What is a Chocolate Conche?

A Chocolate Conche is a specialized machine used in the chocolate-making process to refine, aerate, and smooth the chocolate mass. The term “conche” refers to the continuous mixing, grinding, and aerating of the chocolate to enhance its texture, flavor, and consistency. The machine's primary purpose is to transform the raw chocolate mixture, which contains cocoa solids, cocoa butter, sugar, and other ingredients, into a silky smooth, velvety chocolate with a refined taste profile.

The chocolate conche works by breaking down cocoa solids and sugar particles into finer sizes, which ultimately results in a smoother, more palatable texture. It also helps to eliminate unwanted volatile compounds that may affect the chocolate's flavor, producing a richer and more balanced taste. Conching is one of the key steps in making high-quality chocolate and plays a crucial role in determining the chocolate's final characteristics.

Importance in the Chocolate Manufacturing Process

The Chocolate Conche is vital to the chocolate production process for several reasons, particularly when it comes to refining both the texture and flavor of the chocolate. Without conching, chocolate would remain gritty and have a rough texture, which would diminish its overall quality and appeal. Here’s why the chocolate conche is so important:

Texture Refinement: During conching, the chocolate undergoes continuous grinding and mixing, which reduces the particle size of cocoa solids and sugar. This results in a smooth and uniform texture, which is crucial for creating a premium product.

Flavor Enhancement: The conching process helps to improve the chocolate's flavor by removing bitter and acidic compounds. Additionally, conching allows for the integration of flavors, ensuring a more complex and balanced taste profile.

Viscosity Control: The conche allows manufacturers to control the viscosity of the chocolate, making it easier to mold, coat, or temper the chocolate in subsequent stages. This control ensures that the chocolate is not too thick or thin and can be processed efficiently.

Removal of Unwanted Volatiles: During the conching process, unwanted volatile compounds are driven off, which can affect the flavor. This helps to achieve a cleaner and more refined taste in the final chocolate product.

Role of the Chocolate Conche in the Production Line

In the chocolate production line, the Chocolate Conche serves a critical function after the initial stages of chocolate manufacturing, such as roasting and grinding. It plays a pivotal role in refining the chocolate mass, and it is typically used after the cocoa beans have been processed into a cocoa liquor or chocolate mass, and after the sugar and cocoa butter have been added.

Here's how the chocolate conche fits into the broader chocolate production line:

Post-Grinding Refining: After the grinding process (usually in a ball mill), the chocolate is still coarse and has large particles. The conche further grinds these particles into smaller sizes, ensuring that the chocolate reaches a smooth consistency that is free from any gritty texture.

Flavor Development: As the chocolate is conched, heat and friction help develop the characteristic flavors of the chocolate. The conche also facilitates the release of volatile acids that might contribute to bitterness, improving the overall flavor profile.

Viscosity Adjustment: The conche's action of continuously mixing and aerating the chocolate allows for fine adjustments to the chocolate’s viscosity, ensuring it has the right fluidity for molding, coating, or further processing.

Quality Control: The consistency, texture, and flavor are constantly monitored during conching. The operator can adjust the process time and temperature to meet the desired quality standards.

The Key Stages in Chocolate Making

The process of making chocolate involves several key stages, each contributing to the final product's taste, texture, and quality. The Chocolate Conche plays a pivotal role in refining the chocolate at one of the later stages of production. Here is an overview of the typical stages involved in chocolate making:

1. Harvesting and Fermentation

Cacao Beans are harvested from cacao pods. After harvesting, they undergo fermentation to develop the precursor flavors that will eventually be present in the chocolate.

2. Roasting

The cacao beans are roasted at high temperatures to bring out the chocolate’s rich flavor. Roasting helps to develop the distinct chocolate aroma and removes any remaining bitterness from the raw beans.

3. Grinding and Winnowing

The roasted beans are cracked and winnowed to remove the shells, leaving behind the cocoa nibs. These nibs are then ground into a paste known as cocoa liquor (not alcoholic, but a concentrated form of cocoa).

4. Mixing with Other Ingredients

Cocoa Butter, sugar, and sometimes milk solids are added to the cocoa liquor. These ingredients are mixed together to form the base chocolate mixture, which will later be conched.

