What Trends Are Shaping Modern Candy Bar Line Production

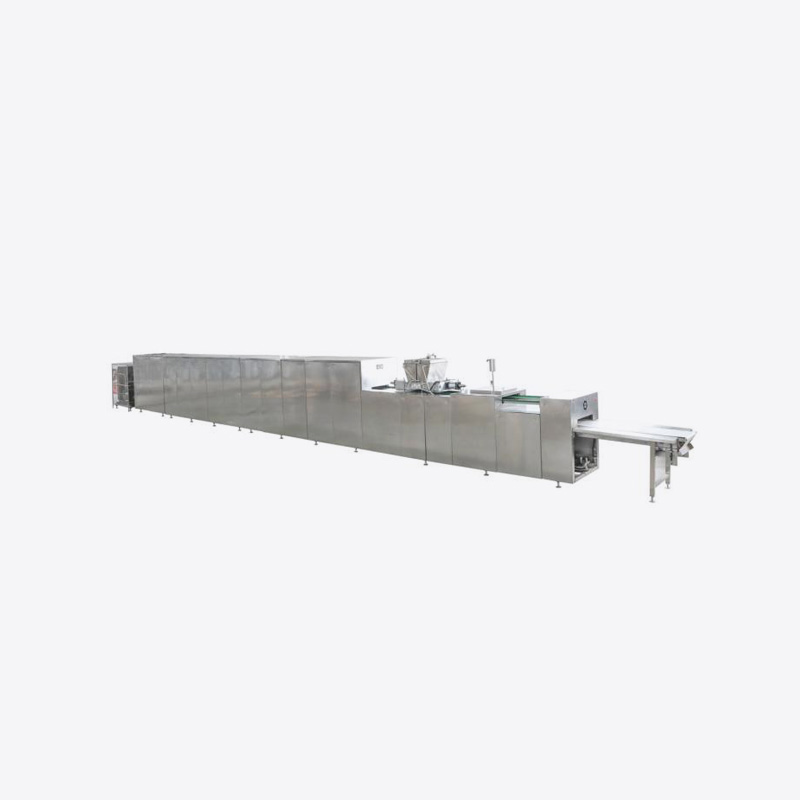

Modern candy bar production is entering a phase of steady transformation. As consumer tastes evolve and factories seek more stable performance, the Candy Bar Line is becoming a platform shaped by technology, workflow design, and market expectations. Understanding the current trends helps manufacturers plan for systems that support long term development and adaptable product strategies.

Growing Interest in Customizable Production Paths

One noticeable trend is the move toward flexible steps that allow different product combinations. Factories working with multiple snack formats want equipment that can shift between recipes without long pauses. This direction comes from the demand for seasonal items, limited editions, or varied textures.

A Candy Bar Line designed with adjustable modules gives manufacturers the ability to test new concepts while keeping the production cycle predictable.

Automation that Supports Consistent Output

Automation continues to influence how candy products are assembled, cooled, cut, and packaged. Instead of focusing on speed alone, many producers now look for systems that help maintain steady quality. Sensors, monitoring units, and coordinated controls make it easier to observe each stage of the process.

This trend has encouraged factories to adopt setups where human oversight works together with automated actions.

Sustainable Approaches in Material Handling

Environmental awareness is shaping production choices in almost every food category. Candy bar manufacturers are exploring ways to reduce resource consumption while keeping the production flow reliable.

Examples include efficient temperature management, optimized conveyor design, and packaging materials that reduce waste. These small changes accumulate to create operational patterns that respect sustainability goals.

Digital Tracking for Process Transparency

Digital tracking tools are gaining attention because they help operators manage recipes, batches, and performance records in one place.

A tracking system offers insights into production interruptions, maintenance cycles, and ingredient flow. With clearer data, teams can adjust processes quickly and maintain stable output across different product runs.

The trend aims to support efficient decision making rather than replace human expertise.

Growing Need for Hygiene Focused Design

Snack producers continue to pay attention to hygiene friendly structures. Smooth surfaces, easy access points, and minimal residue zones help operators clean equipment effectively.

