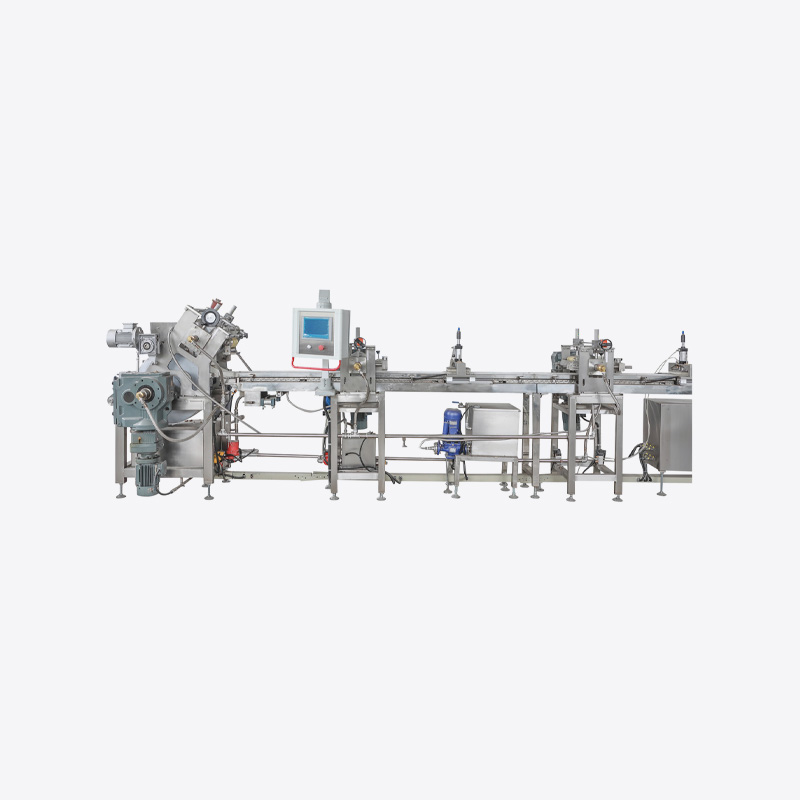

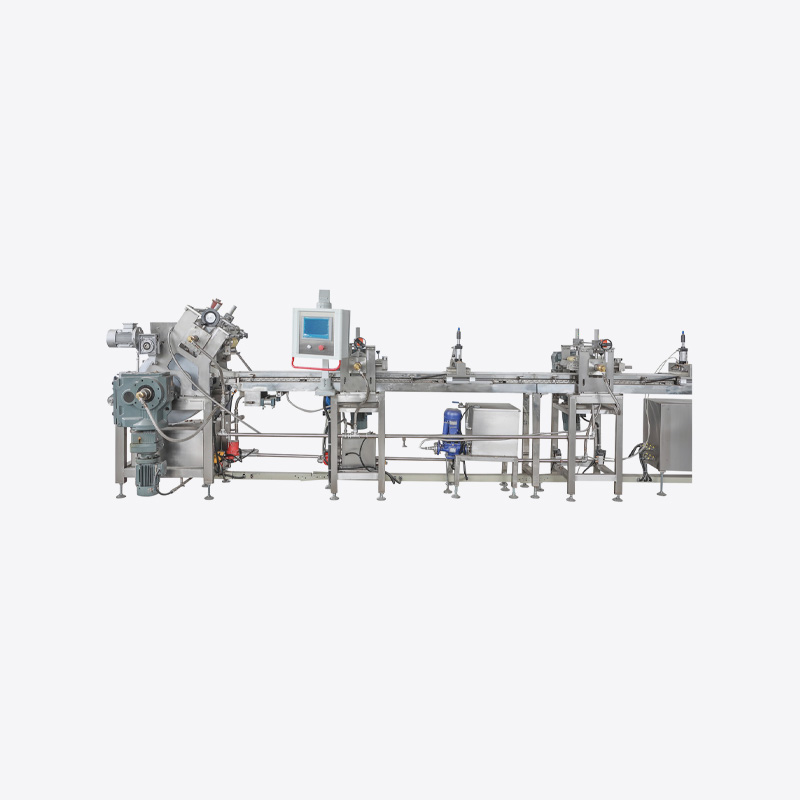

Chocolate Depositor in Modern Chocolate Manufacturing

If you make chocolate — whether you run a small artisanal shop or manage a factory floor — you've probably noticed the push toward more consistent, flexible production. Customers want new shapes, fillings, textures, and seasonal lines, and they want them delivered reliably. A chocolate depositor is one of those pieces of equipment that quietly changes how repeatable those ideas become.

