A chocolate enrober is a specialized machine used in the confectionery and food industries to coat various products with a consistent layer of chocolate. This equipment plays a crucial role in the mass production of chocolate-covered items such as biscuits, nuts, candy bars, cakes, and fruits. Instead of manually dipping or brushing products with chocolate, a chocolate enrober automates the process, ensuring uniform coverage, saving time, and improving overall product quality.

How It Works

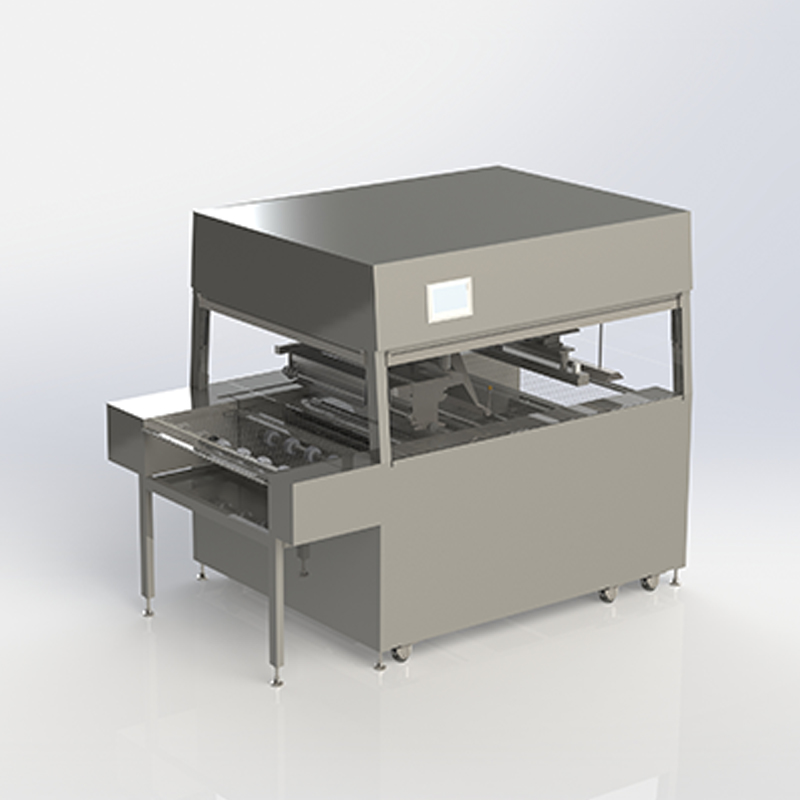

The basic working principle of a chocolate enrober involves conveying items through a curtain of melted chocolate. Products are placed on a moving conveyor belt and passed under a flow of tempered chocolate, which is usually kept at an optimal temperature for consistency and texture. The enrober is equipped with various components such as a chocolate melting tank, pump, curtain flow system, blower (to remove excess chocolate), and cooling tunnel to set the coating.

After the coating process, the excess chocolate is often removed by air blowers or vibrating systems to achieve a smooth, even finish. The coated items are then transported into a cooling tunnel where the chocolate hardens to form a stable and glossy shell.

Why Use a Chocolate Enrober?

Chocolate enrobers are essential for both small-scale and industrial chocolate production due to several key benefits:

Efficiency: They significantly reduce the time needed to coat products compared to manual methods.

Consistency: Every product receives the same amount of chocolate, resulting in uniform appearance and weight.

Hygiene: Automated systems reduce human contact, improving food safety and cleanliness.

Customization: Some enrobers allow adjustments in flow rate, chocolate thickness, and coating patterns to create various textures or designs.

Versatility: They can handle a wide range of products, from cookies and wafers to protein bars and even frozen treats.

Who Uses Chocolate Enrobers?

Artisan chocolatiers who want to scale up production without compromising quality.

Industrial food manufacturers producing high volumes of chocolate-coated products.

Bakeries and dessert brands aiming to add chocolate finishes to pastries or snacks.

Health food companies coating protein bars or dried fruits with dark chocolate.

In short, a chocolate enrober is a vital tool for anyone who needs to apply chocolate coatings in a professional and efficient manner. Whether in a small kitchen or a large factory, this machine helps deliver perfectly enrobed products that meet modern demands for quality, speed, and hygiene.

English

English Español

Español