What is an Energy Bar Line?

An Energy Bar Line refers to a dedicated production line used to manufacture energy bars in an industrial setting. These bars are popular as quick, nutritious snacks, often packed with proteins, vitamins, minerals, and other ingredients aimed at boosting energy levels. The Energy Bar Line encompasses a series of machines and processes that are designed to transform raw ingredients into finished energy bars that meet both consumer demands and quality standards.

Key Components of an Energy Bar Line

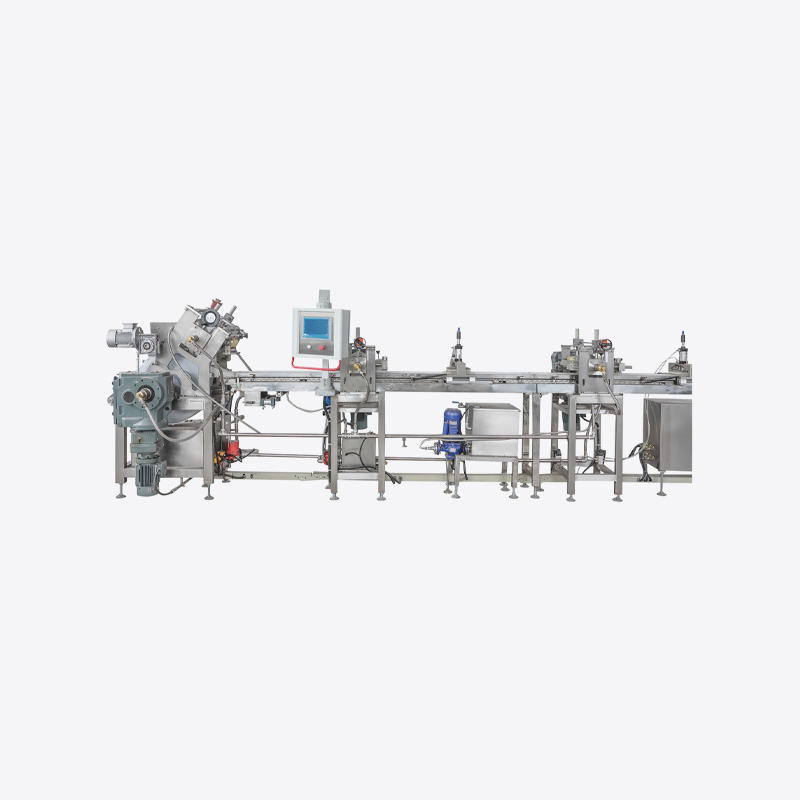

An Energy Bar Line is a highly specialized and automated production system designed to efficiently process raw ingredients into finished energy bars. Each component of the line plays a crucial role in ensuring that the final product is of high quality, consistent, and meets the required standards. Below is an in-depth look at the key components that make up a typical Energy Bar Line.

1. Ingredient Preparation and Handling

The foundation of a successful Energy Bar Line begins with the preparation and handling of raw ingredients. Ingredients such as oats, nuts, seeds, dried fruits, protein powders, and sweeteners need to be sourced, stored, and prepared for mixing. At this stage, the following systems are used:

Ingredient Feeders: Automated feeders deliver precise amounts of each ingredient to ensure consistent formulation.

Storage Silos and Bins: Ingredients like grains, nuts, and powders are stored in large silos to maintain freshness and prevent contamination.

Weighing Systems: Accurate weighing systems ensure that the correct proportions of ingredients are used in each batch.

2. Mixing and Blending

Once the ingredients are ready, the next step is mixing them into a uniform dough-like consistency. Mixing is a critical stage as it determines the texture, flavor, and overall quality of the energy bar.

