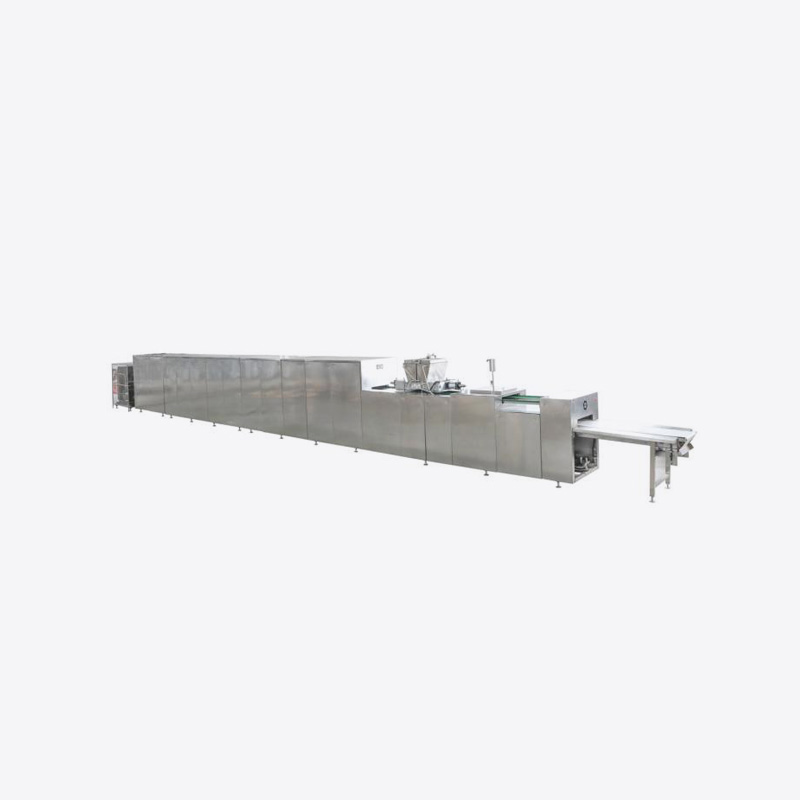

In modern chocolate manufacturing, consistency and texture are vital to producing high-quality products. A chocolate ball mill plays a central role in refining chocolate mass, transforming coarse mixtures into smooth, fine-textured chocolate. This specialized machine grinds ingredients such as cocoa nibs, sugar, milk powder, and cocoa butter into a homogeneous, silky mass. The result is chocolate with enhanced mouthfeel, shine, and flavor consistency—qualities that define premium chocolate.

Unlike traditional refining methods, a chocolate ball mill offers precision, repeatability, and reduced labor costs. Its closed-loop system ensures minimal contamination and energy efficiency, making it a preferred solution for both artisanal producers and large-scale chocolate manufacturers.

How a Chocolate Ball Mill Works: The Refining Process Explained

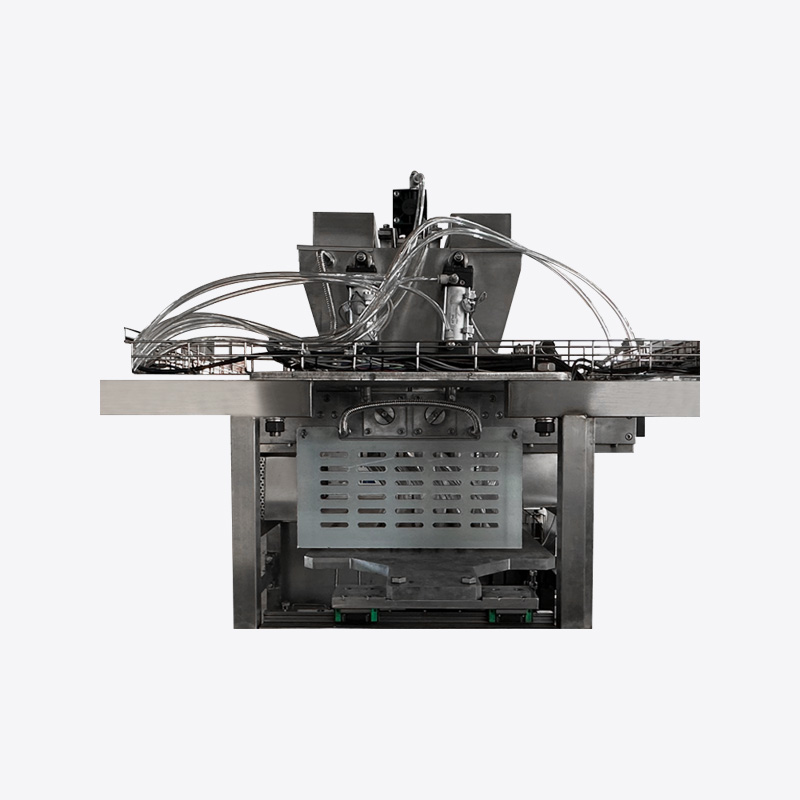

The chocolate ball mill operates on a simple yet highly effective mechanical principle — grinding through impact and friction. Inside the cylindrical chamber of the machine, hardened steel or ceramic balls rotate with the movement of the drum. As the chocolate ingredients circulate, the continuous collisions between the balls and the material gradually reduce particle size until the desired fineness is achieved.

