How Modern Chocolate Chip Production Equipment Supports Scalable Manufacturing

In recent years, chocolate products have continued to expand their presence across global consumer markets. From traditional confectionery shelves to modern bakery applications and premium dessert creations, chocolate chips have become one of the most widely used ingredients in both industrial and artisanal production. This growing demand has pushed manufacturers to examine their production methods more closely, especially the equipment responsible for shaping and forming chocolate chips.

As factories face increasing expectations related to consistency, output planning, and operational stability, production equipment plays a central role in meeting these goals. Many manufacturers are now reviewing their processing workflows, exploring how updated machinery can contribute to smoother operations, better product appearance control, and improved long term planning.

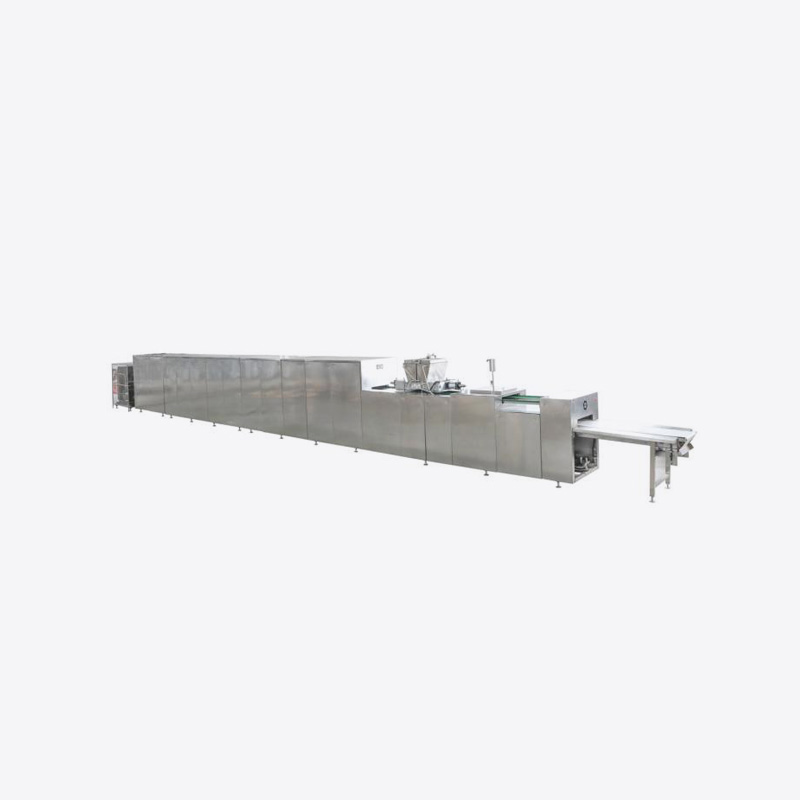

What Makes a Chocolate Chips Machine Suitable for Commercial Production

Understanding Commercial Production Requirements

Commercial chocolate manufacturing operates in an environment where consistency and continuity are essential. Production lines are often required to maintain stable output across long operational periods while responding to changes in product formulation, packaging requirements, and customer expectations.

Equipment used in this environment must support continuous processing without frequent interruptions. This means the system should operate smoothly under extended production cycles and adapt easily to production planning schedules. Stability of operation becomes particularly important when manufacturers supply multiple markets or handle diversified product lines.

Another important factor is the compatibility between the equipment and existing production infrastructure. A production system that integrates easily into current workflows can reduce transition challenges, limit downtime during installation, and allow teams to maintain established operational procedures.

Balancing Efficiency and Process Control

Beyond output considerations, modern manufacturers also pay close attention to how production systems influence process control. The ability to manage flow, temperature stability, and forming precision directly affects the appearance and uniformity of the final chocolate chips.

This balance between efficiency and process management enables production teams to maintain predictable outcomes while adapting to shifts in demand or product development objectives. Over time, such balance supports stronger operational planning and more reliable customer fulfillment.

