Chocolate tempering is a crucial step in the chocolate-making process. It involves carefully controlling the temperature of chocolate to ensure that the cocoa butter crystals are stable, resulting in smooth, glossy chocolate that snaps when broken and does not bloom or melt easily at room temperature. There are two main methods for tempering chocolate: using a chocolate tempering machine and tempering manually. While both methods aim to achieve the same result, the processes, convenience, and consistency vary significantly.

Manual Tempering

Manual tempering is the traditional method of tempering chocolate and relies entirely on skill, patience, and careful temperature control. There are several manual techniques, the most common being the “seeding” method and the “tabling” method.

Seeding Method: In this approach, chocolate is melted to a high temperature, typically around 45–50°C for dark chocolate. Once melted, the chocolate is cooled by adding small pieces of already tempered chocolate, called “seeds.” The seeds help the cocoa butter crystallize correctly, and the chocolate is stirred until it reaches the ideal working temperature (around 31–32°C for dark chocolate).

Tabling Method: This traditional method involves pouring melted chocolate onto a cool marble or stone surface and spreading it with spatulas. The chocolate cools and begins to crystallize. After reaching a certain temperature, it is gathered and mixed again to achieve a uniform temper.

Manual tempering requires close attention to temperature and texture. Even slight deviations can result in chocolate that is dull, soft, or develops fat bloom (white streaks). Experienced chocolatiers can produce excellent results, but the learning curve is steep. Manual tempering is labor-intensive and time-consuming, especially when working with large quantities.

