

Long-Term Savings: Ongoing operational costs decrease due to the efficiency and reduced need for repairs or manual interventions.

10. Compliance with Food Safety Regulations

Automated systems help manufacturers comply with food safety standards and regulations by ensuring that the production process is precise and repeatable.

Hygienic Design: Automated lines are often designed with hygiene in mind, featuring easy-to-clean surfaces and sanitation systems that prevent contamination.

Traceability: Automated systems enable better traceability of ingredients and production processes, ensuring compliance with food safety regulations and enhancing transparency for consumers.

What Technological Innovations Are Shaping the Candy Bar Line?

Technological advancements in manufacturing are continuously shaping the candy bar production line, enhancing efficiency, product quality, and flexibility. The introduction of cutting-edge technologies has revolutionized the candy industry, making production lines more automated, scalable, and capable of handling a variety of products.

1. Automation and Robotics

One of the most transformative technological innovations in candy bar production is the widespread integration of automation and robotics. These technologies help to streamline production, reduce human error, and significantly improve speed and consistency.

Robotic Handling: Robotic arms are now used for tasks like picking and placing candy bars, packaging, and even quality control inspections. Their precision and speed have greatly improved overall productivity, allowing for faster throughput and reduced labor costs.

Automated Assembly Lines: Fully automated candy bar production lines now perform everything from ingredient mixing to packaging, reducing the need for manual labor and ensuring higher consistency in the finished products.

2. Machine Vision and Artificial Intelligence (AI)

Machine vision, powered by artificial intelligence (AI), is increasingly being incorporated into candy bar production lines to enhance quality control and production efficiency.

Real-Time Quality Inspection: Machine vision systems use cameras and sensors to inspect candy bars in real-time as they move through the production line. These systems can detect defects such as uneven coatings, irregular shapes, or any contaminants that might be present, ensuring that only high-quality products reach the packaging stage.

Predictive Maintenance: AI algorithms can monitor machine performance and predict when a machine is likely to require maintenance. This reduces downtime and extends the lifespan of equipment by addressing issues before they cause major failures.

3. 3D Printing Technology

Although still in the early stages, 3D printing has started to make an impact in the candy industry. This innovative technology allows for precise control over the shape and design of candy products, offering new opportunities for customization.

Customization and Design Flexibility: 3D printers can be used to create intricate shapes, designs, and even personalized candy bars. This is especially useful for novelty products, premium candies, or seasonal offerings that require unique molds or logos.

Small-Batch Production: For companies that wish to test new flavors, textures, or designs, 3D printing allows for small-batch production without the need for expensive, large-scale molding equipment.

4. Advanced Coating Technology

The coating of candy bars is an essential part of the production process, and technological advancements in coating machinery have made this step more efficient and consistent.

Enrobing Systems: Enrobing, the process of coating candy bars with chocolate or other substances, has been improved with the introduction of automated enrobing systems. These systems provide a consistent, even coating and are capable of adjusting the thickness of the coating as needed.

Airless Coating Technology: Some candy bar lines now feature airless coating systems that reduce the risk of bubbles and uneven surfaces. These systems ensure that the coating remains smooth and uniform, improving the final product's appearance and texture.

5. Temperature Control and Smart Heating

Temperature management is crucial in the candy-making process, particularly in steps like cooking, cooling, and tempering chocolate. New temperature control technologies ensure that the candy bars are processed at the correct temperature, which is vital for maintaining consistency and quality.

Intelligent Temperature Monitoring: Advanced temperature sensors and controllers are used to monitor and adjust cooking and cooling temperatures in real-time. These smart systems allow manufacturers to make precise adjustments to achieve the desired texture, appearance, and taste of the candy bars.

Efficient Cooling Systems: Innovative cooling technologies, such as cryogenic cooling, use controlled airflow and freezing techniques to rapidly cool the candy bars as they move along the production line. This speeds up the solidification process, improving both productivity and product quality.

6. Integrated Control Systems (PLC and HMI)

Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) are central to modern automated candy bar production lines, providing precise control over all stages of the manufacturing process.

PLC (Programmable Logic Controllers): PLCs are used to control all machines and processes in the production line. These devices manage everything from ingredient mixing and cooking to packaging and wrapping, ensuring seamless coordination across different stages of production.

