What is a Chocolate Depositor?

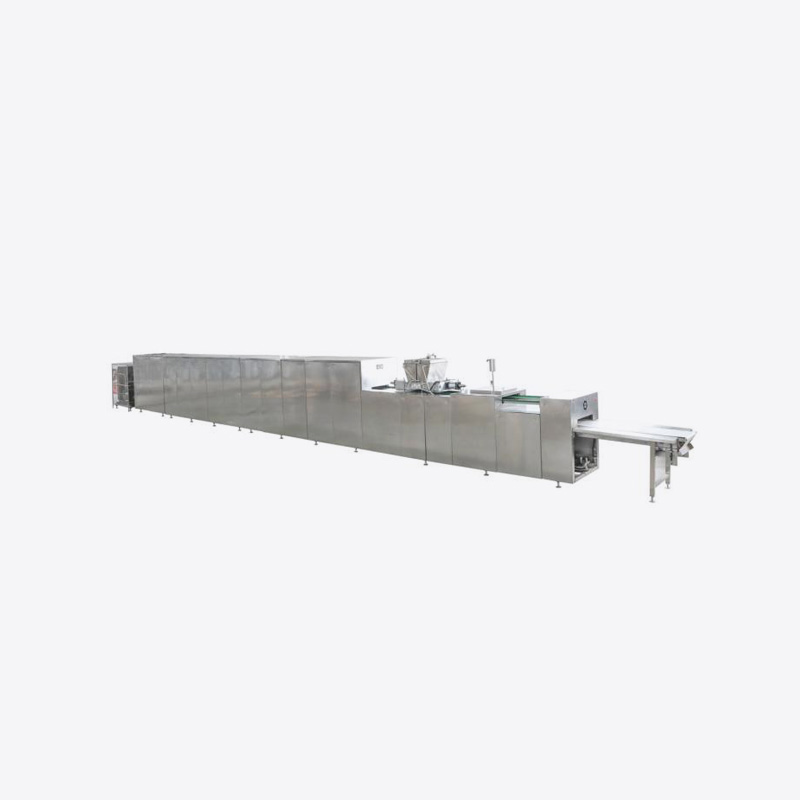

A chocolate depositor is a specialized machine used in the food industry to precisely and efficiently deposit liquid chocolate into molds. It plays a crucial role in the production of a variety of chocolate products, such as bars, bonbons, truffles, and other confectionery items. The machine is designed to handle liquid chocolate at varying temperatures and to deposit it accurately into molds or onto surfaces with consistent weight and shape.

Chocolate depositors are essential for large-scale chocolate manufacturing, providing both consistency and speed in the production process. By automating the chocolate depositing process, manufacturers can achieve higher efficiency, reduce human error, and maintain high-quality standards across large production runs.

Key Features of a Chocolate Depositor

A chocolate depositor is a specialized machine designed to automate the process of depositing liquid chocolate into molds or onto various surfaces. The features of a chocolate depositor ensure precision, efficiency, and quality in chocolate production, making it a crucial piece of equipment for chocolatiers and manufacturers alike.

1. Precise Chocolate Deposition

One of the most important features of a chocolate depositor is its ability to deposit chocolate accurately and uniformly. Whether it's for filling molds, creating chocolate bars, or forming intricate shapes, a chocolate depositor ensures that each piece is consistently formed to meet exact specifications. This precision is especially crucial for maintaining product quality and consumer satisfaction, as irregularities in shape or size can affect the appearance and appeal of the final product.

Benefit:

Ensures consistent and uniform chocolate deposition, enhancing product quality and presentation.

Reduces waste by minimizing over-deposition or under-deposition.

2. Adjustable Speed and Flow Control

Chocolate depositors typically come equipped with adjustable speed and flow control systems, allowing operators to tailor the deposition process to the specific needs of their production. The ability to control the flow rate of the chocolate and the speed of the deposition ensures that the correct amount of chocolate is deposited into each mold or onto the desired surface. This flexibility makes chocolate depositors suitable for a wide range of products, from solid chocolate bars to filled chocolates and other confectioneries.

Benefit:

Customizable settings for different chocolate products and production speeds.

Greater control over chocolate volume and consistency, ensuring minimal waste.

3. Multi-Function Capability

Modern chocolate depositors offer versatility, allowing manufacturers to create a variety of chocolate products. Many machines come with multiple functions, such as the ability to deposit chocolate in layers, create complex designs, or add fillings like nuts or caramel to chocolates. The ability to perform multiple tasks within a single machine enhances production efficiency and saves space in the production facility.

Benefit:

Ability to produce a wide variety of chocolate products, from simple molds to more complex designs.

Reduces the need for multiple machines, saving on floor space and reducing costs.

4. Temperature Control System

Temperature plays a critical role in chocolate production. The chocolate must be kept at a specific temperature for proper viscosity and texture. Most chocolate depositors come with built-in temperature control systems that help maintain the chocolate at the ideal temperature for deposition. This ensures that the chocolate remains smooth and easy to work with while also preventing issues such as chocolate hardening or separating during the production process.

Benefit:

Maintains optimal temperature for smooth, consistent chocolate flow.

Prevents common issues like thickening or separating chocolate, ensuring high-quality end products.

5. Easy to Operate

Chocolate depositors are designed with user-friendly interfaces that make them easy to operate, even for those without extensive technical knowledge. Many machines feature touchscreen controls or simple manual settings that allow operators to adjust chocolate flow, speed, and other parameters quickly and efficiently. This ease of use reduces the time needed for training and helps operators maximize productivity from day one.

Benefit:

Intuitive controls make it easy for operators to set and adjust the machine.

