When people first think about making chocolate at home or in a small business, one of the most common questions is whether they can simply use a regular kitchen blender instead of investing in a professional chocolate making machine. At first glance, both machines look like they can mix and grind ingredients, but in reality, their functions, design, and outcomes are quite different. Let’s break down the main differences so you can understand why specialized chocolate machines exist and why they matter.

1. Purpose and Design

A regular blender is designed for a wide variety of kitchen tasks such as making smoothies, blending soups, or crushing ice. Its blades rotate quickly to chop and mix ingredients into a liquid or semi-liquid form. The main goal is speed and versatility.

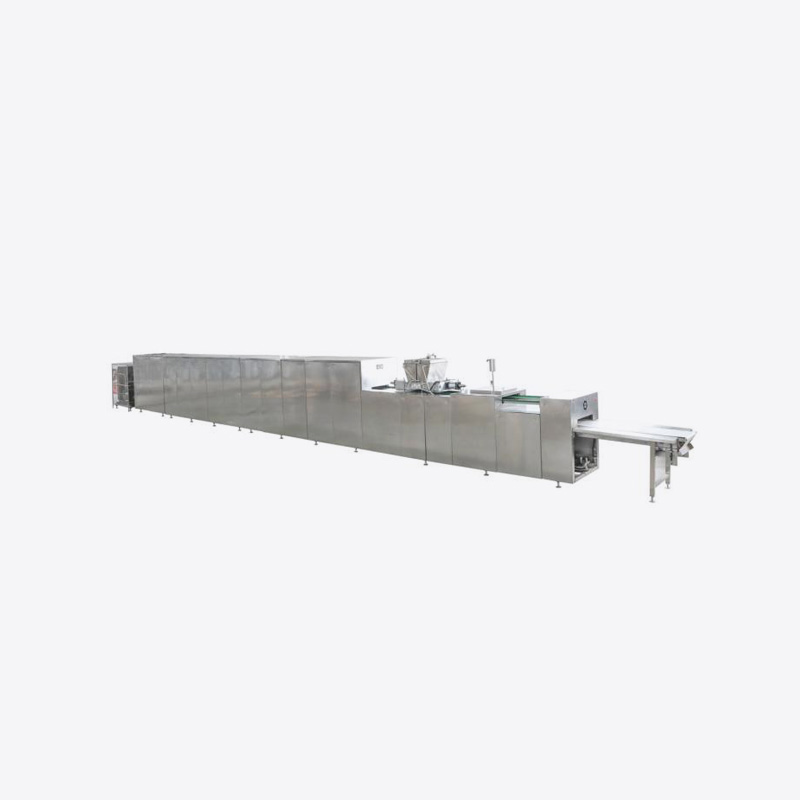

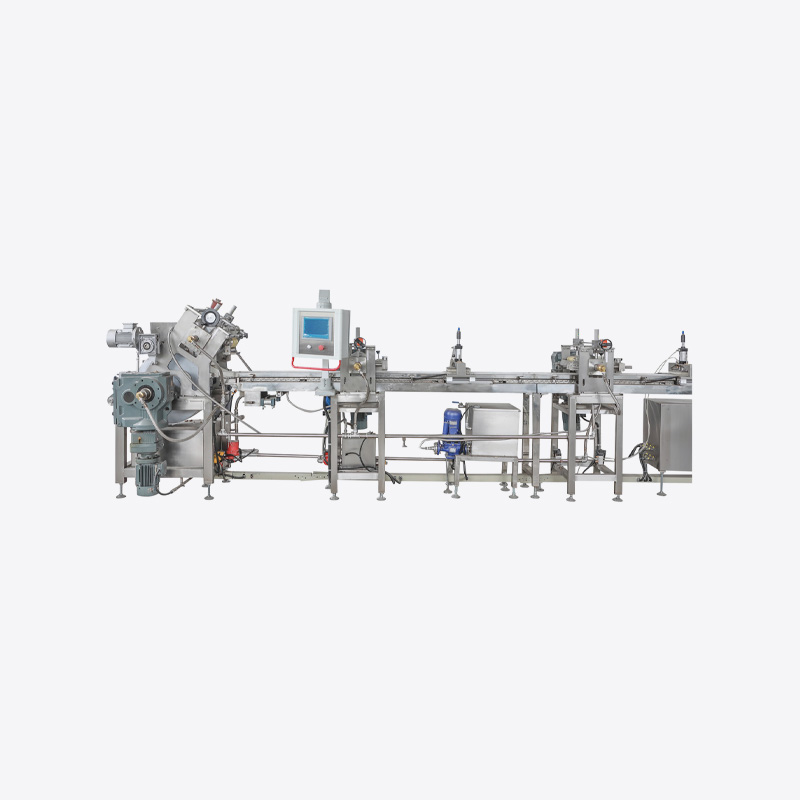

A chocolate making machine, on the other hand, is designed with a single purpose: to transform cocoa beans or cocoa mass into smooth, glossy, and delicious chocolate. Instead of simply cutting ingredients, it grinds them very finely, refines the texture, and in some cases, conches the mixture to improve flavor. The design focuses on slow but precise processing that matches the delicate needs of chocolate production.

2. Texture and Particle Size

One of the biggest differences is particle size. Good chocolate requires the cocoa solids and sugar crystals to be ground down to around 20 microns or less, which is so fine that the tongue can no longer detect graininess.

A blender does not have the ability to achieve such fine grinding. Even high-speed blenders will leave behind a gritty texture that feels sandy in the mouth. A chocolate making machine, especially a melanger or refiner, uses heavy granite rollers or steel grinding systems that slowly but consistently crush the ingredients until they reach the silky smoothness required for premium chocolate.

3. Temperature Control

Chocolate is very sensitive to temperature. If it overheats, it can burn or lose important flavor compounds. If it cools too quickly, it may solidify unevenly.

Blenders generate a lot of heat because of their high-speed blades, but they don’t have built-in temperature control. This makes them risky for chocolate processing. Chocolate making machines, however, are designed with better heat management. Some models have cooling systems, while others maintain a steady, low heat that keeps cocoa butter in the right state without damaging the flavor.

4. Flavor Development

Another crucial step in chocolate production is conching. Conching is the process of mixing, aerating, and gently heating the chocolate for hours to release unwanted acidity and enhance smoothness of flavor.