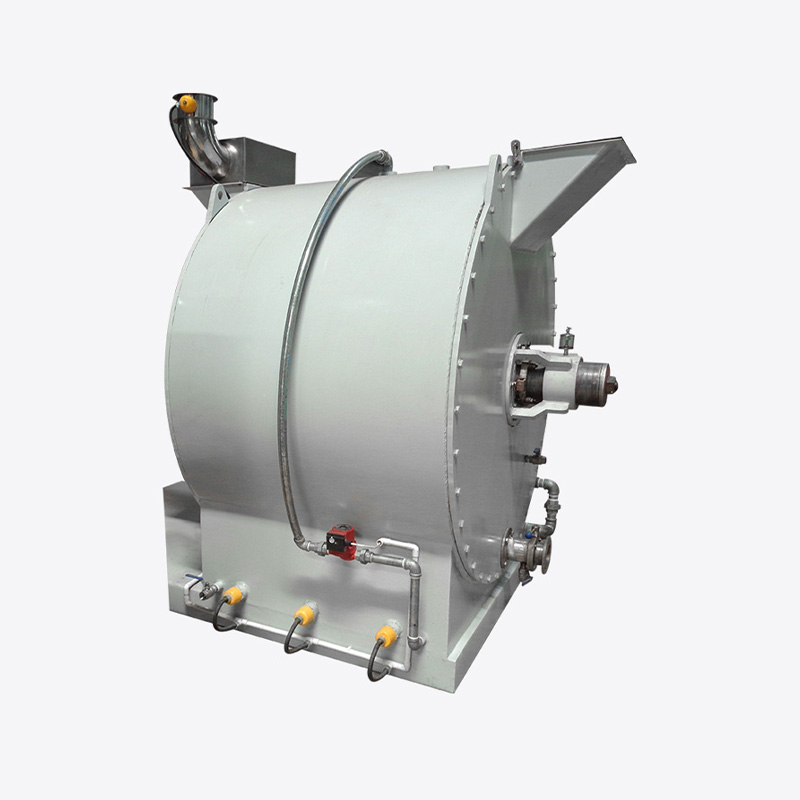

Mixers and Blenders: Heavy-duty industrial mixers are used to blend ingredients thoroughly. They are designed to handle large volumes and can incorporate liquids, such as honey or syrup, seamlessly with dry ingredients.

Vacuum Mixing: Some energy bar lines utilize vacuum mixing, which helps eliminate air pockets and ensure a smoother texture.

3. Forming and Shaping

After mixing, the product needs to be formed into bars or other desired shapes. This step ensures that all bars are uniform in size and shape for consistency and easy packaging.

Extruders: Extrusion machines push the mixture through a die to form bars or other shapes. The extruded material is then cut into individual pieces.

Molders: For bars that require a more defined shape, molders can be used to press the mixture into specific molds that correspond to the desired shape, such as squares, rectangles, or circular shapes.

Compression Systems: Some lines use compression to form denser, compact bars, improving their stability during packaging and handling.

4. Baking or Dehydrating

Depending on the recipe and desired texture, energy bars may need to be baked or dehydrated. This process adds structure and improves shelf life, giving the bars the correct firmness.

Ovens: For baked energy bars, conveyor ovens are commonly used. The bars are baked at controlled temperatures to achieve a crispy or chewy texture, depending on the product.

Dehydrators: In some cases, energy bars are dehydrated to preserve freshness and maintain a soft or chewy consistency. The drying process is carefully controlled to prevent over-drying or under-drying, which can affect taste and texture.

5. Cooling

After the bars are baked or dehydrated, they need to be cooled before packaging to prevent melting, deformation, or condensation. Cooling is an essential part of the Energy Bar Line to maintain product quality.

Cooling Conveyors: These are specialized conveyors designed to carry the energy bars through a cooling chamber. The cooling process ensures that the bars reach the right temperature, making them easier to handle during packaging and minimizing any risk of damage.

Cooling Towers or Fans: In some production setups, cooling towers or fans are used to rapidly lower the temperature of the bars as they move along the conveyor.

6. Cutting and Portioning

Cutting and portioning ensure that each energy bar is the correct size and weight. This is essential for maintaining consistency and meeting the specifications set by the manufacturer.

