How Chocolate Coating Machines Transform Confectionery Production

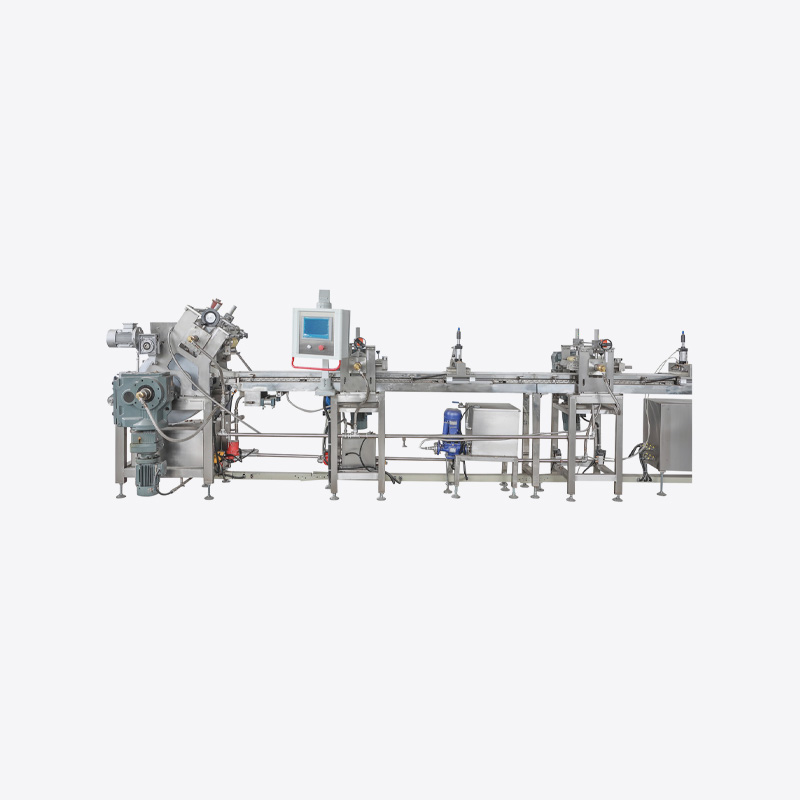

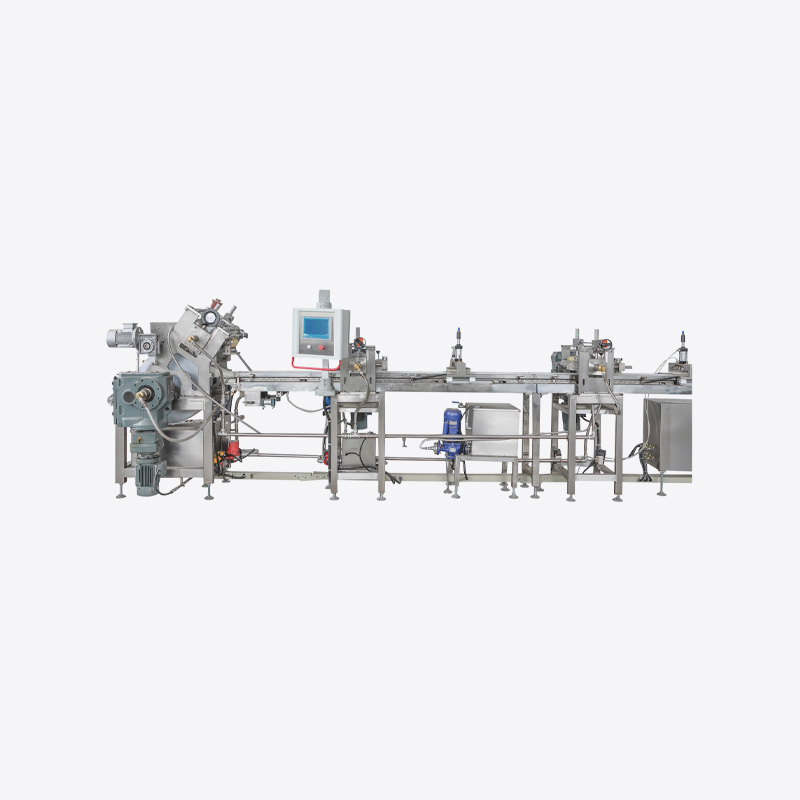

A Chocolate Coating Machine is often the backbone of a modern confectionery line. It brings together precise heat control, measured chocolate flow, and consistent handling to coat bars, pralines, biscuits, and many other centers with an even chocolate layer. For manufacturers who need reliable appearance, controlled costs, and steady throughput, the right coating system changes the way production is planned and executed.

