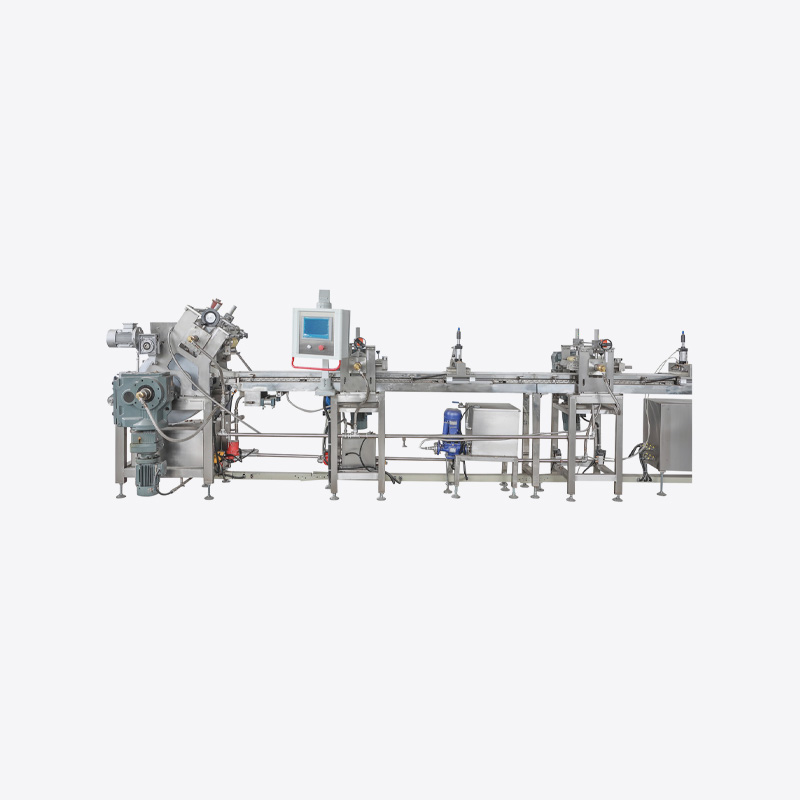

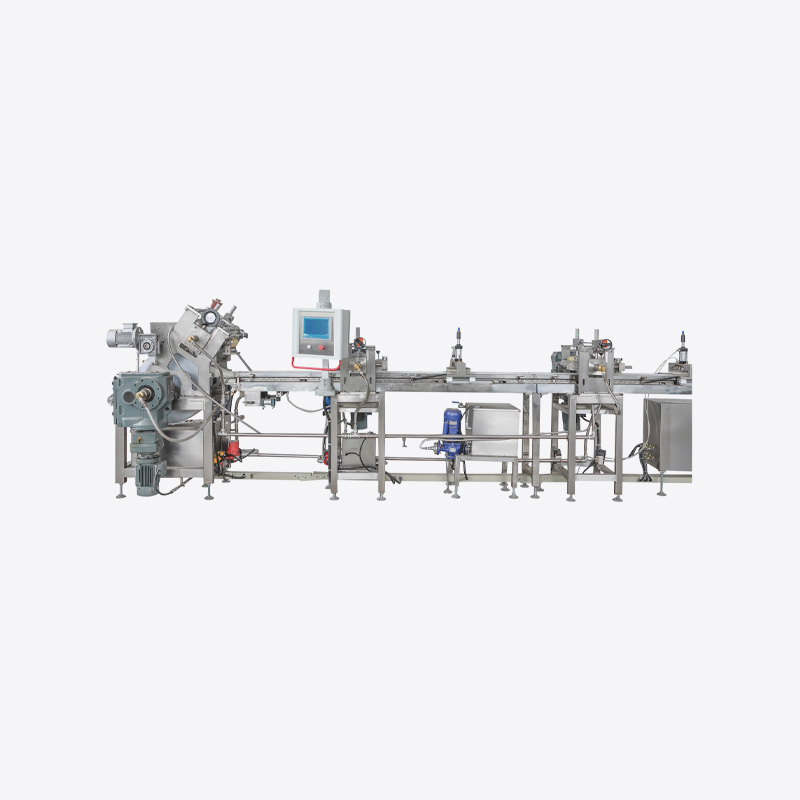

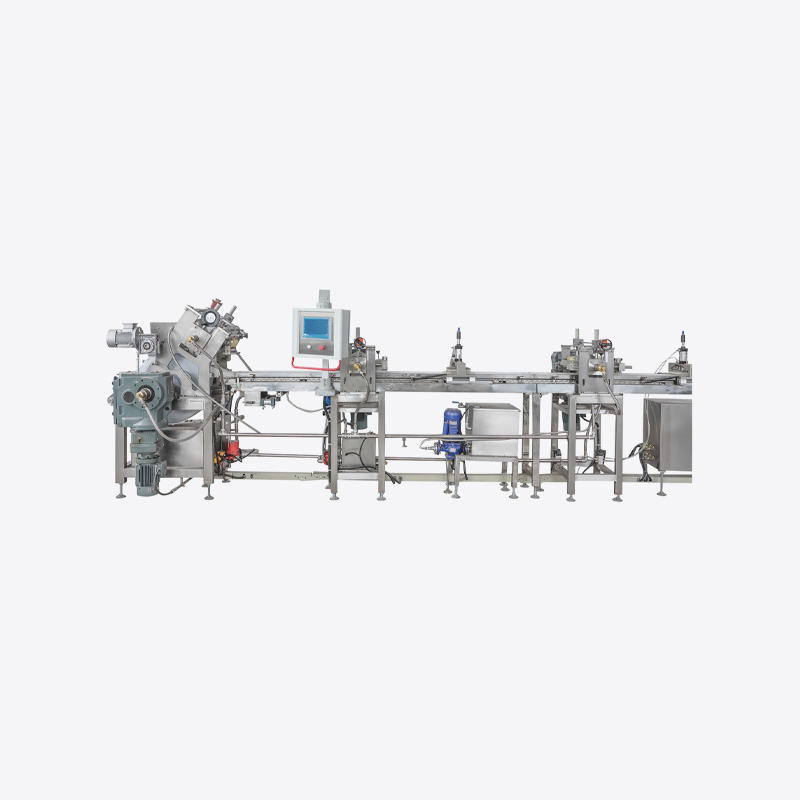

1. Core components of the automation system

An efficient Candy Bar Line automation system usually consists of the following core modules:

