Introduction to Chocolate Delivery Pumps

Chocolate delivery pumps are critical components in modern confectionery production. They ensure the smooth and precise transfer of chocolate from melting tanks to enrobing machines, molds, and filling stations. Without reliable pumps, chocolate flow can become inconsistent, causing defects, waste, and production delays.

In high-speed chocolate manufacturing, maintaining consistent viscosity, temperature, and flow rate is essential. Chocolate delivery pumps help standardize these variables, enabling manufacturers to produce high-quality products while minimizing downtime and operational inefficiencies.

Types of Chocolate Delivery Pumps

There are several types of chocolate delivery pumps used in modern manufacturing, each suited for specific applications. Choosing the right pump is crucial for maintaining product quality and operational efficiency.

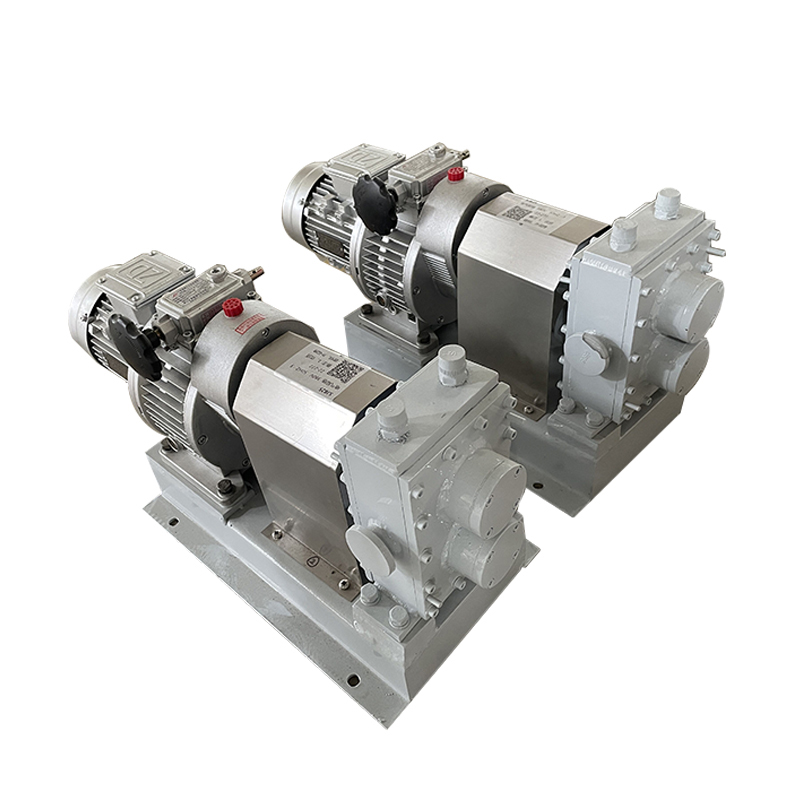

Gear Pumps

Gear pumps provide precise and continuous flow, ideal for coating or filling applications. Their design allows them to handle viscous chocolate with minimal pulsation, ensuring uniform coverage and accurate portioning.

Progressive Cavity Pumps

Progressive cavity pumps are effective for pumping chocolate with inclusions, such as nuts or fruit pieces. They offer gentle handling to prevent damage to delicate ingredients while maintaining consistent flow and pressure.

Peristaltic Pumps

Peristaltic pumps operate by compressing a flexible tube, providing precise flow control without exposing the chocolate to metal surfaces. They are ideal for sensitive or specialty chocolate products where contamination must be avoided.

Key Benefits of Chocolate Delivery Pumps

Chocolate delivery pumps offer numerous advantages that directly impact productivity, quality, and cost-effectiveness in chocolate manufacturing.

Consistent Flow and Viscosity

Maintaining consistent chocolate flow and viscosity is crucial for high-quality products. Delivery pumps regulate the movement of chocolate, ensuring even coating on enrobing lines and uniform filling in molds. This reduces product defects and improves overall appearance.

Reduced Waste

Efficient chocolate pumping minimizes overflow, dripping, and uneven distribution. By delivering precise amounts, pumps reduce material waste and lower production costs, making operations more sustainable.