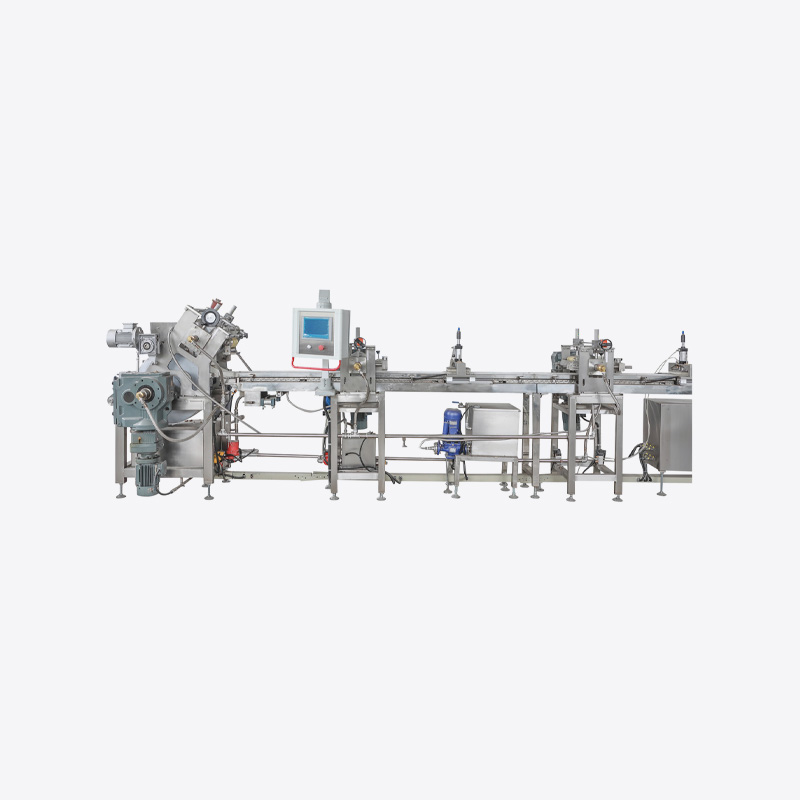

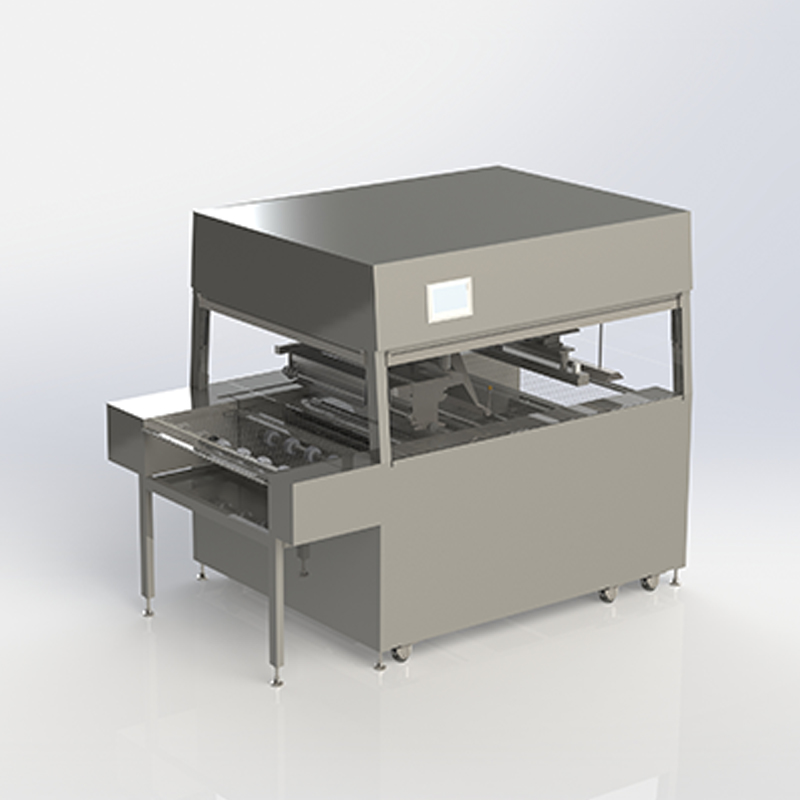

Chocolate Tempering Machines

Chocolate tempering machines, also known as chocolate temperers, automate the tempering process. They are designed to melt, cool, and maintain chocolate at precise temperatures, significantly reducing human error. These machines vary in size, from small countertop units suitable for home use to large industrial machines for professional chocolate production.

Automatic Temperature Control: One of the biggest advantages of a chocolate tempering machine is its ability to control temperature automatically. The machine melts the chocolate to a high temperature, cools it to the crystallization point, and keeps it at the ideal working temperature, eliminating the need for manual monitoring.

Consistency and Efficiency: Machines provide consistent results every time, which is particularly important in commercial production. Unlike manual tempering, the chocolate does not risk overcooling or undercooling, ensuring uniform gloss, snap, and texture. Large batches can be tempered more quickly and with less labor.

Ease of Use: Chocolate tempering machines are user-friendly, even for beginners. They reduce the skill level required to temper chocolate successfully. Some machines even offer pre-set programs for different types of chocolate, further simplifying the process.

Key Differences Between Manual and Machine Tempering

Skill Level: Manual tempering requires significant skill, practice, and attention, while machines allow anyone to achieve professional-quality results with minimal experience.

Time and Labor: Manual tempering is labor-intensive and slower, especially for large quantities. Tempering machines save time and reduce physical effort.

Consistency: Machines offer consistent results and reduce the risk of mistakes. Manual tempering can be inconsistent if not done carefully.

Cost: Manual tempering requires no equipment beyond basic tools, making it cost-effective for small-scale or hobbyist chocolatiers. Tempering machines involve upfront costs but are worthwhile for commercial production or frequent chocolate making.

Batch Size: Manual tempering is practical for small batches, while machines handle both small and large volumes efficiently.

Both manual tempering and chocolate tempering machines have their advantages and ideal applications. Manual tempering offers traditional control and a hands-on approach but requires skill, time, and attention. Chocolate tempering machines simplify the process, ensuring consistent, professional-quality results with minimal effort. For hobbyists, small batches, or those wanting to learn the art of chocolate, manual tempering can be rewarding. For commercial production or frequent chocolate making, a tempering machine provides efficiency, consistency, and reliability. Ultimately, the choice depends on the user’s needs, skill level, and production scale.

English

English Español

Español