You can think of a depositor as a specialist on the line: it doesn't temper chocolate, it doesn't cool it, but it does place the right amount, in the right spot, with less variability than a human hand. That sounds simple. The practical benefits are where manufacturers notice the difference — fewer reworks, smoother demolding, more predictable packaging throughput.

What a Chocolate Depositor Actually Does

At the most basic level, a depositor meters and places chocolate. That seems obvious, but the nuance is where its value lies. A depositor takes tempered or prepared chocolate, measures a volume or weight, and deposits it into a mold, shell, or cavity. Repeatability is the point: the same portion, again and again.

Different depositors accomplish this in different ways. Some use pumps, some use pistons, some use augers — and some use servo-driven systems that give tighter control. The differences matter depending on what you make. For example:

- Solid shapes need even filling and a clean top surface. A depositor that allows vibration or controlled flow can reduce air pockets and improve finish.

- Filled chocolates often require a shell deposit, a center deposit (ganache, caramel, nut paste), and a back-seal deposit. Machines that can sequence those steps save manual assembly time.

- Decorative or multi-layer items need precise placement and control to keep patterns consistent.

On the production floor this translates to fewer surprises: molds release more cleanly, cooling tunnels work more predictably, and packaging lines can run without constant manual adjustment.

How deposit accuracy affects the rest of production

Consistency in deposit size and placement reduces friction downstream. Here are the practical ripple effects:

- Cooling behaves predictably. When portions are the same, cooling times are consistent. No odd-thick pieces that need extra time in the tunnel.

- Demolding is cleaner. Uneven fills can jam molds or cause partial release; a reliable depositor reduces that.

- Packaging is simpler. If each piece is uniform, automated packers and flow wrappers don't need to stop to sort out odd pieces.

- Less waste, less rework. Overfilling, underfilling, and messy edges mean trimming and rework. Accurate depositing reduces those touch-ups.

- Better labeling and compliance. When weight per piece is predictable, you meet labeling and portion rules with less manual checking.

- These are operational benefits you feel in shifts, not just in specs.

Choosing the right depositor: a practical framework

Not every depositor is right for every shop. Here's a pragmatic checklist to guide choices, with questions you can use when talking to suppliers.

Match the depositor to your product mix

Ask: What product families will this machine run? Solid bars, filled centers, layered confections? If you run several families, prioritize flexibility (easy changeovers, adjustable portioning, quick mold swaps).

Consider production rate and scalability

Ask: What's your current throughput—and what will you need in 12–36 months? Don't underspec a machine so it becomes a bottleneck in a year. But also don't overspend on capacity you'll never use. A mid-range unit with modular expansion often makes sense.

Think about chocolate types and temperature control

Different chocolates — couverture, compound, ganache — behave differently. Ask about pump types and whether the depositor integrates with your tempering unit or has independent heating control. Viscosity changes with temperature; good control reduces clogging or dripping.

Check line integration and layout compatibility

Ask: How does the depositor fit physically? Will it align with conveyor widths, mold holders, and cooling tunnel timing? A machine that needs a line rebuild can cost more in installation than in purchase price.

Cleanability and hygiene

Ask: How easy is disassembly and cleaning? Can critical parts be removed without tools? Food safety and rapid changeovers benefit from designs that minimize downtime. Stainless contact parts, minimal crevices, and CIP (clean-in-place) options are worth noting.

Operator skill and control interface

Ask: Is the control interface intuitive? Can operators change portion sizes and set recipes without specialized training? Machines that use touchscreens and save recipes reduce human error.

After-sales support

Don't underestimate spare parts availability and local service. Ask about lead times for critical replacements and whether the vendor offers remote diagnostics or local technicians.

Trial runs: how to test a depositor with your product

Bring the machine to your product — or bring product samples to the vendor. Either way, run a practical trial and check these items:

- Set up a full production simulation. Run continuous cycles for at least a few hours. Watch how the machine behaves when the hopper runs low and during start/stop cycles.

- Test recipe changes. Switch between two recipes (for instance, a thinner couverture and a thicker praline) to see how fast you can adjust and how the deposit changes.

- Measure weight consistency. Pull random samples from multiple cycles and weigh them. Consistency is more important than hitting a single target.

- Inspect finish quality. Look at surface finish, air bubbles, and how the deposit sits in the mold. Does it overhang? Is it smooth?

- Check demolding behavior. Run through your cooling and demolding steps. Does the machine's output release cleanly?

- Simulate packaging. Feed samples to your packing process if possible. That's often where issues surface.

- Time changeovers and cleaning. Time how long it takes to switch molds and clean parts; this affects real daily throughput.