This trend is driven by compliance requirements and by the expectation for safe products in every market. Clean designs also shorten downtime between changeovers, which supports product diversity.

Market Responsiveness and Product Differentiation

As consumer interests evolve, production lines must support varied shapes, fillings, and textures. The ability to introduce new formats without large structural adjustments becomes valuable.

Manufacturers are responding by adopting modular sections that support multiple formulas and different bar characteristics. This approach makes it easier to address new trends while keeping the workflow manageable.

| Trend Category | Main Focus | Impact on Production |

|---|---|---|

| Flexible paths | Adjusting modules for different items | Helps support new product ideas |

| Automation | Stable and consistent actions | Reduces manual variability |

| Sustainability | Lower resource use | Supports long term planning |

| Digital tools | Process visibility | Allows quicker adjustments |

| Hygiene | Clean friendly structures | Shortens cleaning and changeover time |

The modern Candy Bar Line is shaped by changes in consumer expectations, advancements in digital systems, and the search for steady workflow performance. Factories considering upgrades or expansions can benefit from understanding these trends and matching them with their long term production goals.

As the snack industry continues to evolve, these developments will play a central role in how manufacturers plan their operations and respond to new market directions.

How Candy Bar Line Upgrades Support Stable and Efficient Output

Modern snack production environments rely heavily on consistent workflow and dependable equipment performance. As manufacturers evaluate ways to strengthen productivity, upgrades to the Candy Bar Line have become an important path toward stable and efficient output. These improvements are designed to enhance coordination across each processing stage while supporting evolving product demands.

Enhancing Workflow Consistency Through Modern Components

Upgrades often begin with the introduction of new elements that harmonize various steps in the production sequence. When equipment sections communicate more effectively, the flow from mixing to forming and wrapping becomes smoother.

This type of improvement reduces unexpected slowdowns and creates a unified environment where ingredients move predictably across the line.

Improved Coordination Between Production Stages

When different modules are set up to work in closer alignment, the overall operation becomes easier to manage.

For example, forming sections and cooling areas can be adjusted to match each other's pace. By fine tuning this coordination, production teams maintain more stable product characteristics while reducing the chance of process interruptions.

Energy Conscious Adjustments That Support Long Term Operation

Many factories now focus on energy mindful upgrades that improve environmental responsibility and operational stability.

These adjustments may involve refined insulation methods, optimized heating zones, or conveyors designed to reduce friction.

Such changes support a balanced production environment with more predictable energy use throughout the day.

Upgrades That Strengthen Sanitation Efficiency

Sanitation is a priority across the food industry, and Candy Bar Line improvements often reflect this requirement.

Design adjustments focused on easy access, fewer debris collection points, and simplified cleaning surfaces help operators maintain hygiene standards with shorter downtime.

This contributes to a more efficient schedule, especially when frequent changeovers are needed.

Digital Systems That Provide Real Time Insight

Digital monitoring tools continue to play a growing role in candy bar production. New digital layers allow teams to observe temperature ranges, conveyor activity, and performance patterns.

With these insights, operators can adjust processes before minor deviations escalate into delays.

This approach not only supports stability but also assists with planning future production runs.

Operator Friendly Interfaces That Improve Daily Control

Many equipment updates introduce interfaces designed to simplify daily tasks.

Clear screens, organized menus, and visual alerts help operators react quickly to variations in the production sequence.

By supporting smoother communication between staff and equipment, these upgrades help keep output consistent even during complex product cycles.

Versatile Sections That Help Adapt to Product Changes

Market demands shift frequently, which means production lines must respond without heavy modifications.

Versatile modules or interchangeable components allow factories to introduce new textures, fillings, or shapes with minimal disturbance to the existing setup.

This flexibility supports a steady workflow while enabling product development opportunities.