How Does a Chocolate Chips Machine Affect Product Shape Consistency

Why Uniform Appearance Matters

In competitive consumer markets, visual appearance plays an important role in purchasing decisions. Uniform chocolate chips help ensure consistent product presentation in baked goods, confectionery packaging, and retail displays. When shape and size remain predictable, downstream production processes such as packaging, mixing, and portion control also benefit from greater reliability.

Equipment design strongly influences this outcome. The forming process, flow regulation, and discharge behavior all contribute to the final product profile. Even small variations in mechanical control can result in noticeable differences across production batches.

Process Stability and Repeatability

Stable operating conditions help maintain repeatable product results. When process variables remain consistent across production runs, manufacturers gain better control over their quality management systems. This repeatability supports compliance with internal standards and customer specifications, while also simplifying training and supervision for production staff.

Over time, consistent forming performance reduces material waste, limits rework, and strengthens overall production confidence.

Which Chocolate Chips Machine Features Matter for Long Term Operation

Structural Design and Operational Durability

Long term use requires equipment structures that remain reliable under routine industrial workloads. Manufacturing environments expose machinery to continuous mechanical movement, temperature changes, and cleaning procedures. Equipment built with thoughtful structural design can better accommodate these conditions and support steady performance across extended service life.

Ease of maintenance also becomes an important consideration. When access points are designed for convenient inspection and component replacement, maintenance teams can perform routine service more efficiently. This contributes to reduced downtime and improved scheduling control.

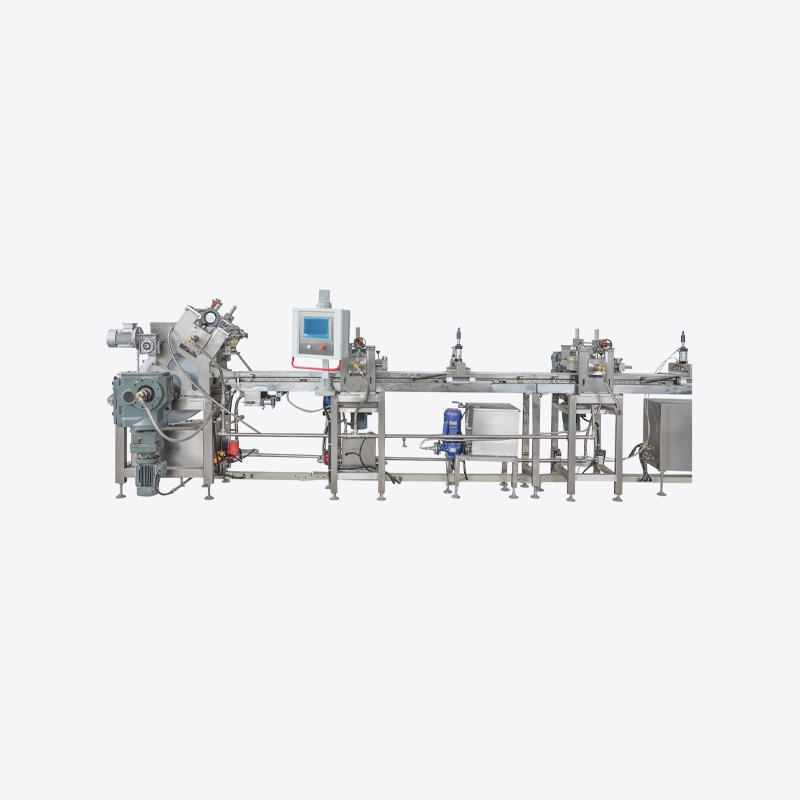

Control Systems and Production Adaptability

Modern production environments often require flexible control capabilities. Adjustable processing settings allow manufacturers to respond to new product requirements, market shifts, and seasonal demand patterns. Systems that support gradual optimization over time enable continuous improvement without requiring frequent major upgrades.