5. Conching

This is where the Chocolate Conche comes into play. The chocolate mass is placed in the conche, where it is continuously mixed, aerated, and refined to develop a smooth texture and rich flavor. This stage can last from several hours to several days, depending on the desired outcome.

6. Tempering

After conching, the chocolate undergoes tempering, a process where it is carefully cooled and reheated to ensure it solidifies with the right crystalline structure. Proper tempering ensures the chocolate has a smooth, glossy finish and snaps when broken.

7. Molding and Cooling

The tempered chocolate is then poured into molds, cooled, and solidified into bars, coins, or other shapes. This final step solidifies the chocolate into its final form for packaging and distribution.

8. Packaging

Once the chocolate has cooled and solidified, it is packaged and prepared for sale or further distribution.

| Stage | Description |

|---|---|

| 1. Harvesting and Fermentation | Cacao beans are harvested from cacao pods and then fermented to develop the precursor flavors. |

| 2. Roasting | Cacao beans are roasted at high temperatures to bring out the chocolate’s rich flavor and remove bitterness. |

| 3. Grinding and Winnowing | Roasted beans are cracked and winnowed to remove the shells, leaving cocoa nibs that are ground into cocoa liquor. |

| 4. Mixing with Other Ingredients | Cocoa butter, sugar, and sometimes milk solids are added to cocoa liquor to form the base chocolate mixture. |

| 5. Conching | The chocolate mixture is refined in a Chocolate Conche through continuous mixing, aerating, and refining to smoothen texture and enhance flavor. |

| 6. Tempering | The chocolate is carefully cooled and reheated to ensure it solidifies with the correct crystalline structure, providing a smooth, glossy finish. |

| 7. Molding and Cooling | The tempered chocolate is poured into molds, cooled, and solidified into its final shape. |

| 8. Packaging | Once cooled and solidified, the chocolate is packaged and prepared for sale or distribution. |

Types of Chocolate Conches and Their Applications

Chocolate conches come in various types and configurations, each designed to meet specific needs in the chocolate manufacturing process. Understanding the different types of chocolate conches and their applications is essential for selecting the right equipment for your chocolate production needs.

Batch Conches

Batch Conches are used for small to medium-scale chocolate production, typically in artisanal chocolate making. In a batch conche, the chocolate mass is added in batches, and the conching process occurs in discrete intervals. This type of conche allows for a high degree of control over the process, making it ideal for producing small batches of high-quality chocolate with precise texture and flavor characteristics.

Application: Batch conches are often used in artisanal chocolate production where small batches and fine-tuned processes are required. This is particularly useful for chocolate makers who want to experiment with different ingredients or create specialty products with unique flavors.

