Chocolate Chips Machine: What Manufacturers and Buyers Need to Know

Chocolate Chips Machine technology has become a practical part of many confectionery production lines. Whether a facility focuses on bakery supply, confection creation, or private label snacks, the appropriate unit helps keep output stable, reduce waste, and integrate with surrounding processes. This comprehensive guide expands on features, workflow impacts, machine categories, selection criteria for enterprises of varying scale, handling of different recipes, timing for upgrades, maintenance routines, installation considerations, safety and regulatory issues, supplier evaluation, return-on-investment aspects and troubleshooting tips that matter for anyone purchasing or operating chip-forming equipment.

Key features that define operational efficiency

Operational efficiency depends on how well the forming unit addresses the production needs while minimizing manual intervention. Core features that typically matter include:

Forming accuracy: Precisely shaped chips reduce rejects and stabilize downstream handling. Mechanisms that deliver consistent portioning simplify packaging and mixing operations.

Thermal control: Accurate and uniform temperature zones in melting, tempering, and holding stages ensure predictable viscosity and flow behavior during deposition.

Dosing precision and synchronization: When the depositor or cutter is tightly synchronized with conveyor speed, material usage is controlled and waste lowers.

Changeover design: Quick tool swaps and modular tooling shorten transition time between SKUs, improving line availability.

Hygienic design and cleanability: Smooth surfaces, quick-release parts and sanitation-friendly layouts speed cleaning cycles and help meet safety inspections.

Control systems with recipe memory: Storing process profiles allows operators to reproduce runs reliably and helps troubleshoot deviations.

Each of these influences uptime, yield and product uniformity, and they should be evaluated together rather than individually.

Workflow and line integration benefits

A chip-forming unit is rarely isolated; it sits between upstream melting/tempering and downstream cooling, inspection and packaging. Integration benefits include:

- Reduced buffer requirements: Synchronization across stages minimizes intermediate storage, keeping floor space usage efficient.

- Lower manual handling: Automated deposition cuts back repetitive tasks, freeing staff for value-added activities like quality checks and packaging.

- Improved packaging flow: Uniform pieces feed more predictably into baggers, weighers or enrobers, reducing stoppages.

- Easier scheduling: With repeatable cycle times, planners can forecast throughput more accurately and coordinate logistics.

- Better traceability: Integrated control systems can log batch data, supporting traceability for audits and supplier claims.

These advantages compound when the forming unit is selected with an eye on the entire line rather than as a standalone purchase.

Machine families and suitability by business scale

Different manufacturing contexts require different equipment types. Here's a practical breakdown:

- Small-scale operations

- Semi-automatic depositors: Good for artisan or bakery environments where control matters more than high volume.

- Compact continuous droppers: Suited to steady, small-batch production with limited floor space.

- Combined tempering/forming frames: Save space and simplify operation in compact plants.

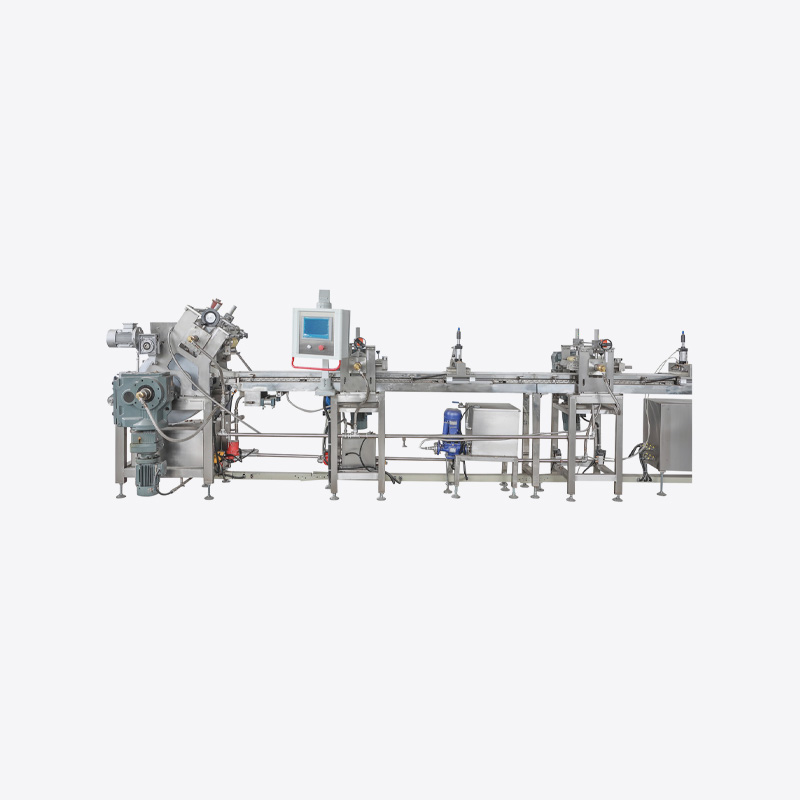

Medium-scale plants

Continuous forming lines with modular tooling: Allow flexibility across several SKUs and moderate throughput.

