In the modern food industry, Chocolate Enrober has become an important equipment for producing high-quality chocolate coated desserts. Whether it is chocolate candy, sandwich biscuits, ice cream or energy bars, chocolate coating not only gives the product an attractive appearance and rich flavor, but also plays a key role in improving taste and shelf life. To achieve the dual improvement of flavor and coating, it is necessary to comprehensively consider equipment selection, process control and raw material ratio.

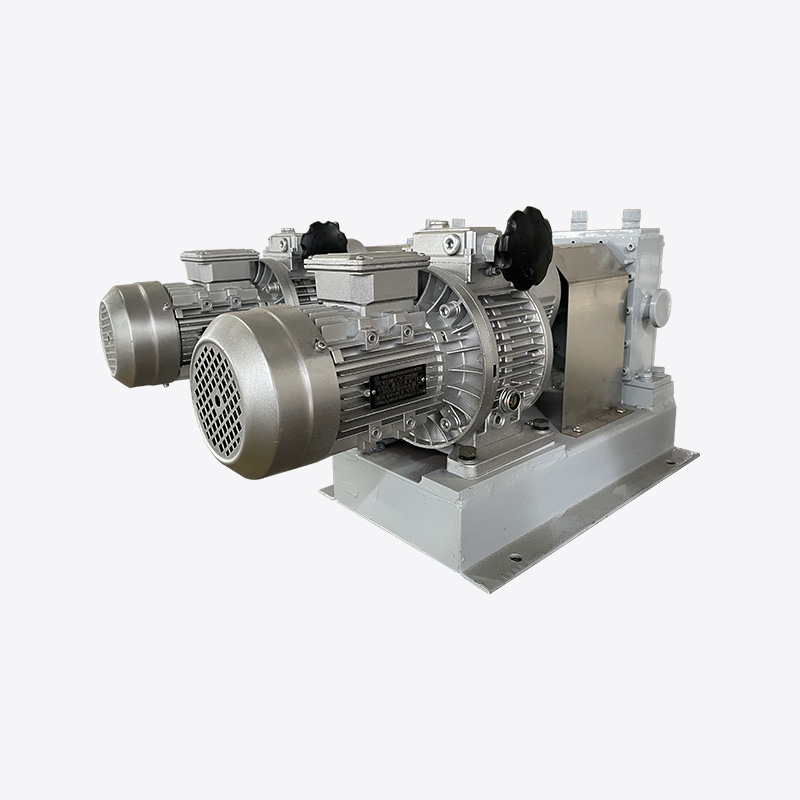

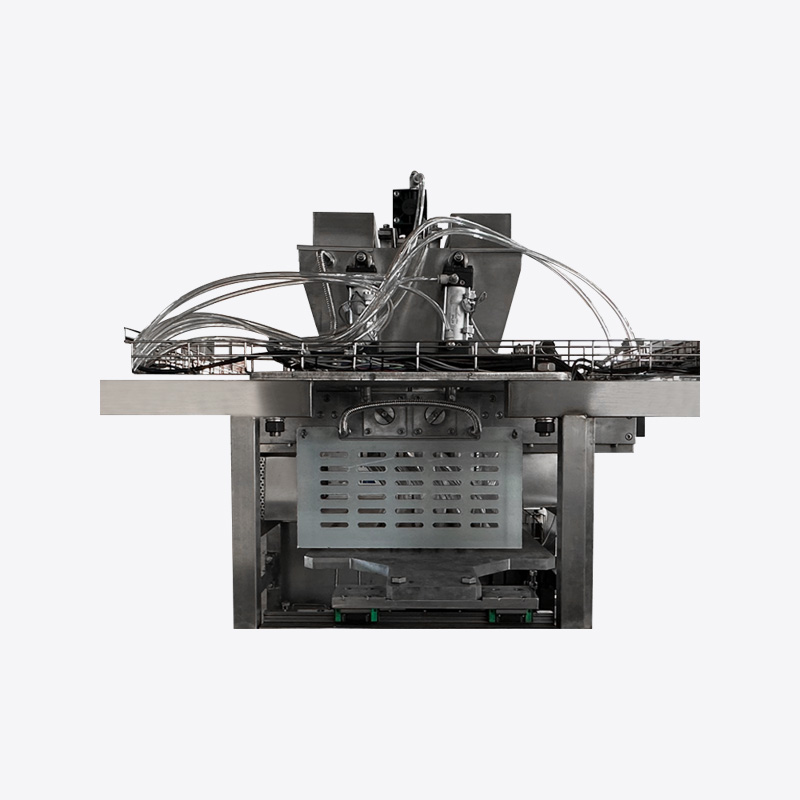

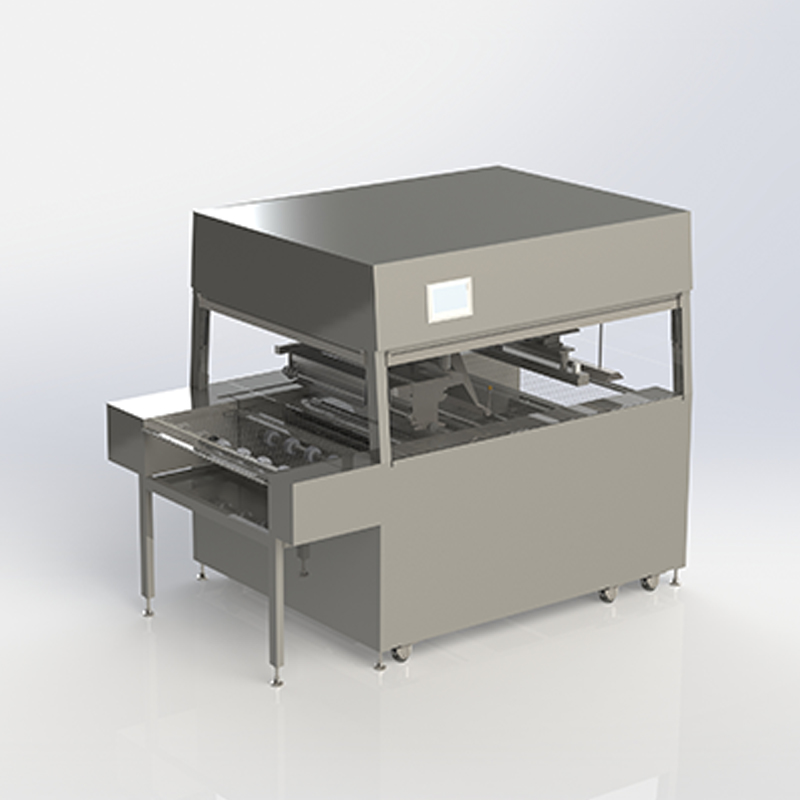

First, the working principle of the chocolate coating machine determines its advantages in coating performance. The equipment delivers the food to be coated into the spraying or dipping area through a conveyor belt, so that the chocolate liquid is evenly covered on the surface of the product, and then solidifies in the cooling and shaping area. Compared with manual coating or simple spraying equipment, Enrober can achieve higher coating uniformity and consistency, thereby ensuring that each product can be fully coated with chocolate, avoiding the problem of partial exposure or uneven thickness.

Secondly, in terms of flavor enhancement, the chocolate coating machine can maintain the optimal fluidity and aroma release state of chocolate through precise temperature control and flow regulation. High-quality chocolate coating should have a smooth taste and rich cocoa flavor, which requires maintaining an appropriate operating temperature (usually 31–32°C) during the coating process to prevent oil separation or poor crystallization. In addition, some advanced models also support multi-layer coating functions, which can add a layer of milk or white chocolate on top of the basic dark chocolate to further enrich the product's layering and taste experience.

In order to achieve good encapsulation, in addition to the technical parameters of the equipment itself, the chocolate formula design is also crucial. The ideal chocolate coating needs to have appropriate viscosity and surface tension so that it can quickly wet and completely encapsulate the target product during the flow process. To this end, manufacturers often adjust the cocoa butter content, add emulsifiers (such as lecithin), and optimize the proportion of powdered sugar to enhance the ductility and adhesion of chocolate. At the same time, for different types of substrates (such as porous biscuits, frozen ice cream, etc.), the corresponding coating thickness and cooling speed must be matched to prevent cracking or falling off due to moisture migration or thermal stress.

Finally, automation and continuous production are another major advantage of chocolate coating machines to improve efficiency and quality consistency. Through the integrated PLC control system, operators can monitor various parameters in real time and quickly switch process modes according to different product requirements. This not only improves production flexibility, but also helps to ensure that the flavor and packaging quality of each batch of products are stable and controllable.

The chocolate coating machine is not only an important tool to enhance the visual appeal of desserts, but also a core technical means to achieve flavor enhancement and good packaging. By rationally selecting equipment, optimizing process flow and formula design, enterprises can create more competitive high-end chocolate desserts while ensuring production efficiency.

English

English Español

Español