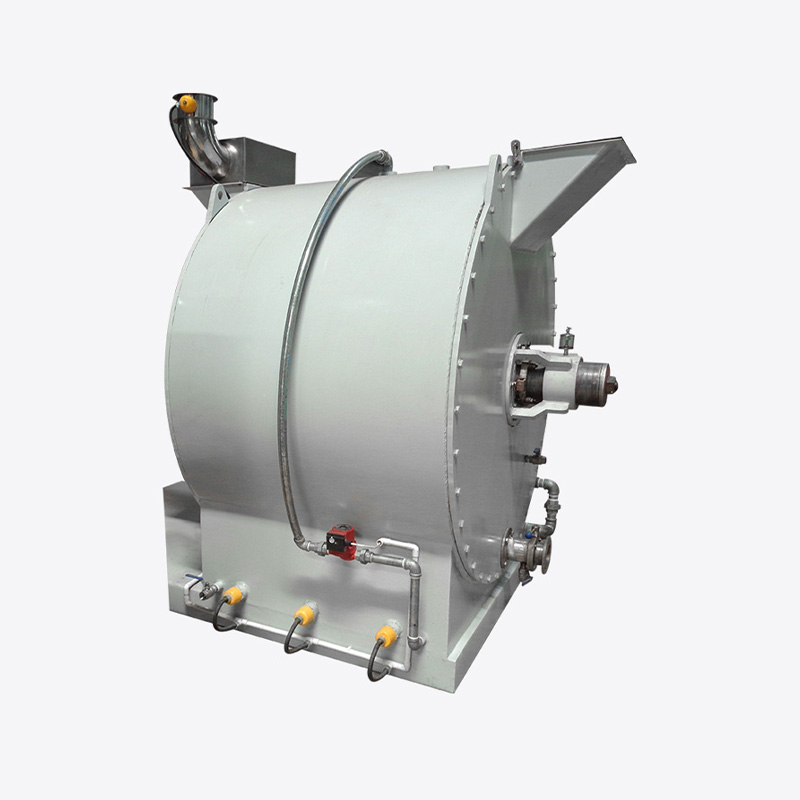

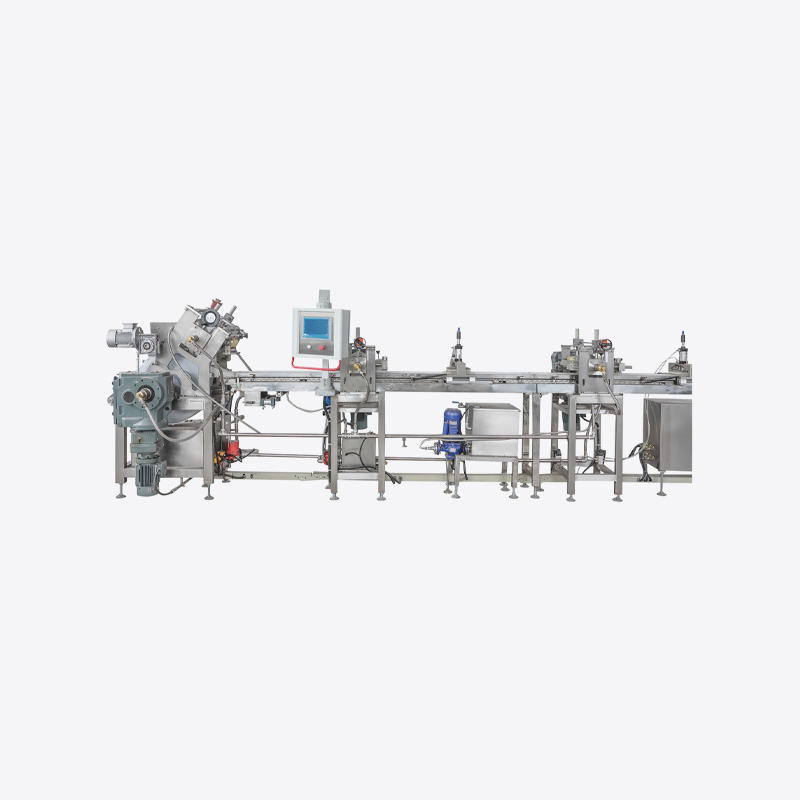

In modern confectionery production, using a Chocolate Coating Machine is essential for applying smooth layers over sweets efficiently. As producers expand their offerings, tailoring the process to suit different treat types ensures that each piece has the desired finish, texture, and visual appeal. Customization involves adjusting temperatures, flow rates, motion patterns, and cooling settings to match specific product requirements, delivering consistent quality across a diverse range of confections.

The Need for Adaptable Coating Systems

Every sweet has unique characteristics that affect how coatings adhere. Hard-centered treats, soft-filled chocolates, or nut clusters each behave differently under heat and motion. A flexible coating system allows manufacturers to respond to these differences, producing products that retain shape, taste, and surface consistency while maintaining operational efficiency. Adapting machine parameters can make a noticeable difference in appearance and mouthfeel, even without changing core ingredients.