Continuous Conches

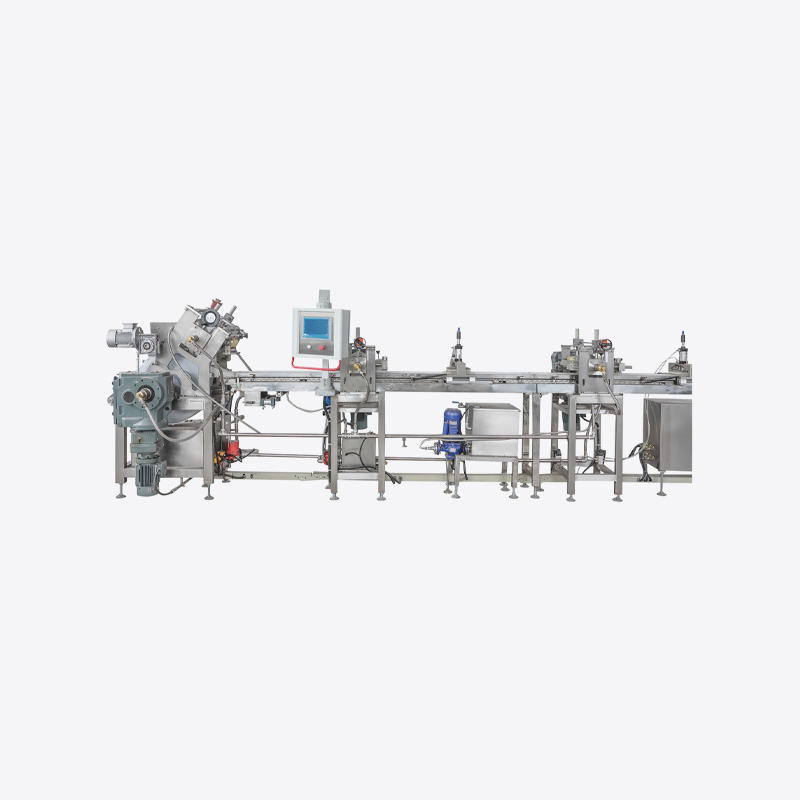

Continuous Conches are designed for large-scale production. Unlike batch conches, continuous conches allow chocolate to flow through the machine continuously, providing efficient and high-volume processing. The continuous nature of the conche ensures that the chocolate undergoes uniform and consistent refining, which is critical for mass production where large quantities of chocolate need to be processed within a short period.

Application: Continuous conches are ideal for large chocolate manufacturers who need to produce a high volume of chocolate with consistent texture and quality. They are widely used in commercial chocolate production lines and are well-suited for mass-market chocolate brands.

Hybrid Conches

Hybrid Conches combine features of both batch and continuous conches, offering the flexibility of batch processing with the efficiency of continuous flow. These machines can switch between different modes, allowing manufacturers to adjust the process according to their needs. Hybrid conches are perfect for companies that require both high production output and the ability to produce smaller, specialty batches.

Application: Hybrid conches are suitable for chocolate manufacturers that need to balance between large-scale production and the need for more precise control over small batches. They are commonly used in mid-sized chocolate factories and specialized production environments.

Small-Scale Laboratory Conches

Small-Scale Laboratory Conches are used for experimental and research purposes. These conches allow chocolate makers to test new recipes, ingredients, or processes before scaling up to larger production volumes. They are compact and designed to handle small amounts of chocolate, making them ideal for research, development, and product testing.

Application: Laboratory conches are primarily used in R&D environments, where chocolate makers and manufacturers can test new products or recipes before committing to large-scale production. They are also used in quality control to ensure that the final chocolate product meets the desired specifications.

Types of Chocolate Conches and Their Applications

| Type of Conche | Description | Application |

|---|---|---|

| Batch Conche | A conche used for small to medium-scale production. Processes chocolate in batches with high control. | Ideal for artisanal chocolate makers who require small batches and precise control over texture and flavor. |

| Continuous Conche | A conche designed for high-volume, continuous processing of chocolate mass. | Best suited for large-scale chocolate manufacturers needing consistent high-volume production. |

| Hybrid Conche | Combines features of both batch and continuous conches, allowing flexibility in production. | Suitable for manufacturers needing a balance between large-scale production and precise batch control. |

| Small-Scale Laboratory Conche | A compact, laboratory-scale conche used for research, development, and testing new recipes. | Used primarily in R&D for testing new products or formulations before scaling up to larger production volumes. |

Benefits of Using a Chocolate Conche

A Chocolate Conche is a crucial machine in chocolate production, offering numerous benefits that directly impact the final product's quality, texture, and flavor. Here's why using a chocolate conche is essential in the chocolate manufacturing process:

1. Improved Texture

One of the primary benefits of using a chocolate conche is its ability to create a smooth, silky texture. During conching, the chocolate mass is continuously mixed and ground, which reduces the size of cocoa particles and sugar crystals. This process eliminates the gritty texture often found in poorly refined chocolate, resulting in a smooth, velvety mouthfeel.

Application: The smoothness achieved through conching is essential for high-quality chocolate products, particularly in premium or artisanal chocolate where texture plays a crucial role in consumer satisfaction.

2. Enhanced Flavor Development

Conching plays a vital role in developing the complex and rich flavors of chocolate. The process helps to release unwanted volatile compounds, such as acids and bitter compounds, which can negatively affect the taste. As the chocolate mass is mixed and aerated, it also allows for the full development of cocoa flavors, creating a balanced and well-rounded taste.

Application: This benefit is especially important for high-end chocolate products where flavor complexity and richness are key factors in consumer preference. Conching ensures that the chocolate tastes smooth, sweet, and balanced without any harsh aftertastes.

