Chocolate, with its rich flavor and luxurious texture, is one of the most beloved treats across the globe. From artisanal chocolatiers to industrial-scale production facilities, preserving chocolate's quality is paramount. One of the most critical components of chocolate processing and storage is the tank in which it is kept. Among the various materials available for storage tanks, stainless steel stands out as the superior choice. Stainless steel chocolate storage tanks offer numerous advantages in terms of hygiene, durability, temperature control, and efficiency, making them the preferred solution in modern chocolate manufacturing.

Hygienic Excellence: Cleanliness and Food Safety

One of the foremost reasons stainless steel is the material of choice in food industries is its outstanding hygiene. In chocolate production, where contamination can ruin an entire batch, the cleanliness of storage equipment is crucial.

Stainless steel is non-porous, which means it does not absorb odors, flavors, or bacteria. This makes it exceptionally easy to clean and sterilize. Unlike plastic or wood, stainless steel surfaces do not harbor microbes, reducing the risk of contamination and spoilage.

Furthermore, stainless steel complies with international food safety standards, including those established by organizations like the FDA (U.S. Food and Drug Administration) and the European Food Safety Authority (EFSA). By using stainless steel tanks, chocolate manufacturers can ensure that their products remain pure, safe, and high-quality.

Corrosion Resistance: A Long-Lasting Investment

Chocolate contains fats, sugars, and acids, which can be corrosive over time. Storage tanks must be able to withstand these conditions without degrading. Stainless steel, especially grades like 304 and 316, is highly resistant to corrosion. This resistance ensures that the tank remains in excellent condition over long periods of use, even under continuous exposure to chocolate and cleaning chemicals.

Compared to materials like carbon steel, which may rust or require coatings that can wear off, stainless steel offers durability without the need for constant maintenance. This not only extends the lifespan of the equipment but also ensures consistent performance.

Temperature Control: Preserving Texture and Flavor

Chocolate is extremely sensitive to temperature. If stored improperly, it can bloom (develop a whitish coating from separated fats or sugars), harden, or melt, affecting both its texture and taste. Maintaining the correct temperature is essential to preserving the quality of chocolate during storage.

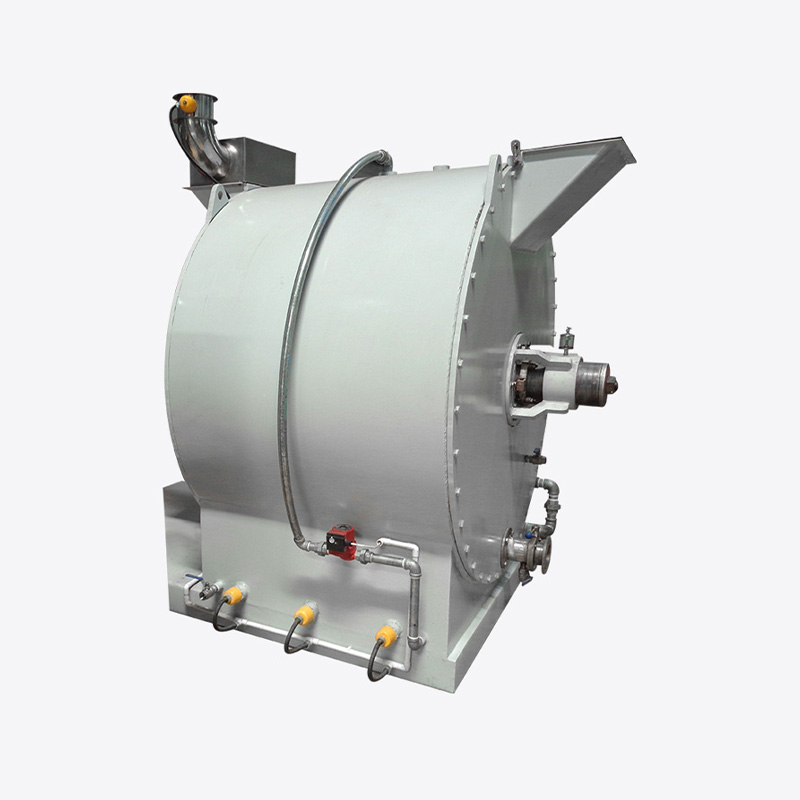

Stainless steel tanks often come equipped with double-wall construction and integrated heating or cooling systems. These features allow for precise temperature regulation, which is crucial during different stages of production. For example, during tempering and storage, chocolate must be kept at specific temperatures to ensure the right crystallization of cocoa butter.

Thanks to the excellent thermal conductivity and compatibility with modern temperature control technologies, stainless steel tanks help maintain a stable internal environment. This stability prevents quality degradation and ensures that chocolate maintains its intended structure and flavor.

Structural Strength and Durability

Stainless steel is a robust and strong material. This physical strength is especially important in industrial settings, where equipment must withstand continuous use, high weight loads, and frequent cleaning.

Stainless steel chocolate storage tanks are designed to endure the mechanical stresses of production without deforming or breaking down. They are also resistant to impact, which reduces the risk of damage during transport or installation.

The longevity of stainless steel tanks means fewer replacements, less downtime, and lower long-term costs. Over the lifetime of a production facility, this makes stainless steel a highly cost-effective investment.

Non-Reactive Nature: Maintaining Chocolate Purity

One of the subtler yet crucial benefits of stainless steel is its chemical inertness. Stainless steel does not react with the ingredients in chocolate, unlike some metals that can alter the taste or safety of stored products.