Bring a simple scoring sheet for trials (e.g., weight variation, surface defects, changeover time, hopper refill behavior). It helps keep trials objective.

Practical tips for running depositors day-to-day

These are operational tricks that reduce headaches.

- Keep temperature steady. Small temperature shifts change viscosity a lot. A stable temperer and a depositor with good thermal design saves time.

- Maintain hopper level sensors. Running the hopper too low can introduce air and cause inconsistent deposits. Use sensors and alarms.

- Use slightly over-tempered chocolate for some depositors. Not all depositors like very runny chocolate; a touch firmer sometimes prevents sagging. Don't guess—test with your recipe.

- Schedule daily quick checks. A short checklist each shift catches small issues before they scale—check seals, nozzles, hopper temperature, and control responses.

- Stock common spares. O-rings, pumps, seals, and nozzles are common failure points. Keep a small inventory.

- Train operators on small repairs. Empower operators to clear blockages and change nozzles quickly. It reduces downtime.

- Use recipe management. Save common recipes in the machine control and avoid manual adjustments unless necessary. That keeps consistency across shifts.

Cleaning and maintenance — keep it practical

Cleaning a depositor is a mix of hygiene and uptime management. Here are realistic steps that balance both:

- Design a cleaning SOP (standard operating procedure). Include step-by-step instructions, who signs off, and how to verify cleanliness (e.g., swab or visual checks).

- Daily quick clean vs. deep clean. Quick cleans between shifts should remove product contact points; deep cleans (weekly or per product change) disassemble more parts.

- Avoid bottlenecks. If disassembly takes many small tools, the changeover will be slow. Favor designs that minimize tools or use captive screws.

- Document issues. If a gasket or nozzle is repeatedly sticky, note it; repeated trouble points suggest a design choice to revisit.

- Sanitizing vs. detergents. Choose food-safe detergents and follow vendor recommendations for sanitizers; Rinse thoroughly to avoid residue.

Recipe handling: what to consider beyond portion size

The depositor is part of a recipe chain. Think about this:

- Viscosity windows. Know the acceptable viscosity range for your depositor and stay within it. Temperature is the main control knob here.

- Fill sequence for layered products. Plan whether you need a shell-first approach or one-shot multi-fill. Some depositors can be programmed to do staged sequences.

- Inclusions and particulates. If your filling includes small nuts or candied bits, test whether the depositor tolerates particulates or whether you need a separate filler.

- Air incorporation. Some fillings trap air during pumping. Consider vacuum degassing for soft centers if you see voids.

- Shelf life concerns. Faster, cleaner depositing that reduces oxygen pickup helps some fillings keep fresher longer.

Troubleshooting quick guide

- Issue: Inconsistent deposit weight. Check hopper level, temperature fluctuation, and any air in the pump. Also verify the control settings and saved recipes.

- Issue: Deposits with air holes. Verify chocolate viscosity and hopper agitation; decrease pump speed slightly or increase vibration to remove air.

- Issue: Nozzle dripping between cycles. Check nozzle seals and backpressure settings; a small increase in retraction or a better shut-off nozzle helps.

- Issue: Clogging with thicker fillings. Reduce particulate size, inspect pump tolerances, and consider a different pump type (piston vs. peristaltic).

- Issue: Poor surface finish. Adjust flow rate, consider a mild vibration or settling period before cooling, and confirm temper stability.

How depositors support product development and market agility

One reason manufacturers invest in depositors is the flexibility they create for R&D and seasonal launches. Instead of rebuilding a line, you can:

- Run prototypes on the depositor and evaluate customer feedback without massive capital changes.

- Produce small batches of limited editions more predictably.

- Introduce variations (a new center, a different portion size) with saved recipes and quick mold swaps.

That agility matters in retail and e-commerce markets where speed to market and consistent presentation can make or break a new SKU.

Final checklist before you buy

Product compatibility: Will it handle all your key recipes?

Throughput match: Can it meet current and near-term needs?

Integration: Does it fit your line and conveyors?

Cleaning: Is disassembly manageable within your changeover windows?

Support: Are spare parts and service accessible in your region?

Trial success: Did the machine pass an on-site trial with your product?

Operator usability: Can your staff run it after standard training?

Total cost: Consider install, spares, training, and downtime, not just purchase price.

Bring this checklist to vendor demos and don't be shy about asking for a trial with your product on your line.

A practical view

A chocolate depositor won't replace good process control or proper tempering, but it's a practical tool that removes variability in a key step. For many manufacturers, that's enough to justify investing: more predictable cooling, cleaner demolding, simpler packaging, and the ability to roll out product variations faster.

English

English Español

Español