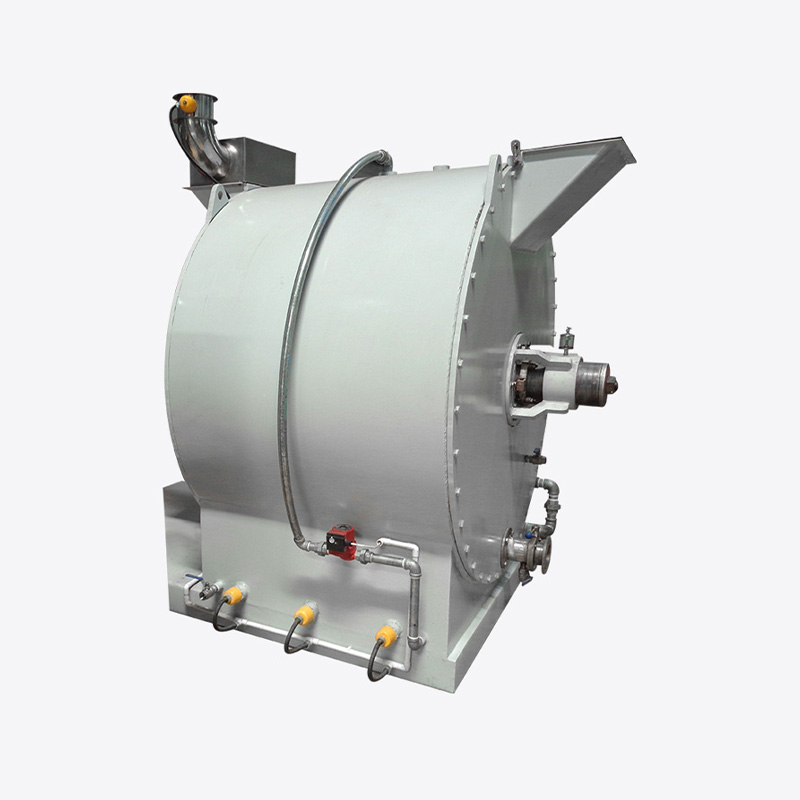

Chocolate Chips Machines Deliver Consistent and Scalable Production

A chocolate chips machine is the most reliable solution for producing uniform chocolate chips at scale. It controls shape, weight, and cooling with precision, ensuring every batch meets commercial standards. For bakeries, confectionery factories, and industrial food producers, these machines replace manual methods that often lead to inconsistent size and unstable output.

Modern chocolate chips machines can increase production efficiency by 50–70% compared to hand-depositing, while significantly reducing labor costs and material waste.

How a Chocolate Chips Machine Works

Chocolate chips machines operate by depositing tempered liquid chocolate through nozzles onto a moving conveyor belt. As droplets fall, their size is controlled by nozzle diameter, pump pressure, and depositing speed.

Core processing stages

- Chocolate feeding and temperature control

- Precision depositing through calibrated nozzles

- Cooling and solidification on conveyor belts

Accurate temperature control, typically between 30–33°C for dark chocolate, is essential to prevent blooming and ensure smooth texture.

Types of Chocolate Chips Machines

Chocolate chips machines are available in different configurations to suit various production scales and product requirements. Selecting the right type directly affects output capacity and flexibility.

| Machine Type | Output Capacity | Typical Users |

|---|---|---|

| Semi-automatic | 50–150 kg/hour | Small bakeries |

| Fully automatic | 300–1000 kg/hour | Industrial factories |

Key Benefits for Bakeries and Manufacturers

Using a chocolate chips machine improves product consistency, which is critical for baking performance and consumer expectations. Uniform chips melt evenly, distribute better in dough, and enhance final texture.

Many manufacturers report waste reduction of 10–15% after switching from manual forming to automated chocolate chips machines, mainly due to improved size control and reduced breakage.

Capacity Planning and Output Efficiency

Choosing the correct capacity is essential to avoid bottlenecks or underutilized equipment. Production volume should align with downstream processes such as cooling tunnels, packaging, and storage.

For example, a medium-sized cookie factory producing 2 tons of dough daily typically requires a chocolate chips machine capable of at least 400 kg/hour to maintain smooth workflow.

Hygiene, Safety, and Food Compliance

Chocolate chips machines are built to meet strict food safety standards. Stainless steel contact parts, smooth welds, and easy disassembly reduce contamination risks and simplify cleaning.

Compliance with standards such as CE and FDA ensures machines are suitable for global food production environments, protecting both product quality and operator safety.

Maintenance and Long-Term Operating Costs

Regular maintenance is straightforward for well-designed chocolate chips machines. Daily cleaning and periodic inspection of nozzles and pumps help maintain consistent output.

Over a five-year period, automated machines typically deliver a return on investment within 18–24 months, driven by labor savings and higher production stability.

Selecting the Right Chocolate Chips Machine

The ideal chocolate chips machine balances capacity, precision, and reliability. Factors such as chocolate type, chip size range, and available space should guide selection decisions.

When properly selected and operated, a chocolate chips machine becomes a core asset that ensures consistent quality, scalable production, and long-term profitability.

English

English Español

Español