What is a Chocolate Ball Mill?

A Chocolate Ball Mill is a specialized machine used in the chocolate manufacturing process to refine chocolate paste. It is a crucial piece of equipment for achieving the smooth, velvety texture that is characteristic of high-quality chocolate. By grinding the cocoa mass, sugar, and other ingredients into a fine, uniform paste, a ball mill helps to enhance the flavor and mouthfeel of the chocolate.

In this article, we will explore how a chocolate ball mill works, its features, benefits, and considerations for choosing the right one for your production needs.

Key Features of a Chocolate Ball Mill

| Feature | Description |

|---|---|

| Capacity | Typically ranges from small lab-scale models (5-10kg) to large-scale production machines (1000kg and more). |

| Fineness | Achieves a particle size of 20-25μm, which is optimal for smooth chocolate. |

| Material of Construction | Made from durable stainless steel or high-quality alloys for extended lifespan and resistance to corrosion. |

| Grinding Media | Steel or ceramic balls are used to grind the mixture. The size and material of the balls influence the grinding efficiency. |

| Control System | Many models come with PLC-based controls that allow precise regulation of grinding time, speed, and temperature. |

| Temperature Control | Equipped with cooling or heating systems to maintain optimal refining temperatures. |

| Maintenance | Easy to maintain with features like automatic lubrication and user-friendly cleaning systems. |

Benefits of Using a Chocolate Ball Mill

Improved Texture:

The fine grinding process results in a smooth and creamy texture, which is essential for high-quality chocolate. A ball mill helps break down the cocoa solids and sugar crystals to achieve the desired mouthfeel.

Enhanced Flavor:

By grinding the ingredients to a fine consistency, a chocolate ball mill helps release more flavor compounds, enhancing the overall taste profile of the chocolate.

Consistent Results:

The machine ensures uniform grinding, which leads to consistent product quality batch after batch. This is crucial for large-scale chocolate production.

Energy Efficiency:

Chocolate ball mills are designed to operate efficiently, optimizing energy use and reducing overall production costs compared to other traditional methods.

Versatility:

While primarily used for chocolate, ball mills can also be employed to grind other food products like nut pastes, jams, and spreads, making it a versatile piece of equipment.

Types of Chocolate Ball Mills

In the chocolate production industry, Chocolate Ball Mills come in a variety of designs and configurations to suit different production scales and needs. Each type of ball mill offers unique features and capabilities that can significantly impact the efficiency, quality, and versatility of chocolate production. In this section, we will explore the various types of chocolate ball mills, their key differences, and what to consider when selecting one for your operations.

1. Laboratory and Small-Scale Chocolate Ball Mills

Laboratory-scale ball mills are designed for smaller production runs and are ideal for research, development, or testing new chocolate formulations. They are typically used for small batches of chocolate and are common in artisanal chocolate-making facilities or R&D departments.

Key Features:

| Feature | Description |

|---|---|

| Capacity | Typically from 5kg to 100kg per batch |

| Fineness | Achieves particle sizes of 20-25μm |

| Material | Stainless steel or food-grade materials |

| Motor Power | Low power (1-5kW) |

| Control System | Simple controls or manual adjustments |

| Size and Footprint | Compact and portable, ideal for limited space |

| Typical Applications | Small-batch chocolate production, product testing, R&D |

Advantages:

Cost-effective for small-scale operations

Easy to operate and clean

Compact design saves space

Ideal for developing custom flavors or recipes

Disadvantages:

Limited production capacity

May not be suitable for large-scale manufacturing

2. Mid-Scale Chocolate Ball Mills

These ball mills are used in medium-sized chocolate manufacturing operations that require larger capacities but still need flexibility in production. They offer more advanced features compared to laboratory models and can handle moderate production volumes.

Key Features:

| Feature | Description |

|---|---|

| Capacity | 100kg to 500kg per batch |

| Fineness | Achieves particle sizes of 20-25μm |

| Material | High-quality stainless steel |

| Motor Power | Medium power (10-30kW) |

| Control System | PLC or digital control with customizable settings |

| Size and Footprint | Larger, but still suitable for smaller factory spaces |

| Typical Applications | Small-to-medium scale chocolate manufacturers |

Advantages:

Higher capacity than laboratory models, suitable for semi-industrial production

Precise control over grinding parameters via PLC control

Versatile for different products beyond chocolate

Disadvantages:

Higher upfront cost compared to smaller models

Requires more maintenance due to increased size and complexity

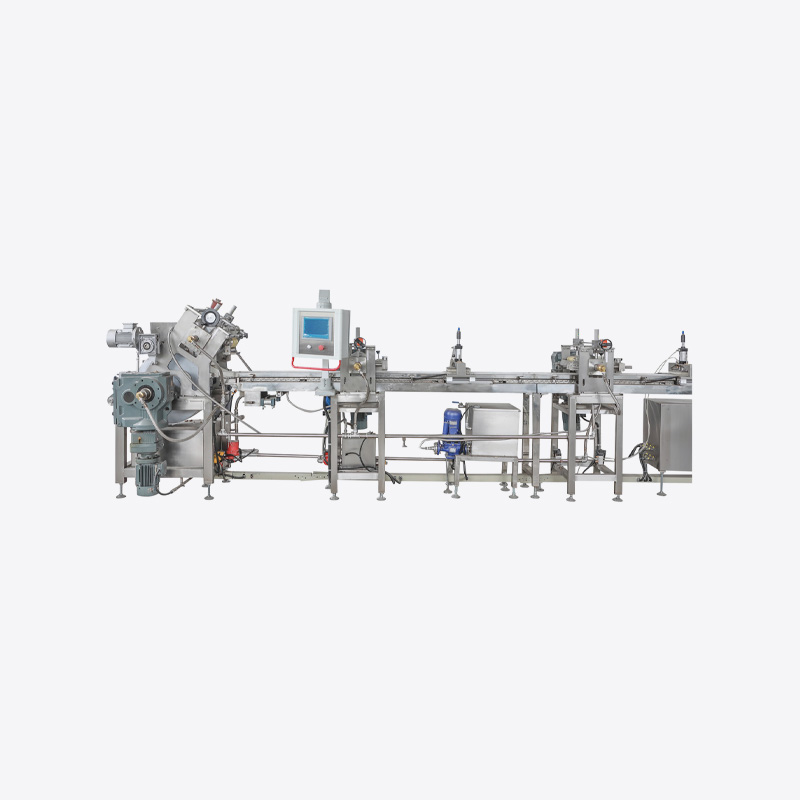

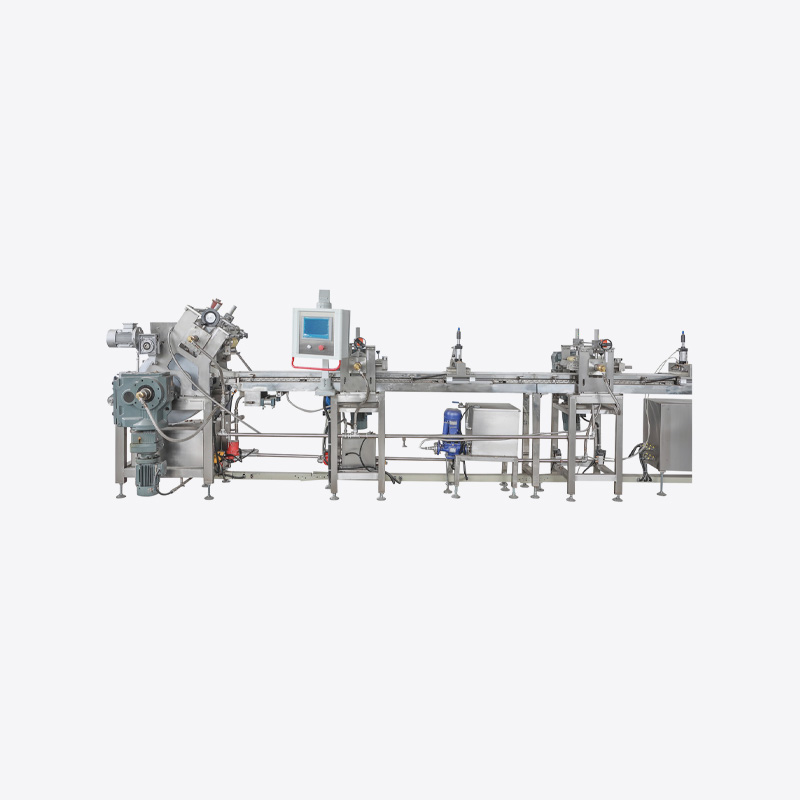

3. Industrial-Scale Chocolate Ball Mills

Industrial-scale Chocolate Ball Mills are designed for large chocolate manufacturers with high-volume production requirements. These mills offer the highest capacity and advanced features to ensure optimal performance in mass production.