Enhanced Production Speed

Chocolate delivery pumps allow factories to maintain high-speed production lines without compromising quality. Continuous flow and stable pressure support fast enrobing, molding, and depositing, helping manufacturers meet tight production schedules.

Sanitation and Maintenance

Modern chocolate pumps are designed for easy cleaning and compliance with food safety standards. Many models feature hygienic construction with minimal dead zones, ensuring chocolate remains uncontaminated and reducing downtime for maintenance.

Applications in Chocolate Manufacturing

Chocolate delivery pumps are versatile and used across various stages of production, from transfer to coating and filling.

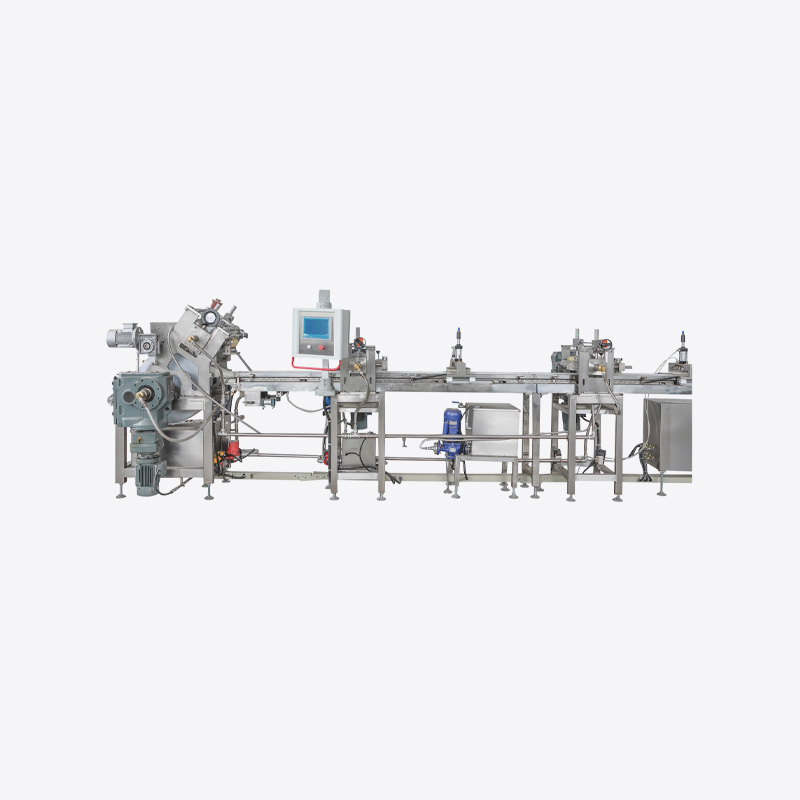

Enrobing Lines

In enrobing lines, pumps deliver a steady flow of chocolate over confections, ensuring complete and even coverage. This precision is essential for maintaining product consistency and visual appeal.

Depositing and Molding

During molding, pumps provide accurate portions of chocolate into molds, reducing excess material and improving shape consistency. This is critical for chocolates with intricate designs or premium fillings.

Specialty Products

For specialty chocolates containing inclusions or delicate ingredients, pumps with gentle handling capabilities prevent breakage and maintain ingredient integrity, supporting high-end product quality.

Considerations for Choosing a Chocolate Delivery Pump

Selecting the right chocolate delivery pump requires careful evaluation of production needs, chocolate type, and operational requirements.

- Viscosity handling: Ensure the pump can manage the specific chocolate formulation.

- Flow rate and pressure: Match the pump capacity to production speed.

- Sanitation requirements: Choose pumps that comply with food safety standards.

- Maintenance and durability: Consider ease of cleaning and longevity for continuous operation.

Conclusion: Pumping Quality and Efficiency Forward

Chocolate delivery pumps are indispensable for modern chocolate manufacturing. By ensuring consistent flow, precise portioning, and gentle handling of chocolate, they support both quality and efficiency. Integrating these pumps into production lines enhances productivity, reduces waste, and meets the exacting standards of today’s confectionery industry.

As chocolate production continues to scale and evolve, delivery pumps remain a cornerstone technology, enabling manufacturers to meet growing consumer demand while maintaining premium quality and operational excellence.

English

English Español

Español