Why Food Brands Are Turning to Flexible Energy Bar Line Solutions

As consumer preferences for energy bars evolve, food manufacturers are exploring production systems that can adapt quickly to new trends. Flexible Energy Bar Line solutions provide the capability to handle diverse recipes, adjust workflows, and accommodate seasonal or limited edition items without disrupting ongoing operations. These systems are increasingly recognized as essential tools for brands aiming to maintain consistent output while exploring innovation.

Adapting to Market Changes

The energy bar market changes rapidly as tastes, nutritional trends, and packaging expectations shift. Flexible production systems allow manufacturers to respond without major structural changes.

By incorporating adjustable modules and versatile conveyor systems, brands can introduce new flavors, shapes, or ingredient combinations efficiently.

This adaptability supports the creation of small batches for testing or seasonal launches while maintaining a stable production schedule.

Supporting Multiple Product Types

Energy bar brands often manage several product lines with distinct textures or ingredient profiles. Traditional fixed lines may struggle to handle varied formulas simultaneously.

Flexible systems allow operators to switch between products without extensive downtime.

This capability helps factories maintain productivity, meet delivery deadlines, and reduce the risk of operational bottlenecks.

Efficiency Through Modular Design

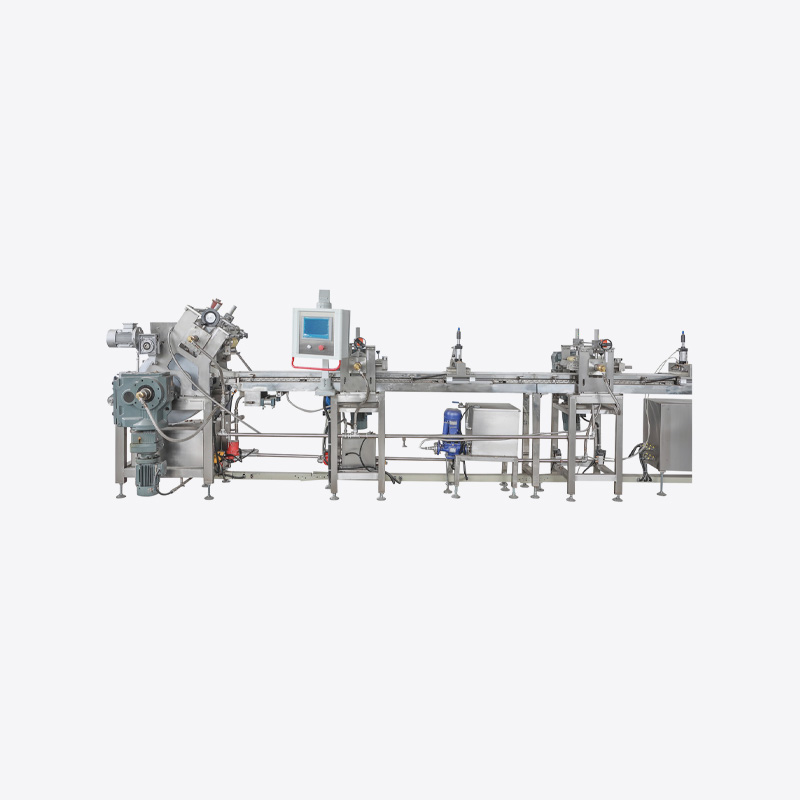

Modular design is a central feature of modern flexible Energy Bar Line systems.

Separate modules for mixing, forming, baking, coating, and packaging can be rearranged or upgraded independently.

This approach makes it easier to adjust production flow for new items, optimize space, and plan maintenance without halting the entire line.

Minimizing Downtime During Changeovers

Frequent product changes can interrupt standard workflows. Flexible lines often integrate quick setup features, easy-to-clean surfaces, and intuitive interfaces.

These enhancements reduce idle time between batches and allow operators to implement new recipes more efficiently.

As a result, manufacturers can manage a wider variety of products with minimal impact on overall output.