Key Features:

| Feature | Description |

|---|---|

| Capacity | 500kg to 2000kg or more per batch |

| Fineness | Achieves particle sizes of 20-25μm |

| Material | Industrial-grade stainless steel, anti-corrosion alloys |

| Motor Power | High power (30-100kW or more) |

| Control System | Advanced PLC or touch screen control with automation |

| Size and Footprint | Large, requires considerable space for installation |

| Typical Applications | High-volume chocolate production, nut pastes, spreads |

Advantages:

High production capacity suitable for large-scale chocolate manufacturing

Precise temperature and speed control for consistent results

Designed for continuous operation over long periods

Disadvantages:

Large footprint, requiring more factory space

Higher energy consumption and operational costs

More expensive to purchase and maintain

4. Continuous Chocolate Ball Mills

Continuous Chocolate Ball Mills are a type of industrial-scale mill designed to process large amounts of chocolate paste continuously. They are built for maximum efficiency and minimal downtime, making them ideal for high-output factories where uninterrupted production is required.

Key Features:

| Feature | Description |

|---|---|

| Capacity | Large capacity, ranging from 500kg to several tons per day |

| Fineness | Achieves consistent fineness of 20-25μm |

| Material | Stainless steel and other heavy-duty materials |

| Motor Power | Very high power (100kW or more) |

| Control System | Advanced PLC control with integrated automation |

| Production Process | Continuous flow, no need to stop for batch changes |

| Typical Applications | Large chocolate manufacturers, continuous production lines |

Advantages:

Continuous processing ensures consistent, high-volume output

Higher production speed compared to batch models

Efficient in terms of energy use and waste reduction

Disadvantages:

Large investment cost and infrastructure requirements

Not suitable for smaller-scale or artisanal chocolate makers

Requires skilled operators for optimal performance

How Does a Chocolate Ball Mill Work?

A Chocolate Ball Mill is a specialized piece of equipment used in the chocolate production process to refine the chocolate mixture to achieve a smooth, velvety texture. It is an essential machine for achieving the fine particle size required for high-quality chocolate, allowing the cocoa solids, sugar, and other ingredients to blend together seamlessly. The chocolate ball mill utilizes steel or ceramic balls that continuously grind the ingredients to create a fine paste with an optimal texture.

In this section, we'll walk through the process of how a Chocolate Ball Mill works, its components, and the factors that contribute to achieving the desired results in chocolate production.

Key Components of a Chocolate Ball Mill

The Chocolate Ball Mill is made up of several key components that work in unison to refine the chocolate mixture. These components are designed to ensure efficient grinding and optimal performance.

| Component | Description |

|---|---|

| Grinding Vessel | The chamber where the chocolate paste is refined. Typically made from durable stainless steel for hygiene and longevity. |

| Grinding Media (Balls) | Steel or ceramic balls are used to grind the chocolate paste. The size and material of the balls affect the grinding process. |

| Motor | Powers the rotation of the grinding vessel, ensuring continuous grinding of the chocolate mixture. |

| Control Panel | Allows operators to monitor and adjust grinding parameters, such as grinding time, temperature, and motor speed. |

| Cooling System | Used to regulate the temperature of the chocolate paste to prevent overheating, ensuring consistent texture and flavor. |

| Discharge Valve | Facilitates the release of the refined chocolate paste from the grinding vessel once the desired fineness is achieved. |

Step-by-Step Process of How a Chocolate Ball Mill Works

1. Loading the Ingredients:

The process begins by loading the raw ingredients (such as cocoa nibs, sugar, and milk powder) into the grinding vessel. This initial mixture will be ground and refined by the balls inside the vessel. At this stage, some additional ingredients like lecithin or flavoring agents may be added.

2. Grinding the Chocolate:

Once the ingredients are loaded, the motor starts the rotation of the grinding vessel. As the vessel rotates, the grinding balls inside collide with the chocolate paste, breaking down the solid particles and reducing their size. This process continues until the chocolate reaches the required fineness, typically between 20-25μm.

The rotation of the drum ensures that the balls move constantly over the mixture, creating an efficient grinding action. Over time, this reduces the size of the cocoa solids and sugar particles, which gives the chocolate its characteristic smooth texture.

