In the fast-paced world of confectionery production, ensuring the smooth operation of equipment is paramount. One such essential piece of machinery is the chocolate chips machine, which plays a crucial role in the efficient production of chocolate chips for various products. However, like any specialized equipment, it is susceptible to certain challenges that can impact productivity and product quality.

1. Inconsistent Chocolate Flow

A common issue encountered is the inconsistent flow of chocolate, leading to irregular chip sizes and shapes. This can result from several factors:

-

Viscosity Variations: Changes in chocolate viscosity can affect its flow rate.

-

Temperature Fluctuations: Inconsistent temperatures can cause the chocolate to thicken or become too runny.

-

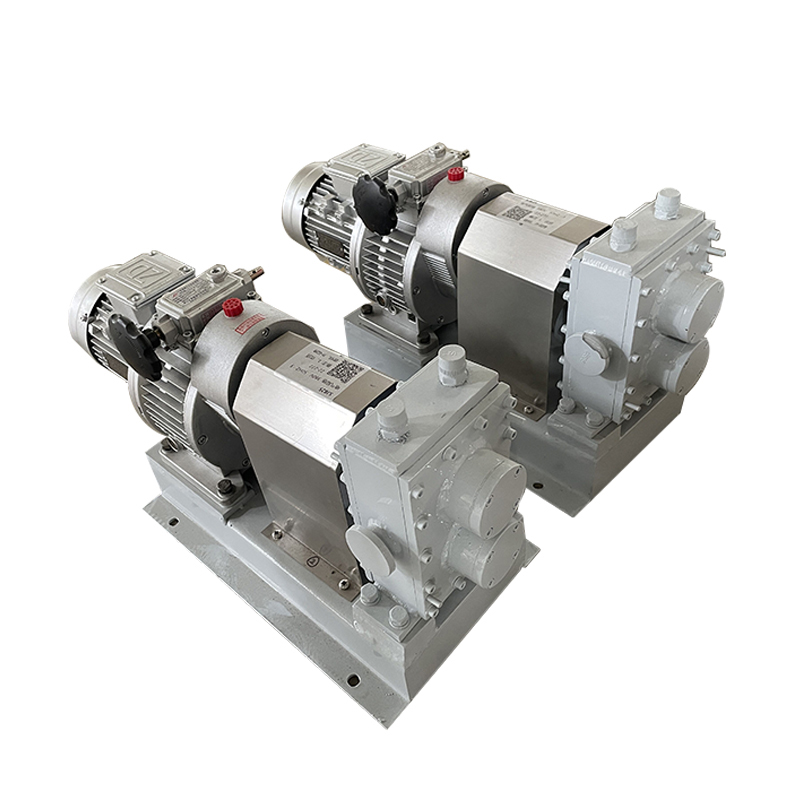

Equipment Malfunctions: Faulty pumps or valves can disrupt the smooth flow of chocolate.

Solution: Regular maintenance and calibration of the machine, along with monitoring the temperature and viscosity of the chocolate, can help maintain a consistent flow.

2. Chocolate Sticking to Molds

Chocolate adhering to molds is another prevalent problem, leading to damaged products and increased cleaning time. This issue can arise due to:

-

Improper Mold Preparation: Insufficient coating or lubrication of molds.

-

Temperature Issues: Molds that are too warm or too cold can cause sticking.

-

Chocolate Composition: High sugar content can increase stickiness.

Solution: Ensuring molds are properly prepared and maintained, and that the chocolate composition is balanced, can reduce sticking incidents.

3. Uneven Cooling

Uneven cooling can lead to inconsistencies in the texture and appearance of chocolate chips. Factors contributing to this issue include:

-

Airflow Variations: Inadequate or uneven airflow in cooling tunnels.

-

Temperature Gradients: Differences in temperature within the cooling area.

-

Overcrowding: Excessive product load hindering proper air circulation.

Solution: Optimizing the layout of the cooling area and ensuring uniform airflow can promote even cooling.

4. Equipment Wear and Tear

Over time, components of the chocolate chips machine can experience wear and tear, leading to decreased efficiency and potential breakdowns. Common causes include:

-

Continuous Operation: Prolonged use without adequate rest periods.

-

Lack of Maintenance: Neglecting regular maintenance and inspections.

-

Poor Quality Components: Using substandard materials that degrade faster.

Solution: Implementing a regular maintenance schedule and using high-quality components can extend the lifespan of the equipment.

5. Contamination Risks

Contamination of chocolate products can occur if the machine is not properly cleaned or if there are issues with the ingredients. Potential sources of contamination include:

-

Residual Materials: Leftover ingredients from previous batches.

-

Unclean Equipment: Inadequate cleaning procedures leading to microbial growth.

-

Ingredient Quality: Using ingredients that are not up to standard.

Solution: Establishing stringent cleaning protocols and sourcing high-quality ingredients can minimize contamination risks.

6. Operational Challenges

Operators may face challenges that affect the efficiency of the chocolate chips machine, such as:

-

Lack of Training: Inadequate knowledge of machine operation and troubleshooting.

-

Poor Workflow Design: Inefficient layout leadi

-

Communication Gaps: Miscommunication between team members affecting coordination.

Solution: Providing comprehensive training for operators and optimizing workflow design can enhance operational efficiency.

7. Environmental Factors

External environmental conditions can impact the performance of the chocolate chips machine. Factors to consider include:

-

Humidity Levels: High humidity can affect chocolate consistency.

-

Ambient Temperature: Extreme temperatures can cause chocolate to harden or melt unexpectedly.

-

Dust and Debris: Presence of particles can contaminate products and damage equipment.

Solution: Maintaining a controlled environment with stable temperature and humidity levels can mitigate these issues.

Operating a chocolate chips machine efficiently requires attention to detail and proactive management. By understanding and addressing common issues such as inconsistent chocolate flow, mold sticking, uneven cooling, equipment wear, contamination risks, operational challenges, and environmental factors, manufacturers can enhance product quality and production efficiency. Implementing the solutions outlined above can lead to smoother operations and a more reliable production process.

English

English Español

Español