Overview of Upgrade Categories

| Upgrade Type | Main Advantage | Contribution to Output Stability |

|---|---|---|

| Workflow components | Smoother ingredient movement | Reduces interruptions |

| Module alignment | Coordinated processing speed | Supports consistent product features |

| Energy conscious design | Balanced resource use | Helps maintain predictable operation |

| Hygiene adjustments | Easier cleaning | Shortens downtime |

| Digital monitoring | Real time insights | Supports quick corrective actions |

| Operator interface | Simplified control | Enhances daily management |

| Versatile modules | Adaptable structure | Helps manage product variety |

Upgrading a Candy Bar Line is not only about adding new equipment but about creating a more dependable production ecosystem.

When improvements are applied strategically, manufacturers gain a more stable workflow, reduced process disruptions, and smoother adaptation to market changes.

As demand for varied snacks continues to grow, these upgrades help ensure that production environments remain efficient and ready for new challenges.

Why Food Manufacturers Are Investing in Flexible Candy Bar Line Systems

As the snack industry moves toward greater product diversity, many factories are prioritizing flexible Candy Bar Line systems. This shift reflects the need for adaptable workflows that can handle new formats without disrupting ongoing operations. Flexibility has become an important consideration for manufacturers who aim to explore innovative product concepts while maintaining stable production routines.

Adapting to Market Shifts with Versatile Configurations

The snack market changes quickly as consumer preferences evolve. Flexible systems allow producers to answer these shifts without large-scale modifications.

By adopting adjustable features, a manufacturing team can introduce new shapes, fillings, or textures while keeping its core production structure intact.

This adaptability provides room for experimentation and gradual expansion of product categories.

Supporting Seasonal and Trial Items Without Heavy Adjustments

Seasonal releases and limited items often require small but noticeable variations in texture, coating, or size.

Traditional setups may struggle to accommodate these changes efficiently.

A flexible Candy Bar Line makes it possible to produce short batches without extensive downtime, helping manufacturers explore seasonal themes and trial concepts in a steady manner.

Improving Workflow Through Modular Design

Modular design is another key reason for the industry's investment.

Sections that can be rearranged or swapped make the setup more responsive to production demands.

A factory can reposition forming units, cooling tunnels, or wrapping stations based on new product requirements.

This approach reduces the need for additional equipment and helps maintain a smooth process flow.

Streamlining Changeovers and Reducing Idle Time

Frequent changeovers are common in facilities that handle diverse product portfolios.

With traditional lines, switching from one recipe to another can introduce long interruptions.

Flexible systems simplify this transition by incorporating features that ease cleaning, setup changes, and configuration updates.

This leads to shorter idle periods and a more predictable schedule.

Enhancing Cost Awareness Through Efficient Use of Resources

Adjustable systems help producers manage resources more responsibly.

Flexibility allows teams to run small batches without wasting materials.

Energy consumption can also become more stable, as operators fine tune each stage based on the specific requirements of the product being prepared.

These improvements contribute to better overall planning and long term operational balance.

Encouraging Innovation with Lower Risk

Flexible lines create an environment where new ideas can be tested with minimal disruption.

Manufacturers can run pilot batches, explore fresh combinations, or try new ingredient profiles while keeping standard items in production.

By lowering the strain associated with experimentation, flexible setups encourage gradual innovation.

Data Driven Adjustments for Smooth Operations

Many flexible systems integrate digital tools that track production patterns.

These tools provide operators with real time visibility into ingredient flow, equipment behavior, and historical performance.

With this data, teams can adjust parameters quickly and maintain a steady workflow across different product runs.

Summary of Benefits Encouraging Industry Investment

| Aspect | Reason for Interest | Resulting Advantage |

|---|---|---|

| Versatility | Adapts to varied product needs | Supports new concepts |

| Modular setup | Rearranged sections | Smooth workflow alignment |

| Efficient changeovers | Reduced downtime | More predictable scheduling |

| Resource awareness | Controlled batch sizes | Balanced operation |

| Innovation support | Lower experimentation risk | Encourages product expansion |

| Digital insight | Real time tracking | Timely adjustments |

The decision to invest in flexible Candy Bar Line systems reflects the broader direction of today's snack industry.

Manufacturers want to accommodate diverse product ideas, maintain consistent production cycles, and respond to changing market conditions with minimal disruption.