3. Generation of Heat and Temperature Control:

Grinding generates heat due to friction between the balls and the chocolate mixture. To prevent overheating, which can negatively affect the chocolate’s texture and flavor, a cooling system is often integrated. This system helps to maintain an optimal temperature throughout the process.

The cooling system typically uses water circulation or a jacketed design around the grinding vessel, ensuring that the chocolate paste does not get too warm and remains within the ideal temperature range for grinding.

4. Adjusting Parameters:

Operators can adjust various parameters during the grinding process, such as grinding time, temperature, and spindle speed, depending on the type of chocolate being produced. For example, adjusting the grinding time can affect the fineness of the chocolate, and fine-tuning the temperature ensures the mixture doesn't overheat, preserving its flavor.

Some machines feature PLC-based control systems, which provide advanced monitoring and allow operators to make precise adjustments to these parameters automatically.

5. Discharge and Final Product:

After the desired fineness has been achieved, the chocolate paste is ready to be discharged from the grinding vessel. The discharge valve opens, allowing the finished chocolate to flow into the next stage of the production process, such as tempering or conching.

Factors That Affect the Chocolate Grinding Process

Several factors influence how well the Chocolate Ball Mill performs and the quality of chocolate it produces:

1. Grinding Media (Balls):

The size, hardness, and material of the grinding media (balls) significantly affect the grinding efficiency and the quality of the final product. Smaller balls are ideal for finer grinding and achieving a smooth texture, while larger balls are better suited for coarser grinding in the early stages of the process.

The material of the balls—whether steel, ceramic, or other types—also plays a role in the grinding efficiency and durability of the machine.

2. Grinding Time:

The duration of the grinding process determines how finely the chocolate is refined. Longer grinding times result in finer, smoother chocolate, but excessive grinding can lead to overheating and damage the flavor. Operators need to monitor and adjust the grinding time to achieve the optimal result for each batch.

3. Temperature Control:

Temperature plays a critical role in the chocolate refining process. If the chocolate mixture gets too hot, it can become too fluid and affect the desired texture. A well-maintained cooling system is crucial for keeping the chocolate at the ideal temperature during grinding, preventing any compromise in the final product.

4. Spindle Speed:

The spindle speed (rotation speed of the grinding vessel) affects how quickly the grinding balls move and how effectively they break down the chocolate mixture. Adjusting the speed allows the operator to control the grinding process for different types of chocolate and to achieve the ideal consistency.

Benefits of Using a Chocolate Ball Mill in Chocolate Production

A Chocolate Ball Mill plays a crucial role in the chocolate-making process, offering a range of benefits that directly impact the quality, efficiency, and scalability of chocolate production. This machine is specifically designed to refine and grind the chocolate paste to achieve the smooth texture and rich flavor that high-quality chocolate is known for. Below, we will explore the key benefits of using a chocolate ball mill in chocolate production, demonstrating why it is an essential tool for both small-scale and large-scale chocolate manufacturing.

1. Consistent Product Quality

One of the main advantages of using a Chocolate Ball Mill is its ability to consistently produce high-quality chocolate. The grinding process ensures that the chocolate mixture is refined to the same fine particle size each time, typically between 20-25μm, which is essential for achieving that smooth, velvety mouthfeel. The uniformity in texture and particle size ensures that the final product maintains the same premium quality throughout the production batch.

Improved Texture: The continuous grinding process results in a smooth, creamy texture, free from gritty cocoa solids and sugar crystals, which are common in poorly refined chocolate.

Enhanced Flavor Profile: Fine grinding allows the chocolate to develop a more uniform and richer flavor, as the cocoa solids and sugar are properly blended.

2. Increased Production Efficiency

Using a Chocolate Ball Mill significantly increases production efficiency. This machine is designed to handle large batches of chocolate paste while maintaining precision and consistency in the grinding process. Unlike traditional methods, where grinding is done manually or with slower machines, a chocolate ball mill can grind chocolate in a much shorter amount of time, helping manufacturers meet high production demands.

Higher Output: The mill's large capacity allows it to process large quantities of chocolate at once, reducing the time spent on each batch.

Automation: Many ball mills come equipped with automatic controls and PLC systems, minimizing the need for constant manual oversight and improving overall productivity.

3. Precise Control Over Grinding Parameters

A Chocolate Ball Mill provides operators with the ability to finely control essential parameters such as grinding time, spindle speed, and temperature. This level of control is vital for achieving the desired chocolate texture and consistency, as different types of chocolate and formulations require different settings.