Raw material conveying and proportioning system

The automatic weighing and proportioning system can accurately control the proportion of raw materials such as syrup, nuts, chocolate, etc., avoid human errors, and ensure product consistency.

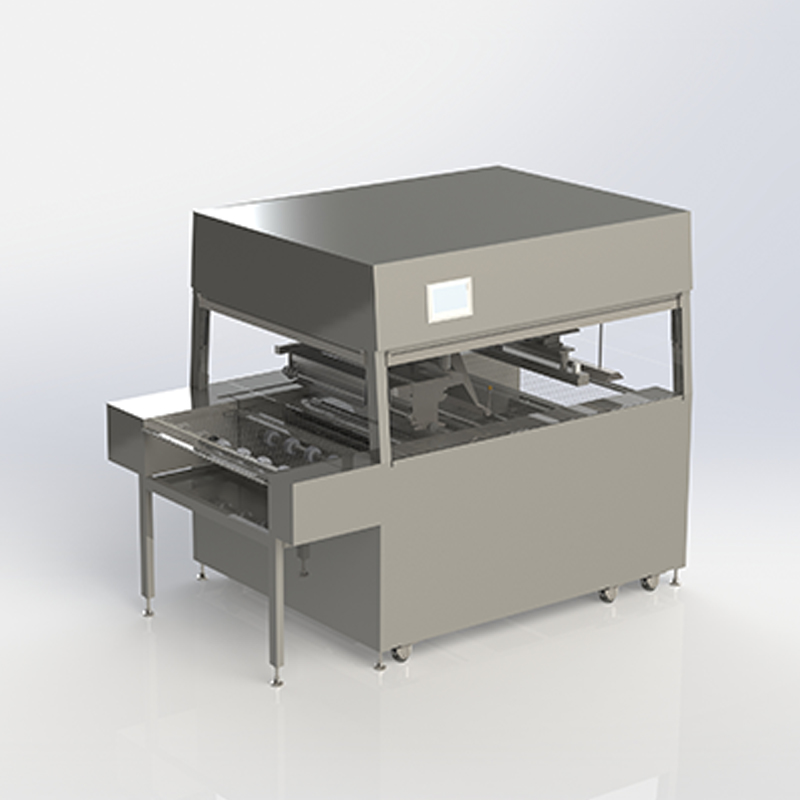

Forming and cooling system

The mold forming or extrusion forming technology is used in conjunction with the automatic cooling tunnel to achieve rapid shaping of candies. This process does not require human intervention, which greatly improves production speed and product stability.

Cutting and sorting system

The high-speed servo-driven cutting equipment can accurately cut candy bars according to set specifications, and combined with the visual recognition system, it can automatically sort and remove defective products.

Packaging and labeling system

The automatic packaging machine can complete the single or combined packaging of candies, and integrates automatic labeling and coding functions to improve packaging efficiency and meet traceability requirements.

Central control system (PLC+HMI)

Through the programmable logic controller (PLC) and the human-machine interface (HMI), the entire production line can be centrally monitored and operated to improve overall collaborative efficiency.

2. Key technologies support efficient automation

Application of industrial robots

Introducing collaborative robots in loading and unloading, handling, packing and other links can reduce manual participation, improve operational safety and flexible production capacity.

Intelligent sensors and machine vision

Sensors installed at key nodes can monitor parameters such as temperature, pressure, flow rate in real time; machine vision is used to detect candy appearance defects, dimensional deviations, etc. to ensure product quality.

Internet of Things (IoT) and data management

After the equipment on the production line is connected to the Internet, remote monitoring, fault diagnosis and data analysis can be carried out through the cloud platform to achieve predictive maintenance and lean management.

Modular design and flexible manufacturing

The modular structure facilitates rapid replacement and adjustment of equipment, adapts to the production needs of different types of candies, and improves the flexibility of the production line.

3. Optimization strategies and implementation points

Preliminary planning and process matching

Select appropriate automation solutions according to product types (such as sandwich candies, coated candies, etc.) to ensure that the equipment and process flow are highly compatible.

Staff training and technical support

Provide professional training for operators to enable them to master equipment operation, daily maintenance and exception handling skills to ensure stable operation of the system.

Quality control system construction

Establish a quality monitoring mechanism for the entire process from raw materials to finished products, combined with automated testing methods to achieve controllable and traceable quality.

Energy-saving and environmentally friendly design

Select environmentally friendly equipment such as energy-saving motors and heat recovery devices to reduce energy consumption and carbon emissions, in line with the development trend of green manufacturing.

By introducing advanced automation technology and scientific management methods, Candy Bar Line can not only significantly improve production efficiency and product quality, but also save labor costs for enterprises and enhance market competitiveness. With the continuous integration of emerging technologies such as artificial intelligence and big data, the future candy production line will develop in a more intelligent, efficient and sustainable direction.

/>

/>

English

English Español

Español