Flexible systems offer a balanced path that supports innovation, efficient scheduling, and adaptable workflows, making them a valuable asset in modern confectionery production environments.

What to Consider When Expanding Your Candy Bar Line for New Product Varieties

Introducing new product varieties is an important step for many confectionery manufacturers. As consumer preferences diversify, factories often explore fresh combinations of textures, fillings, and shapes. Expanding a Candy Bar Line requires careful planning to ensure that new items fit smoothly into existing workflows without interrupting ongoing production. The process involves evaluating equipment, workflow design, ingredient handling, and operational goals.

Understanding the Requirements of Each New Product Concept

Each new bar design brings unique requirements. Some concepts may need a softer base, others may require layered structures, additional toppings, or different cutting patterns.

Before making adjustments, production teams should map out how the new item behaves during forming, cooling, decorating, and packaging.

A clear outline helps determine whether the current setup can handle the new characteristics or whether upgrades are necessary.

Evaluating the Capacity of Existing Modules

Expanding product variety may place additional demands on forming units, transfer sections, or finishing modules.

Careful evaluation ensures that current components can manage multiple recipes without compromising workflow stability.

If a particular stage becomes a bottleneck, introducing a modular upgrade or reconfiguring the layout may create the extra flexibility required for smooth performance.

Assessing Ingredient Handling and Flow Pattern Adjustments

New ingredients may behave differently when processed.

Some fillings may require more sensitive handling, while certain layers need additional support.

Adjusting conveyor materials, applying refined temperature control, or modifying sequence timing can help maintain stable movement across the line.

Ensuring ingredient uniformity prevents disruptions during the shaping and coating phases.

Considering Packaging Options That Match New Product Forms

New bar shapes or textures may require different packaging styles.

Manufacturers should review the compatibility between the product and wrapping equipment.

Changes in length, surface features, or topping designs could influence sealing methods or wrapper materials.

Ensuring packaging alignment early in the planning stage helps avoid delays during final production.

Planning for Process Adjustments Without Excessive Downtime

Introducing new varieties often requires short periods of testing and fine tuning.

Minimizing downtime involves preparing changeover steps in advance, training operators, and optimizing cleaning routines.

A well planned transition ensures that both new items and existing products can be produced without extended interruptions.

Ensuring Hygiene and Safety Standards Remain Consistent

As products diversify, hygiene expectations must remain steady across all items.

Any additional toppings, coatings, or ingredients should be evaluated for their influence on cleaning frequency and sanitation.

Design features that provide easy access for cleaning help teams maintain safe and compliant production environments.

Digital Tools That Support Expansion Planning

Digital monitoring and recipe management tools can simplify transitions during expansion.

By storing parameters for each new product, operators can switch between recipes efficiently.

Tracking data from test runs also helps refine settings for consistent quality across batches.

Cost Awareness and Resource Planning

Adding new varieties affects material usage, energy consumption, and labor distribution.

Conducting a resource assessment helps determine the economic impact of expansion.

Optimizing batch sizes and organizing production cycles can prevent resource waste while supporting sustainable growth.

Comparison of Key Considerations for Expansion

| Consideration | Focus Area | Influence on Production |

|---|---|---|

| Product requirements | Texture and structure needs | Guides equipment planning |

| Module capacity | Ability to manage new items | Helps prevent bottlenecks |

| Ingredient handling | Flow characteristics | Supports stable processing |

| Packaging alignment | Compatibility with new forms | Ensures smooth finishing |

| Downtime planning | Efficient changeovers | Keeps schedules predictable |

| Hygiene expectations | Safe production | Maintains compliance |

| Digital support | Recipe and batch data | Enhances control |

| Resource strategy | Material and energy use | Strengthens long term planning |

Expanding a Candy Bar Line for new product varieties is a strategic process that blends equipment evaluation, operational planning, and careful ingredient assessment.

By addressing layout flexibility, packaging compatibility, sanitation needs, and resource management, manufacturers can introduce new products with confidence.

Thoughtful preparation ensures that expansion enhances creativity while maintaining a stable and reliable production environment.

English

English Español

Español