Energy bars and candy bars have carved out their own unique niches, appealing to different consumer needs and preferences. While both options tantalize the taste buds and provide a quick bite on the go, they serve distinct purposes and are crafted from different ingredients. Energy bars are often marketed as nutritious snacks designed to fuel your active lifestyle, while candy bars tend to focus on indulgence and sweetness.

The candy bar line was perfected for sugar, cocoa butter, and milk powder that melt beautifully and set like glass. The energy bar line has to wrestle with sticky dates, honey, peanut butter, protein isolates, and chunks of almonds that love to jam rollers and tear foil. Same factory floor, completely different beasts.

So when manufacturers ask us why they can't just "add a few nuts and call it an energy bar," we show them the real differences in formulation, temperature control, cooling tunnels, cutting blades, and even the wrapping material.

Ready to discover why a true energy bar line is an entirely different animal from its candy bar cousin, and what it really takes to switch from one to the other without losing your mind?

Understanding Energy Bars

What Are Energy Bars?

Energy bars are specially formulated snacks designed to provide a quick source of energy and nutrition. They are typically made from a combination of whole food ingredients, such as nuts, seeds, grains, and dried fruits, along with protein sources like whey or plant-based proteins. Energy bars are marketed as convenient snacks for athletes, fitness enthusiasts, and busy individuals seeking a nutritious option on the go.

What Are Candy Bars?

Candy bars, on the other hand, are primarily indulgent treats made from a combination of sugar, chocolate, and various flavorings. They often contain ingredients like caramel, nougat, nuts, and other sweet components. Candy bars are primarily designed for enjoyment and are marketed as satisfying snacks for those with a sweet tooth.

Recipe Behavior: Predictable vs Chaotic

Candy bar fillings (nougat, caramel, fondant, praline) are engineered to be smooth, low-moisture, and temperature-stable. They flow like thick toothpaste at 28–32 °C and set firmly once cooled.

Energy bar mixes are the opposite: high in sticky binders (dates, honey, brown rice syrup, agave), loaded with chunky inclusions (nuts, seeds, crisps, dried fruit), and packed with hygroscopic proteins that can seize or separate if you look at them wrong. One degree too warm and the slab turns into glue; one degree too cold and it cracks like concrete.

Forming Technology

Candy bar lines use heated triple-roller slab formers or continuous extruders running at 40–60 °C. The mass is soft, uniform, and loves to be squeezed thin.

Energy bar lines almost always run cold (10–20 °C) with heavy-duty, low-speed rollers or cold presses. Many modern lines use a “slab-on-belt” system where the mix is pre-chilled and gently compressed to avoid crushing inclusions and squeezing out oils.

Cooling Tunnel Philosophy

Candy lines: short, aggressive cooling (0 to −5 °C air) to snap-set chocolate and prevent bloom. Total time: 3–6 minutes.

Energy lines: long, gentle cooling (8–12 °C) with high humidity control to prevent condensation on sticky surfaces and case-hardening. Total time: 12–25 minutes. Some high-protein lines even use two-stage cooling to avoid cracking.

Cutting Methods

Candy bars: traditional guillotine or wire blades that slice through soft, uniform mass like butter.

Energy bars: ultrasonic knives, servo-driven guillotines with non-stick coatings, or high-pressure water jets. Normal steel blades gum up in minutes with almond pieces and date paste.

Coating & Enrobing

Candy bars: full chocolate enrobing is standard. The base mass is dry and cool, so chocolate sticks perfectly.

Energy bars: many are sold naked or with a thin yogurt-style drizzle because full chocolate enrobing causes cracking when the dense core expands/contracts at different rates. When full coating is required, special "tension-controlled" enrobers and longer pre-cooling zones are mandatory.

Wrapping Challenges

Candy bars: standard flow-wrap film (BOPP, CPP) works fine.

Energy bars: need stronger seals, often nitrogen flushing, and sometimes matte or paper-based films because the bars are oilier and more abrasive. Zero-tail sealing machines are common to prevent sticky residue at the ends.

Speed Reality

Classic candy bar lines routinely hit 800–1200 bars/min on a single stream.