This non-reactive property is particularly important when working with high-quality chocolate formulations that include natural flavorings, essential oils, or alcohol-based ingredients. Any interaction between the storage material and these ingredients can lead to off-flavors or safety issues.

By storing chocolate in stainless steel tanks, manufacturers can rest assured that the final product retains its original taste, aroma, and nutritional value.

Easy Maintenance and Cleaning

Stainless steel tanks are not only hygienic but also easy to maintain. Their smooth surfaces reduce the likelihood of chocolate sticking to the walls, which minimizes waste and simplifies cleaning.

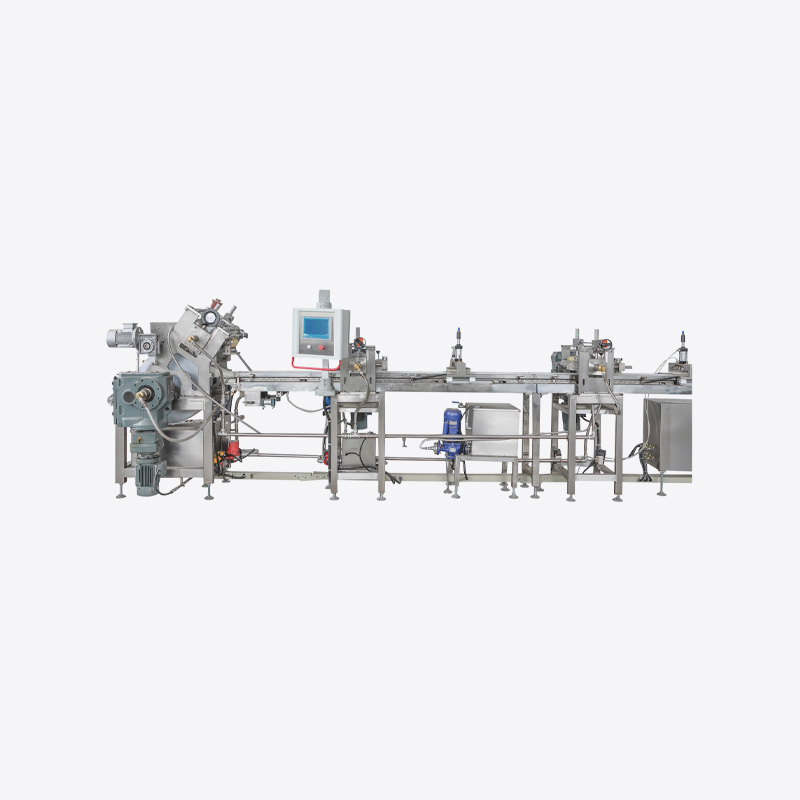

CIP (Clean-In-Place) systems can be easily integrated into stainless steel tanks. These systems automate the cleaning process without the need to disassemble the equipment. This saves time and labor while ensuring consistent sanitation.

In addition, stainless steel resists staining and retains its appearance even after repeated cleaning cycles, maintaining a professional and clean look in the production environment.

Compatibility with Modern Manufacturing Systems

As chocolate production becomes more advanced and automated, storage systems must be compatible with modern machinery and control technologies. Stainless steel tanks are highly adaptable and can be equipped with a wide range of accessories and features, such as:

Agitators and mixing paddles for maintaining uniform consistency

Level sensors and flow meters for accurate monitoring

Heating jackets for temperature control

Pressure valves and safety mechanisms

This adaptability allows manufacturers to customize tanks to fit specific production needs and integrate them seamlessly into automated processing lines.

Sustainability and Environmental Responsibility

Sustainability is becoming increasingly important in food production. Stainless steel is 100% recyclable, making it an environmentally friendly option. At the end of its lifecycle, a stainless steel tank can be recycled without losing its properties, reducing industrial waste.

Moreover, because of its durability and long service life, stainless steel reduces the need for frequent replacements, which in turn lowers the environmental footprint of equipment manufacturing and disposal.

Choosing stainless steel tanks contributes to a more sustainable production process and supports corporate responsibility goals.

Aesthetic and Professional Appearance

Though appearance is secondary to functionality in most industrial settings, stainless steel also offers a clean, modern look that reflects professionalism and quality. This is especially relevant in customer-facing production environments, such as those found in chocolate boutiques, small-scale artisanal factories, or high-end demonstration kitchens.

The sleek, polished appearance of stainless steel helps to convey a message of cleanliness, high standards, and technological advancement to clients and visitors.

Cost Efficiency Over Time

While stainless steel chocolate storage tanks may require a higher initial investment than alternatives such as plastic or aluminum, their long-term advantages more than make up for the cost.

Because of their durability, low maintenance, and extended lifespan, stainless steel tanks offer a better return on investment. There are fewer breakdowns, lower repair costs, and reduced downtime, all of which contribute to operational efficiency.

For businesses focused on long-term quality and performance, stainless steel is a cost-effective and reliable solution.

Stainless steel chocolate storage tanks are more than just containers—they are essential components of a high-quality chocolate production system. Their benefits in hygiene, temperature control, durability, safety, and efficiency make them indispensable in both small-scale and industrial chocolate manufacturing.

As the global demand for premium chocolate continues to rise, investing in stainless steel storage solutions ensures that manufacturers can consistently deliver products that meet the highest standards. Whether you're crafting luxury truffles or mass-producing chocolate bars, stainless steel tanks are the key to preserving flavor, ensuring safety, and maintaining excellence in every bite.

English

English Español

Español