In the chocolate production process, the Chocolate Refiner Machine is one of the key equipment that determines the taste, texture and quality of the final product. It is mainly used to further grind raw materials such as cocoa nibs and powdered sugar into fine chocolate paste, which affects the smoothness and texture of chocolate. Therefore, when choosing a chocolate grinder, it is necessary to make a comprehensive assessment based on your own production scale, product type, budget and process requirements.

Clarifying the production scale and capacity requirements is the basis for choosing a suitable grinder. For small handmade chocolate workshops or start-ups, small laboratory-grade or semi-automatic grinders can be selected. They are usually easy to operate, occupy a small area and have a low investment cost. For medium and large food production companies, it is more suitable to choose fully automatic, continuous or industrial-grade chocolate grinding systems to meet the needs of high-efficiency and large-scale production.

It is very important to understand the different types of chocolate grinders and their working principles. Common grinders on the market include:

Roller Refiner: It uses multiple sets of rotating rollers to squeeze and shear the material, which is suitable for fine adjustment of particle size and is widely used in high-quality chocolate production;

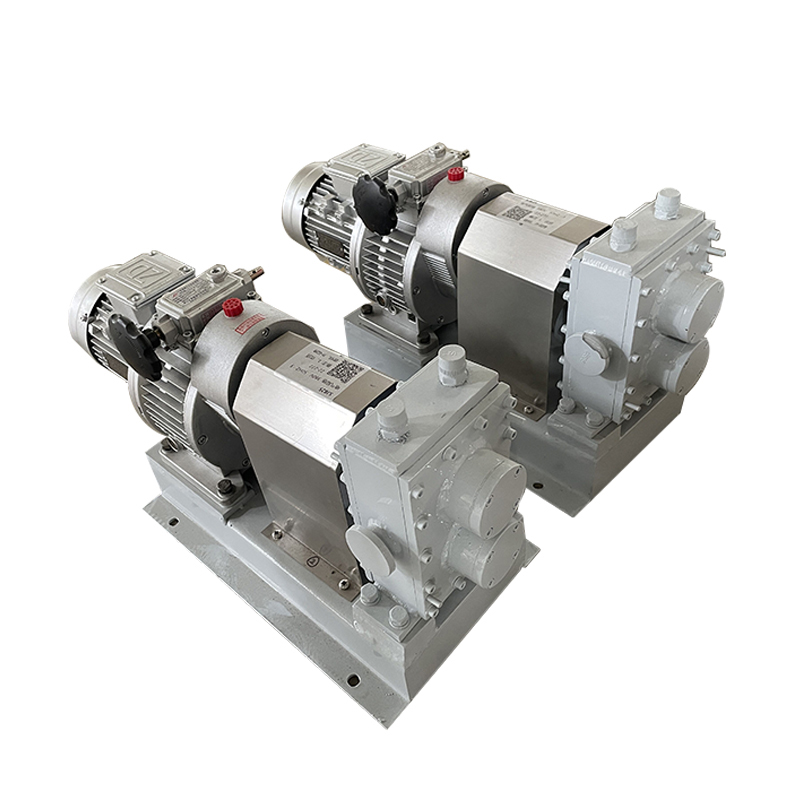

Ball Mill: It uses the impact force of steel balls in high-speed rotation to achieve efficient grinding, which is suitable for large-scale continuous production, but the initial investment is high;

Stirring Mill: It uses stirring media to grind materials with high energy, which has the advantages of high fineness and low energy consumption, and is suitable for products with extremely high requirements for the fineness of the finished product.

Pay attention to grinding accuracy and temperature control capabilities. The quality of chocolate depends largely on its particle fineness and temperature stability. A high-quality grinder should have a good temperature control system to prevent high temperature from destroying the flavor of cocoa butter, and can accurately adjust the grinding gap to ensure that the fineness of the final product meets the standard.

Consider the cleaning convenience and maintenance cost of the equipment. Chocolate contains oil components, which are prone to residue after long-term operation, affecting the quality of subsequent batches of products. Therefore, it is crucial to choose equipment that is easy to disassemble, easy to clean, and made of materials that meet food safety standards. In addition, the durability of the equipment, the supply of accessories and the after-sales service system need to be evaluated to reduce the long-term use cost.

Combine the production process to select the matching model. Chocolate grinding usually follows mixing and refining, so the grinder needs to be well connected with the front-end equipment such as refiners and mixers to form a smooth production line. A highly automated system can also improve overall production efficiency and reduce manual intervention.

Budget and brand selection are also factors that cannot be ignored. It is recommended to compare the technical parameters, user reviews and after-sales service support of different brands before purchasing, and give priority to manufacturers with good reputation, mature technology and fast service response.

Choosing a Chocolate Refiner Machine that really suits your production needs requires not only considering the performance of the equipment itself, but also combining production scale, process flow, product quality goals and other dimensions for comprehensive evaluation. Only in this way can we ensure that the selected equipment can not only meet current production needs, but also have good scalability and long-term use value.

English

English Español

Español