Features to Consider When Choosing a Chocolate Chips Machine

In contemporary food manufacturing, achieving consistent quality, efficiency, and hygiene is paramount. A Chocolate Chips Machine plays a crucial role in producing cookies that not only taste excellent but also maintain uniformity in appearance and texture. Evaluating the right features ensures that manufacturers can optimize production while safeguarding product quality and operational efficiency.

Consistency in Chocolate Distribution

Uniform distribution of chocolate chips is critical for both visual appeal and taste balance in cookies. Machines designed with precise depositing systems guarantee that each cookie contains the correct amount of chocolate chips, avoiding overloading or sparse distribution. Consistency reduces waste, improves the reliability of batch production, and ensures that consumers receive the same quality in every product.

Adjustable Output and Recipe Flexibility

Modern bakeries often produce multiple cookie varieties, each requiring different chip sizes, spacing, or density. Chocolate chips machines with adjustable settings enable operators to modify output to suit diverse recipes. This flexibility supports variations in dough types, chip compositions, and product shapes, allowing a single machine to handle multiple production requirements efficiently. Adjustable settings also facilitate quick changeovers between batches, saving time and reducing downtime.

| Feature | Purpose | Production Benefit |

|---|---|---|

| Adjustable Nozzles | Modify chip size or pattern | Supports recipe variety |

| Speed Control | Match dough and deposit timing | Ensures synchronized production |

| Digital Interface | Store operational presets | Simplifies workflow management |

Energy Efficiency and Maintenance Accessibility

Energy consumption is an important consideration for sustainable and cost-effective production. Machines engineered for efficient power usage help minimize energy loss while maintaining high output. Easy access to internal components for cleaning and maintenance reduces downtime, supports hygiene protocols, and prolongs equipment life. Designs that allow operators to remove parts quickly, inspect critical mechanisms, and perform routine maintenance are highly valued in high-volume production environments.

Hygiene and Safety Design

Food safety standards demand that production equipment be simple to clean, resistant to corrosion, and constructed with smooth surfaces to avoid contamination. Machines with rounded edges, fewer gaps, and washable panels ensure that chocolate chip deposition occurs in a hygienic environment. Safety mechanisms, including protective covers and automatic shutdown systems, protect operators during continuous operation, reducing the risk of accidents and promoting compliance with food safety regulations.

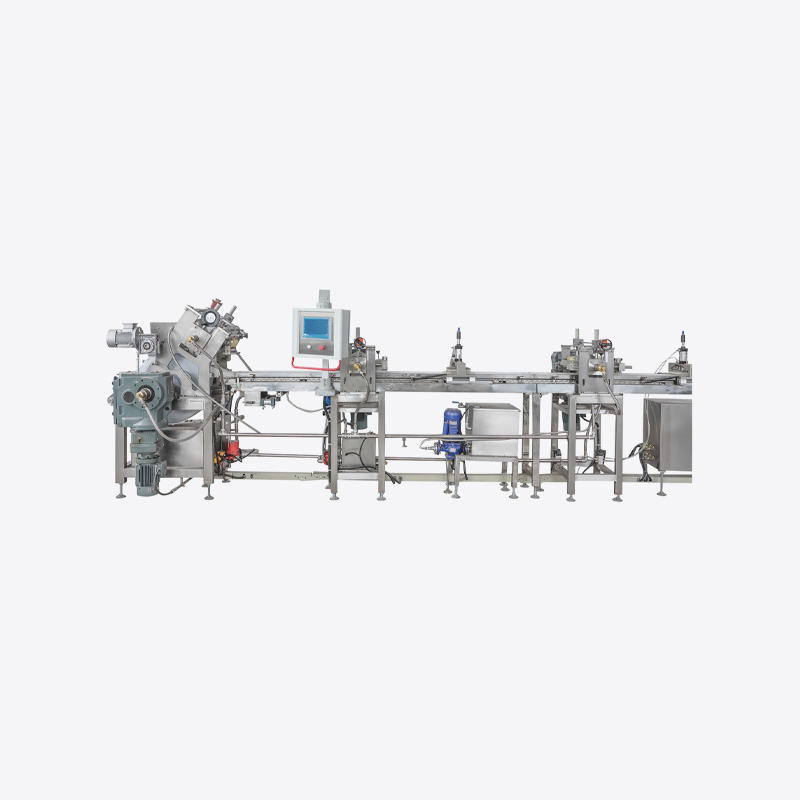

Integration With the Overall Production Line

Efficient production requires seamless interaction between different pieces of equipment. A chocolate chips machine that integrates smoothly with mixers, conveyors, and ovens ensures a continuous workflow. Synchronization through programmable interfaces allows precise timing, batch tracking, and coordination with temperature management systems. This integration supports uniformity across production batches, reduces errors, and enhances operational stability.

