Energy bars have become a popular snack choice worldwide due to their convenience, nutritional benefits, and portability. As demand for energy bars grows, manufacturers are increasingly focused on optimizing production efficiency, maintaining consistent quality, and reducing labor costs. A common question in the industry is: can an energy bar production line be automated? The answer is yes, and automation can cover nearly all stages of production, from ingredient handling to packaging.

1. Automation in Ingredient Handling

The first step in energy bar production involves precise measurement and mixing of ingredients such as nuts, grains, dried fruits, protein powders, sweeteners, and binding agents. Automated ingredient handling systems use digital weighing machines, hoppers, and conveyor systems to ensure accuracy and consistency. These systems minimize human error, reduce waste, and allow manufacturers to scale up production without significantly increasing labor costs. Additionally, programmable logic controllers (PLCs) can store multiple recipes, enabling rapid switches between different types of energy bars.

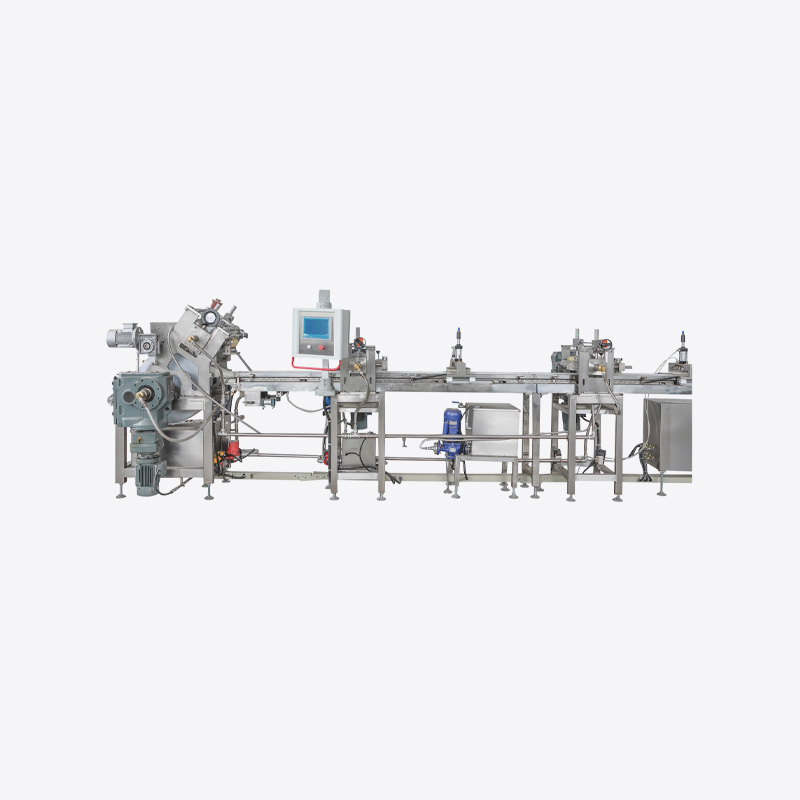

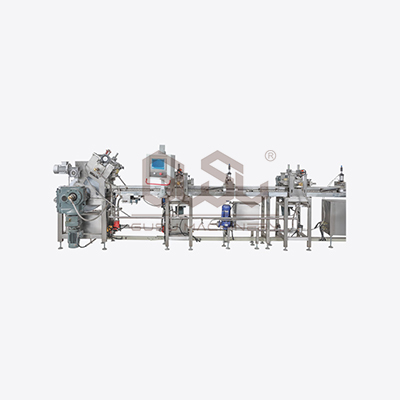

2. Mixing and Forming Automation

Once ingredients are measured, they must be thoroughly mixed and formed into bars. Industrial mixers with automated control systems ensure uniform blending of dry and wet ingredients. For forming, automated extrusion or molding machines shape the mixture into uniform bars or clusters. Some systems use adjustable molds to produce bars of different sizes or shapes, offering flexibility in product design. Automation in mixing and forming ensures consistent texture, density, and weight of each energy bar, which is critical for quality control and consumer satisfaction.

3. Cooking and Baking Automation

Depending on the type of energy bar, cooking or baking may be required. Automated ovens or heating tunnels maintain precise temperature and time control to ensure the bars achieve the desired texture and moisture content. Advanced systems include temperature sensors, conveyor speed control, and humidity regulation to maintain uniformity across the production line. By automating these processes, manufacturers can avoid undercooked or overcooked bars, ensuring consistent quality while reducing the need for manual monitoring.