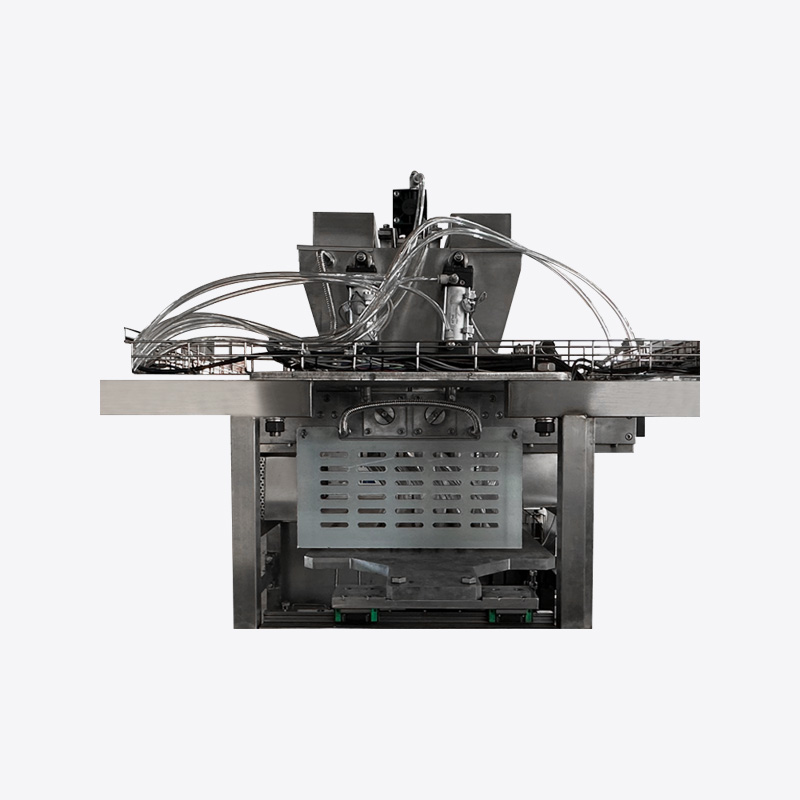

Cutting Machines: Automated cutting machines are employed to slice large slabs of baked or extruded dough into evenly-sized bars. These machines can be adjusted for different bar sizes and shapes.

Rotary Cutters: These are often used for high-volume production, ensuring a quick and precise cut.

Portion Control Systems: Portioning systems measure the weight of each bar to ensure consistency. They are often integrated with automated checkweighers to maintain uniformity in weight and size.

7. Packaging

Once the energy bars are cut, they need to be packaged to ensure freshness, shelf life, and product safety. The packaging process also plays an important role in branding and marketing.

Flow Wrapping Machines: These machines are designed to individually wrap each energy bar in a protective film that ensures freshness. The flow wrap is quick and efficient, making it ideal for high-speed production.

Vertical Form-Fill-Seal Machines: Some energy bars are packaged in pouches rather than individual wraps. These machines form, fill, and seal bags or pouches around the bars.

Tray Packaging: In some cases, bars may be packaged in trays for bulk sale or display, especially when they are sold in multi-bar packs.

Labeling Machines: Automated labeling systems ensure that each packaged energy bar is labeled with nutritional information, ingredients, and branding.

8. Quality Control and Inspection

Quality control is critical in any food production line, and an Energy Bar Line is no exception. Ensuring that each bar meets the required standards for taste, texture, size, and weight is essential.

Metal Detectors: Metal detectors are used to ensure that there are no contaminants in the product. These detectors help identify any metal objects that could have accidentally entered the production line.

Weight Check Systems: Automated checkweighers are used to verify that each energy bar falls within the specified weight range. Any bars that fall outside the acceptable range are rejected.

Vision Systems: High-tech cameras or vision systems are used to inspect the shape, color, and consistency of each bar, ensuring that all products meet the desired appearance and quality.

Advantages of an Energy Bar Line

1. Enhanced Production Efficiency

One of the most significant benefits of an Energy Bar Line is its ability to streamline production, allowing for large quantities of energy bars to be produced within a short period. By automating key stages such as mixing, forming, baking, cutting, and packaging, the production line reduces manual labor and speeds up the entire process.

Faster Production Speed: Automation reduces the time spent on each task, enabling manufacturers to produce thousands of energy bars daily, meeting high demand.

Continuous Operation: Automated systems can run continuously, with minimal downtime, allowing for a more efficient, round-the-clock production process.

2. Consistency in Product Quality

Maintaining uniform quality across every batch of energy bars is crucial, especially when meeting consumer expectations for taste, texture, and appearance. An automated Energy Bar Line ensures that each bar is consistently produced to the same specifications.

