In recent years, the confectionery market has seen remarkable growth driven by changing consumer tastes and technological innovation. Among the many processes in this industry, the Candy Bar Line has become an essential part of efficient and flexible confectionery production. This system integrates several functions—from mixing and forming to cooling and wrapping—creating a smooth workflow that ensures consistent quality and scalability.

For companies like Gusu Machinery, which specializes in confectionery processing solutions, the evolution of candy bar manufacturing represents both a challenge and an opportunity. As production methods continue to advance, manufacturers are focusing on sustainability, efficiency, and product diversity to meet global demand.

1. Understanding the Candy Bar Line

A Candy Bar Line is a comprehensive system designed to produce various types of bars, including chocolate bars, cereal bars, protein bars, and nougat-based bars. Unlike traditional manual production, a modern candy bar line allows automatic control over each stage of production.

The process typically includes the following stages:

| Stage | Function | Description |

|---|---|---|

| Mixing | Ingredient preparation | Combines ingredients such as sugar, chocolate, nuts, and cereals for uniform texture. |

| Forming | Shaping the bar | Forms a continuous bar sheet with controlled thickness and width. |

| Cooling | Stabilization | Ensures the mixture sets properly without losing texture. |

| Cutting | Portioning | Divides the sheet into consistent bar sizes. |

| Coating | Finishing | Applies layers such as chocolate, caramel, or other coatings. |

| Wrapping | Packaging | Protects the bars and prepares them for shipment. |

Each step requires precision and synchronization to maintain product consistency while minimizing waste.

2. Technological Progress in Candy Bar Production

The last decade has brought noticeable progress in candy bar production systems. The focus has shifted toward automation, energy efficiency, and flexibility. For instance, modern machinery now allows adjustable production speeds, modular layouts, and recipe programming.

These advancements mean that manufacturers can switch between different bar types without long downtimes. For example, a single line can be configured to produce a nut bar in the morning and a chocolate-filled bar in the afternoon, all with minimal manual adjustment.

Moreover, the introduction of digital monitoring systems has made it easier to track parameters like temperature, mixing speed, and cooling time. Such data helps operators maintain consistency and traceability throughout the entire process.

3. The Role of Sustainability and Resource Efficiency

Sustainability has become a central topic in global food production, and candy bar manufacturing is no exception. The confectionery industry is actively looking for methods to reduce resource consumption, optimize energy use, and minimize product loss.

Manufacturers of candy bar lines, including Gusu Machinery, are developing systems that consume less energy and produce less waste. Energy-saving cooling tunnels, precise dosing systems, and recyclable packaging solutions are now common features of modern production lines.

By optimizing process flow and machine design, companies can achieve higher output with lower operational costs, benefiting both the environment and the production budget.

4. Flexibility for Diverse Market Demands

Consumer preferences in confectionery products continue to diversify. Health-conscious customers look for low-sugar or high-protein options, while traditional candy lovers still favor rich chocolate bars. This demand diversity requires flexible equipment capable of handling multiple formulations and textures.

A modular candy bar line provides the adaptability needed to produce different recipes with minimal changeover time. Whether for a small batch of premium bars or large-scale production of mainstream products, flexibility ensures that manufacturers can stay competitive in dynamic markets.

Key Advantages of Modular Systems:

-

Easy product changeover

-

Reduced downtime between runs

-

Adaptability to new market trends

-

Efficient use of production space

These benefits make modular systems increasingly popular among confectionery producers worldwide.

5. Safety, Hygiene, and Compliance Standards

Food safety and hygiene are vital in any confectionery production environment. Candy bar lines are designed with materials and finishes that meet international standards, ensuring that every surface in contact with food can be cleaned effectively.

The use of stainless steel, sanitary design principles, and easy-access components are essential to maintain hygiene. Additionally, compliance with international regulations—such as HACCP, GMP, and ISO food safety standards—is critical.

Automated cleaning systems and closed-loop control reduce human contact with ingredients, lowering the risk of contamination. This not only enhances safety but also improves overall operational reliability.

6. Integration of Digital Technologies

Digital transformation is reshaping how production lines operate. Smart manufacturing technologies such as IoT (Internet of Things), machine learning, and remote diagnostics are now being incorporated into candy bar production.

These tools allow operators to:

-

Monitor performance in real time

-

Predict maintenance needs before breakdowns occur

-

Adjust parameters automatically for consistent output

-

Access production data remotely through secure platforms

Through such digital integration, companies gain better insight into production efficiency, enabling data-driven decision-making that supports long-term improvement.

7. Global Market Trends and Future Outlook

The global candy bar market continues to grow, with emerging markets in Asia, Africa, and South America showing rising demand. Factors such as increasing disposable income, urbanization, and innovation in flavors and packaging contribute to this expansion.

Meanwhile, the focus on natural ingredients, reduced sugar, and functional nutrition is pushing manufacturers to adapt their production lines. Candy bar lines are becoming more sophisticated to accommodate ingredients like plant-based proteins, nuts, and fruits without compromising texture or shelf life.

As the market evolves, machinery manufacturers are expected to continue innovating toward greater automation, hygiene, and energy efficiency. The future of the candy bar line will likely involve even more integration between digital monitoring, eco-friendly design, and versatile processing capabilities.