3. Consistency and Quality Control

Chocolate conches offer the advantage of consistent texture and flavor across large batches. The continuous or batch-based process ensures that each batch of chocolate has the same smoothness, viscosity, and flavor, leading to a consistent product every time. This consistency is crucial for mass production where uniformity is expected across all units.

Application: For large chocolate manufacturers, consistency is essential for meeting quality standards and consumer expectations. Conching ensures that the chocolate maintains the same high quality and consistency throughout the production cycle.

4. Improved Viscosity for Molding and Coating

Chocolate that has undergone the conching process has better viscosity control, making it easier to mold, coat, or temper. The process helps to reduce the thickness of the chocolate, ensuring it flows smoothly during the molding and coating stages. This is particularly beneficial in applications where chocolate needs to be spread evenly, such as in coatings for confectionery, biscuits, or pralines.

Application: Conching is vital in chocolate coating applications, where the chocolate needs to flow easily over other products, creating a smooth, even layer without streaks or bubbles.

5. Increased Shelf Life

The removal of volatile compounds and unwanted flavors during the conching process contributes to a chocolate product’s stability. Chocolate that has been properly conched is less prone to spoilage and has a longer shelf life, which is crucial for manufacturers and retailers aiming to sell chocolate over extended periods.

Application: The extended shelf life is especially important for mass-market chocolate brands and products that need to be stored and transported over long distances.

6. Customization of Product Characteristics

One of the key benefits of conching is that it allows chocolate makers to fine-tune the characteristics of their product, such as texture, flavor, and viscosity. By adjusting the conching time, temperature, and speed, manufacturers can create chocolate with a specific flavor profile or texture that suits particular customer preferences or product requirements.

Application: This flexibility makes conching an ideal process for chocolate manufacturers who wish to create a wide range of chocolate products with different flavors, textures, and appearances to cater to various markets.

Benefits of Using a Chocolate Conche

| Benefit | Description | Application |

|---|---|---|

| Improved Texture | Conching refines the chocolate’s texture, creating a smooth, velvety mouthfeel by reducing particle size. | Essential for high-quality chocolate, particularly in premium and artisanal products where texture is key. |

| Enhanced Flavor Development | Conching removes bitter and acidic compounds, allowing for a balanced, rich flavor profile to develop. | Crucial for high-end chocolate products, ensuring complex, well-rounded flavors without harsh aftertastes. |

| Consistency and Quality Control | Ensures uniformity in texture, flavor, and viscosity across large batches, providing consistent product quality. | Important for large-scale manufacturers who require the same quality and characteristics in each batch produced. |

| Improved Viscosity for Molding and Coating | Conched chocolate has better flow properties, allowing it to mold or coat other products more evenly. | Beneficial in coating applications like confectionery, biscuits, and pralines, ensuring a smooth, even finish. |

| Increased Shelf Life | The removal of volatile compounds helps extend the shelf life of the chocolate, keeping it fresher longer. | Important for mass-market chocolate brands that need to maintain quality over longer storage periods. |

| Customization of Product Characteristics | Allows for precise adjustments to texture, flavor, and viscosity to meet specific product requirements. | Ideal for manufacturers who wish to offer a range of chocolate products with different characteristics. |

The Working Principle of a Chocolate Conche

1. Grinding and Refining

The main function of the chocolate conche is to refine the chocolate by grinding the cocoa solids, sugar, and cocoa butter into much smaller particles. Initially, after the cocoa beans have been roasted and ground into cocoa liquor (the base chocolate mass), this mixture is coarse and gritty. The conche uses friction and heat to break down these particles to a finer size, which is essential for creating smooth, high-quality chocolate.

Grinding Action: In the conche, the chocolate mass is continuously mixed and passed through a system of rollers or blades. The grinding process helps to smooth the chocolate and reduces the size of the cocoa particles.

Friction: The friction generated by the conche's moving components also helps to break down the particles further, contributing to a more uniform texture in the chocolate.

2. Aeration and Flavor Development

As the chocolate is mixed in the conche, the process of aeration occurs. The air incorporated into the mixture plays a vital role in enhancing the chocolate’s flavor profile. Aeration helps to evaporate volatile acids and other compounds that can contribute to bitterness or undesirable flavors.

Flavor Refining: During the conching process, heat and friction cause the chocolate to undergo chemical changes that improve its taste. This allows the chocolate to develop a more balanced, richer flavor, free from harsh or bitter notes.

