What Is a Chocolate Chips Machine

A Chocolate Chips Machine is a specialized piece of food processing equipment designed to produce uniform chocolate chips efficiently and consistently. These machines are widely used in confectionery factories, commercial bakeries, and chocolate production lines. They play a critical role in automating the process of forming, shaping, and cooling small pieces of chocolate into chips used for baking, mixing, or direct consumption.

Main Function of a Chocolate Chips Machine

At its core, the chocolate chips machine takes melted chocolate and deposits it into small, consistent drops on a moving cooling belt or tray. Once the chocolate is shaped, it is cooled and solidified, forming the familiar teardrop or round-shaped chocolate chips commonly used in cookies, muffins, and other desserts.

Key Components and Their Functions

| Component | Function |

|---|---|

| Chocolate Feeding Tank | Holds and maintains the temperature of the melted chocolate. |

| Depositing Head/Nozzles | Drops melted chocolate onto the belt in precise amounts and patterns. |

| Cooling Conveyor Belt | Moves chocolate drops through a controlled cooling tunnel. |

| Cooling System | Ensures rapid and uniform solidification of the chocolate chips. |

| Control Panel | Allows operators to adjust speed, deposit volume, temperature, etc. |

Advantages of Using a Chocolate Chips Machine

Consistent Shape and Size

Uniformity in chocolate chip size enhances packaging and baking performance.

High Production Efficiency

Machines can run continuously, allowing for large-scale production.

Temperature Control

Maintains the ideal environment to preserve chocolate quality and texture.

Hygienic and Easy to Clean

Stainless steel construction and automated cleaning features help maintain food safety standards.

Customizable Output

Machines can be configured to produce different shapes, sizes, or even flavored chips.

What Are the Types of Chocolate Chips Machines?

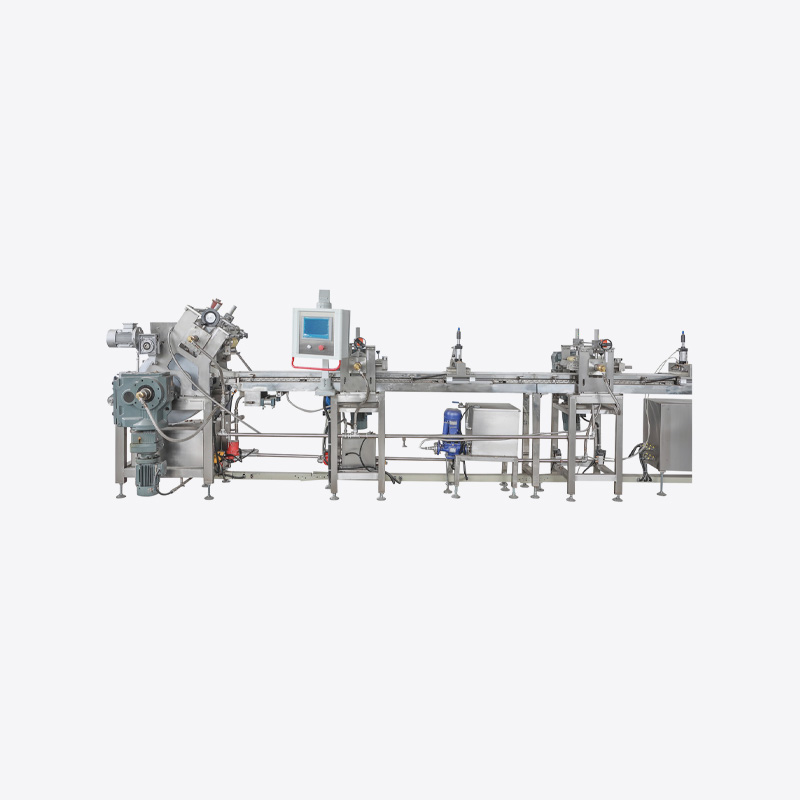

1. Automatic Chocolate Chips Depositing Machine

Description:

Fully automated machines that deposit melted chocolate onto a conveyor belt using precision nozzles, then cool and form them into uniform chips.

Key Features:

High-speed depositing

Programmable controls

Suitable for large-scale factories

Consistent shape and size

2. Semi-Automatic Chocolate Chips Machine

Description:

Combines manual loading with automatic depositing and cooling. Operators may manually feed chocolate into the hopper, but depositing and cooling are automated.