HMI (Human-Machine Interface): HMIs allow operators to interact with the system, monitor production data, and make adjustments when necessary. They provide real-time feedback on machine performance, enabling quick responses to potential issues and improving overall efficiency.

7. Data Analytics and Industry 4.0 Integration

The integration of data analytics and Industry 4.0 technologies into candy bar production lines is helping manufacturers achieve higher levels of operational efficiency and product customization.

Real-Time Data Monitoring: By connecting machines and devices on the production line, data can be collected in real-time, allowing manufacturers to monitor performance metrics such as production speed, material consumption, and energy usage. This data helps in decision-making and optimizing processes.

Industry 4.0 and IoT (Internet of Things): Many candy production lines now integrate IoT devices that enable machines to communicate with each other. This connected ecosystem helps monitor every stage of the production process, providing better control, faster decision-making, and predictive analytics.

8. Sustainable Packaging Solutions

Sustainability is becoming an important consideration in the food manufacturing industry, and candy bar production is no exception. New technologies in packaging are reducing the environmental impact of candy production while maintaining product integrity.

Eco-Friendly Materials: Many candy bar manufacturers are adopting biodegradable or recyclable packaging materials to reduce their carbon footprint. Advanced packaging machines now handle these materials effectively, ensuring that candy bars are safely packaged without compromising the environment.

Minimal Packaging: Innovative packaging machines are designed to use minimal material, optimizing packaging to reduce waste. This can lower production costs and appeal to environmentally conscious consumers.

9. Flexible Production Systems

Modern candy bar production lines are highly flexible, enabling manufacturers to easily adapt to changing consumer demands, new product formulations, and seasonal variations.

Quick Changeovers: Thanks to technological innovations, production lines can now be adjusted quickly between different candy bar types. This flexibility is crucial for manufacturers who need to produce various products, such as seasonal candy bars or custom formulations, without lengthy downtime.

Batch and Continuous Production Integration: New systems can integrate both batch and continuous production processes, providing the flexibility to produce smaller, niche batches alongside large-scale production without major interruptions.

What Does the Future Hold for Candy Bar Lines?

The candy bar industry is evolving rapidly, driven by advancements in technology, changing consumer preferences, and a growing focus on sustainability. As manufacturers adapt to these shifts, the candy bar production process is expected to undergo significant transformations.

1. Increased Automation and Robotics

As the demand for faster production times and greater efficiency continues to grow, automation and robotics will play an even more central role in candy bar lines. The future of candy bar production will likely involve fully automated lines, with robotics handling everything from ingredient mixing and molding to packaging and quality control.

Improved Speed and Precision: Advanced robotic systems will enable faster, more precise handling of candy bars, allowing for quicker changeovers and reducing production downtime.

Collaborative Robots: These robots, designed to work alongside human operators, will enhance productivity while maintaining a safe and efficient working environment. Their ability to perform repetitive tasks will free up human workers for higher-level duties.

2. Customization and Personalization

Consumer preferences are increasingly leaning towards unique, customized products, and the candy bar industry is no exception. In the future, manufacturers will likely offer more personalized candy bars, allowing consumers to choose flavors, fillings, coatings, and even packaging designs.

3D Printing Technology: As 3D printing technology becomes more refined, candy manufacturers may be able to print custom shapes, logos, and designs directly onto candy bars, offering an entirely new level of product personalization.

Tailored Flavors and Ingredients: Future candy bar production lines will be able to accommodate a greater variety of fillings, coatings, and nutritional profiles, allowing brands to create candy bars that cater to specific tastes, dietary restrictions, or health-conscious consumers.

3. Sustainability and Eco-Friendly Practices

Sustainability is one of the key drivers of innovation in the candy bar industry. With growing concerns over environmental impact, the future of candy bar production will likely involve a shift towards more sustainable practices, both in terms of manufacturing and packaging.

Eco-Friendly Ingredients: Manufacturers will increasingly look to source ingredients from sustainable and ethical sources, including organic or plant-based components, to appeal to eco-conscious consumers.