Production data monitoring further supports this adaptability by providing operators with insights into performance trends and operational stability. Such information helps teams make informed decisions related to maintenance planning, resource allocation, and production scheduling.

When Should Manufacturers Upgrade Their Chocolate Chips Machine

Upgrades don't need to wait for a breakdown. Watch for practical signals that an update will actually help the line.

Signs to act now

Output no longer matches sales plans. If demand has risen and the machine is throttling throughput, an upgrade makes sense.

New product specs require different forming or cooling. When customers ask for new shapes or sizes, the old tooling may not cope.

Maintenance is eating shifts. If routine fixes are common and spare parts are slow to source, downtime will keep costing more.

Energy or labour costs push you to rethink the process. Sometimes newer control systems reduce wasted cycles and operator time.

A simple rule: upgrade when staying put costs more than change. Do the math on lost production, repair bills, and scrap. That arithmetic often makes the decision obvious.

Practical approach to upgrading

Pilot small: fit one line with the new unit, run it for a few weeks and compare yield and waste.

Keep tooling compatible where possible, so you can swap between old and new without large changeover time.

Plan spare parts and training up front. New tech without trained staff is just a paper plan.

Why Are More Factories Switching to Automated Chocolate Chips Machines

Automation is less about replacing people and more about predictable output and fewer surprises.

What automation buys you

Consistent forming and reduced manual handling, which cuts errors in size and weight.

Data from runs — throughput, reject rates, occasional faults — that helps tune the process.

Easier compliance with traceability and food safety checks. Digital logs make audits simpler.

Real-world trade-offs

Upfront cost and integration effort are real. But many teams find that lower rework and steadier quality pay back over a production cycle.

Staff shift from manual tasks to supervision and process improvement. This needs training and a small cultural change on the floor.

If you plan for incremental automation — add control modules or sensors before full robotics — you can spread cost and learning over months, not years.

Practical Tips for Choosing a Chocolate Chips Machine for a New Line

Keep this grounded. Don't buy on brochure claims alone.

Start with the job to be done

- Define the product profile: size range, shape tolerance, and what downstream handling expects.

- Note the line speed you realistically need, not the maximum the vendor quotes. Peak capacity is useless if daily demand is lower.

- Check real performance, not specs

Ask for reference runs or a site visit to another customer. Request data on yield, rejects, and downtime.

Ask how the machine handles product changes. How long does a size change take? What parts need swapping?

Service matters more than features

Spare parts lead times and local service response shape uptime. A faster local tech is worth more than an extra option on paper.

Get training included. An operator who understands the machine will keep it running longer and with fewer mistakes.

Build for margin, not minimum price

Consider lifecycle cost: energy, maintenance, spare parts, and the cost of scrap. A slightly higher purchase price can be cheaper over five years.

Market Outlook and Practical Trends

A few patterns are shaping short-term choices.

Modular machines are winning

Buyers prefer units that slot into a line and can take extra modules later — a feeder here, a sensor array there. This lets factories respond to new SKUs without full replacement.

Data is no longer optional

Even smaller factories want basic run metrics. Vendors who provide clear dashboards and exportable logs get more attention.

Energy efficiency and space-saving designs

Plants in denser urban zones care about footprint and power draw. Equipment that does the same job in less space and with simpler ventilation is attractive.

Sustainability and waste reduction

Less scrap and easier cleaning are selling points. Machines that minimise hold-up zones or allow fast changeovers reduce product loss and cleaning time.

Practical Value of Thoughtful Equipment Choice

Choosing the right chocolate chips machine is a mix of hard numbers and shop-floor judgement. Don't be swayed by marketing flourishes. Look for proven yield, easy servicing, sensible automation paths, and tooling flexibility.

Start small, measure results, and scale what works. Plan for service, training, and spare parts as much as for the machine itself. Over time, those practical moves keep lines running, reduce waste, and make scheduling predictable — which is the real advantage in a busy factory.

English

English Español

Español