Resource and Cost Awareness

Flexible systems support better resource planning. By producing smaller batches efficiently, factories can reduce material waste and balance energy consumption.

Digital monitoring features provide insights into energy use, ingredient flow, and equipment performance.

These data-driven adjustments contribute to sustainable operation while ensuring stable production across multiple products.

Encouraging Innovation With Low Risk

Flexible Energy Bar Line solutions provide a platform for testing new concepts.

Manufacturers can introduce alternative ingredients, coating styles, or shapes without affecting the main product line.

Lowering the operational risk associated with experimentation encourages innovation and allows brands to respond to market trends faster.

Example Overview of Flexible Energy Bar Line Benefits

| Feature | Focus | Advantage |

|---|---|---|

| Modular layout | Separate production sections | Easy adaptation to new products |

| Adjustable workflow | Reconfigurable steps | Supports seasonal or limited editions |

| Digital monitoring | Real time data | Helps maintain stable output |

| Efficient changeovers | Quick setup and cleaning | Reduces downtime |

| Resource planning | Ingredient and energy tracking | Supports cost efficiency |

| Innovation support | Test new recipes | Encourages product diversity |

Food brands are increasingly investing in flexible Energy Bar Line solutions to remain competitive in a rapidly evolving market.

By enabling adaptability, efficient workflows, and resource-conscious operation, these systems allow manufacturers to produce multiple product types reliably while exploring innovation.

The move toward flexible lines reflects a broader trend in the food industry, where responsiveness, efficiency, and sustainable operation are key to meeting both consumer expectations and operational goals.

How Energy Bar Line Upgrades Support Stable Production for Growing Demand

As the demand for energy bars continues to rise, manufacturers are seeking solutions that enhance stability and consistency across production. Upgrading the Energy Bar Line is a practical approach to maintain reliable output while adapting to expanding product portfolios. These upgrades focus on improving workflow coordination, minimizing interruptions, and supporting flexible product development.

Enhancing Workflow Coordination

Energy bar production involves multiple stages, including mixing, forming, baking, coating, and packaging. Upgrades that improve communication between these stages help ensure smooth transitions.

By integrating modular adjustments and synchronized controls, manufacturers can reduce delays caused by equipment misalignment or uneven ingredient flow.

This creates a predictable workflow, allowing operators to focus on product quality rather than troubleshooting interruptions.

Supporting Consistent Product Quality

Maintaining uniform texture, shape, and ingredient distribution is essential when producing high volumes.

Line upgrades that stabilize temperature control, conveyor speed, and processing rhythm help reduce variability.

Consistent quality ensures that all batches meet brand standards while minimizing waste and rework, which becomes increasingly important as demand grows.

Reducing Downtime During Changeovers

High-demand facilities often need to switch between flavors or bar types quickly.

Upgrades can introduce quick-clean features, easy-to-adjust modules, and operator-friendly interfaces.

Shorter changeover periods allow manufacturers to meet multiple product requirements without significant interruptions, maintaining output levels while accommodating diverse recipes.

Energy and Resource Efficiency

Upgraded systems often include energy-conscious adjustments such as optimized conveyor movement, improved heating or cooling distribution, and reduced friction points.

These enhancements help factories maintain consistent output without excessive resource use.

Additionally, monitoring tools provide insights into energy consumption and ingredient usage, supporting more efficient planning and stable operation.

Facilitating Product Innovation

With demand growing and consumer tastes changing, introducing new formulations becomes essential.

Upgraded lines with adaptable modules allow manufacturers to trial new bars, test alternative ingredients, or explore layered textures without halting existing production.

This capability balances creativity with operational reliability, enabling brands to respond to market trends effectively.

Example Overview of Upgrade Benefits

| Upgrade Area | Focus | Contribution to Production Stability |

|---|---|---|

| Workflow coordination | Synchronized stages | Reduces delays and interruptions |

| Product quality control | Temperature and conveyor management | Maintains consistency across batches |

| Changeover optimization | Quick-clean and adjustable modules | Minimizes downtime |

| Energy and resource planning | Efficient material and energy use | Supports predictable output |

| Innovation support | Adaptable modules for testing | Encourages new product development |

Upgrading an Energy Bar Line is an investment in both stability and flexibility.