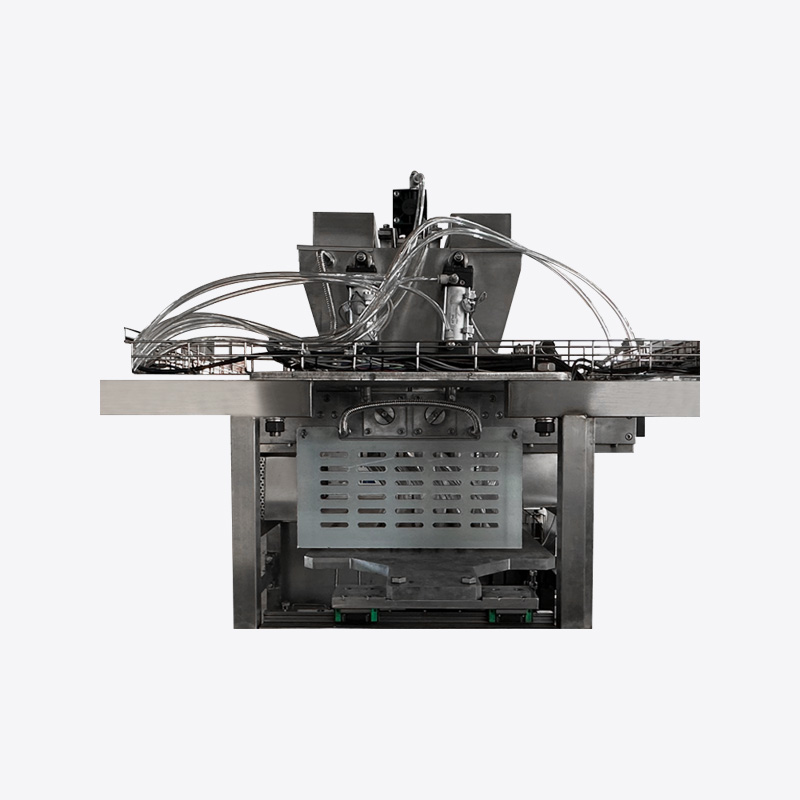

4. Cooling and Coating Automation

After cooking, some energy bars require cooling or coating, such as chocolate or yogurt coatings. Automated cooling tunnels gradually lower the temperature of the bars to stabilize their shape and texture. Coating machines can evenly apply chocolate, yogurt, or other toppings while controlling thickness and coverage. Automation in this stage reduces labor-intensive tasks, prevents contamination, and maintains product consistency, which is especially important for premium or high-volume energy bar production.

5. Packaging Automation

Packaging is one of the most labor-intensive stages in manual production but can be fully automated in modern energy bar lines. Automated packaging machines wrap individual bars, seal them, and place them into boxes or cases. Some systems include labeling, batch coding, and quality inspection sensors to detect misaligned or damaged bars. Automation in packaging not only speeds up production but also ensures hygiene, reduces material waste, and maintains product traceability.

6. Quality Control and Monitoring

Automation also enhances quality control. Sensors and cameras integrated into the production line can monitor weight, size, color, and surface defects in real-time. If any bar does not meet specifications, the system can automatically reject it. Data collected from sensors can be used to analyze production efficiency, detect trends, and optimize processes. This level of automation ensures consistent product quality while minimizing manual inspection efforts.

7. Benefits of Automation in Energy Bar Production

Efficiency: Automated lines can operate continuously with minimal human intervention, significantly increasing production capacity.

Consistency: Uniform mixing, forming, cooking, and packaging ensures each bar meets strict quality standards.

Cost Reduction: Reduced labor requirements lower operational costs, and precise ingredient handling minimizes waste.

Scalability: Automated systems allow manufacturers to scale up production quickly in response to market demand.

Safety and Hygiene: Automation minimizes human contact with food, reducing the risk of contamination.

8. Challenges and Considerations

While automation offers many advantages, it also requires significant upfront investment. Manufacturers need to consider the cost of machinery, installation, and training staff to operate and maintain automated systems. Customization for different bar types, recipes, and packaging formats may also require flexible or modular automation solutions. Additionally, routine maintenance and calibration are essential to ensure long-term reliability.

In conclusion, an energy bar production line can indeed be automated, covering all major stages from ingredient handling to packaging. Automation improves efficiency, consistency, scalability, and hygiene, while reducing labor costs and waste. Modern automated systems also incorporate quality control mechanisms that ensure each bar meets desired standards.

For manufacturers looking to meet growing consumer demand and maintain competitive advantage, investing in automation is a practical and strategic solution. While initial costs may be high, the long-term benefits—higher production rates, consistent quality, and operational efficiency—make automated energy bar production lines a compelling choice for both small-scale and large-scale operations.

English

English Español

Español