Key Features:

Lower cost

Easier maintenance

Ideal for mid-size businesses

Flexible for small batch production

3. Rotary Chocolate Chip Former

Description:

This machine uses a rotary system with mold impressions to shape the chocolate into chips. It’s less common but offers unique shaping possibilities.

Key Features:

Unique chip shapes

Mold-based shaping

Compact design for limited space

Suitable for boutique or specialty chocolate brands

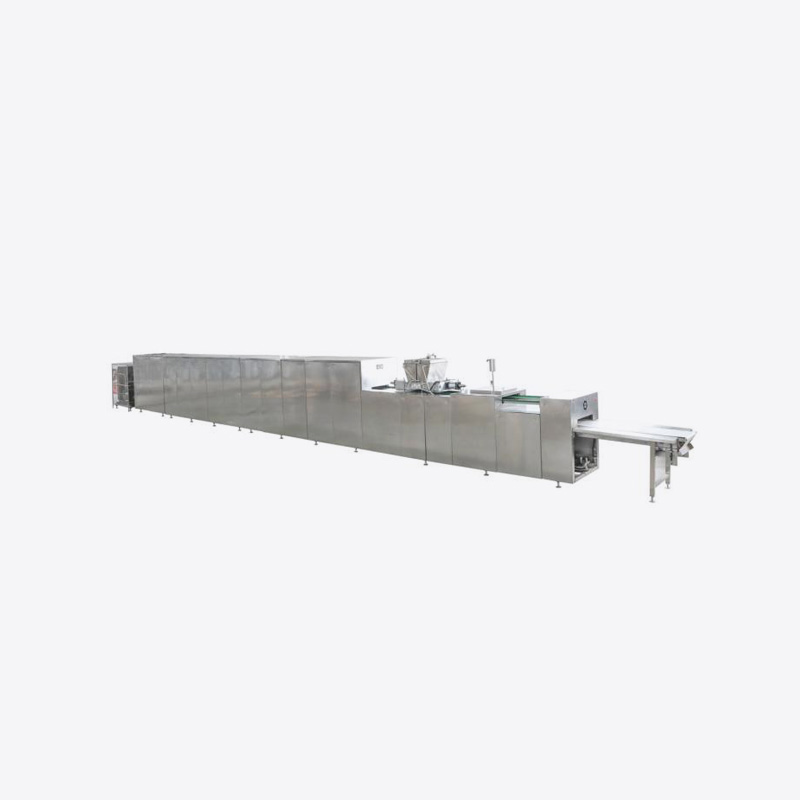

4. Cooling Tunnel + Depositor Combo Line

Description:

A complete production line integrating a chocolate depositor with a temperature-controlled cooling tunnel.

Key Features:

Continuous production

Designed for high-capacity operation

Uniform cooling and solidification

Scalable with additional conveyor belts

5. Customized Chocolate Chips Equipment

Description:

Tailor-made machines built to specific production needs, such as dual-flavor chips, multi-size outputs, or special ingredient inclusions.

Key Features:

Fully customizable molds and controls

Ideal for innovative product lines

Often includes special dosing or mixing functions

Comparison Table: Chocolate Chips Machine Types

| Type | Automation Level | Production Scale | Best For |

|---|---|---|---|

| Automatic Depositor | Fully Automatic | Large-scale | Industrial factories |

| Semi-Automatic Machine | Semi-Automatic | Medium-scale | Small to medium businesses |

| Rotary Chip Former | Manual/Auto Combo | Small-scale | Specialty or creative producers |

| Cooling Tunnel Line | Fully Automatic | Large-scale | Continuous high-volume output |

| Customized Equipment | Varies | Any scale | Unique or special applications |

Typical Uses of Chocolate Chips Machines

1. Baked Goods Manufacturing

Chocolate chips are a core ingredient in many bakery items such as cookies, muffins, brownies, and cakes. These machines supply large volumes of chips for use in dough mixing or as decorative toppings.

2. Snack Food Production

In snack lines, chocolate chips are added to granola bars, trail mixes, cereals, and protein bars. Their consistent size and texture make them easy to blend and package with other ingredients.

3. Ice Cream & Frozen Dessert Processing

Chocolate chips machines are often used to create chips for inclusion in ice cream, frozen yogurt, and gelato. Their precise shape and hardness are ideal for mixing into cold desserts without melting or deforming.