Sustainable Packaging Solutions: Advances in packaging technology will lead to the widespread adoption of biodegradable, recyclable, or reusable materials. Candy bar production lines will evolve to incorporate these sustainable packaging solutions, reducing waste and the carbon footprint of production.

Energy Efficiency: Future production lines will be designed with energy efficiency in mind, using renewable energy sources, optimizing production processes, and reducing waste.

4. Health-Conscious and Functional Candy Bars

As consumer demand shifts towards healthier options, candy bar manufacturers will focus on creating products that are not only indulgent but also offer functional health benefits. The future of candy bar production will see a rise in "functional" bars that serve as snacks or meal replacements.

Protein and Nutrient-Rich Bars: The demand for protein-packed, high-fiber, and nutrient-rich candy bars is expected to grow. Manufacturers will focus on adding functional ingredients like vitamins, minerals, and probiotics to appeal to health-conscious consumers.

Sugar-Free and Low-Calorie Options: With increasing concerns about sugar consumption and obesity, candy bars with reduced sugar or natural sweeteners will continue to gain popularity. The future will see more sugar-free, low-carb, and even keto-friendly candy bar options.

Clean Label Ingredients: Consumers are becoming more aware of the ingredients in their food, leading to a rise in clean-label candy bars that are free from artificial preservatives, colors, and flavors.

5. Advanced Data Analytics and IoT Integration

The future of candy bar lines will be closely tied to the integration of advanced data analytics and the Internet of Things (IoT). By connecting machines, sensors, and devices on the production line, manufacturers will be able to gather real-time data, optimize processes, and improve quality control.

Real-Time Monitoring: IoT sensors will monitor various parameters such as temperature, humidity, and production speed in real-time, allowing manufacturers to make immediate adjustments for optimal performance.

Predictive Maintenance: With advanced data analytics, manufacturers will be able to predict when machines will need maintenance or repairs, reducing downtime and preventing costly breakdowns.

6. Smart Packaging and Digitalization

Packaging technology will continue to evolve, with smart packaging becoming an essential part of the candy bar industry. Digitalization in packaging will allow for new ways to engage consumers and enhance product experience.

Interactive Packaging: The future of candy bar packaging will include features like QR codes or augmented reality (AR), allowing consumers to engage with the brand in innovative ways, such as accessing promotions, information about ingredients, or sustainability efforts.

Enhanced Shelf-Life: Smart packaging solutions will help extend the shelf life of candy bars by providing real-time information about freshness and storage conditions. This will improve the quality of products and reduce food waste.

7. Speed to Market and Smaller Batch Production

As consumer trends and preferences continue to change rapidly, manufacturers will need to adapt quickly to market demands. The future will see more flexible candy bar production lines capable of switching between products with minimal downtime.

Quick Changeovers: Future candy bar lines will be designed to switch between different products, flavors, and packaging quickly, reducing the time required for retooling and minimizing production delays.

Small-Batch Production: In response to consumer demand for variety and customization, production lines will allow for smaller batch runs. This will enable manufacturers to experiment with new products or seasonal varieties without the need for major reconfiguration.

8. Global Expansion and Localization

The candy bar market is expanding globally, and manufacturers are increasingly focusing on local preferences and regional variations. The future of candy bar production lines will involve flexibility to cater to diverse tastes while maintaining efficiency.

Localization of Products: As candy bar brands expand into new regions, production lines will be adapted to accommodate local flavors, ingredients, and dietary preferences.

Global Supply Chains: Manufacturers will need to streamline their global supply chains, using advanced logistics and production technologies to ensure timely and cost-effective delivery of raw materials and finished products worldwide.

The future of candy bar production lines is filled with exciting possibilities, from fully automated systems and customized products to sustainability efforts and health-conscious options. As technological innovations continue to shape the industry, candy manufacturers will be better equipped to meet evolving consumer demands while improving efficiency and product quality. With the continuous advancement of production technologies, the candy bar industry will continue to thrive and innovate.

For businesses seeking to invest in cutting-edge candy bar production technology, consider working with a trusted supplier like Gusu Food Processing Machinery Suzhou Co., Ltd. Their expertise in designing and manufacturing efficient and reliable candy bar production lines can help your company stay competitive in an ever-changing market.

English

English Español

Español