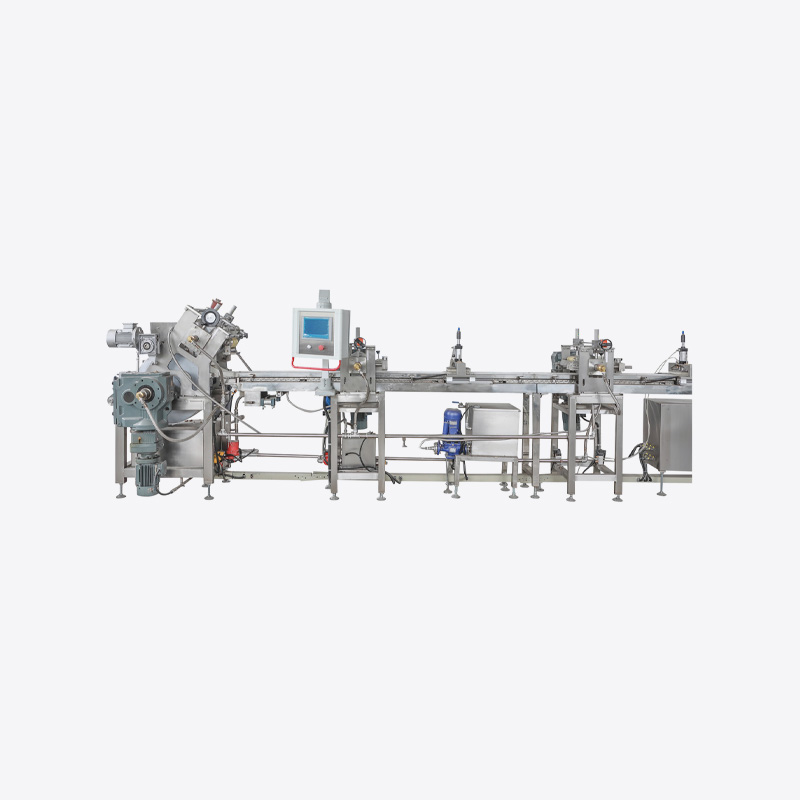

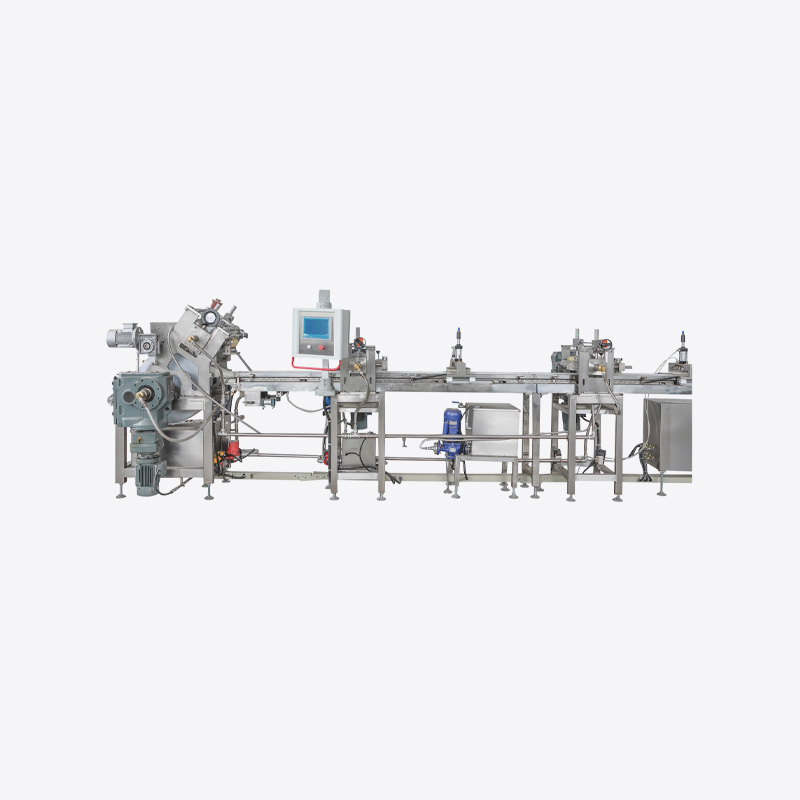

8. Gusu Machinery and Its Commitment to Industry Development

As a professional manufacturer of confectionery equipment, Gusu Machinery provides integrated solutions for chocolate, candy, and related products. The company's candy bar line is built upon years of experience in equipment design, focusing on practicality, reliability, and ease of operation.

With a global customer base, Gusu Machinery continuously refines its production systems through research and collaboration with industry partners. The company emphasizes consistent quality control, precision engineering, and adaptable configurations suitable for diverse production requirements.

While maintaining efficiency and consistency, the design philosophy aims to support sustainable manufacturing and cost-effective operation. From small-scale setups to full production plants, Gusu Machinery's systems help confectionery producers improve workflow and product diversity.

9. Toward a Smarter and More Efficient Future

The Candy Bar Line has transformed from a basic production setup into a sophisticated system capable of meeting the complex demands of the global confectionery industry. With advancements in automation, sustainability, and digital integration, candy bar production has entered a new era of precision and efficiency.

As consumer trends evolve and environmental awareness increases, equipment manufacturers will continue to innovate toward cleaner, smarter, and more flexible production systems. Companies such as Gusu Machinery are at the forefront of this transformation—supporting confectionery producers with reliable solutions that align with the future of modern food manufacturing.

English

English Español

Español