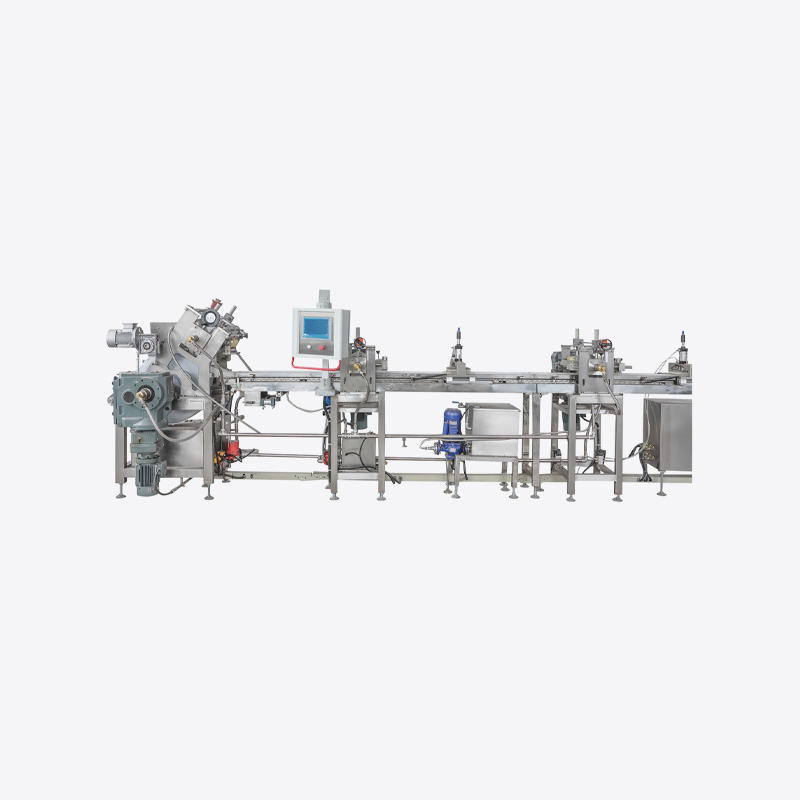

The Chocolate Refiner Machine has adopted a variety of design and technical measures to ensure that chocolate is not contaminated by the outside world, mainly through the following key points to ensure the purity and safety of chocolate:

1. Sealing system design

Closed design: Many chocolate conches use a closed working environment to prevent chocolate from contacting with the outside air or contaminants during the refining process. The contact between chocolate and the external environment is minimized through a sealed cover and a special import and export system.

Dust and moisture-proof measures: The inside of the equipment is usually equipped with efficient sealing strips or sealing rings to prevent external dust, moisture or air from entering. This not only avoids contamination of chocolate, but also keeps the humidity and temperature of chocolate under optimal control.