Shorter learning curve for staff, resulting in faster onboarding and increased efficiency.

6. Hygienic and Easy to Clean

Maintaining hygiene in food production is essential, and chocolate depositors are designed with easy-to-clean surfaces to comply with food safety regulations. Many machines feature removable parts, such as nozzles and chocolate tanks, that can be disassembled for thorough cleaning. This design ensures that the equipment stays sanitary, reducing the risk of contamination and improving the overall cleanliness of the production area.

Benefit:

Easy-to-clean components help maintain high hygiene standards in the production process.

Reduces downtime for cleaning, ensuring smooth, uninterrupted operation.

7. Continuous Operation

Most chocolate depositors are designed for continuous operation, meaning they can run for long periods without requiring frequent stops for maintenance or adjustments. This feature is essential for high-volume production, where maintaining a consistent output is critical. The robust construction of chocolate depositors ensures that they can withstand long production runs, making them ideal for both small and large-scale chocolate manufacturers.

Benefit:

Ability to operate continuously for extended periods, increasing production efficiency.

Suitable for high-demand environments, ensuring a reliable, uninterrupted flow of products.

8. Energy-Efficient Design

Energy efficiency is an important consideration in modern production, and many chocolate depositors are designed with this in mind. The machines are built to use less energy during operation, which helps reduce overall energy costs and minimizes the environmental impact of the production process. This is especially beneficial for businesses looking to reduce their operating costs and improve their sustainability.

Benefit:

Lower energy consumption, leading to reduced operating costs.

More environmentally friendly operation, aligning with sustainability goals.

9. Built-in Safety Features

Safety is a top priority in food production, and chocolate depositors are often equipped with various safety features to protect operators and the machine. These safety features can include automatic shut-offs, protective covers, and emergency stop buttons, which help prevent accidents or damage during operation. Such features ensure that the chocolate depositor operates in a safe environment, minimizing risks for employees.

Benefit:

Enhances operator safety with built-in safety mechanisms.

Reduces the likelihood of accidents or machine damage.

10. Durability and Reliability

A high-quality chocolate depositor is built to last. These machines are made with durable materials that can withstand the rigors of continuous use, even in high-volume environments. The durability of the chocolate depositor ensures that it will continue to perform efficiently over time, reducing the need for frequent repairs or replacements and providing a good return on investment.

Benefit:

Long-lasting performance with minimal need for repairs or replacements.

Provides a solid return on investment by minimizing operational disruptions.

How Does Chocolate Depositor Works

A chocolate depositor is an essential machine used in the chocolate production process. It automates the deposition of liquid chocolate into molds, onto surfaces, or into specific shapes, ensuring precision and consistency in chocolate products.

1. Chocolate Preparation and Feeding

The process begins with the preparation and feeding of liquid chocolate into the depositor. Depending on the type of chocolate being used (dark, milk, or white), the chocolate is melted and kept at a controlled temperature to maintain the right consistency for easy flow. A tank or reservoir holds the liquid chocolate, which is pumped into the depositor's system.

How It Works:

The chocolate is melted and stored at the correct temperature in a tank or container.

The chocolate is transferred to the depositor through a pump or feeding system that ensures a consistent flow of chocolate.

2. Chocolate Flow Control

Once the chocolate is inside the depositor, it needs to be controlled for smooth and accurate deposition. The depositor typically has a flow control system that regulates the amount of chocolate dispensed. This system is essential for ensuring the right amount of chocolate is deposited in each mold or on the desired surface, avoiding over-deposition or under-deposition.

How It Works:

A flow control valve adjusts the flow rate of chocolate, ensuring the correct amount is dispensed.

The speed of chocolate flow can be adjusted depending on the requirements of the production line or specific product being made.

3. Temperature Regulation

Temperature control is a critical aspect of the chocolate depositing process. If the chocolate cools too much, it may become too thick and difficult to deposit accurately. If it's too hot, it can be runny and difficult to manage. Most chocolate depositors have a built-in heating system to regulate the temperature of the chocolate, ensuring it remains at the optimal consistency for smooth deposition.

How It Works:

A heating system or jacket surrounding the chocolate tank keeps the chocolate at a steady, consistent temperature.

The temperature is continually monitored to prevent overheating or cooling of the chocolate, ensuring smooth, consistent deposition throughout the process.