Grinding Time: Adjusting the grinding time allows manufacturers to achieve the optimal fineness, from coarse to ultra-smooth chocolate paste.

Temperature Control: Overheating can damage chocolate, affecting its taste and texture. Ball mills with built-in cooling systems maintain the ideal temperature during grinding, preventing any degradation in quality.

Speed Control: The rotational speed of the grinding vessel can be adjusted to optimize grinding efficiency for different ingredients or chocolate formulations.

4. Energy Efficiency

Chocolate ball mills are designed to operate efficiently, helping reduce energy consumption during the chocolate production process. The design of the machine, including its motor and grinding vessel, ensures that energy is used effectively while still achieving the desired results in a shorter period of time. This contributes to both cost savings and environmental sustainability.

Optimized Grinding Efficiency: The combination of rotating balls and controlled temperature ensures that energy is used for grinding, reducing unnecessary energy wastage.

Reduced Operational Costs: The higher grinding efficiency leads to less energy consumption per unit of output, making it a more cost-effective solution for large-scale production.

5. Versatility in Processing Different Products

While primarily used for chocolate, the Chocolate Ball Mill is highly versatile and can be used for processing other semi-liquid products such as peanut butter, nut pastes, jam, and other confectionery products. This versatility makes the ball mill an invaluable tool for manufacturers producing a variety of products in addition to chocolate.

Multi-purpose Use: The mill can grind and refine different materials, allowing manufacturers to expand their product offerings without needing separate equipment.

Customizable Settings: The machine's adjustable parameters make it easy to switch between products with different textures and consistencies.

6. Scalability and Flexibility

The Chocolate Ball Mill is available in different sizes, making it suitable for both small artisanal operations and large industrial-scale production. Whether a business is just starting with small batches of premium chocolate or is scaling up to meet high-volume demands, the ball mill can be adapted to meet the specific needs of the production process.

Small-Scale Production: Smaller models are available for smaller, boutique chocolate manufacturers who need a machine that fits their limited production capacity.

Large-Scale Production: Larger models are capable of processing thousands of kilograms of chocolate at once, meeting the high demands of large-scale factories.

7. Reduced Labor Costs

By automating the grinding process, a Chocolate Ball Mill reduces the need for manual labor in the chocolate production process. The automation of parameters such as grinding time, temperature control, and discharge makes the operation more efficient, allowing workers to focus on other tasks. This results in a more streamlined production process with fewer human interventions.

Minimized Manual Labor: Automation in both grinding and temperature control reduces the need for constant supervision, lowering labor costs.

Easy Operation: Modern chocolate ball mills are designed for ease of operation, with intuitive interfaces and simple maintenance procedures.

8. Easy Maintenance and Longevity

A Chocolate Ball Mill is built for durability and longevity, ensuring that it performs efficiently over time with minimal wear and tear. With proper maintenance, the ball mill can operate for many years without significant breakdowns. The materials used in the construction of the machine, such as stainless steel for the vessel and high-grade steel for the grinding balls, are designed to withstand continuous operation and harsh conditions.

Durable Construction: The robust materials used in the machine's construction ensure long-lasting performance, reducing downtime and replacement costs.

Simplified Maintenance: Many ball mills come with easy-to-replace components and a user-friendly design that simplifies maintenance and repair tasks.

Chocolate Ball Mill vs. Traditional Conche: Which is Better for Chocolate Refining?

In the world of chocolate production, refining the chocolate paste to achieve the perfect smoothness and flavor profile is a critical step. Two primary machines used in the refining process are the Chocolate Ball Mill and the Traditional Conche. Both are essential in the chocolate-making process, but they differ significantly in their operation, efficiency, and results. This article compares the two machines, discussing their advantages, limitations, and which is better suited for different production needs.

What is a Chocolate Ball Mill?

A Chocolate Ball Mill uses steel or ceramic balls to grind the chocolate paste. The grinding process occurs in a rotating vessel where the balls move around and collide with the mixture, breaking down the particles into fine sizes. The goal is to achieve a smooth, uniform texture with particles as small as 20-25μm.

Key Features of a Chocolate Ball Mill:

Precision Grinding: Achieves fine, uniform texture and smoothness.

Fast Processing: Can refine chocolate much faster than traditional conches.

Energy Efficiency: Uses less energy while maintaining high output.

Versatility: Capable of processing chocolate as well as other products like peanut butter and nut pastes.