Temperature Management Strategies

Precise heat control is vital when applying chocolate or similar coatings. Different recipes have varying melting and solidifying points. By modifying the heating and cooling zones, operators can achieve a uniform flow that envelops candies properly.

| Candy Type | Temperature Approach | Adjustment Tip |

|---|---|---|

| Hard-Centered | Moderate heat to avoid softening | Slightly reduce heating intensity |

| Soft-Filled | Gentle, steady warmth | Slow conveyor for careful coverage |

| Nut-Based | Warm enough for smooth adhesion | Stir continuously to prevent uneven layer |

Conveyor Speed and Motion Considerations

The movement system impacts coating thickness and uniformity. Faster conveyor motion creates thinner layers, while slower pacing allows chocolate to settle more generously. Configurable motion patterns help manage multiple passes or partial coatings, providing opportunities for layered or decorative effects. Operators can fine-tune speed and tilt angles to optimize coverage without causing dripping or uneven surfaces.

Enrobing Techniques for Various Fillings

Enrobing involves fully covering a sweet with chocolate or similar coating. Delicate fillings require gentle application, whereas firm centers can withstand stronger flows. Adjustments to curtain height, chocolate waterfall intensity, and flow rate can ensure a consistent layer that protects the interior and enhances appearance. Specialized equipment may also allow vibration or shaking to improve adhesion and eliminate air pockets.

Cooling Adjustments for Stability

Once coated, treats need to solidify evenly. Rapid cooling works well for hard candies, while gradual temperature drops are preferable for softer centers. Modifying air flow, tunnel temperature, and humidity helps maintain surface quality and texture.

| Cooling Feature | Benefit | Applicable Treats |

|---|---|---|

| Adjustable Air Flow | Reduces streaks or bloom | Soft-Filled Confections |

| Temperature Gradient | Maintains structural integrity | Hard-Centered Products |

| Humidity Control | Prevents moisture-related defects | Nut- or Sugar-Coated Sweets |

These adjustments contribute to both visual appeal and mouthfeel, ensuring customer satisfaction.

Managing Viscosity and Flow

Proper tempering is crucial for smooth coating that sets with an appealing snap and shine. Machines may include integrated tempering units, allowing operators to control thickness and flow consistency. Slightly thicker coatings are ideal for robust shells, while thinner layers suit intricate designs. Agitation mechanisms can maintain uniform chocolate movement, reducing the likelihood of clumps or uneven layers.

Modular Components and Flexibility

Many modern systems feature interchangeable parts, including rollers, curtains, and nozzles. This modularity enables quick adaptation to different product sizes and shapes. By changing components, producers can handle multiple candy types without needing separate machines, improving efficiency and supporting creative experimentation.

Additional accessories like sprayers, pattern rollers, or vibrators can enhance product variety. These tools allow the creation of textured surfaces, layered coatings, or decorative finishes, adding visual interest while keeping production streamlined.

Workflow Integration

Customizing a coating process also involves aligning upstream and downstream activities. Gentle feeding systems prevent damage to delicate products, while synchronized cooling and handling maintain coating quality. Adjusting trays, conveyors, or even feeding angles can optimize throughput and reduce material waste.

Adapting for Creative Confections

Market trends often demand unique coatings or combination layers, such as chocolate with caramel or decorative drizzles. Fine-tuning flow rates, curtain positioning, and cooling profiles allows manufacturers to produce complex designs while maintaining consistent quality. This flexibility supports experimentation and helps distinguish product lines in a competitive marketplace.

Maintenance and Operator Training

Proper upkeep ensures reliable performance over time. Regular cleaning, inspection, and calibration prevent mechanical issues that could compromise coating quality. Training staff to adjust parameters for different product types empowers operators to respond quickly to new recipes or production shifts, improving efficiency and reducing defects.

Safety and Energy Considerations

Customizing operational parameters can also enhance safety and sustainability. Optimizing heat zones and conveyor motion reduces energy use, while safety features protect operators from moving parts or hot surfaces. These adjustments contribute to long-term cost savings and a safer production environment.

Conceptual Example

Imagine a facility producing three types of candies: hard caramel centers, soft-filled chocolates, and nut clusters. By applying customized settings:

-

Adjust the curtain flow for even coverage of caramels.

-

Reduce conveyor speed and use gentle heating for soft fillings.

-

Add vibration and controlled air cooling for nut clusters.

The result is a visually appealing assortment with consistent coating quality, achieved without purchasing additional machines.

Tailoring a chocolate coating process is an effective way for manufacturers to meet the needs of diverse products. By adjusting temperature, conveyor speed, enrobing methods, cooling profiles, and flow properties, operators can maintain consistency and visual appeal across multiple candy types. Modular components and specialized accessories further expand possibilities, allowing creativity while sustaining efficiency.

With careful attention to customization, producers can offer a wide range of treats that satisfy aesthetic and sensory expectations, making each product line a reliable reflection of quality craftsmanship.

English

English Español

Español