Intermittent cutter systems: Permit variable chip geometry for product differentiation.

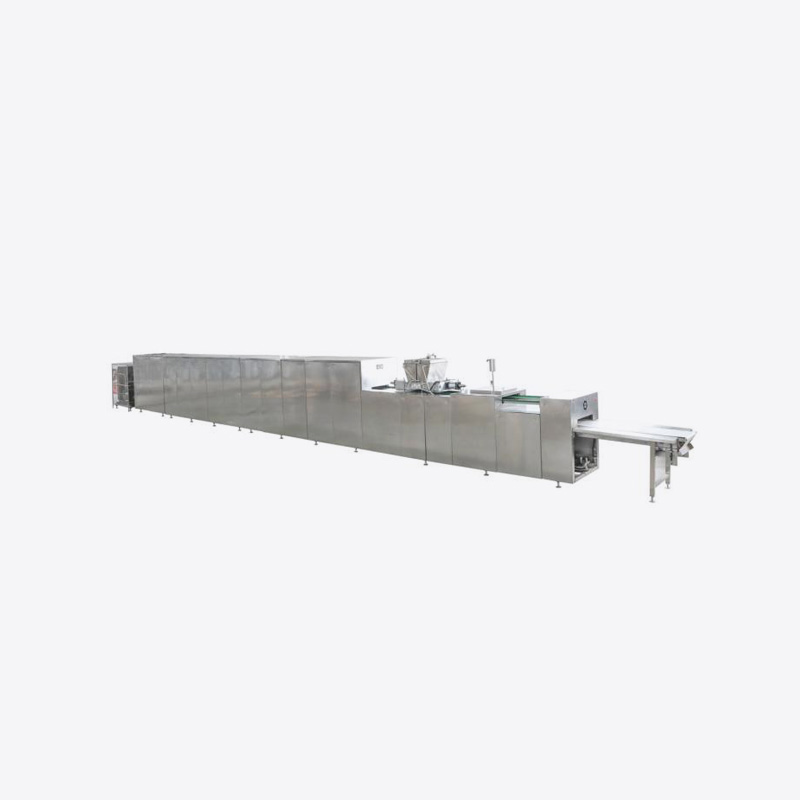

Large-scale industrial lines

High-throughput continuous formers: Designed for sustained runs, integration with automated packaging, and remote control.

Specialized lines with multiple cooling zones: For very consistent crystal structure and minimal post-process rework.

Matching capacity with demand is essential: undersized units create bottlenecks while oversized systems idle and increase capital burden.

Quality control and product consistency considerations

Maintaining product uniformity relies on control at each stage:

Dose repeatability: Reduces mass variance and maintains consistent melt-in-mouth behavior across batches.

Crystal management: Well-controlled cooling prevents bloom and preserves texture; this is especially relevant for products that will be subjected to further processing.

Hygiene and contamination control: Easily accessible parts and closed conveyors limit cross-contamination risk, which is critical for allergen management.

Statistical process control: Logging weight, temperature, and cycle metrics enables trend analysis and earlier detection of drift.

Quality assurance teams should work with operations to define acceptable tolerances and integrate sampling stations into the line.

Upgrade triggers and capacity planning

Knowing when to upgrade helps avoid disruptive breakdowns or lost sales. Common triggers include:

Rising maintenance frequency: If downtime and repair costs escalate, replacement may be more economical.

Volume growth: Consistent orders that exceed capacity necessitate higher throughput equipment.

New product range: Introducing heavier inclusions, new shapes, or coatings could require different forming mechanics.

Labor constraints: When skilled operators are scarce, machines with greater automation and simpler interfaces reduce dependency on specific personnel.

Regulatory shifts: Upgrades might be needed to meet updated hygiene or traceability requirements.

A phased replacement strategy helps spread capital expense while improving reliability progressively.

Practical selection checklist

Use this checklist during vendor assessment and on-site demos:

Production target and speed compatibility

Clean-in-place or easy disassembly for sanitation

Temperature control precision and number of thermal zones

Changeover time and tooling flexibility

Spare parts lead times and local support presence

Energy use and utility compatibility

Control protocol and line integration capability

Safety guards and guarding interlocks

Footprint versus available floor area

Historical references and site visits

Shortlist vendors that respond clearly to each checklist item and provide sample runs with your raw materials.

Recipe compatibility: handling different cocoa and inclusions

Different formulations affect forming behavior:

- High cocoa butter mixes: Typically flow more readily; control cooling to avoid excessive spreading.

- High solids blends: Thicker mixtures need higher dosing force and may require different nozzle geometry.

- Inclusions: These can block small channels; choose depositors with anti-clogging features and wider passages.

- Filling and compound layers: Multi-layer chips or filled variants require synchronized deposition and possibly dual head systems.

Trial runs with production-scale samples are essential—adjust depositor settings, temperature, and conveyor speed until the forming profile matches the target.

Maintenance plan and spare parts strategy

A proactive maintenance plan extends service life and reduces unplanned stops:

- Daily cleaning and inspection: Quick checks of critical wear items and cleaning of contact surfaces after runs.