What is a Traditional Conche?

A Traditional Conche operates by using a combination of heat and mechanical agitation to refine chocolate. The chocolate paste is processed in a vessel where paddles continuously move the mixture over time. The conching process involves both mechanical shear and heat to smoothen the chocolate and develop its flavor. Conching typically takes longer compared to the ball mill but plays a key role in the flavor development of the chocolate.

Key Features of a Traditional Conche:

Longer Processing Time: Can take several hours to refine chocolate, often 24 hours or more.

Flavor Development: Ideal for enhancing and mellowing the chocolate's flavor.

Uniform Texture: Provides an even and smooth texture, but it's a more time-consuming process.

Chocolate Ball Mill vs. Traditional Conche: A Comparison

| Feature | Chocolate Ball Mill | Traditional Conche |

|---|---|---|

| Grinding Method | Uses grinding balls for particle size reduction. | Uses mechanical agitation with paddles. |

| Grinding Time | Faster grinding, typically 16-24 hours. | Slower, takes 24-72 hours depending on recipe. |

| Particle Size | Achieves fine particle sizes of 20-25μm. | Achieves similar particle size, but takes longer. |

| Energy Efficiency | More energy-efficient compared to conching. | Consumes more energy due to longer processing. |

| Flavor Development | Limited influence on flavor development. | Enhances and develops the chocolate flavor more effectively. |

| Ease of Operation | Automated systems make it easier to control. | Requires more manual monitoring and adjustments. |

| Versatility | Can process chocolate, nut butters, and jams. | Primarily for chocolate. |

| Cost | Generally more cost-effective for large-scale production. | More expensive due to longer operation and larger energy consumption. |

Key Differences Between the Two Machines

1. Processing Speed and Efficiency

The Chocolate Ball Mill is designed for faster processing, allowing for quicker refining of chocolate paste. This is especially beneficial for large-scale manufacturers looking to meet high production demands without sacrificing consistency.

The Traditional Conche, on the other hand, requires a longer processing time, sometimes taking up to 72 hours to refine the chocolate. This extended time is essential for developing complex flavor profiles but may not be as efficient for high-output production.

2. Impact on Chocolate Flavor

The Traditional Conche excels in developing the flavor of the chocolate. During conching, the mixture is exposed to heat and mechanical shear for extended periods, allowing for the volatile acids to evaporate and allowing the chocolate's flavors to mellow and blend harmoniously. This makes conching the preferred method for high-end, artisanal chocolate producers focused on flavor development.

The Chocolate Ball Mill is not as effective in flavor development, as it primarily focuses on refining texture. While it produces a smooth and consistent chocolate, it may lack the depth of flavor achieved by conching. However, it can still produce high-quality chocolate with consistent results, especially when flavor development is secondary to texture.

3. Control Over Particle Size

Both the Chocolate Ball Mill and the Traditional Conche can achieve a particle size of 20-25μm, which is essential for smooth and creamy chocolate. However, the Chocolate Ball Mill offers more precision in controlling particle size in a shorter amount of time. The mill's continuous grinding ensures the particles are reduced uniformly.

The Traditional Conche also achieves a fine particle size but does so over a longer period. The grinding is less intensive, but the prolonged conching time allows for the fine-tuning of the chocolate's texture, especially for specific recipes.

Choosing the Right Chocolate Ball Mill for Your Production Line

Selecting the right Chocolate Ball Mill is crucial for ensuring the efficiency, quality, and consistency of your chocolate production process. A ball mill plays an essential role in refining chocolate by grinding the paste to the desired particle size, typically between 20-25μm, to achieve the smooth, velvety texture and uniform flavor that high-quality chocolate is known for. With various models and configurations available, understanding your specific production requirements is key to making the right choice.

In this guide, we'll explore the key factors to consider when selecting a Chocolate Ball Mill for your production line and provide tips on how to choose the best machine based on your needs.

Key Factors to Consider When Choosing a Chocolate Ball Mill

1. Production Capacity

One of the most important factors when selecting a chocolate ball mill is the production capacity. Depending on your operation size and production goals, you'll need to choose a machine that can handle your required batch sizes efficiently. The capacity refers to the amount of chocolate paste the mill can process in a single batch, typically measured in kilograms per batch.

Small-scale Production: For artisanal or small-scale chocolate manufacturers, a smaller ball mill with a capacity of 500kg to 1000kg per batch may be ideal.