A blender cannot perform this process. It can only chop and blend quickly. A chocolate making machine, however, can run for 12–72 hours at a low speed, continuously mixing and refining the chocolate. This long processing time develops the deep, complex taste that people expect from fine chocolate.

5. Batch Size and Consistency

Blenders are made for small, quick jobs—maybe a liter or two of liquid at a time. They work well for one smoothie or soup, but they are not designed to maintain consistency in large batches.

Chocolate making machines are built to process larger quantities consistently. Even small home melangers can handle 2–5 kilograms of chocolate at once, while industrial machines can handle hundreds of kilograms. The machine ensures that every batch has the same fine texture and balanced flavor, something a blender cannot guarantee.

6. Durability and Cleaning

When blending thick mixtures like melted cocoa and sugar, a regular blender may quickly wear out. The motor is not made for continuous heavy grinding, and the blades may dull. Cleaning is also difficult, since sticky cocoa butter tends to harden on blender surfaces.

Chocolate making machines are designed for such heavy-duty work. Their rollers and drums are made from stone or stainless steel, built to run for hours without overheating. They are also easier to clean with warm water or food-safe scrapers, since the parts are designed to handle oily cocoa butter.

7. Professional vs. Homemade Results

If you want to make a quick chocolate-inspired dessert at home, a blender can help you mix cocoa powder, sugar, and butter. But this will never produce true, silky chocolate like you find in a chocolate bar. The texture will be rough, and the flavor less refined.

A chocolate making machine, by contrast, is the only way to make real bean-to-bar chocolate at home or in a small workshop. It produces professional-grade results with a texture and flavor that matches what people expect from artisan chocolate brands.

Conclusion

The difference between a chocolate making machine and a regular blender comes down to purpose, precision, and performance. Blenders are versatile kitchen tools, but they are not designed to meet the unique needs of chocolate production. Chocolate making machines specialize in grinding, refining, conching, and controlling temperature to create smooth, flavorful, and professional-quality chocolate.

So, while a blender may work for a quick homemade experiment, anyone serious about chocolate making—whether for personal passion or for business—will quickly realize that a specialized chocolate machine is an essential investment.

English

English Español

Español