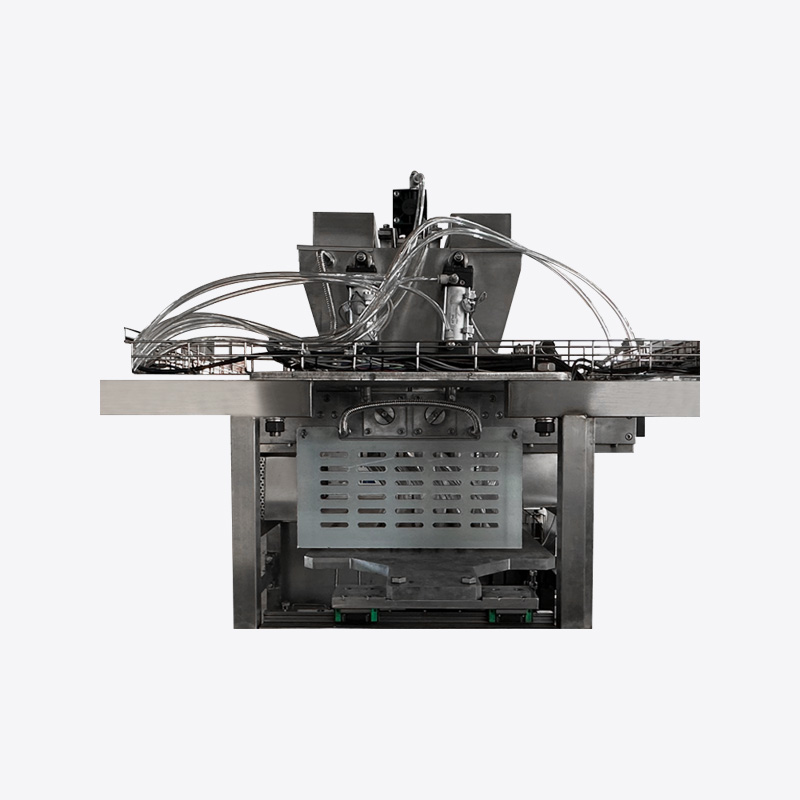

4. Deposition Mechanism

The actual deposition of chocolate occurs through a nozzle or series of nozzles. These nozzles can be adjusted to different shapes and sizes to create a variety of products, from filled chocolates to solid bars or intricate designs. Some depositors may have multiple nozzles that allow for different patterns or designs to be created simultaneously, further improving production efficiency.

How It Works:

Chocolate is dispensed from the reservoir through nozzles onto molds or trays.

The depositor may have various nozzle configurations for different shapes, such as circular, rectangular, or custom patterns.

The depositor may include additional features, such as vibration systems or air jets, to ensure the chocolate flows smoothly and fills the molds evenly.

5. Molding and Shaping

Many chocolate depositors are designed to deposit chocolate directly into molds, which are then cooled to solidify the product. In more advanced models, the depositor can deposit chocolate with precision to create detailed shapes and intricate patterns. Molding systems work in conjunction with the depositor to form products like chocolates, truffles, bars, and other confectioneries.

How It Works:

Molds are placed on a conveyor or moved into position beneath the depositor.

The depositor precisely fills the molds with the correct amount of chocolate, ensuring uniformity and consistency in each product.

Once filled, the molds are transported to a cooling or setting area to solidify the chocolate.

6. Automation and Efficiency

One of the key advantages of using a chocolate depositor is the level of automation it brings to the production process. The machine can operate continuously, allowing for high-speed, high-volume production. The automation of the depositing process reduces the need for manual labor, speeding up the production process, and ensuring consistency in product quality.

How It Works:

The depositor is typically integrated with a production line that includes cooling, molding, and packaging systems.

Sensors, controls, and automated systems monitor and adjust the deposition process in real time, maintaining high standards of quality and reducing the chances of human error.

The depositor operates with minimal supervision, freeing up workers for other tasks on the production line.

7. Post-Deposit Cooling and Packaging

After the chocolate has been deposited into molds or onto surfaces, the next step in the process is cooling and solidifying the chocolate. The molded chocolate products are typically transferred to a cooling tunnel or cooling system to solidify the chocolate before being packaged. This step ensures that the final product has a smooth, glossy finish.

How It Works:

After deposition, chocolate products are cooled in a controlled environment to set the shape and texture.

The cooling system uses air or refrigeration to rapidly cool the chocolate and ensure it solidifies evenly.

Once solidified, the chocolate products are ready for packaging, further handling, or distribution.

8. Cleaning and Maintenance

To ensure continued efficiency and hygiene in the chocolate depositing process, the machine requires regular cleaning and maintenance. Most chocolate depositors are designed for easy disassembly, with removable parts that can be cleaned between production runs. Proper maintenance helps prevent clogs, reduces the risk of contamination, and ensures the machine continues to operate at peak performance.

How It Works:

The depositor is disassembled or cleaned between production cycles to prevent chocolate buildup.

Parts such as nozzles, tanks, and molds are thoroughly cleaned and sanitized before the next production run.

What Are the Different Types of Chocolate Depositors and Their Applications?

Chocolate depositors are essential in the mass production of chocolate products, offering manufacturers the ability to create a wide variety of confectionery with precision and speed. However, not all chocolate depositors are the same. There are different types of chocolate depositors, each designed to meet specific production needs and product requirements.

1. Piston-Type Chocolate Depositors

Piston-type chocolate depositors are among the most common and widely used in chocolate manufacturing. These machines use a piston system to push liquid chocolate through a nozzle into molds, ensuring precise and consistent portions. The piston can be adjusted to control the amount of chocolate deposited, making this type of depositor highly flexible.

Applications:

Solid Chocolate Bars: Piston-type depositors are ideal for producing solid chocolate products, such as bars, by accurately filling molds with chocolate.

Filled Chocolates: These depositors are also used in the production of chocolates with fillings, such as truffles or bonbons. The piston can deposit chocolate around a center filling, creating a uniform shell.

Multi-Layer Chocolates: For layered chocolate products, the piston-type system can be programmed to deposit different layers of chocolate, ensuring consistent patterns.

2. Gravity-Fed Chocolate Depositors

Gravity-fed chocolate depositors rely on the natural force of gravity to flow chocolate from the melting tank through a nozzle and into molds. These machines are simple and effective, especially for thicker chocolate that flows easily. Gravity-fed systems tend to be cost-effective and ideal for applications requiring larger batches.

Applications:

Bulk Chocolate Products: This type of depositor is often used for bulk chocolate items like large chocolate blocks or simple molds, where the chocolate does not need to be deposited in very precise portions.

Coating Products: Gravity-fed depositors can be used for coating items like cookies, fruit, or other confections, where the aim is to cover the surface with a uniform layer of chocolate.

Chocolate Bars with Simple Designs: For chocolate bars or items with basic shapes and no intricate details, gravity-fed depositors are sufficient for fast production.

3. Rotary Chocolate Depositors

Rotary chocolate depositors are more advanced machines, featuring a rotating drum that deposits chocolate into molds. The rotating system ensures even distribution and is often used for high-speed production lines. This type of depositor provides high efficiency and can handle continuous operations.