2. Use of food-grade materials

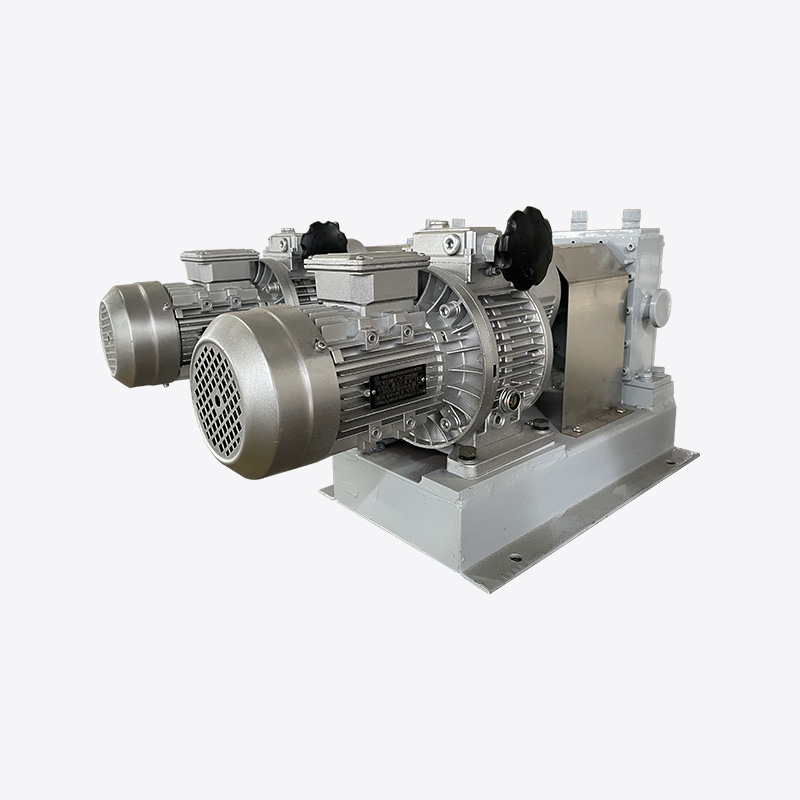

Food-grade stainless steel: The contact parts of the chocolate conch (such as grinding discs, grinding rollers, pipes, etc.) are usually made of food-grade stainless steel materials. These materials are corrosion-resistant, anti-oxidation, non-toxic, and tasteless, which can effectively prevent chocolate from being contaminated by any chemical substances.

Uncoated design: Avoid using coating materials that may fall off, which can reduce the risk of contaminating chocolate after the coating falls off.

3. Temperature control system

Constant temperature control: Temperature is a key factor in the chocolate refining process. The conching machine is usually equipped with a precise temperature control system to maintain a constant operating temperature. Too high or too low temperature will affect the taste and texture of chocolate, and may even cause the ingredients to decompose or produce adverse reactions. Therefore, through a precise temperature control system, it can be ensured that the chocolate is not affected by overheating or excessive cooling.

Thermal isolation design: The internal and external parts of the chocolate refining machine are usually thermally isolated to prevent the temperature changes of the external environment from affecting the chocolate refining process and avoid contamination or instability caused by ambient temperature fluctuations.

4. Prevent cross contamination

Modular design: Some chocolate refining machines adopt a modular design, which allows for quick disassembly and replacement of various parts to avoid mixing or cross contamination of different batches of chocolate.

Cleaning and disinfection: The machine design usually considers the characteristics of easy cleaning and disinfection to prevent chocolate from being contaminated by old materials or residues during the production process. The cleaning process of most chocolate refining machines is very simple, which can ensure thorough cleaning before and after each production and reduce the risk of cross contamination.

5. Air filtration system

Air purification: Some advanced chocolate conching machines are equipped with air purification systems that can filter dust, microorganisms and other possible pollutants in the air, keep the working environment clean, and prevent these pollutants from entering the refining process.

Negative pressure design: The negative pressure system ensures that no air and external impurities enter the machine during the refining process, further reducing the possibility of contamination.

6. Automation and intelligent monitoring

Intelligent control system: Modern chocolate conching machines are equipped with intelligent monitoring systems that can detect various indicators in the chocolate refining process in real time, such as temperature, humidity, particle size, etc. These systems can automatically adjust working parameters to ensure the stability of the refining process of each batch of chocolate and avoid chocolate contamination due to human operating errors or equipment failures.

Alarm system: Some equipment is also equipped with an alarm system. If the machine is abnormal (such as abnormal temperature, poor sealing, etc.), the system will automatically alarm and remind the operator to deal with it in time to avoid contamination.

7. Preventing external substances from entering

Protective cover design: Chocolate refining machines are usually equipped with protective covers or nets to prevent external substances (such as operator's clothing, gloves, etc.) from accidentally contacting the inside of the machine, reducing the risk of contamination.

Inlet design: The inlet is usually designed as a sealed structure that meets food hygiene standards to prevent external contaminants from entering the machine.

8. Regular maintenance and testing

Regular inspection and cleaning: To ensure that the equipment is always in the best working condition, manufacturers usually recommend regular equipment inspection and maintenance. This includes checking the integrity of the sealing system, cleaning all parts that contact chocolate, and ensuring that there are no contamination sources remaining.

Quality control and tracking: Many refiners provide quality control options to record the production data of each batch so that the production process can be traced back to ensure that the chocolate produced each time meets hygiene standards.

Chocolate Refiner Machine ensures that chocolate is not contaminated by the outside world during the refining process through a series of measures such as sealing design, use of food-grade materials, temperature control system, cleaning and maintenance specifications. These measures help improve the quality of chocolate, ensure the taste and safety of the final product, and meet strict food hygiene and safety standards.

English

English Español

Español