Aromatic Compound Removal: The conche also helps remove any unwanted volatile aromatic compounds, which can be detrimental to the flavor, ensuring that the chocolate develops a more refined taste.

3. Viscosity Adjustment

The viscosity of chocolate is crucial for its final appearance, texture, and behavior during molding and coating. The conche adjusts the viscosity by breaking down the size of particles and allowing the ingredients to fully integrate. By regulating the amount of friction and heat applied to the chocolate mixture, the conche ensures that the chocolate has the desired consistency, whether it’s for molding, coating, or further processing.

Smooth Flow: The reduced particle size and fully integrated ingredients allow the chocolate to flow more smoothly, making it easier to handle in later stages of production like coating biscuits or tempering.

4. Time and Temperature Control

A key feature of the conching process is time and temperature control. The length of time the chocolate spends in the conche, along with the temperature it is exposed to, directly influences the quality of the final product. Conching can last anywhere from several hours to several days, depending on the type of chocolate being produced.

Temperature: The heat applied during the conching process helps in releasing volatile compounds, refining the chocolate's flavor, and improving its flow characteristics. The precise control over temperature is essential to avoid overheating, which can negatively impact the flavor and texture.

Time: Longer conching times generally result in smoother, more refined chocolate. However, the optimal time varies depending on the specific chocolate recipe and desired characteristics.

Maintenance and Care for Chocolate Conches

Proper maintenance and care for chocolate conches are essential for ensuring consistent performance and extending the lifespan of the equipment. A well-maintained conche ensures that the chocolate-making process runs smoothly and that the chocolate produced is of the highest quality.

1. Regular Cleaning

Cleaning the conche after every production run is critical to maintain its performance and ensure that no residual chocolate or other ingredients affect the next batch. Residual chocolate can harden over time, making it more difficult to clean and potentially causing contamination.

Cleaning Procedure: Use non-abrasive cleaning agents and warm water to clean the conche. Avoid harsh chemicals that could damage the internal parts or affect the chocolate's quality.

Disassembly: Depending on the conche's design, it may be necessary to disassemble certain components for thorough cleaning. This ensures that no chocolate remnants or oils remain within the machine.

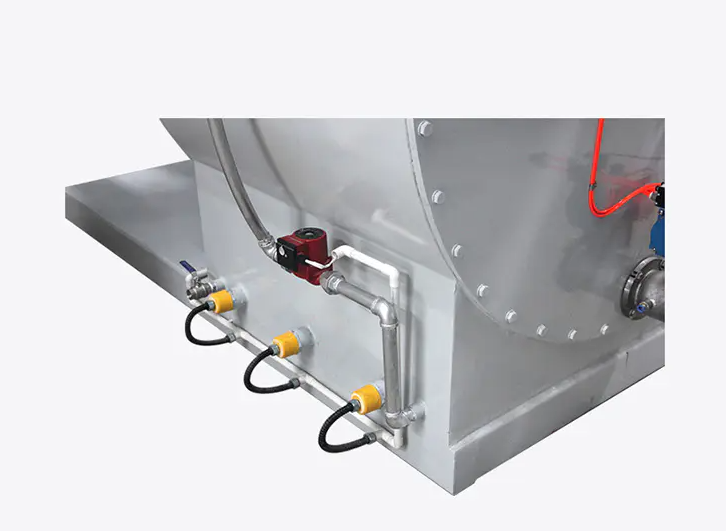

2. Lubrication of Moving Parts

The chocolate conche contains numerous moving parts that require lubrication to ensure smooth operation. The internal components, such as rollers, gears, and blades, must be regularly lubricated to prevent wear and tear and ensure optimal functionality.

Lubrication Frequency: Lubrication schedules should be followed based on the manufacturer's recommendations. In general, lubrication should occur after each production cycle or at regular intervals to reduce friction and prevent mechanical failures.

3. Inspection for Wear and Tear

Frequent inspection of the machine's components is necessary to detect any signs of wear and tear. Regular inspection can help identify problems early, preventing more costly repairs in the future.

Wear on Blades and Rollers: Blades, rollers, and other contact surfaces should be inspected for signs of damage or excessive wear. If any parts are worn down, they should be replaced promptly to prevent suboptimal chocolate refining.