Main Stages of the Refining Process

- Feeding: The pre-mixed chocolate ingredients are fed into the milling chamber.

- Grinding: The rotating shaft and grinding media apply pressure and friction to break down particles.

- Circulation: The chocolate mass is continuously circulated through the mill for even particle distribution.

- Refining: Particle size typically reduces to 20–25 microns, creating a fine and smooth texture.

- Discharge: Once the desired consistency is achieved, the refined chocolate is discharged into a storage tank or tempering system.

The efficiency of a chocolate ball mill depends on parameters like rotation speed, ball size, grinding time, and temperature control. Proper optimization ensures not only energy savings but also a consistently high-quality chocolate output.

Key Components of a Chocolate Ball Mill

Every chocolate ball mill is composed of several critical components that work together to ensure smooth, efficient grinding and refining. Understanding these parts helps operators maintain the machine properly and optimize performance.

| Component | Function |

|---|---|

| Grinding Chamber | Houses the grinding media and chocolate mass; where refining takes place. |

| Grinding Balls | Usually made of stainless steel or ceramic; reduce particle size through friction. |

| Rotary Shaft | Drives the grinding motion, ensuring even distribution of energy. |

| Cooling System | Maintains optimal temperature to prevent chocolate from overheating. |

| Control Panel | Allows adjustment of speed, temperature, and time for precision operation. |

Advantages of Using a Chocolate Ball Mill

The chocolate ball mill has become the industry standard for refining chocolate and similar confectionery masses because of its multiple advantages. From production quality to energy consumption, it offers measurable improvements over traditional refining systems.

- Uniform Particle Size: Achieves fine, consistent texture ideal for premium chocolate and coatings.

- Energy Efficiency: Optimized motor and circulation system reduce energy consumption.

- Compact Design: Combines refining and mixing functions in a single piece of equipment, saving floor space.

- Low Maintenance: Simple mechanical design and durable materials ensure long service life.

- Scalable Production: Available in laboratory, medium, and industrial sizes to suit different production needs.

Choosing the Right Chocolate Ball Mill for Your Production Needs

Selecting the right chocolate ball mill depends on several factors, including production capacity, batch size, product type, and desired texture. Whether you operate a small artisan workshop or an industrial chocolate plant, matching equipment specifications to your production goals is crucial.

Factors to Consider

- Capacity: Machines range from 5 kg laboratory models to 1000 kg industrial systems.

- Grinding Time: Choose a model that achieves your desired fineness within your production schedule.

- Cooling Efficiency: A reliable cooling system prevents chocolate from losing flavor due to overheating.

- Ease of Cleaning: Detachable tanks and self-cleaning functions improve hygiene and reduce downtime.

- Automation Level: Automated models with PLC controls improve precision and minimize human error.

Batch vs. Continuous Ball Mills

Chocolate ball mills are available in batch and continuous versions. A batch mill processes one batch at a time, making it ideal for small-scale or specialty chocolate production. In contrast, continuous ball mills allow for nonstop production, where chocolate mass circulates between the mill and a storage tank for consistent output and higher efficiency.

Maintenance and Operation Tips for Optimal Performance

Proper maintenance ensures the chocolate ball mill operates efficiently for years while maintaining the quality of your chocolate mass. Neglecting cleaning or lubrication can lead to mechanical wear, contamination, and inconsistent results.

Daily Maintenance Checklist

- Inspect grinding media for wear and replace as necessary.

- Check oil levels and lubrication points.

- Clean the grinding chamber and discharge valves after each batch.

- Ensure temperature sensors and control panels function correctly.

- Monitor noise levels — unusual sounds may indicate misalignment or worn bearings.

Regular preventive maintenance not only extends the lifespan of the machine but also maintains consistent quality in every batch. Scheduling professional inspections annually can prevent costly repairs and unplanned downtime.

Final Thoughts: The Importance of Precision in Chocolate Refining

The chocolate ball mill is a cornerstone of modern chocolate production, providing the precision and control required to produce superior products. Its ability to refine, mix, and homogenize ingredients efficiently allows manufacturers to achieve consistent quality and flavor.

Whether used in small workshops or large factories, investing in a well-designed chocolate ball mill enhances productivity, reduces waste, and ensures a smooth, luxurious chocolate texture that delights consumers worldwide. With proper operation and maintenance, it becomes not just a machine but a key ingredient in the art of chocolate making.

English

English Español

Español