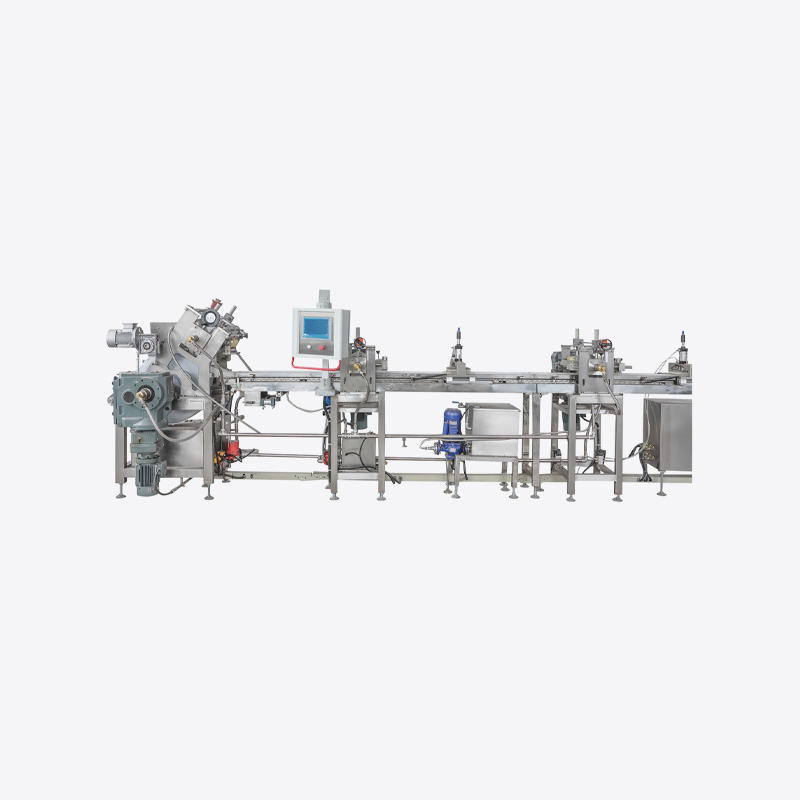

A Chocolate Fat Melting Machine is a specialized piece of equipment designed to melt and maintain chocolate and other fats at a consistent temperature. These machines are particularly used in the food industry, especially in chocolate production and confectionery, where precise temperature control is crucial to achieve the desired texture, consistency, and appearance of chocolate products. Understanding how this machine works can help businesses optimize their chocolate production processes.

1. The Basic Function of a Chocolate Fat Melting Machine

At its core, the purpose of a chocolate fat melting machine is to melt solid chocolate or cocoa fats, ensuring they reach a smooth, liquid state while retaining their chemical properties. This is critical for the chocolate to be easily molded, coated, or processed into a variety of chocolate products, such as bars, truffles, or pralines.

A typical melting machine uses a heating element to gently and evenly melt the fat content in the chocolate, which is typically cocoa butter, along with any other fats or oils that may be part of the recipe. This process prevents the chocolate from overheating and ensures that it maintains its quality, flavor, and texture.

2. The Heating Mechanism

Most chocolate fat melting machines employ a water jacket system or an electric heating element to melt the chocolate. The water jacket system involves a chamber that surrounds the container holding the chocolate. Water is heated in this outer chamber, and the heat is transferred to the chocolate inside, allowing it to melt gradually without the risk of direct heat, which could cause burning or uneven melting. This is ideal for delicate chocolate that needs to be kept at a precise temperature.

In some machines, electric heating coils are used to heat the chocolate directly. These coils are placed inside the melting container or underneath it, transferring heat directly to the chocolate. However, this method requires more careful monitoring to avoid overheating the chocolate, which can cause the cocoa butter to separate and result in undesirable textures.

3. Temperature Control and Consistency

One of the most important features of a chocolate fat melting machine is its precise temperature control. Chocolate should be melted at a consistent, controlled temperature to preserve its smooth texture and avoid burning. Typically, chocolate is melted at around 40-45°C (104-113°F). However, this can vary depending on the type of chocolate (dark, milk, or white) and the specific recipe used.

The machine’s temperature control system allows operators to set the desired temperature, which is monitored by thermostats or digital temperature sensors. These sensors ensure that the chocolate is melted evenly and remains at the right consistency for further processing. If the temperature is too high, the chocolate may become grainy or lose its smooth, glossy finish; if the temperature is too low, the chocolate may not melt fully, leading to clumps or inconsistent texture.

Some high-end machines come with advanced features, such as programmable settings for different types of chocolate or fat. This allows operators to adjust the machine's settings based on the specific needs of the product being made.

4. Agitation and Stirring

To achieve an even melt and prevent the chocolate from forming lumps, many chocolate fat melting machines are equipped with agitation or stirring mechanisms. These mechanisms help to keep the chocolate constantly moving as it melts, ensuring that no part of the chocolate gets overheated or under-heated. The agitation also helps incorporate any fats, oils, or additives into the chocolate, ensuring a smooth, homogeneous consistency.

Stirring can be done by mechanical paddles, stirring rods, or turbine-like blades that rotate inside the melting chamber. This movement also helps to release any trapped air bubbles, ensuring the final chocolate product is dense and smooth without air pockets.

5. Cooling and Solidification

Once the chocolate has melted and achieved the desired consistency, some chocolate fat melting machines have an integrated cooling system that gradually reduces the temperature of the chocolate. This cooling process is essential for the chocolate to solidify properly when poured into molds or used for coating other confectioneries.

Cooling can be achieved through an external system that circulates cool air around the melting chamber, or by running cooled water through the jacket if a water jacket system is in use. Once the chocolate has reached a stable, manageable temperature, it is ready for use in a variety of applications, including molding, coating, or packaging.

6. Efficiency and Automation

Modern chocolate fat melting machines are designed to be efficient and easy to operate. Many machines are fully automated, meaning they can melt large batches of chocolate with minimal supervision. These machines can be programmed to melt the chocolate, monitor its temperature, and even stir or cool the chocolate automatically.

Some systems allow for continuous melting, where chocolate is constantly added to the machine while a steady flow of melted chocolate is removed for use in production. This is ideal for large-scale chocolate manufacturing operations, where consistent output is required.

7. Advantages of Using a Chocolate Fat Melting Machine

Using a chocolate fat melting machine offers several advantages over traditional methods of melting chocolate, such as using stovetops or microwave ovens:

Consistent Quality: These machines ensure that the chocolate is melted to a precise temperature, preserving its texture and appearance.

Time Savings: By automating the process, chocolate fat melting machines can save time and labor, particularly for businesses that need to melt large quantities of chocolate.

Improved Safety: With features like temperature sensors and automatic shut-off functions, these machines reduce the risk of overheating, burning, or other safety hazards.

Ease of Use: Most chocolate melting machines are user-friendly, with simple controls that allow operators to easily set temperatures and manage the melting process.

The chocolate fat melting machine is a crucial tool in chocolate production, ensuring that the chocolate is melted smoothly and consistently without compromising its quality. Through effective temperature control, stirring, and cooling systems, these machines allow chocolatiers and confectionery businesses to produce high-quality chocolate products that meet strict standards. Whether for small batch production or large-scale operations, the chocolate fat melting machine is an indispensable piece of equipment in modern chocolate manufacturing processes.

English

English Español

Español