What a chocolate coating machine actually does on the line

At its core, a coating machine performs three tasks: it melts and conditions chocolate, delivers a controlled amount of liquid chocolate onto the product, and manages excess chocolate (for example, by sieving, air knives, or vibration). Systems range from simple enrobers that pass centers under a chocolate waterfall to complex multi-head depositors with tempering, curtain control, and enrobing tunnels.

Key functional blocks typically include:

- Tempering and reservoir: holds chocolate at a target viscosity and crystalline state.

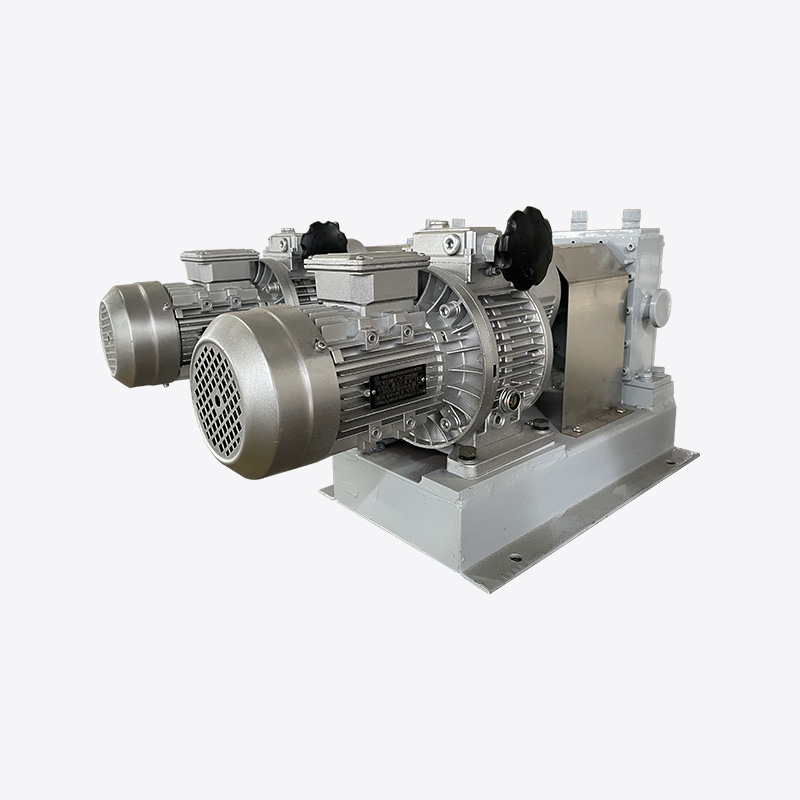

- Pumping and dosing: moves chocolate at controlled flow rates to the coating head or curtain.

- Coating zone: where products pass under the chocolate curtain, through a spray system, or beneath a depositor nozzle.

- Excess chocolate removal: vibrators, knock-off rollers, and air knives reduce chocolate thickness to specification.

- Cooling tunnel: brings the coated product through controlled cooling zones to set the chocolate before packaging.

A well-integrated machine coordinates these blocks so the chocolate arrives at the coating point in a stable state and the coated product exits ready for packaging.

Core features to evaluate when selecting a machine

Not every factory needs every feature, but the following capabilities tend to make a measurable difference in day-to-day operations.

Precise temperature control

Chocolate is temperature-sensitive. The reservoir, pumps, and piping should be heated with accurate PID controls so viscosity remains consistent. Fluctuations translate directly into film thickness changes and surface finish differences.

Dosing and flow stability

Pumps and dosing valves must deliver a steady chocolate flow. Pulsing pumps or inconsistent dosing lead to streaks, uneven thickness, and higher scrap rates.

Conveying and product handling

Belts, spacers, and timing systems must keep products centered and synchronized with chocolate flow. Poor alignment creates gaps, overcoats, and inconsistent edges.

Excess chocolate removal and smoothing

Knock-off rollers, vibrating decks, and adjustable air knives let operators dial in coating thickness precisely. Adjustable systems are particularly valuable when switching between thin and thick coatings.

Clean-in-place and hygiene features

Quick disassembly for cleaning or a built-in CIP cycle reduces downtime. Surfaces that avoid dead zones and allow rapid chocolate drainage shorten cleaning cycles.

Integration with tempering and upstream processes

A coating machine that pairs tightly with the temperer and upstream depositor reduces rework and simplifies material handling. Look for coordinated controls or compatible communication protocols.

Flexibility and quick changeover

Tooling for different product sizes and quick-change conveyors let a line move from one SKU to another with minimal downtime. Modular platforms simplify upgrade paths and spare-parts management.

When assessing equipment, prioritize features that align with your product mix and production rhythm rather than a long feature list that you will rarely use.