Applications:

High-Speed Production: Rotary depositors are ideal for environments where large volumes of chocolate need to be deposited quickly, such as in the mass production of chocolate bars and other confections.

Automated Production Lines: These depositors are often used in automated systems where minimal human intervention is required. They can seamlessly integrate with other machines, such as cooling tunnels, to maintain a smooth production flow.

Chocolate Molds with Complex Designs: Rotary depositors can also be used to deposit chocolate into molds with intricate shapes or patterns, as the rotary motion ensures an even distribution.

4. Enrobing Chocolate Depositors

Enrobing chocolate depositors are used primarily for coating confections, such as biscuits, candies, and fruit. These depositors feature a continuous stream of chocolate that coats products as they pass through the machine. The chocolate can be deposited evenly on all sides of the product, creating a smooth, uniform coating.

Applications:

Coating Confections: Enrobing depositors are perfect for coating a variety of products, such as cookies, nuts, marshmallows, and fruit, with a smooth and even layer of chocolate.

Chocolate-Covered Snacks: For snack foods, such as chocolate-covered pretzels or granola bars, enrobing depositors ensure an even coating that enhances the product's appearance and texture.

Chocolate Dipping: Enrobing machines are also used for dipping smaller items into chocolate, ensuring full coverage and consistency.

5. Injecting Chocolate Depositors

Injecting chocolate depositors are specialized machines designed to inject liquid chocolate into products to create hollow centers or cavities. These machines are used when producing chocolate products with fillings or creating multi-layered chocolates.

Applications:

Hollow Chocolates: For producing hollow chocolate products like Easter eggs or chocolate figures, injecting depositors create the outer shell by injecting chocolate into molds, leaving an empty center.

Chocolate with Multiple Layers: These depositors are used for products with multiple layers, where chocolate is injected into molds, followed by fillings, and then additional chocolate layers.

Filled Chocolates: For confections such as chocolate-filled truffles, these depositors inject liquid chocolate into molds, leaving space for various types of fillings such as ganache, caramel, or cream.

6. Customizable Chocolate Depositors

Customizable chocolate depositors are designed to meet specific, unique production needs. These machines often combine features from different depositor types, such as piston, gravity, or rotary systems, to create a versatile and tailored solution for manufacturers with specific requirements.

Applications:

Bespoke Chocolate Products: Customizable depositors are ideal for high-end or bespoke chocolate products where precision, design, and flexibility are crucial.

Seasonal and Promotional Items: For companies that produce limited edition or promotional chocolate items, these depositors can be adjusted to create custom shapes, sizes, and fillings.

Chocolate Sculptures and Decorations: Customizable depositors can be adapted to create intricate chocolate decorations, sculptures, or novelty items that require a high level of design detail.

How Do You Choose the Right Chocolate Depositor for Your Production Line?

Selecting the right chocolate depositor for your production line is a critical decision that directly impacts the efficiency, quality, and consistency of your chocolate products. There are various types of chocolate depositors available, each designed for different production needs. To choose the best one for your line, it is essential to consider several factors that align with your manufacturing process, product requirements, and budget.

1. Production Volume and Speed Requirements

One of the first things to evaluate when choosing a chocolate depositor is your production volume and speed. If you are operating a large-scale production line with high-volume output, a machine with higher speed capabilities is essential to meet demand. For small to medium-sized production, a slower, more manual machine might suffice. Rotary and gravity-fed depositors are typically suited for high-speed, high-volume operations, while piston and injection depositors are better for more intricate, lower-volume production runs.

2. Type of Product and Complexity

The type of chocolate product you plan to produce will also influence your choice of depositor. If your production line is focused on simple molded chocolates or bulk products, a gravity-fed or piston-type depositor may be the best option. For more complex products such as multi-layered chocolates, filled chocolates, or chocolates with intricate designs, an injection or rotary chocolate depositor would be more suitable. Customizable depositors offer flexibility for bespoke designs and specialized chocolate products.

3. Consistency and Precision

Precision and consistency are critical factors in chocolate production. If your business demands uniform chocolate products—whether it’s for standard-sized chocolate bars or chocolates with specific patterns—a piston-type or rotary depositor may be the best fit. These machines offer high precision, ensuring consistent deposition of chocolate into molds. If your production line requires less precision, a gravity-fed system may work well for more straightforward applications, though it sacrifices some accuracy.

4. Chocolate Type and Viscosity

Different types of chocolate, such as dark chocolate, milk chocolate, or chocolate with varying fillings, have different viscosities and require specific temperature control. Ensure that the chocolate depositor you select is compatible with the type of chocolate you are working with. Some depositors are equipped with integrated temperature control systems that ensure the chocolate maintains optimal viscosity for smooth flow during the deposition process. If your line involves multiple chocolate types or complex chocolate formulations, look for a machine that can easily accommodate these variations.

5. Automation vs. Manual Operation

Consider the level of automation required for your production line. Automated chocolate depositors offer greater efficiency, speed, and precision, making them ideal for high-volume production environments. They reduce the need for manual labor, which can be time-consuming and prone to errors. However, automated systems come at a higher cost. If you are operating a smaller-scale facility or a line with more straightforward processes, a manual or semi-automated chocolate depositor may be a more cost-effective choice, offering sufficient performance at a lower price point.

6. Cleaning and Maintenance

Maintaining hygiene and cleanliness in food production is paramount. Chocolate depositors should be easy to clean and maintain, particularly if you are working with different types of chocolate or switching between products. Machines with removable parts, easy-to-clean nozzles, and self-cleaning features can save valuable time between production runs and reduce the risk of contamination. Look for depositors designed for easy disassembly and cleaning, ensuring that they meet food safety regulations and maintain optimal performance.