By improving workflow coordination, reducing variability, optimizing resource use, and supporting new product trials, manufacturers can sustain reliable production in the face of growing demand.

These upgrades ensure that facilities remain responsive to market trends while maintaining consistent quality and efficiency.

What Trends Are Influencing Modern Energy Bar Line Development

The energy bar industry is undergoing steady transformation as consumer preferences, nutrition trends, and manufacturing expectations evolve. Modern Energy Bar Line development reflects a combination of technological adoption, workflow optimization, and market-driven demands. Understanding these trends allows manufacturers to plan systems that are both adaptable and reliable.

Shift Toward Flexible Production Paths

One prominent trend is the emphasis on flexible production steps. Manufacturers are increasingly adopting lines that can handle multiple recipes, ingredient variations, and seasonal items without long interruptions.

Adjustable modules and versatile conveyors allow factories to test new concepts while keeping the main production flow stable.

This flexibility also helps brands respond to emerging consumer trends, such as alternative protein sources, functional ingredients, or novel flavor combinations.

Integration of Automation for Consistent Output

Automation continues to influence modern energy bar production, but the focus has shifted from speed alone to maintaining stable quality.

Sensors, synchronized controls, and digital monitoring systems help operators oversee each stage, from ingredient dosing to forming and packaging.

This trend emphasizes reducing variability and ensuring that batches meet consistent standards without heavy reliance on manual adjustments.

Sustainable Manufacturing Approaches

Environmental awareness is shaping Energy Bar Line design. Factories are exploring ways to reduce energy consumption, optimize material flow, and minimize packaging waste.

Examples include improved temperature management, low-friction conveyors, and eco-friendly wrappers.

Sustainable practices not only reduce operational costs but also align production with consumer expectations for environmentally responsible products.

Digital Tracking and Process Visibility

Data-driven production is another emerging trend. Monitoring tools allow operators to track ingredient usage, batch history, and equipment performance in real time.

These insights help prevent disruptions, streamline troubleshooting, and support efficient planning.

Rather than replacing human oversight, digital systems complement operator expertise, enhancing decision-making for both standard and new product runs.

Hygiene-Focused Equipment Design

Cleanability and sanitation continue to influence Energy Bar Line upgrades. Smooth surfaces, easily accessible areas, and minimized residue zones help reduce downtime during cleaning and changeovers.

Hygiene-focused design supports compliance with food safety regulations while maintaining workflow efficiency, particularly in facilities producing multiple product types.

Market Responsiveness and Product Differentiation

Modern Energy Bar Lines are increasingly designed to support diverse product characteristics, including shape, texture, and nutritional composition.

Modular sections allow manufacturers to introduce new bars without extensive structural adjustments, enabling rapid adaptation to changing consumer interests.

This approach fosters innovation while maintaining consistent production flow.

Example Overview of Influential Trends

| Trend | Main Focus | Impact on Production |

|---|---|---|

| Flexible paths | Adjustable modules | Supports diverse product trials |

| Automation | Coordinated controls | Ensures consistent output |

| Sustainability | Energy and material efficiency | Reduces waste and aligns with consumer values |

| Digital monitoring | Real-time data tracking | Facilitates quick process adjustments |

| Hygiene design | Easy-to-clean surfaces | Shortens downtime and maintains safety |

| Market adaptability | Modular production sections | Allows introduction of new products without disruption |

Modern Energy Bar Line development is shaped by flexibility, automation, sustainability, digital monitoring, hygiene, and market responsiveness.

Manufacturers who understand and implement these trends can achieve stable workflows while responding to evolving consumer preferences.

By planning production systems that integrate these factors, energy bar producers position themselves for sustainable growth and innovation in a competitive market.

English

English Español

Español