Which settings impact coating quality the most

Several machine settings have outsized effects on the final product. Understanding their interactions helps operators tune a recipe and reproduce results consistently.

Temperature of the chocolate

Viscosity is primarily temperature-driven. A correct target depends on the chocolate formulation and the desired film thickness. Small temperature changes — even 1–2 °C — can alter flow characteristics noticeably.

Pump speed and dosing rate

These determine how much chocolate is presented to the product per unit time. Dosing must be balanced with conveyor speed to achieve the targeted weight per piece.

Conveyor speed and dwell time

Faster conveyor speeds reduce chocolate contact time and may require higher dosing or reduced removal to maintain coverage. Slower speeds allow more time for coating to settle but reduce throughput.

Air-knife or roller settings

Air knife pressure and angle change how much chocolate is removed and how the surface texture forms. Similarly, roller speed and pressure influence film thickness and edge definition.

Cooling profile (zone temperatures and fan speed)

The cooling tunnel solidifies the chocolate and sets the temper. Too rapid cooling can cause contraction and bloom; too slow can leave the product sticky and susceptible to marking.

Operators should document successful combinations of these variables for each SKU and treat them as the baseline for shifts and operators.

A practical settings comparison table

| Setting Area | Thin Coating (e.g., enrobed biscuit) | Thick Coating (e.g., fully enrobed truffle) | High-Gloss Finish |

|---|---|---|---|

| Reservoir Temp | Slightly higher viscosity (°C up) | Slightly lower viscosity for flow | Precise, narrow band; avoid rapid swings |

| Pump/Dose | Lower flow rate, stable dosing | Higher flow rate, larger volume per piece | Smooth, pulseless pump delivery |

| Conveyor Speed | Faster to maintain throughput | Slower to allow thicker application | Balanced with removal for smooth surface |

| Air Knife / Roller | Higher removal force to thin film | Lower removal for greater coverage | Fine-tuned angle and pressure |

| Cooling Tunnel | Faster set, shorter dwell | Longer dwell, controlled acceleration | Even zone cooling to avoid stress |

Practical maintenance and cleaning practices that keep lines running

Poor cleaning practices are a major source of downtime and quality problems. Chocolate is sticky, sensitive to contamination, and builds up in dead zones. A maintenance plan focused on speed and thoroughness prevents scrap and reduces unplanned stops.

Daily checks

- Wipe or scrape chocolate from critical surfaces before it cools.

- Verify pump seals and filter screens are clean.

- Check belt alignment and guiding rails for residue build-up.

Weekly tasks

- Disassemble dosing heads and check valve seating and wear.

- Inspect air-knife nozzles and vibration systems for blockages.

- Verify temperature sensors and calibration points.

Monthly or shift-based deeper cleaning

- Conduct a full clean of reservoirs and piping (CIP if available).

- Verify the temperer's crystal bank and polishing elements.

- Check electrical enclosures for chocolate ingress and moisture.

Preventive maintenance

- Keep spare seals, gaskets, and pump diaphragms in stock.

- Log pump hours and plan service before expected wear life ends.

- Replace belts on a planned schedule to avoid sudden failure.

Good cleaning procedures also consider personnel safety and ergonomics. Use tools and fixtures that minimize manual handling and speed disassembly.

Common production issues and troubleshooting approaches

Problems will happen. Here are common issues and practical checks to locate root causes quickly.

Streaking or uneven film

- Check for pulsations in pump output or air in the line.

- Confirm reservoir temperature stability and chocolate homogenization.

- Verify nozzle condition or curtain uniformity.

Excessive chocolate build-up on belts

- Review knock-off roller pressure and air-knife efficiency.

- Inspect product centering to ensure consistent exposure.

- Check belt speed and whether product spacing is correct.

Dull or mottled surface finish

- Verify tempering parameters and cooling tunnel profile.

- Check for contamination — fats from fillings or prior product runs can change surface behavior.

- Confirm humidity and production environment controls.

Differences between operators or shifts

- Ensure standardized recipes and shift handover reports.

- Use training aids and quick start guides for common SKUs.

- Keep a logbook for parameter changes and observations.

Systematic recording and small experiments (change one variable at a time) help isolate causes without creating new variables.

How to reduce waste with better machine use

Reducing scrap is both a quality problem and a cost issue. Machines that deliver predictable results let you run longer before intervention, reducing start-up waste and off-spec batches.

Use consistent recipes and pre-approved change procedures

Documented recipes for temperature, dose, conveyor, and air-knife allow quicker changeovers and fewer test runs.

Optimize start-up routines

Warm the temperer and reservoir fully before the first product; otherwise early pieces will be thicker or have streaks. Use a short pre-run to condition the system and discard minimal chocolate rather than full batches.