4. Confectionery Product Lines

Some candy manufacturers use chocolate chips as ingredients or decorative additions in chocolate-covered nuts, energy bites, and filled chocolates. The ability to produce flavored or colored chips further expands their utility.

5. Food Service & Catering Supply

These machines support bulk production for distributors supplying hotels, restaurants, bakeries, and catering services with ready-to-use chocolate chips in various sizes and flavors.

How Chocolate Chips Machines Work

1. Chocolate Melting & Feeding

The process begins with melted chocolate being poured or pumped into a feeding tank. This tank maintains the ideal temperature to keep the chocolate in a smooth, flowable state, ready for shaping.

2. Precision Depositing

Using nozzles or a depositing head, the machine drops small, uniform portions of chocolate onto a moving conveyor belt. The depositing system is calibrated to control the size, shape, and spacing of each chip. Some machines also allow for programmable patterns.

3. Cooling & Shaping

As the chocolate drops move along the cooling tunnel or belt, cold air or chilled surfaces gradually reduce their temperature. This cooling step helps the chocolate chips harden into their final shape without cracks or deformities.

4. Solidification

Once cooled, the chocolate chips are fully solidified. The conveyor carries them to the collection area, where they can be discharged into packaging trays, containers, or transferred for further processing.

5. Final Collection or Packaging

The finished chips are either automatically packed or manually collected depending on the level of automation. Chips can be stored in bulk or portioned for retail or industrial use.

Key Features of the Process

Consistent Output: Uniform chip size improves packaging and product quality.

Hygienic Design: Machines are built from food-grade materials like stainless steel to ensure safety.

Programmable Control: Operators can adjust speed, volume, temperature, and patterns.

Energy-Efficient Cooling: Modern cooling systems help reduce energy use while maintaining performance.

Automatic vs. Semi-Automatic Chocolate Chips Machines: Which One Should You Choose?

What Is an Automatic Chocolate Chips Machine?

An automatic chocolate chips machine performs all production steps without the need for manual intervention. From feeding the chocolate to depositing the drops and cooling them down into chips, the entire process is managed by a programmable control system.

Typical Features:

Continuous feeding system with temperature control

Programmable depositing nozzles for uniform chip sizes

Built-in conveyor and cooling system

Automatic chip discharge and collection

Best For: Large-scale food processing plants that need high-speed, uninterrupted production.

What Is a Semi-Automatic Chocolate Chips Machine?

A semi-automatic chocolate chips machine blends manual operation with automated functions. While certain steps like depositing and cooling are handled by the machine, the operator usually feeds the melted chocolate manually and may collect the finished chips by hand.

Typical Features:

Manual chocolate input (hopper or tray)

Automated depositing system

Cooling section, usually with basic controls

Manual collection or semi-assisted tray unloading

Best For: Small- to medium-sized businesses, product testing lines, and manufacturers looking for affordability and flexibility.

Side-by-Side Comparison Table

| Category | Automatic Machine | Semi-Automatic Machine |

|---|---|---|

| Level of Automation | Full automation across all stages | Partial automation (manual feeding/collection) |

| Production Capacity | High-speed, continuous operation | Moderate-speed, batch-based production |

| Operator Involvement | Minimal – monitor and adjust settings | Medium – manual loading and occasional supervision |

| Control System | Advanced PLC or touchscreen interfaces | Basic switches or simple control panels |

| Labor Efficiency | Ideal for reducing labor costs | Requires dedicated staff during operation |

| Maintenance | Requires skilled technicians for upkeep | Easier to clean and maintain manually |

| Cost | Higher initial investment, lower long-term labor costs | Lower initial cost, potentially higher operational costs |

| Flexibility | Designed for standardized, high-output operations | Easier to adapt for specialty runs or smaller batches |

| Factory Size | Best for large-scale, space-equipped facilities | Suitable for compact production spaces |

Pros and Cons Overview

Automatic Chocolate Chips Machine

Pros:

High output with consistent chip size

Minimal labor required

Programmable for different chip styles

Best for continuous, 24/7 production

Cons:

Higher purchase and setup cost

Requires skilled operators for programming and maintenance

May need more factory space

Semi-Automatic Chocolate Chips Machine

Pros:

Affordable for smaller operations

Easier to maintain and operate

Allows for manual quality checks

Compact and flexible

Cons:

Slower throughput

Labor-dependent

Limited to simpler production tasks

Which One Should You Choose?