7. Budget and Investment

The cost of a chocolate depositor can vary greatly depending on the complexity, automation level, and specific features. It is important to set a clear budget and evaluate the long-term return on investment (ROI) based on the machine's performance, efficiency, and expected product yield. While high-end, automated depositors may have a higher upfront cost, they often provide greater long-term savings through increased production efficiency and reduced waste. For small to medium businesses, it might make sense to start with a more affordable, simpler model and upgrade as production demands grow.

8. Space and Integration with Your Production Line

Finally, consider the physical space and how the chocolate depositor will integrate with your existing production line. The size and layout of the machine must be compatible with your production facility and other equipment. Additionally, check if the chocolate depositor can seamlessly integrate with your automation systems or production line controls. This ensures smooth operations and minimizes disruptions during production.

9. Supplier and Support Services

When selecting a chocolate depositor, it is also essential to choose a reputable supplier that offers reliable customer support and after-sales services. A trustworthy supplier will not only provide the right equipment but also offer training, troubleshooting, and maintenance support. Ensuring that you have access to professional help in case of issues will prevent downtime and ensure your production line remains efficient.

What Are the Latest Innovations and Trends in Chocolate Depositing Technology?

As the chocolate industry continues to evolve, so too does the technology behind chocolate depositing. Manufacturers are increasingly focusing on innovations that enhance efficiency, precision, and customization in chocolate production. From automation to sustainability, new trends in chocolate depositing technology are revolutionizing the way chocolate products are made, allowing for greater production capabilities and higher-quality end products.

1. Increased Automation and Integration with Smart Manufacturing

One of the most significant trends in chocolate depositing technology is the increased automation and integration of machines with Industry 4.0 technologies. Smart manufacturing systems are now being incorporated into chocolate depositors to monitor and adjust processes in real time. These systems enable predictive maintenance, ensuring minimal downtime and optimizing machine performance by analyzing data from sensors embedded in the machines.

Trend:

Automation is allowing for more precise control over chocolate deposition, reducing the need for manual labor while increasing production efficiency.

Advanced software integrates with the depositors, enabling seamless communication between machines, enhancing process control and minimizing human error.

2. Robotic Integration for Multi-Tasking

Robots are increasingly being integrated with chocolate depositing systems to carry out multi-tasking functions such as filling molds, applying chocolate coatings, and even packaging the finished products. Robotic arms, equipped with precision controls, can handle delicate chocolate products without damaging them, making them ideal for high-quality confectionery production.

Trend:

The integration of robotics enhances the efficiency of chocolate depositing lines and expands their capabilities to handle more complex tasks.

This robotic technology helps manufacturers create products with consistent quality and intricate designs, such as filled chocolates or layered confections.

3. Enhanced Temperature Control Systems

Temperature control plays a crucial role in chocolate depositing, as the viscosity of chocolate is highly sensitive to temperature changes. Recent innovations focus on advanced temperature control systems that maintain the ideal chocolate temperature throughout the entire depositing process. These systems ensure that the chocolate maintains its fluidity and texture, preventing issues like improper filling or chocolate seizing during the deposition.

Trend:

More sophisticated temperature regulation ensures consistent flow and precision, even with different types of chocolates or formulations.

Temperature-controlled depositing systems are particularly important for applications where precise texture and finish are required, such as in premium chocolates or chocolate coatings.

4. Customization and Flexible Designs for Unique Products

Customization is a growing trend in chocolate production, as consumers demand more personalized and unique products. Chocolate depositors are now designed to accommodate a wider range of mold designs, from simple shapes to more intricate, multi-layered, and customized items. Machines can easily switch between various mold designs without the need for extensive downtime or adjustments.

Trend:

Customizable depositors allow manufacturers to produce limited-edition products, novelty chocolates, or artisanal chocolates that cater to niche markets.

The ability to rapidly switch between different designs and patterns allows for flexibility and creativity, enabling chocolate manufacturers to cater to specific customer preferences.

5. Sustainability and Eco-Friendly Materials

With increasing consumer demand for sustainable products, chocolate manufacturers are placing a greater emphasis on eco-friendly materials and processes. In response, chocolate depositors are being designed to work with sustainable, biodegradable, and recyclable materials. Additionally, energy-efficient machines are being developed to reduce energy consumption during chocolate depositing, making the process more environmentally friendly.

Trend:

Manufacturers are turning to recyclable or biodegradable packaging, and even the chocolate itself is being made with more sustainable ingredients.

New depositing technologies focus on reducing energy consumption and minimizing waste, both of which are increasingly important to modern consumers and businesses alike.

6. Improved Precision and Speed

As demand for high-quality chocolate products rises, there is an increasing focus on improving the precision and speed of chocolate depositors. Innovations in sensor technologies and machine design have significantly enhanced the precision with which chocolate can be deposited into molds or onto products. This is particularly important for high-volume production lines, where maintaining consistency and product quality is essential.

Trend:

Enhanced precision in chocolate deposition ensures that each product meets strict quality standards.

Faster deposition speeds allow manufacturers to meet the growing demand for chocolate products, while still maintaining high levels of accuracy and consistency.

7. Touchscreen Interfaces and Advanced User Control

Chocolate depositors are also becoming more user-friendly, thanks to the introduction of intuitive touchscreen interfaces. These advanced control panels allow operators to easily adjust settings, monitor production, and troubleshoot issues without the need for complex programming or manual adjustments. Additionally, real-time feedback on the production process is available, giving operators greater insight into the performance of the machine.