Uniform Size and Shape: Automated cutting and forming systems ensure that each energy bar is the same size and shape, which is important for both consumer satisfaction and packaging efficiency.

Accurate Ingredient Proportions: Precise mixing machines ensure the correct ratio of ingredients, which contributes to uniform texture, flavor, and nutritional content.

3. Customization and Flexibility

A modern Energy Bar Line offers flexibility in production, allowing manufacturers to easily switch between different formulations, sizes, and product types without significant downtime or reconfiguration. This is particularly important in today’s market, where consumer preferences are continually evolving.

Variety in Formulations: Manufacturers can easily adjust their production lines to handle different ingredient profiles, including organic, gluten-free, high-protein, or plant-based formulations.

Multiple Bar Sizes and Shapes: The ability to produce energy bars in various sizes and shapes means that manufacturers can meet different market demands, from small snack-sized bars to larger, meal-replacement options.

4. Cost-Effectiveness and Reduced Labor Costs

While the initial investment in an Energy Bar Line can be significant, the long-term savings in labor costs and operational efficiency are substantial. Automation reduces the need for manual labor in various stages of production, resulting in cost savings.

Labor Savings: Automated systems handle most of the labor-intensive tasks such as mixing, cutting, and packaging, reducing the need for large workforces.

Lower Overhead: With fewer manual interventions, the overall overhead costs associated with running the production line are minimized.

5. Improved Food Safety and Hygiene

Energy Bar Lines are designed with hygiene and food safety in mind. By integrating automated cleaning systems and advanced quality control, manufacturers can ensure that their production processes meet strict health and safety standards.

Automated Cleaning: Modern energy bar production lines come with self-cleaning features that help maintain a sanitary production environment, reducing the risk of contamination.

Compliance with Regulations: The lines are designed to meet international food safety regulations, including HACCP, FDA standards, and other industry-specific guidelines, ensuring the final product is safe for consumption.

6. Real-Time Monitoring and Quality Control

Automated Energy Bar Lines are equipped with advanced sensors and monitoring systems that allow for real-time quality control and process optimization. These systems ensure that any deviations in product quality can be detected and corrected immediately.

Automated Inspection: Vision systems, metal detectors, and weight check systems ensure that each bar meets the desired quality standards. Bars that do not meet the specified criteria are automatically rejected.

Data-Driven Insights: The integration of IoT and AI technologies allows manufacturers to monitor performance metrics and make data-driven decisions to optimize production processes, reduce waste, and improve efficiency.

7. Scalability and Adaptability

As demand for energy bars grows, manufacturers can easily scale up their production capacity by adding more machines or expanding the production line. The modular design of Energy Bar Lines makes it easy to adapt to changing market needs and increase production output.

Adaptability to Demand: Production lines can be adjusted to handle fluctuating demand, whether it's a seasonal increase in sales or a surge due to new product launches.

Expansion Capabilities: Manufacturers can expand their production capabilities without having to replace the entire line. Additional machinery can be added, such as extra mixers or packaging units, to meet the increased demand.

8. Sustainability and Waste Reduction

With growing concerns over sustainability, many modern Energy Bar Lines are designed to minimize waste and optimize resource use. This includes efficient use of raw materials, energy, and packaging.

Waste Minimization: The precise measurements of ingredients and automated portioning systems ensure that raw materials are used efficiently, reducing waste.

Energy Efficiency: Newer production lines are designed to be energy-efficient, consuming less power and reducing the carbon footprint of the manufacturing process.

Eco-Friendly Packaging: Many production lines are also adapted to handle eco-friendly packaging materials, allowing manufacturers to meet the increasing consumer demand for sustainable products.

9. Higher Shelf Life and Freshness

One of the key advantages of an Energy Bar Line is the ability to produce energy bars with an extended shelf life while maintaining freshness. Automated baking, cooling, and packaging systems are designed to preserve the quality of the product over time.

Controlled Environment: The use of automated cooling and packaging processes ensures that energy bars remain fresh, with minimal exposure to contaminants or air.

Packaging Integrity: Proper sealing and packaging techniques prevent moisture or air from compromising the quality of the energy bars, ensuring that they stay fresh for longer periods.