Implement staged sampling

Take small samples after tool changes, then progressively increase run volume once parameters hold within acceptance criteria. This helps avoid scrapping entire lots.

Improve material handling upstream

Consistent chocolate quality from tempering and stable ingredient addition reduce in-line corrections and the chance of waste.

Capture and reuse trim

Many factories collect trim and excess chocolate for rework if handled hygienically and in line with food safety rules. A controlled rework loop reduces material loss.

Designing for changeover and mixed production

As markets demand more SKUs and seasonal items, lines that changeover quickly have an advantage. Design choices and practices that help include:

- Quick-change molds, conveyors, and nozzles.

- Modular cooling sections that can be enabled or bypassed.

- Recipe management in the machine PLC for instant recall.

- Standardized tooling sets where possible so parts are interchangeable.

Plan changeovers in a checklist-driven fashion: stop, purge, disassemble the minimum required parts, clean, install new tooling, and start with a short qualification run. Document the timing of each step to refine the process and reduce changeover minutes.

Energy and sustainability considerations

Coating machines consume energy in heating, pumping, and cooling. Small improvements in efficiency compound across long production runs.

Temperature management

Use insulated piping and tanks to reduce heat loss. PID controls tuned to avoid overshoot limit energy spikes.

Recovery and reuse

When safe and compliant, controlled capture of excess chocolate for reprocessing reduces raw-material waste. Ensure traceability in rework streams.

Optimized flow and reduced purge

Pumping systems that minimize dead volume and use efficient purge cycles reduce chocolate loss at startup and SKU change.

Water use for cleaning

CIP systems reduce manual water use when designed correctly, but also require energy for heated water. Balance frequency and method to reduce total water and energy footprint.

Sustainability efforts should be practical and measurable. Start with the most energy-intensive operations and evaluate options for incremental improvement.

Matching machine type to factory needs

Different factories need different machines. Choose by product mix, batch sizes, and flexibility requirements.

Small-batch artisan producers

A compact, flexible enrober with quick tooling changes and simple cleaning may be ideal. Emphasize fast changeovers and minimal footprint.

Medium-sized multiproduct factories

Look for modular enrobers with recipe memory, robust dosing systems, and medium-capacity cooling tunnels. Automation that reduces operator variance pays off.

High-volume continuous lines

Large-scale systems with multiple enrobing heads, advanced tempering, and long multi-zone cooling tunnels deliver throughput. Robust maintenance programs and redundancy for key pumps are critical.

Talk to your production planners about SKU forecasts, desired batch sizes, and expected product mix. A machine that sits well within the operational cadence delivers better value than one with extra unused features.

Operator training, documentation, and quality culture

Even the best machine needs clear, practiced operating procedures.

- Create step-by-step checklists for start-up, changeover, and shutdown.

- Train operators on parameter effects, not only the button sequence. Understanding why a setting matters reduces ad-hoc changes.

- Maintain a shift log where operators record anomalies and corrective actions. Over time, this becomes the single best tool for troubleshooting.

- Encourage small, controlled trials for recipe changes rather than blind adjustments.

A culture that prizes measured updates and documentation reduces the "operator variability" that plagues many lines.

Practical example: tuning a new line for consistent enrobing

A medium-sized confectioner introduced a new bar SKU. The first runs showed edge buildup and dull finish. A measured plan fixed it:

- Verify temperer output and reservoir stability; adjust to maintain narrow temperature band.

- Smooth the pump output: replace a worn diaphragm and switch to a continuous gear pump for the run.

- Reduce air-knife pressure and adjust angle to remove excess without creating friction marks.

- Slow the conveyor by 5% to increase dwell time in the coating zone.

- Calibrate cooling zones to prevent too-rapid set.

After changes, the line achieved repeatable weight control and a glossy finish. The lesson: incremental changes, measured after each step, identified the true contributors to the defect.

Purchasing and installation checklist

If you are planning a purchase, use this checklist during vendor selection and commissioning:

- Confirm temperer and machine compatibility for your chocolate types.

- Request test runs with your chocolate formulation and product.

- Verify dosing accuracy and pump type; ask about pulsation and flow stability.

- Inspect cleaning and access features; ask for CIP details if available.

- Check spare-parts availability and mean time to repair for critical components.

- Schedule operator training and perform a pilot production period before full commercialization.

Clear acceptance criteria set expectations for both buyer and supplier and reduce commercial risk.

Chocolate coating machines combine mechanical handling, thermal control, and fluid dynamics. Getting them right is a blend of equipment selection, operator skill, and rigorous process control. When these elements come together, factories see better product consistency, reduced waste, and faster changeovers.

English

English Español

Español