Trend:

Touchscreen interfaces make it easier for operators to manage production, enhancing user experience and minimizing operational errors.

Real-time monitoring and control systems allow for faster decision-making and greater production efficiency.

8. Increased Focus on Hygiene and Easy Cleaning

Hygiene is paramount in the food industry, and chocolate manufacturers are paying more attention to the cleanliness of their equipment. Recent advancements in chocolate depositors focus on improving ease of cleaning and preventing contamination. Machines are now designed with smooth surfaces, removable parts, and self-cleaning mechanisms that make it easier to maintain the necessary sanitary conditions for food production.

Trend:

Chocolate depositors are designed with food safety and hygiene in mind, ensuring that operators can clean machines easily between production runs.

Self-cleaning and quick-disassembly features are reducing downtime and enhancing the overall efficiency of the chocolate depositing process.

What Are the Common Challenges and Solutions with Chocolate Depositors?

Chocolate depositors are essential machines in the confectionery industry, ensuring that chocolate products are produced with precision, speed, and efficiency. However, like any piece of machinery, chocolate depositors can encounter various challenges that can impact production quality and efficiency. Understanding these challenges and implementing appropriate solutions can help manufacturers maintain smooth operations and ensure high-quality products.

1. Inconsistent Chocolate Flow

One of the most common issues with chocolate depositors is inconsistent chocolate flow, which can result in products with irregular shapes, thicknesses, or incomplete filling. This issue can occur due to various reasons, including incorrect temperature settings, clogged nozzles, or uneven chocolate viscosity.

Solution:

Temperature Control: Ensure that the chocolate is kept at the proper temperature throughout the deposition process. Use advanced temperature control systems that maintain optimal viscosity, ensuring consistent flow.

Regular Maintenance: Clean the machine regularly to prevent chocolate buildup in the nozzles or pipes. Implement a maintenance schedule that includes checking for blockages or other factors that may cause inconsistent flow.

Proper Chocolate Mixing: Ensure the chocolate is properly mixed to achieve the correct consistency and viscosity for the depositing process.

2. Chocolate Crystallization or Seizing

Chocolate crystallization or seizing occurs when the cocoa fat in chocolate begins to harden prematurely, causing the chocolate to become thick, grainy, or difficult to work with. This issue can result in uneven deposition or clogged machines, causing delays and wastage.

Solution:

Temperature Control: Crystallization often happens when the chocolate is either too cold or overheated. Ensure that your depositing machine is equipped with precise temperature regulation to keep the chocolate at an ideal temperature.

Use of Stabilizers: Add stabilizers or emulsifiers to the chocolate mix to help maintain the chocolate's fluidity and prevent premature hardening.

Check for Contaminants: Make sure that no water or impurities come into contact with the chocolate, as even small amounts can cause seizing.

3. Inaccurate Depositing or Mold Filling

Inaccurate depositing or incomplete mold filling can result in defective chocolate products, waste, and low productivity. This issue can occur when the chocolate depositor does not consistently deposit the correct amount of chocolate into the molds, leading to under-filled or uneven products.

Solution:

Calibration: Regularly calibrate the chocolate depositor to ensure it is accurately dispensing the correct amount of chocolate. Calibration should be performed according to production requirements to ensure precise deposition.

Upgrade to a High-Precision Depositor: Consider upgrading to a more advanced depositor with precise control mechanisms, such as piston or rotary depositors, which offer greater accuracy in mold filling.

Automated Control Systems: Implement automated control systems that monitor the deposition process in real-time and make necessary adjustments to maintain consistency.

4. Depositor Jams or Blockages

Chocolate depositors can experience jams or blockages, particularly if the chocolate is not adequately filtered or if the machine is not cleaned regularly. These blockages can cause production downtime, increased maintenance costs, and reduced efficiency.

Solution:

Regular Cleaning and Maintenance: Regular cleaning of the machine, including the nozzles and pipes, is crucial to prevent chocolate buildup. Implement a routine cleaning process to ensure that the chocolate depositor remains clear and functional.

Filter the Chocolate: Use filtration systems to remove any unwanted particles or impurities from the chocolate before it enters the depositor. This will reduce the risk of clogging and jams.

Monitor Flow Rate: Adjust the flow rate and temperature of the chocolate to ensure smooth deposition and minimize the risk of blockages.

5. Inconsistent Quality and Appearance

Inconsistent chocolate quality or appearance, such as streaks, bubbles, or uneven surfaces, can occur if the chocolate is not deposited uniformly. This can be due to variations in temperature, viscosity, or the chocolate formula.

Solution:

Control Viscosity: Ensure that the chocolate has the right viscosity for consistent deposition. If necessary, adjust the chocolate's ingredients or use additives to maintain uniformity in texture.

Improve Mold Design: Ensure that the molds used in the deposition process are of high quality and are designed for uniform filling. Molds with proper vents and precise cavity shapes will help achieve consistent results.

Monitor Machine Speed: Adjust the speed of the depositor to maintain smooth deposition. High speeds can sometimes cause issues with consistency, so finding the right balance between speed and accuracy is key.

6. Machine Downtime and Maintenance Issues

Like any production equipment, chocolate depositors may experience downtime due to mechanical failures, wear and tear, or other technical issues. These interruptions can disrupt production schedules and lead to costly delays.

Solution:

Regular Preventative Maintenance: Establish a regular maintenance schedule to check for any potential issues before they lead to breakdowns. Replace worn parts, lubricate moving components, and ensure that the machine is running smoothly.

Use High-Quality Parts: Invest in high-quality components to reduce the likelihood of failures. Reliable parts will ensure that the depositor performs optimally for longer periods, reducing downtime.