Optimizing the Energy Bar Line for Mass Production

1. Streamlining the Ingredient Handling Process

The first step to optimizing any Energy Bar Line for mass production is ensuring the smooth handling and preparation of ingredients. Large-scale production requires precision, especially when it comes to raw material distribution. Automation plays a key role in accurately weighing, mixing, and dispensing ingredients at high speeds.

Ingredient Feeders and Mixers: Automated ingredient feeders ensure that the right amounts of each component—such as oats, nuts, seeds, and sweeteners—are dispensed efficiently. Mixing systems, such as high-powered blenders or vacuum mixers, help blend these ingredients thoroughly, creating a consistent dough-like mixture ready for shaping. The key is to optimize the mixing time to prevent overprocessing or underprocessing, both of which can affect texture and consistency.

Batch Processing: Batch processing can help maintain consistency and reduce downtime between product changes. By adjusting batch sizes and optimizing the flow of ingredients, manufacturers can achieve high throughput without sacrificing quality.

2. Maximizing Speed and Efficiency in Forming and Shaping

After mixing, the next stage is forming the energy bars into the desired shape. The Energy Bar Line must be optimized to handle high volumes of raw material without compromising on uniformity and product consistency.

Extruders and Molders: Extrusion systems are widely used in energy bar production, allowing for the creation of uniform bars at high speeds. Extruders push the blended mixture through a die to form the desired shape, and molds can provide additional customization in terms of bar dimensions or designs. For large-scale production, it’s essential to ensure that these machines can operate seamlessly without frequent stoppages, ensuring high production speeds.

Compression Systems: Depending on the recipe, some bars require compression to achieve the desired density. Compressing the dough can improve the firmness and shelf life of the product, but this must be balanced with speed to ensure maximum throughput.

3. Efficient Baking and Cooling Systems

For baked energy bars, the baking stage is crucial for achieving the right texture and taste. Optimizing the baking process is essential for mass production, as it directly impacts both quality and throughput.

Conveyor Ovens: Conveyor ovens are commonly used to bake energy bars at consistent temperatures. The bars move through the oven on a conveyor belt, where temperature and airflow are carefully controlled. By fine-tuning these parameters, manufacturers can reduce energy consumption while maintaining a high level of baking quality.

Rapid Cooling Systems: After baking, cooling is critical to prevent the bars from becoming too soft or sticky. Cooling conveyors or specialized cooling tunnels help bring down the temperature quickly, ensuring that the bars hold their shape and texture. Optimizing the cooling process also reduces the risk of contamination or damage during packaging.

4. Automating Cutting and Portioning

Cutting and portioning are critical stages that ensure each energy bar is uniform in size and weight. This not only guarantees consistency but also ensures that the final product meets packaging specifications.

Precision Cutting Machines: Automated cutting machines with adjustable blades and sensors ensure precise, uniform cuts at high speeds. These machines can be programmed to handle different bar sizes and formulations, accommodating fluctuations in demand or product variety without downtime.

Portion Control Systems: Portion control systems are integrated into the production line to ensure that each bar is the correct weight. By automatically checking weight and adjusting the cutting process, manufacturers can maintain consistent portion sizes and minimize product loss.

5. Optimizing Packaging for High-Volume Production

Packaging is the final step in the energy bar production process, and optimizing it is crucial for mass production. Packaging plays a significant role in ensuring product freshness, durability, and brand visibility.

High-Speed Packaging Systems: For mass production, Energy Bar Lines often include high-speed packaging machines that wrap individual bars or fill trays in a matter of seconds. Flow wrapping machines are ideal for wrapping bars in protective film, ensuring that they stay fresh while maintaining high throughput. Vertical form-fill-seal machines can also be used for bulk packaging, creating multi-bar pouches or boxes at rapid speeds.

Automation for Sealing and Labeling: Automated sealing systems are used to ensure that packaging is airtight and tamper-proof. At the same time, labeling machines automatically apply branded labels, nutritional information, and barcodes, which helps reduce labor costs and ensure accuracy.