Medium to Large-scale Production: Larger ball mills with a capacity of 2000kg to 3000kg per batch are more suited to medium-to-large chocolate factories that need to produce large quantities of chocolate within a short time frame

| Capacity | Suitable for |

|---|---|

| 500kg - 1000kg | Small-scale or boutique chocolate manufacturers |

| 1000kg - 2000kg | Medium-scale production lines |

| 2000kg - 3000kg | Large-scale, high-volume chocolate production |

2. Grinding Time and Fineness

Another critical aspect to consider is grinding time and the fineness of the final product. The fineness of the chocolate paste, which is typically measured in micrometers (μm), directly affects the texture and mouthfeel of the finished chocolate. A fine grind ensures that the chocolate has a smooth, creamy consistency.

Grinding Time: Faster grinding times are crucial for large-scale operations that need to meet tight production deadlines. However, longer grinding times may be needed for fine-tuning the texture and flavor in smaller batches or artisanal production.

Fineness: Most chocolate ball mills can achieve a particle size of 20-25μm, which is ideal for chocolate. Ensure that the ball mill you choose can consistently deliver this level of fineness for smooth texture.

| Grinding Time | Fineness | Ideal for |

|---|---|---|

| 16-24 hours | 20-25μm | High-volume, consistent production |

| 24-48 hours | 20-25μm | Premium, high-quality artisanal chocolate |

| 48+ hours | 20-25μm | Special formulations requiring long processing |

3. Control and Automation

When selecting a ball mill, consider how much control and automation you need in your production process. Modern chocolate ball mills come with PLC-based control systems that allow operators to easily monitor and adjust various parameters, including grinding time, temperature, spindle speed, and discharge rate.

Manual Control: Simple machines with manual control are usually sufficient for small-scale production or artisanal businesses with fewer demands on automation.

Automated Control: Larger operations may benefit from advanced control systems that allow for more precise adjustments and reduced labor costs.

| Control Type | Ideal for |

|---|---|

| Manual control | Small-scale, boutique manufacturers |

| PLC-based automated | Large-scale, high-volume production lines |

4. Material Quality and Durability

Durability and the quality of materials used in the construction of the chocolate ball mill are vital for ensuring long-lasting performance, especially in high-production environments. The grinding vessel should be made from high-quality stainless steel, while the grinding balls can be either steel or ceramic.

Stainless Steel: Stainless steel is highly durable, corrosion-resistant, and easy to clean, making it ideal for handling chocolate paste.

Grinding Balls: The material and size of the grinding balls affect the efficiency and effectiveness of the grinding process. Steel balls are commonly used, but ceramic balls are also available for more refined grinding.

| Material | Advantages |

|---|---|

| Stainless Steel | Durability, corrosion resistance, easy to clean |

| Steel Balls | Efficient grinding, cost-effective for high volumes |

| Ceramic Balls | Suitable for finer grinding, durable but more expensive |

5. Energy Efficiency

For both environmental and cost-saving reasons, energy efficiency is an important factor to consider when selecting a chocolate ball mill. Machines designed with energy-efficient motors and optimized power consumption help reduce operational costs while maintaining high output levels.

Energy Efficiency Features: Look for machines that are designed to use energy effectively while still offering the high production capacity and grinding precision required for chocolate refinement.

| Energy Efficiency | Benefit |

|---|---|

| High-efficiency motors | Reduced operational costs and environmental impact |

| Standard motors | Suitable for lower production needs but may cost more in the long term |

6. Maintenance and Ease of Use

Choosing a chocolate ball mill that is easy to maintain is essential for minimizing downtime and ensuring that your production line runs smoothly. Machines that require complex maintenance or frequent repairs can disrupt production and increase operational costs.

Ease of Maintenance: Opt for models with easy-to-replace components and self-cleaning features to simplify the maintenance process.

User-Friendliness: Machines with user-friendly interfaces, such as PLC controls or touchscreens, can streamline operation and reduce the likelihood of user error.

Maintenance and Care of Chocolate Ball Mills

Proper maintenance and care are essential for ensuring the long-term performance and efficiency of your Chocolate Ball Mill. This piece of equipment plays a crucial role in your chocolate production process, and keeping it in optimal condition helps prevent costly repairs, minimize downtime, and ensure that your chocolate products meet the highest quality standards. In this article, we'll explore the best practices for maintaining and caring for your chocolate ball mill to ensure smooth operation.

