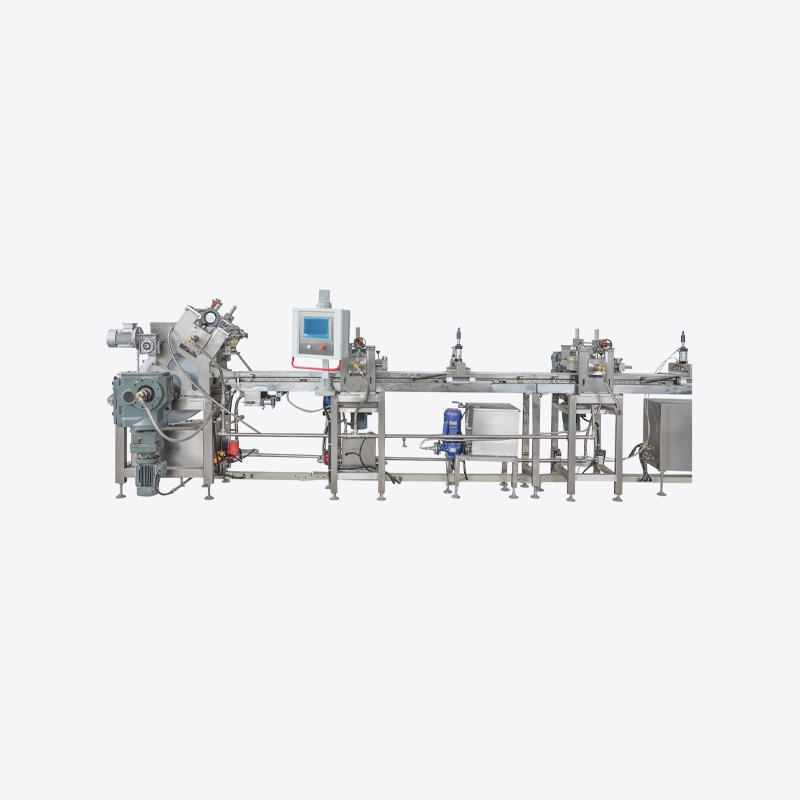

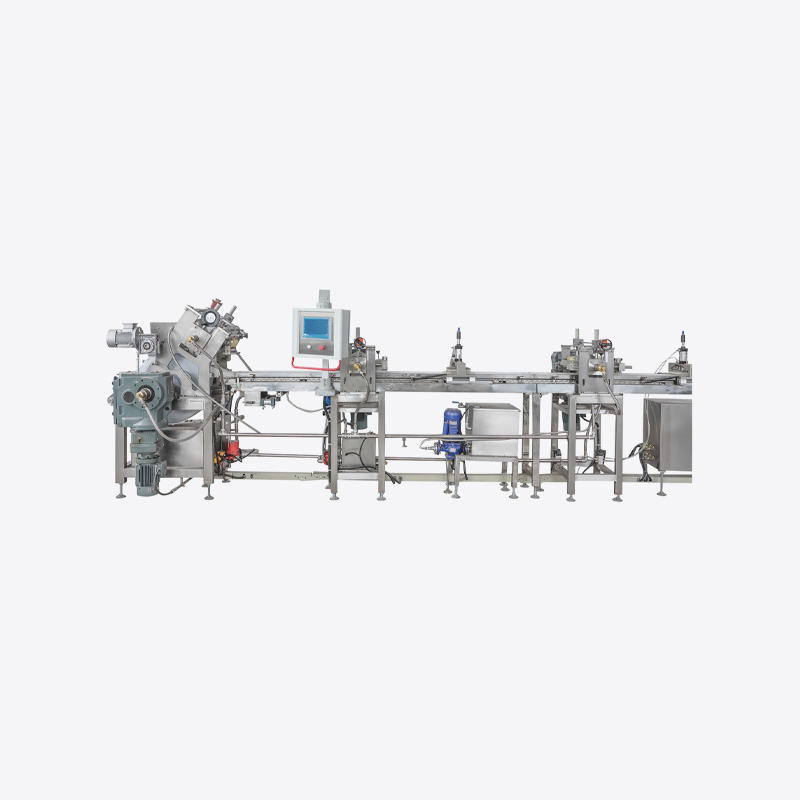

In modern baking production, Chocolate Chips Depositor plays a key role. It not only improves production efficiency, but also ensures the quality and consistency of each product through precise measurement. The following will analyze the role of this equipment in detail from the aspects of working principle, implementation method of precise measurement, and application advantages in production lines.

1. Core technology for achieving precise measurement

High-precision measurement system

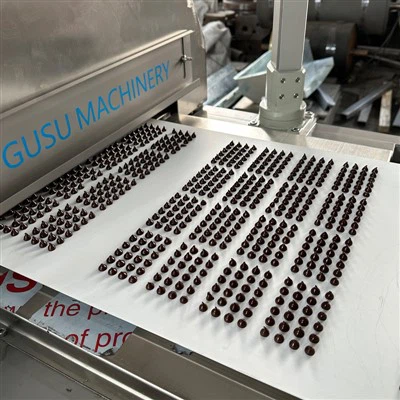

Depositor is usually equipped with a high-precision electronic control system, which controls the action of the feeding device through a stepper motor or servo motor. According to the set parameters (such as quantity, placement position, time interval, etc.), the equipment can accurately control the number of particles each time the material is discharged, and the error is controlled within a very small range (±1 or even lower).

Intelligent sensor and recognition system

Modern depositors integrate image recognition or infrared sensor systems to identify the position and size of products and realize synchronous feeding. For example, when producing multiple rows of cookies, the equipment can automatically identify the tray arrangement, so that the chocolate beans are accurately distributed on each cookie.

Precision matching of molds and tracks

The feeding head or distribution port is precisely designed to prevent the chocolate beans from jamming or jumping during transportation. Some equipment also adopts a multi-track channel design to ensure consistency when multiple rows of products are fed at the same time, preventing overflow or shortage.

2. Production advantages brought by precise measurement

Improve product consistency

By accurately controlling the number of chocolate beans for each product, manufacturers can ensure uniform appearance and stable taste, effectively improve product quality and enhance brand credibility.

Reduce raw material waste

Manual feeding or traditional methods are prone to over-feeding or missing raw materials. The use of automated Depositor can achieve the maximum output ratio and improve production efficiency without wasting raw materials.

Improve the level of production line automation

After docking with the automatic conveying system and oven, the Chocolate Chips Depositor can realize continuous and unmanned feeding operations, greatly reducing manual intervention and improving overall production efficiency.

3. Flexibility in practical applications

Applicable to a variety of raw materials and product forms

In addition to chocolate beans, the Depositor can also handle a variety of granular raw materials such as dried blueberries, nuts, and sugar balls, suitable for baked products of different flavors and styles.

Adjustable parameters, flexible switching of production tasks

The operator can quickly set parameters according to product requirements (such as 8 or 12 pieces per cookie) without changing hardware, greatly improving production flexibility.

Modular design for easy cleaning and maintenance

Most Depositors adopt a detachable module design, which is easy to clean and disinfect, and meets food safety standards. At the same time, maintenance is simple, reducing the equipment failure rate.

In the era of baking industry that pursues standardization and efficiency, Chocolate Chips Depositor is not only a tool to improve production efficiency, but also a key equipment to achieve accurate measurement and ensure product quality. It ensures that every chocolate bean falls on the product just right through high-precision control systems, intelligent recognition technology and flexible mechanical structures, providing strong guarantees for baking brands to create high-quality and high-consistency products. With the continuous improvement of automation, this equipment will play an increasingly important role in future baking production.

English

English Español

Español