6. Integrating Real-Time Monitoring and Quality Control

To truly optimize an Energy Bar Line for mass production, manufacturers must implement real-time monitoring and quality control systems. These technologies ensure that every batch produced meets the desired quality standards.

Sensors and Vision Systems: Advanced sensors and cameras can monitor every stage of production, checking for imperfections, size discrepancies, or texture issues. For example, vision systems are used to inspect the color and shape of bars, ensuring that they meet branding and quality requirements.

Automated Quality Assurance: Quality control stations can be integrated into the production line to perform checks such as weight measurement, metal detection, and product integrity inspection. Automated systems can reject defective products without interrupting the overall flow, ensuring that only high-quality bars are packaged and shipped.

7. Reducing Downtime and Increasing Flexibility

One of the keys to optimizing an Energy Bar Line for mass production is minimizing downtime. This can be achieved by implementing predictive maintenance and ensuring the line can adapt quickly to changing product demands.

Predictive Maintenance: IoT devices and machine learning algorithms can predict when equipment will require maintenance, reducing unplanned downtime and increasing production uptime. This allows for efficient scheduling of repairs, preventing delays in production.

Modular Design for Flexibility: A modular production line design allows manufacturers to easily switch between different product formulations or adjust the production line to meet varying demand. This adaptability ensures that the line can handle seasonal spikes, new product introductions, or changes in consumer preferences without significant downtime or production interruptions.

Global Market Demands and the Energy Bar Line

The global demand for energy bars has surged in recent years, driven by growing consumer interest in health-conscious snacking, fitness nutrition, and on-the-go meal replacements. With busy lifestyles and a greater focus on healthy eating, energy bars are seen as a convenient, nutritious solution for people seeking quick energy boosts. To meet these increasing demands, manufacturers need to optimize their Energy Bar Lines for high production volumes while ensuring product quality, customization, and compliance with international standards.

In this article, we explore how global market demands are shaping the design and operation of Energy Bar Lines and how manufacturers can adjust their production lines to meet these evolving consumer needs.

Key Global Market Trends Impacting the Energy Bar Line

1. Rising Consumer Health Consciousness

Consumers are becoming more aware of the nutritional value of the products they consume, which has led to a surge in demand for healthier energy bars. These bars must meet various dietary requirements, including being high in protein, low in sugar, gluten-free, or organic.

Protein-Packed Energy Bars: The growing trend of high-protein diets, particularly in fitness and wellness communities, has led to a demand for energy bars that offer significant protein content. This has encouraged manufacturers to incorporate plant-based protein sources, such as pea, soy, and hemp, into their products.

Low-Sugar and Sugar-Free Options: Consumers are increasingly avoiding high-sugar snacks in favor of lower glycemic alternatives. This has led to the development of energy bars that use natural sweeteners like stevia, monk fruit, or dates.

Allergen-Free and Clean Label Products: There is also a shift towards allergen-free energy bars that cater to individuals with dietary restrictions. Clean label products, with minimal and easily recognizable ingredients, are growing in popularity.

2. Growing Demand for Convenience and On-the-Go Snacking

The convenience of energy bars is one of their biggest selling points. Busy consumers are looking for quick, portable, and easily consumable snacks that fit into their hectic lifestyles. This trend has made energy bars a popular choice for athletes, professionals, and individuals leading active lifestyles.

Single-Serve Packaging: As consumers seek more convenient ways to consume energy bars, manufacturers are increasingly opting for single-serve, portable packaging options that are easy to carry around.

Multi-Pack Options: For families or those who consume energy bars regularly, multi-bar packs have become popular. These larger packaging solutions offer value while maintaining the convenience factor of individually wrapped bars.

3. Sustainability and Eco-Conscious Packaging

With growing concerns over environmental issues, consumers are favoring brands that align with sustainability principles. As a result, energy bar manufacturers are focusing on eco-friendly packaging and reducing their carbon footprint.

Sustainable Sourcing: The global trend towards sustainably sourced ingredients has led manufacturers to choose organic, non-GMO, and ethically sourced raw materials for their energy bars. These changes ensure that energy bars appeal to eco-conscious consumers.

Biodegradable and Recyclable Packaging: Packaging innovation is moving towards biodegradable and recyclable materials. Manufacturers are investing in sustainable packaging that reduces waste and appeals to environmentally conscious buyers.