1. Regular Cleaning

Cleaning your chocolate ball mill after each use is essential to prevent the buildup of chocolate residue, which can impact both the performance of the machine and the quality of your next batch. Chocolate and other ingredients can solidify inside the mill, leading to contamination and inefficiency in the refining process.

Cleaning Steps:

Disassemble the Parts: After each use, disassemble parts such as the grinding vessel, grinding balls, and scrapers to remove any chocolate residue.

Use Food-Safe Cleaning Agents: Always use food-safe, non-corrosive cleaning agents to ensure no harmful residues are left behind.

Clean the Cooling System: If the machine is equipped with a cooling system or water pump, clean these parts regularly to prevent blockages and ensure smooth functioning.

2. Lubrication and Bearings Care

The moving parts of the chocolate ball mill, such as the bearings and spindles, require proper lubrication to ensure smooth operation and prevent unnecessary wear and tear. Failure to lubricate these components regularly can result in inefficient performance, leading to costly repairs.

Lubrication Steps:

Use High-Quality Lubricants: Always use food-grade lubricants that are safe for use in food processing equipment.

Check Oil Levels: Regularly inspect the oil levels and change the lubricant at the intervals recommended by the manufacturer.

Inspect Bearings for Wear: Inspect the bearings for signs of wear or damage and replace them as needed to maintain smooth operation.

3. Inspecting Grinding Balls

The grinding balls play a crucial role in the efficiency of the ball mill. Over time, these balls may wear down, which can lead to suboptimal grinding and impact the texture of the chocolate.

Grinding Ball Maintenance:

Regular Inspections: Periodically inspect the grinding balls for cracks, chips, or other signs of wear. Worn-out balls should be replaced to ensure an even grind and consistent texture.

Monitor Ball-to-Paste Ratio: Pay attention to the ratio of balls to paste during grinding. Too many or too few grinding balls can result in inefficient processing.

4. Motor and Electrical System Checks

The motor is a vital component of the chocolate ball mill. Regular checks on the motor and electrical system are essential to prevent unexpected breakdowns and to ensure smooth operation.

Motor and Electrical Care:

Inspect Wiring and Connections: Periodically check the wiring and electrical connections for signs of wear or fraying, and ensure that all connections are secure.

Clean Electrical Components: Dust and debris can accumulate on electrical components, so it is important to clean them regularly to maintain proper functioning.

Monitor Motor Performance: Check the motor for any unusual sounds or vibrations. If you notice any issues, have the motor inspected by a professional technician.

5. Temperature and Pressure Control Systems

Maintaining the temperature and pressure control systems in your chocolate ball mill is vital for ensuring that the chocolate paste is refined under optimal conditions. Improper temperature or pressure settings can negatively affect the texture and quality of the chocolate.

Temperature and Pressure Care:

Monitor Temperature Regularly: Always check the temperature during the refining process to ensure it stays within the recommended range for chocolate refinement.

Pressure Settings: The pressure in the jacket should not exceed safe limits. Regularly check the pressure gauges and ensure that the pressure stays within the safe range.

Inspect Thermostats and Sensors: Test and calibrate the thermostats and pressure sensors to ensure accurate readings.

6. Regular Calibration and System Checks

To maintain optimal performance, the control systems of the chocolate ball mill must be calibrated regularly. The Programmable Logic Controller (PLC) should be checked to ensure that the machine is operating as intended.

Calibration and System Checks:

Calibration of Control System: Periodically calibrate the PLC and control systems to ensure precise control over parameters such as grinding time, temperature, and spindle speed.

System Diagnostics: Run diagnostic tests to detect potential issues before they lead to more significant mechanical problems.

By regularly performing maintenance and care on your Chocolate Ball Mill, you can extend the lifespan of the machine, minimize downtime, and ensure that your chocolate production is consistent and high quality. Proper cleaning, lubrication, and inspection of the grinding balls and motor, as well as maintaining temperature and pressure control systems, are essential for smooth operations. Additionally, regular calibration of the control systems will ensure your machine operates at its peak performance.

At Gusu Food Processing Machinery Suzhou Co., Ltd., we are dedicated to providing high-quality chocolate production equipment built for durability, efficiency, and ease of maintenance. Our machines are designed to meet the needs of both small-scale chocolatiers and large-scale manufacturers. For more information about our machines or guidance on maintenance, feel free to contact us. We're here to help optimize your chocolate production process!

English

English Español

Español