The Essential Guide To Modern Chocolate Chips Machine Operation

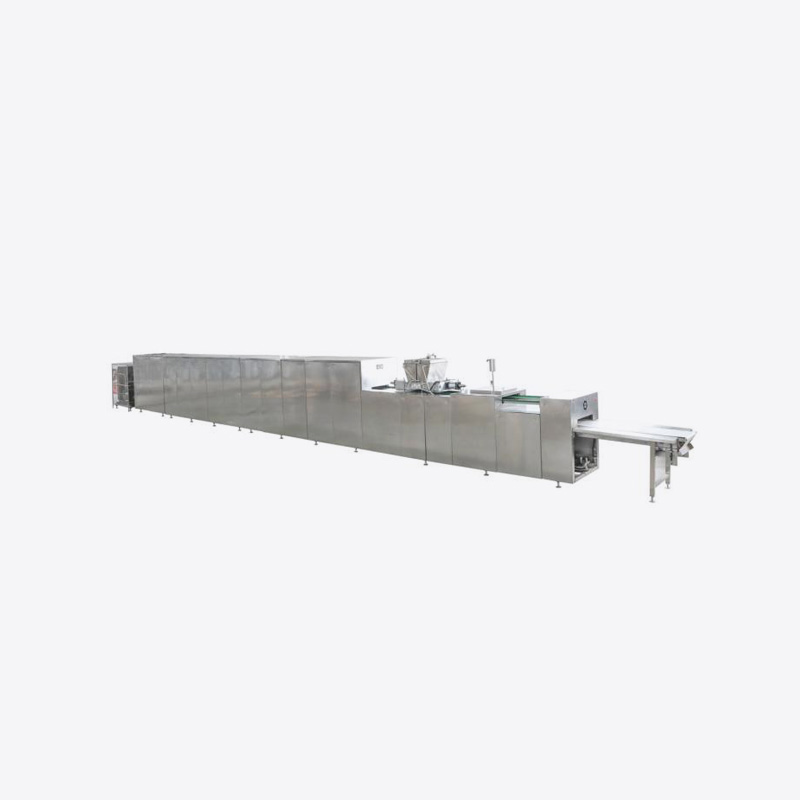

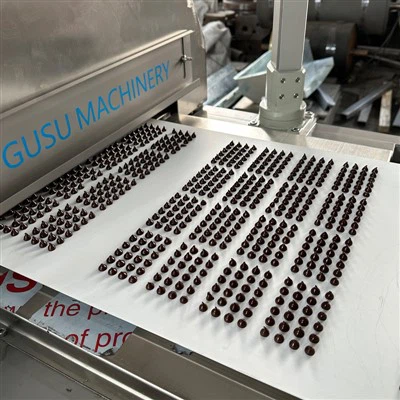

Chocolate Chips Machine technology represents a cornerstone in the efficient, high-quality production of this beloved confectionery staple. Specifically engineered to form and deposit uniform chocolate chips with precision and speed, these sophisticated systems transform liquid chocolate into the consistent, free-flowing chips essential for countless recipes and products. Understanding their core features and operation is key to maximizing output and quality.

What Makes A Chocolate Chips Machine Effective?

Modern chocolate chips machines integrate several critical features designed to streamline the depositing process, ensure product consistency, and maintain stringent hygiene standards:

1. Intelligent Control Systems: At the heart lies an automated PLC unit. This sophisticated control system simplifies operation, allowing precise monitoring and adjustment of the entire depositing cycle. An interactive HMI touchscreen provides intuitive access for operators to manage recipes, adjust settings, and monitor performance in real-time. Crucially, recipe storage capabilities enable operators to save exact parameters for different chip types, ensuring perfect replication of size, shape, and volume every time production resumes.

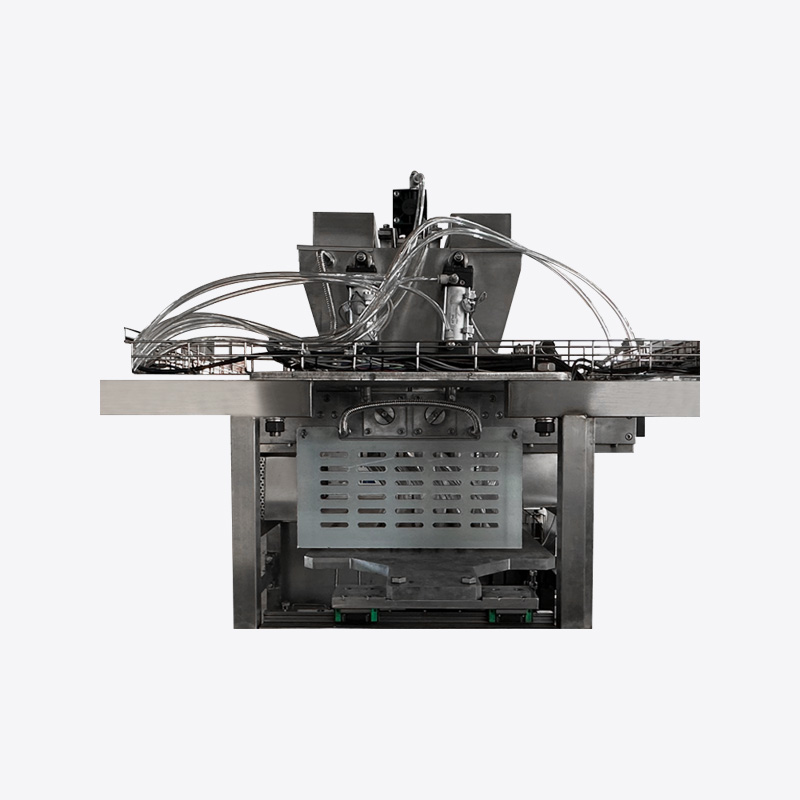

2. Precision Deposition Mechanism: A high-performance piston depositor is fundamental. This mechanism guarantees exceptional accuracy in depositing the chocolate batter, critical for achieving uniform chip weight and dimension. It operates at high speeds, enabling rapid production cycles essential for meeting large volume demands. This precision is vital whether producing miniature chips or larger baking varieties.

3. Versatile Flow Management: Internal mass channels engineered into the nozzle plates are specifically designed to handle the unique flow characteristics of chocolate batters destined for chips. These channels accommodate variations in viscosity, ensuring smooth, uninterrupted flow even with formulations that might be thicker or more complex. The system's flexibility also allows for potential integration of specialized units to handle inclusions or specific flavor additions during the depositing stage.

4. Hygienic Material Construction: Meeting food safety regulations is paramount. Chocolate chips machines are predominantly constructed from high-grade stainless steel. This material is chosen for its exceptional durability, inherent corrosion resistance, ease of cleaning, and non-reactive properties. It prevents product contamination and withstands the rigorous sanitation protocols required in food processing environments.

5. Robust Quality Compliance: Adherence to international and regional standards is non-negotiable. Reputable chocolate chips machines are designed and built to comply with critical certifications like the CE Mark and principles of Good Manufacturing Practice (GMP). This compliance underpins the machine's safety, reliability, and longevity, providing essential assurance for manufacturers.

6. Optimized Footprint & Integration: A compact design philosophy allows these machines to fit efficiently into existing production lines, maximizing available factory space without compromising functionality. The use of single-drive technology often incorporates independent control mechanisms, enhancing the machine's ability to integrate smoothly with upstream (melting, tempering) and downstream (cooling, packaging) equipment while allowing standalone operation when needed.

English

English Español

Español