4. Increasing Customization and Personalization

The demand for personalized and customized products is also influencing the energy bar market. Consumers are looking for bars that cater to their specific dietary needs, taste preferences, and lifestyle goals.

Customizable Ingredients: With personalized nutrition becoming more popular, consumers are looking for energy bars with customizable ingredient profiles, including specific ratios of protein, fats, and carbohydrates tailored to their dietary requirements.

Functional Ingredients: There is a rising trend for adding functional ingredients to energy bars, such as adaptogens, superfoods, probiotics, and electrolytes, to address specific health concerns like immunity, stress, and hydration.

5. E-Commerce and Direct-to-Consumer (DTC) Sales

E-commerce platforms and direct-to-consumer sales channels are becoming increasingly important in the energy bar market. Online sales enable consumers to easily access a wide variety of energy bars, from niche brands to mainstream options, while providing manufacturers with valuable data on consumer preferences.

Online Subscription Models: Subscription-based models are gaining traction in the energy bar industry, offering customers regular deliveries of their favorite products at discounted prices.

Impact on the Energy Bar Line

As global demands evolve, manufacturers must adapt their Energy Bar Lines to meet these new consumer preferences and production challenges. The following table summarizes the key trends impacting the Energy Bar Line and the necessary adjustments manufacturers must consider.

| Global Market Demand | Required Adaptations for Energy Bar Line |

|---|---|

| Health-Conscious Products | Use of natural sweeteners, plant-based proteins, allergen-free ingredients |

| Convenience and On-the-Go Snacking | Focus on high-speed, single-serve packaging systems and efficient handling |

| Sustainability and Eco-Friendly Packaging | Incorporate biodegradable or recyclable packaging, and sustainably sourced ingredients |

| Customization and Personalization | Flexible production systems for a variety of ingredient combinations and flavors |

| E-Commerce and DTC Sales Growth | Ability to quickly scale production and adapt to small-batch, direct-to-consumer packaging |

Optimizing the Energy Bar Line to Meet Market Demands

To effectively meet the global market demands, energy bar manufacturers must optimize their production lines in several key areas:

1. Automation and Flexibility in Production

Automation plays a pivotal role in scaling up production while maintaining flexibility to meet the customization demands of various consumer segments. Advanced Energy Bar Lines should be designed to quickly switch between different product formulations, flavors, and sizes. Automated systems for ingredient dispensing, mixing, forming, and packaging are critical to maintaining high efficiency without compromising on product quality.

2. Efficient Packaging Solutions

The growing demand for sustainable and convenient packaging requires manufacturers to invest in packaging solutions that are both eco-friendly and capable of meeting high-volume production needs. Automated packaging systems that can handle different sizes, from single-serve bars to multi-pack options, will be essential for staying competitive.

3. Quality Control and Traceability

As consumer expectations for high-quality, safe products continue to rise, manufacturers must integrate advanced quality control systems throughout the Energy Bar Line. Implementing real-time monitoring systems, metal detectors, and weight checkers will ensure product consistency, safety, and traceability.

4. Adapting to Dietary and Functional Trends

The increasing demand for functional ingredients and allergen-free bars requires manufacturers to implement flexible production lines capable of handling diverse ingredient profiles. These lines should be able to quickly adapt to new recipes and incorporate ingredients like superfoods, probiotics, or adaptogens.

The global energy bar market is evolving rapidly, driven by consumer preferences for healthier, more sustainable, and convenient snack options. Manufacturers must optimize their Energy Bar Lines to meet these demands, focusing on flexibility, automation, and quality control. By investing in advanced production systems and staying ahead of market trends, manufacturers can ensure their ability to meet the growing demand for energy bars while maintaining product excellence.

At Gusu Food Processing Machinery Suzhou Co., Ltd., we specialize in providing cutting-edge Energy Bar Lines that are designed to meet the needs of the global market. Our high-quality machinery ensures that manufacturers can produce a variety of energy bars efficiently, with the flexibility to adapt to consumer preferences. Whether you're looking to scale up production, implement sustainable practices, or introduce new product formulations, Gusu is your trusted partner for optimizing energy bar production.

English

English Español

Español