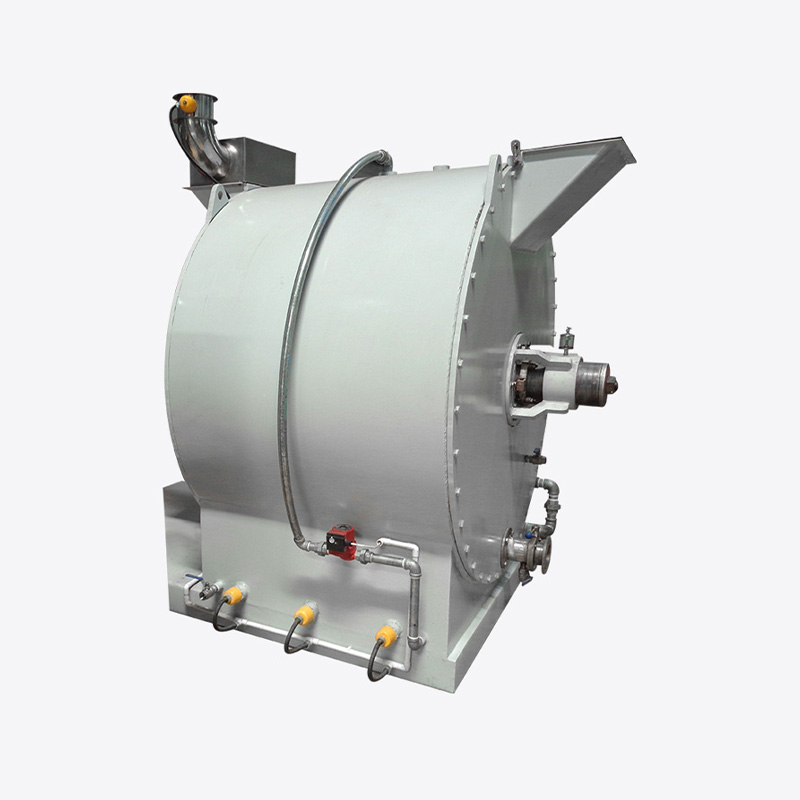

Material Durability and Longevity

The materials used in the construction of chocolate chips machines directly influence durability and performance. Machines made from strong, corrosion-resistant metals or engineered composites withstand frequent cleaning, extended operational hours, and the stress of high-speed production. Durable construction reduces maintenance needs, lowers the frequency of part replacements, and ensures reliable performance throughout the equipment's operational life.

Automation and Data Monitoring

Automation is increasingly important in modern cookie production. Machines equipped with sensors and data monitoring systems allow operators to track production metrics in real time, identify minor deviations, and make timely adjustments. Data-driven insights help maintain consistency, improve workflow efficiency, and support continuous process improvement. Such systems also reduce human error and enhance overall productivity in busy production environments.

Selecting a Trusted Manufacturer

Choosing the right supplier is essential for ensuring equipment quality, durability, and service support. Reliable manufacturers provide guidance for integrating machines into existing production lines, offer after-sales support, and ensure compliance with industry standards. Collaborating with experienced suppliers enables food producers to tailor equipment solutions according to production scale, desired flexibility, and hygiene requirements.

Sustainable Practices Supported by Chocolate Chips Machines

Sustainability is becoming an essential aspect of modern food production. A chocolate chips machine can significantly contribute to more eco-conscious operations by optimizing energy use, reducing waste, and enhancing process efficiency.

Energy Optimization Across the Production Line

Modern equipment designs focus on efficient energy consumption without compromising performance. Machines that operate with consistent power reduce unnecessary electricity use, supporting both cost management and environmental responsibility. Energy-efficient systems help maintain a smooth workflow, lowering production costs while promoting sustainable manufacturing practices.

Accurate Portioning for Resource Efficiency

Precise chocolate chip deposition minimizes material waste. By controlling the quantity and placement of inclusions in each cookie, machines prevent overuse of raw materials, support consistent product quality, and reduce overall production costs. Over time, careful ingredient management translates into measurable savings and environmental benefits.

| Sustainability Factor | How It Works | Production Impact |

|---|---|---|

| Precise Portioning | Controls ingredient use | Reduces waste and ensures consistency |

| Energy Efficiency | Optimized power consumption | Minimizes unnecessary energy draw |

| Automated Timing | Aligns with production flow | Enhances efficiency and reduces waste |

Waste Through Improved Material Handling

Equipment designed to handle chocolate chips gently and accurately helps prevent spillage and misplacement. Reducing waste from mishandled ingredients supports sustainability goals and lowers the need for reprocessing or discarding products. Properly designed machines maintain product integrity while improving overall workflow efficiency.