Operator Training: Ensure that operators are well-trained in troubleshooting and identifying common issues. This can help minimize downtime by allowing quick fixes when small problems arise.

7. Energy Consumption and Cost Efficiency

Chocolate depositors, particularly those with advanced automation and high-speed capabilities, can consume a significant amount of energy. Excessive energy consumption can lead to higher operational costs and impact the overall profitability of the production line.

Solution:

Invest in Energy-Efficient Machines: Look for chocolate depositors designed with energy-saving features, such as variable speed drives and optimized heating systems.

Optimize Production Schedules: Plan production runs efficiently to reduce idle times and ensure that the machine is running at optimal capacity during working hours.

Regularly Monitor Energy Use: Track the energy consumption of your chocolate depositor and make adjustments as needed to optimize energy usage.

Why Should You Invest in a Chocolate Depositor for Your Business?

Investing in a chocolate depositor is a significant decision for any business involved in the production of chocolate products. These machines are designed to streamline the production process, ensure precision, and ultimately enhance product quality. Whether you're a small-scale chocolatier or a large confectionery manufacturer, a chocolate depositor can provide several key benefits that will positively impact your business.

1. Increased Production Efficiency

One of the most compelling reasons to invest in a chocolate depositor is the substantial increase in production efficiency. These machines automate the chocolate deposition process, reducing the need for manual labor and increasing the overall throughput of your production line. This automation allows for faster production cycles, ensuring that you can meet higher demand without sacrificing quality. As a result, you can produce more products in less time, improving your business’s overall output and profitability.

Benefit:

Automated chocolate deposition speeds up the production process, reducing production time and increasing output.

Less manual intervention leads to fewer human errors and a more streamlined workflow.

2. Consistency and Quality Control

Maintaining consistent quality is crucial in the chocolate industry. A chocolate depositor ensures that each piece of chocolate is deposited with precision and uniformity. This consistency in size, shape, and filling ensures that the final product meets high-quality standards. Chocolate depositors are especially beneficial when producing large quantities, as they eliminate the variability that often comes with manual deposition, resulting in products that look and taste the same every time.

Benefit:

Chocolate depositors provide consistent and uniform results, ensuring high-quality production with minimal variation.

Improved control over the chocolate deposition process leads to better end-product consistency.

3. Customization and Versatility

Another advantage of chocolate depositors is their versatility. These machines can be used for a wide range of products, including filled chocolates, molded chocolates, bars, and intricate designs. With the ability to customize the deposition settings, you can produce chocolates with varying fillings, textures, and coatings. This versatility is particularly valuable if your business caters to diverse markets and customer preferences.

Benefit:

Chocolate depositors can accommodate a variety of chocolate products, from simple bars to complex designs with multiple fillings.

The ability to customize recipes and deposition settings allows for flexibility in product offerings and can help meet consumer demand for unique and personalized chocolates.

4. Reduction of Labor Costs

Manual chocolate deposition can be labor-intensive and time-consuming, especially in large-scale operations. By automating the chocolate depositing process, you can significantly reduce the amount of labor required to produce your products. Not only does this reduce labor costs, but it also helps minimize human error, improving the overall efficiency of your production line.

Benefit:

Reduced dependence on manual labor leads to lower operational costs.

Automation minimizes the risk of human error, leading to more consistent results and reducing waste.

5. Enhanced Hygiene and Food Safety

In the food industry, maintaining high hygiene standards is essential, particularly in chocolate production where contamination can affect the quality and safety of the product. Chocolate depositors are designed with hygiene in mind, featuring easy-to-clean surfaces and parts that can be disassembled for thorough cleaning. These features help ensure that your production line meets food safety standards and minimizes the risk of contamination.

Benefit:

Chocolate depositors are easy to clean and sanitize, helping maintain high hygiene standards.

Regular cleaning reduces the risk of chocolate contamination, which is crucial for food safety.

6. Increased Production Flexibility

A chocolate depositor offers increased flexibility by allowing you to quickly change production setups, making it easier to switch between different products or flavors. Whether you're producing seasonal chocolates, limited editions, or customized orders, a chocolate depositor can handle the necessary adjustments without the need for complex retooling or downtime. This adaptability allows your business to stay competitive and responsive to changing market demands.

Benefit:

Quick adjustments to production setups enable flexibility in product offerings and faster response times to market changes.

Increased flexibility allows your business to produce a variety of products without significant downtime or resource allocation.

7. Improved Waste Management

Waste reduction is a key concern in chocolate production, as leftover or excess chocolate can result in increased costs and inefficiency. Chocolate depositors help minimize waste by ensuring that the right amount of chocolate is deposited into each mold or product. Additionally, some machines come with features like recycling systems that allow for unused chocolate to be re-melted and reused in the production process, further reducing waste and maximizing resources.

Benefit:

Precision deposition reduces chocolate waste, leading to more efficient use of ingredients.

Some machines include recycling mechanisms that allow for unused chocolate to be reprocessed, enhancing resource efficiency.

8. Long-Term Investment and Return on Investment (ROI)

While the initial investment in a chocolate depositor may seem significant, it often delivers substantial long-term returns. The increased efficiency, quality control, and reduced labor costs can lead to a faster return on investment (ROI). Over time, the cost savings from these improvements will outweigh the upfront cost of the machine. Additionally, the ability to produce a higher volume of quality products can open up new revenue opportunities and boost your business’s profitability.

Benefit:

Increased efficiency and reduced costs lead to a quick return on investment.

Higher product quality and consistency can attract new customers and increase sales, further enhancing ROI.