Gears and Motors: Ensure that all gears, motors, and electrical components are functioning properly. Unusual sounds or vibrations may indicate a need for repair or adjustment.

4. Calibration and Adjustment

Regular calibration of the chocolate conche ensures that it continues to operate within the optimal parameters, such as temperature, mixing speed, and viscosity control. Proper calibration helps to achieve the desired chocolate texture and flavor.

Temperature Control: Check and adjust the temperature settings to ensure consistent heat during the conching process.

Mixing Speed: Monitor the mixing speed to ensure it aligns with the production requirements. Inconsistent speeds can affect the texture and consistency of the final product.

5. Proper Storage

When not in use, the chocolate conche should be stored in a clean, dry environment. Exposure to dust, moisture, or extreme temperatures can lead to rusting or malfunctioning of the machine.

Covering the Equipment: Use protective covers or storage procedures to protect the conche from contaminants.

Environment: Store the conche in a temperature-controlled room to avoid any damage due to humidity or extreme temperatures.

Choosing the Right Chocolate Conche Manufacturer

When it comes to selecting a chocolate conche manufacturer, several key factors should guide your decision-making process. A high-quality chocolate conche is essential to ensuring smooth, flavorful chocolate with the right texture. The right manufacturer not only provides a reliable and durable machine but also offers the support and customization needed to meet the unique needs of your chocolate production. Here are several aspects to consider when choosing the right chocolate conche manufacturer:

Experience and Expertise

Choosing a manufacturer with significant experience in the chocolate-making machinery sector is crucial. Manufacturers who specialize in chocolate conches typically have a deep understanding of the intricacies of chocolate production, from refining cocoa liquor to enhancing flavor. A manufacturer with years of experience will be able to offer insight into optimizing production processes and improving product quality.

Reputation for Quality and Reliability

Quality and reliability are at the heart of any successful chocolate production operation. The manufacturer you select should be known for producing high-quality, durable machines that can handle the demands of continuous chocolate production. A reliable conche machine reduces downtime, minimizes repairs, and ensures consistent product quality, all of which are crucial for maintaining operational efficiency and meeting consumer expectations.

Customization Capabilities

Every chocolate producer has unique requirements. A good chocolate conche manufacturer should offer flexibility in design and features to meet your specific production needs. Whether you're producing artisanal chocolate or mass-market products, the ability to customize the conche to suit your batch sizes, production speeds, and texture preferences can make a significant difference in the outcome.

After-Sales Support

After-sales service is a vital factor in choosing the right manufacturer. Once your chocolate conche is installed, the support provided by the manufacturer is key to ensuring smooth operation. This includes offering ongoing technical assistance, troubleshooting, and maintenance services to keep the machine functioning at its best. Comprehensive support ensures your chocolate production line remains efficient, minimizing downtime and avoiding costly delays.

Technological Innovation

As the chocolate industry evolves, so do the technologies behind chocolate-making equipment. Manufacturers that keep up with technological advancements offer machines that incorporate the latest innovations, such as energy-efficient designs, advanced temperature controls, and automation. Such improvements can significantly enhance the conching process, improving the chocolate's flavor, texture, and consistency while also optimizing production efficiency.

Why Choose Chocolate Conche from Gusu Food Processing Machinery Suzhou Co., Ltd.

When selecting a chocolate conche, Gusu Food Processing Machinery Suzhou Co., Ltd. stands out as a leader in the field. With a rich history of excellence and a commitment to quality, Gusu offers a range of benefits that make it a top choice for chocolate manufacturers worldwide. Here's why Gusu is the ideal partner for your chocolate production needs:

Unmatched Expertise and Industry Knowledge

Gusu has a long-standing reputation for producing high-quality chocolate machinery. With years of industry experience, their team possesses deep knowledge of the chocolate-making process, ensuring their machines are finely tuned for optimal performance. Whether you’re looking to refine texture, enhance flavor, or optimize production efficiency, Gusu's expertise ensures they provide the perfect solution for your chocolate conche needs.

Commitment to Quality

Quality is the cornerstone of Gusu's manufacturing philosophy. They use only the best materials and the most advanced production techniques to create chocolate conches that meet the highest industry standards. The reliability and longevity of Gusu's conches are proven through their widespread use in chocolate production facilities worldwide, where performance consistency is essential.