Your decision should be guided by the following factors:

Production Volume: If your daily chip output is high and consistent, automatic machines will save time and labor in the long run.

Budget: Semi-automatic machines are more affordable upfront and suitable for new businesses or pilot lines.

Workforce Availability: If skilled labor is limited or expensive, automation helps reduce dependency.

Product Variety: Semi-automatic systems offer greater control for short-run, multi-flavor, or specialty chocolate production.

Space Constraints: Semi-automatic systems are usually more compact and easier to install in small workshops.

How to Maintain and Care for Your Chocolate Chips Machine

1. Daily Cleaning and Hygiene

Importance:

Daily cleaning ensures that all parts in direct contact with chocolate, such as hoppers, nozzles, and cooling trays, remain free from any residue. If chocolate residue is left unchecked, it can clog up components and degrade the quality of your chips.

Tips:

Clean all surfaces and removable parts after every production cycle.

Use non-abrasive cleaning agents that are safe for food machinery.

Focus on areas where chocolate tends to accumulate, such as nozzles, depositing heads, and conveyors.

2. Regular Lubrication of Moving Parts

Importance:

Lubricating moving parts reduces friction, ensuring smooth operation and minimizing wear and tear. It helps maintain consistent production speeds and prevents overheating.

Tips:

Apply food-grade lubricant to gears, chains, and bearings regularly.

Keep a lubrication schedule to ensure that no parts run dry, which could cause unnecessary wear.

Only use oils or greases that meet food safety standards.

3. Check and Calibrate Temperature Controls

Importance:

Temperature regulation is critical in chocolate production. If the heating or cooling system malfunctions, it can lead to improperly melted chocolate, uneven chip formation, or inconsistent cooling.

Tips:

Periodically check temperature sensors and thermostats for accuracy.

Ensure that the cooling system is functioning properly to solidify the chips.

Recalibrate temperature controls if necessary to avoid fluctuations during production.

4. Inspect and Clean Depositing Nozzles

Importance:

Depositing nozzles play a crucial role in shaping the chocolate chips. Clogged nozzles or those with irregular openings can lead to uneven chip sizes, which affects both the quality and presentation of the finished product.

Tips:

Regularly inspect the nozzles for any blockages or signs of wear.

Soak them in warm water or approved cleaning solutions to dissolve any chocolate build-up.

Use soft tools like brushes or air compressors to clear obstructions without damaging the nozzles.

5. Monitor and Clean the Cooling System

Importance:

The cooling system ensures that the chocolate chips solidify properly before they are discharged. A malfunctioning cooling system can result in soft or misshaped chips.

Tips:

Clean fans, ducts, and cooling belts regularly to maintain proper airflow.

Check for any debris or residue that may block airflow.

Ensure that temperature regulators within the cooling system are working to provide an even cooling process.

6. Tighten Bolts and Belts

Importance:

Loose bolts or belts can cause machines to vibrate, misalign, or even malfunction. Tightening these components helps maintain smooth operation and prevents unexpected breakdowns.

Tips:

Inspect all fasteners, including screws and bolts, especially on the frame, conveyor system, and motor.

Check belts for wear, cracks, or loosening. Replace damaged belts promptly.

Tighten bolts and nuts to the manufacturer's recommended torque specifications.

7. Perform Regular Electrical Inspections

Importance:

Electrical malfunctions can cause production to halt, leading to significant downtime. Regular inspections ensure that wiring, motors, and switches remain in good condition.

Tips:

Check electrical connections for signs of wear, corrosion, or loose connections.

Test motor performance to ensure it's operating at full efficiency.

Replace any faulty wiring or electrical components promptly to avoid costly damage.

8. Keep a Maintenance Log

Importance:

Tracking maintenance tasks ensures that all actions are performed on time and can help detect recurring issues or wear patterns. A log is invaluable for planning long-term repairs or equipment replacements.

Tips:

Keep a detailed log of all maintenance tasks, including cleaning, lubrication, and inspections.

Record the date and nature of repairs and part replacements.

Use the log to track patterns and prevent neglecting critical tasks.

9. Operator Training and Awareness

Importance:

Well-trained operators are essential for the proper functioning of the chocolate chips machine. A lack of understanding can lead to improper handling, unnecessary wear, and potential safety hazards.