9. Sustainability Benefits

As sustainability becomes an increasingly important consideration for consumers, businesses are focusing on reducing their environmental impact. Chocolate depositors help support sustainability efforts by reducing waste, optimizing energy consumption, and allowing for more efficient use of materials. Additionally, more and more manufacturers are designing machines with eco-friendly features, such as energy-efficient motors and recyclable components, to align with environmental goals.

Benefit:

Chocolate depositors contribute to sustainability by reducing waste and optimizing resource use.

Energy-efficient machines help lower operational costs and reduce your business's carbon footprint.

Why Should You Choose Chocolate Depositor Factory Gusu?

When it comes to investing in a chocolate depositor, selecting the right manufacturer is crucial for ensuring you get the best quality, performance, and support. Gusu is a well-established name in the chocolate machinery industry, known for its commitment to providing high-quality chocolate depositors that meet the needs of businesses worldwide.

1. High-Quality Manufacturing Standards

One of the primary reasons to choose Gusu as your chocolate depositor supplier is their focus on quality. The factory follows stringent manufacturing standards to ensure that each chocolate depositor is built to last and capable of performing at its best. Gusu's commitment to quality control ensures that every machine undergoes thorough testing and quality checks before it reaches the customer.

Benefit:

Machines are built to last, offering reliability and durability for continuous production cycles.

Consistent performance and reduced risk of mechanical failure.

2. Customization for Specific Needs

Gusu understands that every business has different needs when it comes to chocolate production. Whether you’re creating chocolate bars, truffles, filled chocolates, or other products, Gusu offers customizable chocolate depositors tailored to meet the specific requirements of your production line. This flexibility allows you to create a machine configuration that fits your process, ensuring the best results for your chocolate products.

Benefit:

Customizable solutions to meet unique production requirements.

Flexible designs to accommodate various types of chocolate products and production processes.

3. Advanced Technology and Innovation

Gusu invests heavily in research and development to incorporate the latest technological innovations into their chocolate depositors. Their machines feature cutting-edge technology, which helps improve deposition accuracy, efficiency, and speed. Whether it's the integration of automated systems, temperature control features, or advanced nozzles, Gusu keeps pace with the evolving needs of the confectionery industry.

Benefit:

Advanced features that enhance production efficiency, quality, and precision.

Incorporation of the latest technology to keep your business competitive.

4. Comprehensive Customer Support

When you invest in a chocolate depositor, it's important to know that you will receive reliable customer support for maintenance, troubleshooting, and upgrades. Gusu provides excellent after-sales service, with a dedicated team available to assist you with any technical issues or questions. Whether you need help with setup, troubleshooting, or part replacements, Gusu is committed to ensuring your machine runs smoothly and efficiently.

Benefit:

Reliable customer support to resolve any issues quickly and effectively.

Ongoing assistance for machine maintenance and troubleshooting.

5. Efficient Production Process

Gusu's chocolate depositors are designed to streamline the production process, enabling faster production times without sacrificing product quality. The automation capabilities of their machines ensure that chocolate is deposited uniformly, reducing the need for manual labor and increasing overall production efficiency. With optimized workflows and precise control, Gusu's depositors help you achieve high productivity levels in a shorter time.

Benefit:

Improved production efficiency with automated, high-speed deposition.

Reduced need for manual labor, leading to cost savings and faster production cycles.

6. Cost-Effective Investment

Investing in a Gusu chocolate depositor can help you maximize your return on investment. While the initial cost of purchasing the machine may seem high, the long-term benefits—such as increased efficiency, reduced labor costs, and consistent product quality—more than make up for the initial investment. Additionally, Gusu's products are designed for longevity, ensuring that your machine will continue to perform at a high level for many years, offering long-term value.

Benefit:

Cost-effective solution for businesses looking to optimize production processes.

High return on investment due to improved efficiency and reduced operational costs.

7. Global Reach and Reputation

Gusu is a trusted name in the global chocolate machinery industry. The company has built a solid reputation for delivering high-quality products to customers worldwide. Whether you're a small-scale artisan chocolatier or a large commercial manufacturer, Gusu has the experience and expertise to meet your needs. Their international presence and satisfied customer base reflect their commitment to excellence and customer satisfaction.

Benefit:

Established reputation with a global customer base.

Trust and reliability in the chocolate machinery industry.

8. Sustainability Focus

As sustainability becomes a growing concern in the food industry, Gusu recognizes the importance of eco-friendly manufacturing practices. They are committed to minimizing the environmental impact of their machines by using energy-efficient technologies, reducing waste, and ensuring that their machines comply with environmental standards. Choosing Gusu means you're investing in equipment that aligns with your sustainability goals.

Benefit:

Eco-friendly machines that align with sustainability goals.

Energy-efficient designs that help reduce operational costs and environmental impact.

9. Ease of Operation and Maintenance

Gusu's chocolate depositors are designed with user-friendly interfaces that make them easy to operate. The machines are intuitive, allowing operators to adjust settings easily for different products or production speeds. Furthermore, Gusu ensures that their machines are easy to clean and maintain, which is essential for food production environments. Regular maintenance and simple operation contribute to the longevity and reliability of the machines.

Benefit:

User-friendly machines that require minimal operator training.

Easy maintenance and cleaning processes to ensure machine longevity.

Choosing Gusu as your chocolate depositor supplier is a decision that brings numerous advantages to your business. From high-quality manufacturing to advanced technology, customization options, and exceptional customer support, Gusu offers the ideal solution for chocolate manufacturers looking to improve production efficiency, quality, and consistency. With Gusu, you're not just purchasing a machine; you're investing in a reliable partner that will support your business for years to come. If you're looking to enhance your chocolate production process, Gusu provides the expertise, innovation, and support to make that happen.

English

English Español

Español