Tailored Solutions for Diverse Needs

Whether you're a boutique chocolatier or a large-scale manufacturer, Gusu understands that different chocolate makers have different needs. They offer highly customizable chocolate conches to suit various production scales, from small batches to large industrial operations. This flexibility ensures that you get the right machine for your unique production requirements, allowing you to optimize the conching process according to your product’s specific texture and flavor needs.

Exceptional After-Sales Support

Gusu's commitment to customer satisfaction extends beyond the sale of their machines. They provide exceptional after-sales support, including installation services, operator training, and access to technical support when needed. Their knowledgeable customer service team ensures that any issues are promptly addressed, allowing you to keep production running smoothly.

Innovative Technology

At Gusu, staying ahead of industry trends is a key priority. They continuously integrate the latest technological advancements into their machines, ensuring that their chocolate conches feature cutting-edge features like precise temperature controls, automated functions, and energy-efficient designs. These innovations make the chocolate-making process more efficient, sustainable, and cost-effective.

The Future of Chocolate Conches

The future of chocolate conches is shaped by a growing focus on innovation, efficiency, and sustainability. As the chocolate industry faces increasing demands for higher-quality products, faster production, and more eco-friendly solutions, chocolate conches are evolving to meet these challenges. Below are some trends that are shaping the future of chocolate conches:

Automation and Smart Technology

As automation becomes more prevalent across industries, the chocolate-making process is also seeing the rise of smart technology. Chocolate conches equipped with automated systems will allow manufacturers to achieve even greater precision and control over the conching process. With features such as real-time monitoring and adjustments, these machines will help ensure consistent quality and streamline production workflows.

Sustainability and Energy Efficiency

Sustainability is an increasing concern within the food processing industry, and chocolate manufacturers are no exception. The future of chocolate conches will include machines designed to be more energy-efficient, reducing their carbon footprint and operational costs. Manufacturers will be able to produce high-quality chocolate while minimizing energy consumption, making the process more sustainable.

Customization and Flexibility

The demand for diverse chocolate products is on the rise, with consumers seeking everything from artisanal dark chocolate to milk chocolate with unique flavors. To accommodate this growing demand, chocolate conches will continue to evolve in terms of customization. Future conches will offer even greater flexibility, allowing manufacturers to tailor the conching process to a wide variety of chocolate types, from bean-to-bar products to specialty confections.

Integration with IoT and Data Analytics

The integration of Internet of Things (IoT) and data analytics into chocolate conches will allow manufacturers to gather valuable insights into production processes. By tracking and analyzing data in real-time, chocolate producers will be able to optimize their operations, improve efficiency, and detect potential issues before they lead to equipment failure or product inconsistencies.

The chocolate conche is a cornerstone of high-quality chocolate production, playing a vital role in refining the texture, enhancing the flavor, and ensuring consistency in every batch of chocolate. From artisanal chocolatiers to large-scale manufacturers, this machine helps achieve the smooth, velvety finish and well-rounded taste that chocolate lovers around the world cherish.

As we've explored, conching involves more than just mixing—it's a delicate process that involves controlling temperature, aeration, and time to create chocolate with the perfect mouthfeel. By breaking down cocoa solids, reducing bitterness, and improving viscosity, the chocolate conche transforms raw ingredients into a product that delights the senses.

In choosing the right conche and understanding its role, manufacturers can ensure that their chocolate products meet the highest standards of quality, texture, and flavor. With continuous advancements in technology, such as automation and energy efficiency, the future of chocolate conches looks even brighter, offering enhanced capabilities for precision and sustainability.

Whether you're a small-batch producer or scaling up for mass production, understanding the importance of a well-maintained, high-quality chocolate conche will make all the difference in the final product. With the right equipment and care, the chocolate conche unlocks the true potential of chocolate, allowing manufacturers to craft exceptional products that captivate consumers and stand out in the market.

As the chocolate industry continues to evolve, staying informed about the latest innovations in conching technology will be key to staying ahead of consumer demands and maintaining a competitive edge. The chocolate conche, in its many forms and applications, is a true investment in the future of chocolate-making.

English

English Español

Español