Tips:

Provide regular training sessions on operating procedures, safety protocols, and maintenance basics.

Train staff to recognize common issues like inconsistent temperature or chocolate clogging.

Encourage staff to immediately report any unusual sounds, malfunctions, or inefficiencies.

Choosing the Right Mold Type for Your Chocolate Chips Machine

1. Silicone Molds

Benefits:

Non-stick surface: Silicone molds are easy to clean, as the chocolate doesn't stick to the surface. This reduces labor time and prevents waste.

Flexible design: They can be molded into various shapes, sizes, and designs, offering versatility in chocolate chip production.

Heat resistance: Silicone molds can withstand high temperatures without warping, ensuring durability in high-speed production.

Best for: Small to medium-scale production where flexibility and ease of cleaning are critical. Silicone molds are ideal for customizing chip designs.

2. Stainless Steel Molds

Benefits:

Durability: Stainless steel molds are incredibly strong and resistant to corrosion, making them suitable for long-term use in industrial environments.

Uniformity: The hard surface ensures that the chocolate chips maintain a consistent shape and size, which is crucial for packaging and product appearance.

Easy to sanitize: Stainless steel is easy to clean and sanitize, meeting hygiene requirements for food production.

Best for: Large-scale production where uniformity and long-lasting performance are essential. Stainless steel molds work well for high-volume operations where maintaining consistent product quality is important.

3. Aluminum Molds

Benefits:

Excellent heat conduction: Aluminum molds provide fast cooling, which is ideal for quickly solidifying chocolate chips and maintaining their shape.

Lightweight: Aluminum molds are lighter than stainless steel, reducing machine load and allowing for faster mold changes.

Cost-effective: They are typically more affordable compared to stainless steel molds while still offering good durability.

Best for: Medium to large-scale operations that require fast production and efficient cooling. They are a good choice for manufacturers who need an affordable and high-performance solution.

4. Teflon-Coated Molds

Benefits:

Non-stick surface: Teflon coating provides an extra layer of non-stick protection, making it easier to remove chocolate chips without damaging their shape.

Enhanced release: The smooth surface ensures that chocolate chips don’t get stuck, reducing wastage and ensuring higher production efficiency.

Heat resistance: Like silicone, Teflon can withstand high temperatures, making it suitable for chocolate production processes.

Best for: Industries focusing on high-volume, high-speed production where non-stick properties are critical for maintaining efficient output and preventing chocolate residue build-up.

5. Custom Molds

Benefits:

Tailored designs: Custom molds are designed to meet specific product requirements, whether it's a unique shape or size of chocolate chips.

Branding opportunities: Custom molds can help your products stand out on the market by creating signature chip designs that align with your brand.

Flexibility in production: Custom molds can be adjusted to produce multiple sizes or configurations of chocolate chips, providing flexibility in production.

Best for: Companies looking for branding differentiation or those with specific production needs, such as creating signature or seasonal chocolate chip products.

Key Considerations When Choosing the Right Mold

When selecting the mold type for your chocolate chips machine, consider the following factors:

| Factor | Considerations |

|---|---|

| Production Volume | Larger volumes may require durable molds like stainless steel or aluminum. |

| Shape and Design | Choose flexible molds like silicone or custom molds for unique shapes. |

| Ease of Cleaning | Non-stick materials such as silicone or Teflon are easier to clean. |

| Cost Efficiency | Aluminum molds are often more cost-effective compared to stainless steel. |

| Speed of Production | For fast production, consider molds that allow quick cooling, such as aluminum or stainless steel. |

Choosing the right mold for your chocolate chips machine is essential to achieving consistent product quality and maximizing production efficiency. Whether you're looking for the flexibility of silicone molds, the durability of stainless steel, or the speed and cost-effectiveness of aluminum, selecting the right mold type can significantly impact your operation's overall success.

At Gusu Food Processing Machinery Suzhou Co., Ltd., we specialize in providing high-quality, custom-made solutions for chocolate production, including a variety of molds tailored to your specific needs. Our team of experts is dedicated to ensuring that your production process runs smoothly, efficiently, and with the highest standards of product quality.

If you're looking to optimize your chocolate chips production, don't hesitate to reach out to us for advice, solutions, and equipment that suit your unique requirements.

English

English Español

Español