- Scheduled preventive maintenance: Replace seals, belts, bearings and filters on a time or throughput basis.

- Spare parts inventory: Stock consumables (nozzles, cutters, belts) on-site to avoid lead-time delays.

- Service contract: Consider a support agreement with response SLAs to reduce outage window.

- Maintenance logs: Track events to spot recurring failures and plan design improvements.

A maintenance calendar aligned with production cycles prevents clashes with peak demand periods.

Site preparation and layout recommendations

Plan the installation site to optimize flow and serviceability:

- Flooring and drainage: The forming station should sit on a robust, level surface with adequate drainage for cleaning.

- Temperature control: Ambient conditions influence tempering; HVAC measures reduce seasonal variance.

- Power and utilities: Check electrical supply, grounding, and power quality for electronic controls and heaters.

- Material flow: Position upstream storage and melting close to the forming station to minimize heat loss and handling.

- Noise and ergonomic layout: Designing operator stations for visibility and comfort reduces error rates.

- Service access: Ensure sufficient clearance around the unit for maintenance and cleaning.

An installation checklist reduces surprises during commissioning and shortens ramp-up time.

Safety, hygiene and regulatory compliance

Compliance protects consumers and the business:

- Food contact materials: Surfaces must be compliant with relevant food safety standards in your market.

- Allergen controls: The design should enable segregation or thorough cleaning to avoid cross-contact.

- Machine guarding and interlocks: Protect operators while allowing quick access for service when locked out.

- Documentation: Maintain maintenance records, calibration logs, and cleaning schedules for audits.

- Local regulations: Comply with electrical, fire, and workplace safety legislation specific to the installation region.

Engage QA and EHS teams during procurement to avoid rework after installation.

Supplier evaluation and after-sales support

Vendor choice matters as much as machine specs:

Reference visits: Inspect lines running similar formulations to evaluate long-term reliability.

Demonstrations with your raw materials: Ask vendors to run trials using your typical mixes.

- Training offering: Confirm operator and maintenance training is part of the package.

- Parts availability: Regional inventory or fast shipping reduces downtime risk.

- Technical documentation: Detailed manuals, exploded views, and wiring diagrams speed diagnosis.

- Upgradability: Check whether software updates and retrofit options exist to extend functionality.

A clear service contract with response commitments protects production continuity.

Costing, ROI and lifecycle thinking

Purchase price is only part of the picture. Consider:

- Operating costs: Electricity, heating, and cleaning labor contribute to running expense.

- Yield and waste: Improved forming accuracy often reduces raw-material loss.

- Downtime costs: Each hour offline impacts orders; faster serviceability improves margins.

- Longevity: Equipment built for maintainability often outlives cheaper alternatives.

- Flexibility value: The ability to produce multiple SKUs without major investment supports market responsiveness.

Calculate ROI using conservative throughput, realistic downtime, and expected parts expenditure.

Troubleshooting common problems

Practical problem-solving tips:

- Inconsistent chip size: Check depositor timing, nozzle wear, and conveyor speed matching.

- Stringing or elongation: Review melt viscosity, holding temperature and nozzle design.

- Clogging with inclusions: Increase channel size, add agitation or switch to intermittent operation.

- Surface bloom later in life: Verify cooling profile and storage conditions; check tempering consistency.

- Excess rejects at packaging: Confirm size distribution and conveyor alignment into packing equipment.

Document fixes and correlate them with process data to prevent recurrence.

Operator training and documentation

Skilled operators reduce variance:

- Structured training: Include setup, changeover, daily checks, and basic troubleshooting.

- Visual SOPs: Photos and short steps placed near the machine guide correct actions.

- Cross-training: Ensure at least two operators per shift can run and maintain the line.

- Knowledge transfer: Record recipes, settings and lessons learned for new staff.

Good documentation shortens learning curves and reduces human error.

Sample case study scenarios

Bakery seeking greater product variety

A mid-size bakery moved from manual drop pans to a compact continuous former. They prioritized flexible tooling and quick cleaning. Result: faster product introduction, reduced manual labor and improved portion uniformity.

Industrial snack line scaling up

A snack manufacturer upgraded to an inline high-capacity former with multiple cooling stages. Investment reduced packaging interruptions and lowered scrap, enabling a new private-label contract.

Artisan chocolatier wanting cleaner finish

A boutique operation adopted a small tempering-forming unit with precise thermal control. The company achieved more uniform gloss and reduced room-temperature dependency during summer months.

These examples illustrate that alignment between business goals and machine choice matters more than raw specifications alone.

A forming unit for chips is a hub in the confectionery workflow. Careful selection—based on temperature control, dosing precision, hygienic design, changeover speed and service support—yields predictable production outcomes. Rather than chasing a single metric, align equipment choice with operational strategy: planned SKUs, staffing model, maintenance capability and future product plans. With the right approach, the equipment becomes a stable contributor to product quality, process efficiency and commercial agility.

English

English Español

Español