Recyclable and Durable Components

Machines made from long-lasting, corrosion-resistant materials reduce the frequency of replacements, lowering waste and environmental impact. Components that endure extended use while maintaining structural integrity contribute to a more sustainable production system. Choosing durable materials enhances both machine longevity and operational reliability.

Efficient Cleaning Practices

Sanitation is essential for both food safety and sustainability. Machines designed for easy access and efficient cleaning minimize water and detergent consumption. Components that are easy to disassemble, wash, and reassemble reduce the resources needed for regular maintenance while supporting compliance with hygiene standards.

Data-Driven Sustainability Monitoring

Digital tracking systems enable operators to monitor energy use, ingredient consumption, and machine efficiency. Analyzing these data points helps identify areas for improvement and facilitates resource-saving strategies. This feedback loop enhances sustainability, operational control, and production planning.

Trends Influencing Chocolate Chips Machine Demand

Industry demand for chocolate chips machines is influenced by evolving consumer expectations, market trends, and technological innovation. Key trends shape the way manufacturers select equipment for cookie production.

Product Diversity and Customization

Consumers increasingly seek variety in flavors, textures, and visual appeal. Machines that can accommodate different chocolate chip sizes, patterns, and compositions enable manufacturers to offer diverse product lines without extensive reconfiguration. Flexible deposition settings support innovation in recipe development and align with market demands for creative cookie designs.

Digital Integration and Automation

Automation and real-time monitoring are transforming production processes. Machines capable of connecting to central control systems allow precise tracking of operational parameters, including ingredient use, timing, and output quality. Data-driven automation enhances consistency, reduces human error, and supports efficient production management.

| Trend | Description | Production Impact |

|---|---|---|

| Automation Integration | Real-time monitoring and control | Higher precision and reduced errors |

| Sustainability Focus | Energy-efficient and recyclable design | Lower resource consumption |

| Flexible Output | Adjustable deposition settings | Supports varied product lines |

Compact and Modular Designs

Space-efficient equipment is increasingly important in modern production facilities. Compact machines with modular designs allow easy expansion, reconfiguration, or relocation of production lines. This adaptability supports growth and enables manufacturers to optimize facility layout while maintaining productivity.

Small-Scale Automation

Automation is no longer exclusive to large facilities. Smaller producers seek machines that simplify operations while ensuring product quality. Equipment designed for accessible automation helps maintain consistency, reduce labor demands, and manage material use effectively.

Sustainability Across Operations

Sustainable production encompasses energy efficiency, ingredient management, and material selection. Machines that minimize waste, optimize energy use, and incorporate durable or recyclable components contribute to environmentally responsible manufacturing. Aligning equipment choice with sustainability goals supports long-term operational stability.

Collaboration Between Manufacturers and Producers

Close collaboration between equipment suppliers and food producers ensures machines meet specific production requirements. Sharing knowledge on workflow, material handling, and desired output allows for tailored solutions that optimize efficiency and align with environmental or quality objectives.

Responding to Consumer Lifestyles

Consumer preferences toward healthier, ethical, or specialty products influence machinery design. Equipment capable of handling alternative ingredients or reduced-sugar formulations supports evolving market demands. Machines that accommodate diverse product recipes allow manufacturers to respond to consumer trends effectively.

Workforce Transformation Through Automation

As machines handle more repetitive tasks, operator roles shift toward monitoring, maintenance, and optimization. User-friendly interfaces and automation reduce operational complexity, making it easier to train staff and improve productivity while maintaining high quality standards.

Evaluating a chocolate chips machine involves considering functionality, efficiency, sustainability, and adaptability. Machines that provide precise depositing, flexible settings, durable materials, and easy maintenance enhance production consistency, reduce waste, and improve operational efficiency. Integration with automated systems and real-time monitoring further strengthens manufacturing reliability.

Sustainable operation is increasingly central to the food industry, with energy optimization, resource management, and recyclable components forming key decision factors. Flexibility in machine settings, compact modular designs, and automation support diverse product offerings, operational scalability, and workforce efficiency.

By focusing on these features, snack and bakery producers can ensure long-term value, maintain product quality, and operate responsibly. Strategic equipment selection supports consistent cookie production while aligning with industry standards and environmental considerations, ultimately contributing to a more efficient and sustainable food manufacturing process.

English

English Español

Español