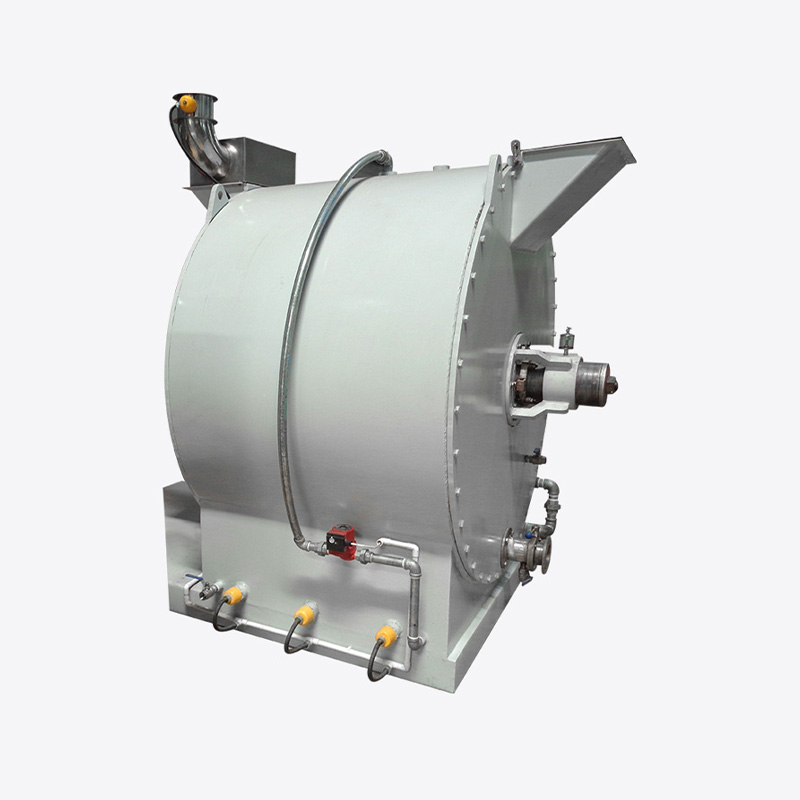

Chocolate Ball Mill: Core Equipment for Smooth Chocolate Refining

Chocolate Ball Mill is key in modern chocolate production, renowned for its ability to finely grind cocoa mass, sugar, and additives into a silky, high-quality chocolate liquor. It is a staple in many production lines because of its efficiency and consistency.

How the Chocolate Ball Mill Operates

At the heart of the Chocolate Ball Mill is a rotating cylindrical chamber with stainless-steel grinding balls. As the chamber spins, the balls lift and tumble over the chocolate mix, exerting friction, shearing and impact to reduce particles to a uniform size. This dynamic motion ensures consistent texture and enhanced product quality.

Precision Temperature Control for Quality

Chocolate is sensitive to heat, and overheating can cause separation, flavor loss, or texture defects. That’s why modern ball mills include temperature regulation features like cooling jackets and real-time thermal control. These systems preserve the integrity of cocoa butter crystals and keep the chocolate glossy and smooth throughout processing.

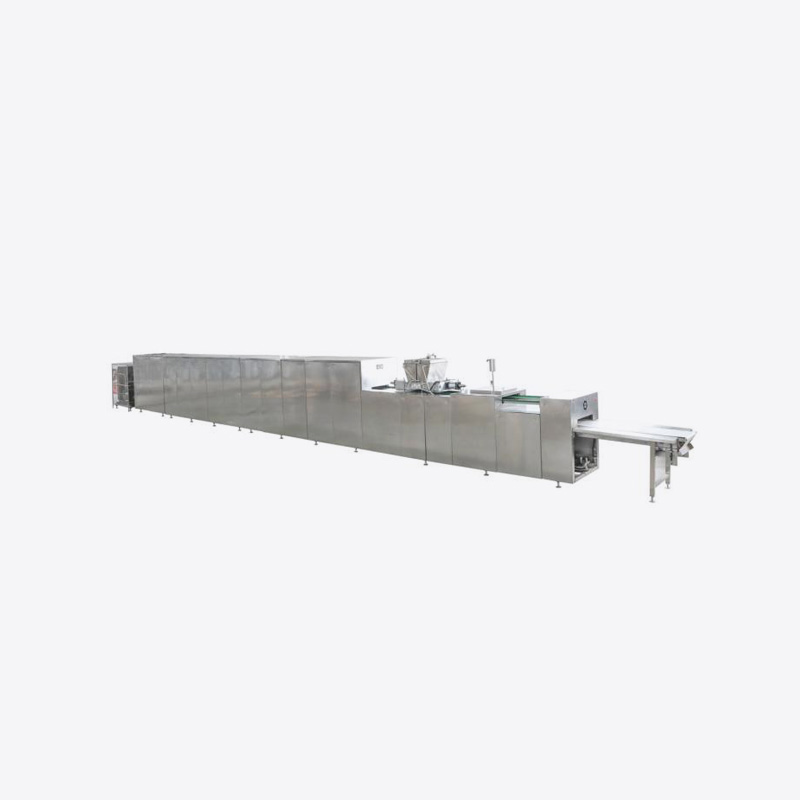

Comparing Grinding Technologies in Chocolate Production

Chocolate Ball Mill vs. Conche vs. Roll Mill:

Ball Mills offer continuous refining and blending in one step. They are energy-efficient and suited to a wide range of production scales.

Conches focus on flavor development and texture through mixing and aeration. They are typically used after refining to remove volatile compounds and enhance smoothness.

Roll Mills use heavy rollers to crush particles. They provide excellent control over size distribution but require more maintenance and operator skill.

For many chocolate producers, ball mills offer the ideal balance of efficiency, consistency, and manageable operation.

Why Particle Size Matters

The ideal particle size in chocolate refining ensures a creamy mouthfeel and optimal viscosity. Chocolate ball mills typically reduce particle size to the smooth range needed for premium confectionery. Particles above that can feel gritty, while reducing too far yields diminishing benefits.

Final Thoughts

For chocolate manufacturers aiming for consistent texture, uniform flavor distribution, and scalable efficiency, the Chocolate Ball Mill remains the go-to solution in refining. It delivers precise control over particle size, effectual cooling, and consistent production flow.

English

English Español

Español