Energy bar lines rarely exceed 400–600 bars/min in real factories, even with the latest equipment, because the mix simply refuses to be rushed.

Bottom Line Comparison Table

|

Feature |

Candy Bar Line |

Energy Bar Line |

|

Mix temperature |

Warm (28–60 °C) |

Cold (8–20 °C) |

|

Inclusion size |

Tiny or none |

Large chunks |

|

Cooling time |

3–6 min |

12–25 min |

|

Cutting method |

Guillotine/wire |

Ultrasonic or servo |

|

Typical speed |

800–1200 pcs/min |

300–600 pcs/min |

|

Chocolate enrobing |

Easy, standard |

Difficult, often partial |

|

Downtime cause |

Chocolate temper |

Sticky mix & inclusions |

The distinction between energy bars and candy bars goes beyond mere taste; it encompasses ingredients, nutritional value, target demographics, and intended use. Energy bars are designed to provide sustained energy and nutrition, often incorporating wholesome ingredients that cater to health-conscious consumers. On the other hand, candy bars focus on indulgence, delivering a sweet treat that appeals to those looking for a quick, enjoyable snack. Understanding these differences can help consumers make informed choices based on their dietary needs and lifestyle preferences.

Trying to force an energy bar recipe through a traditional candy line is the fastest way to create downtime, wasted material, and bars that look like they lost a fight with the machine. The smartest manufacturers don't fight the differences; they invest in equipment designed from the ground up for the product they actually want to sell tomorrow.

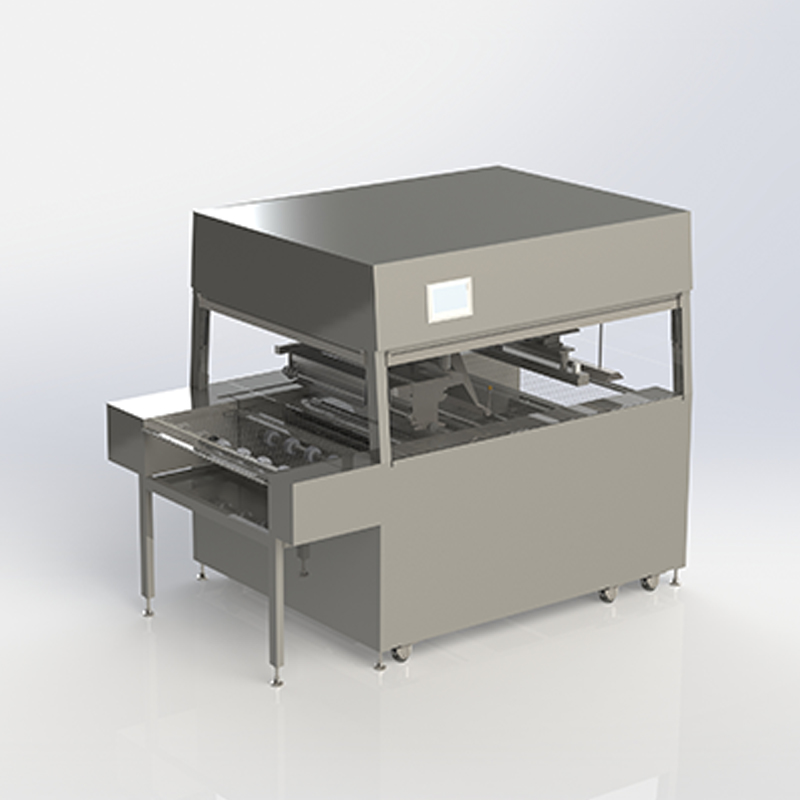

That's exactly why, at Gusu Food Processing Machinery Suzhou Co., Ltd., we've spent many years developing two completely separate platform families: our classic chocolate and candy bar systems that still set the benchmark for glossy enrobing, and our dedicated energy & protein bar lines with cold-slabbing technology, ultrasonic cutting, zero-tail sealing, and sticky-mix-proof rollers that keep running when date paste and peanut butter would shut every other line down.

English

English Español

Español