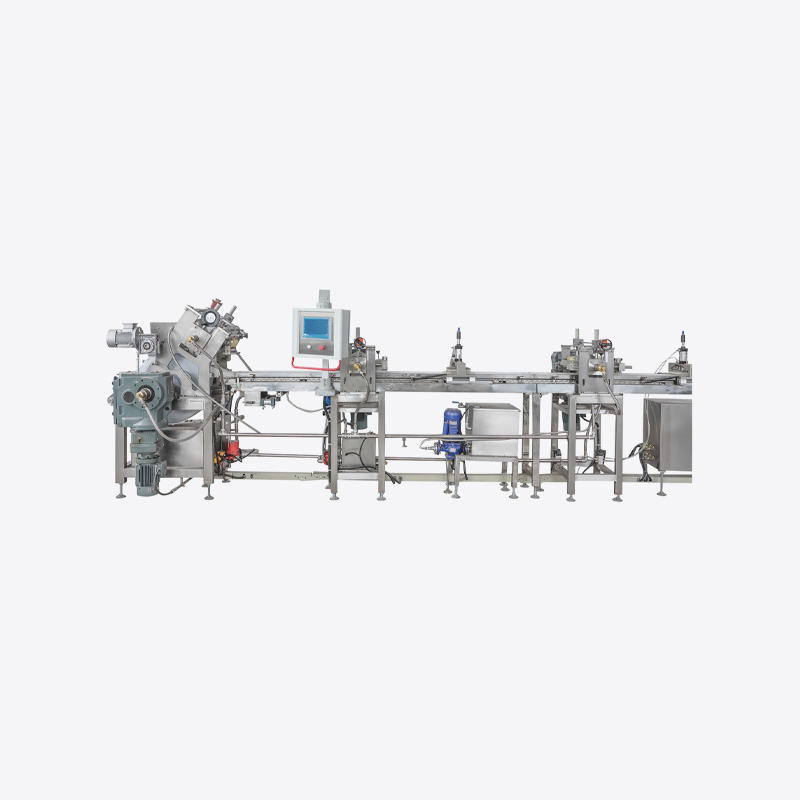

The manufacturing industry is witnessing a remarkable transformation as advanced production solutions reshape processing capabilities across multiple sectors. These developments are revolutionizing operations throughout pharmaceutical, chemical, and food processing industries.

Recent technological breakthroughs have introduced sophisticated processing systems that provide enhanced precision and improved production efficiency. These innovations particularly benefit facilities requiring strict quality control and consistent output in their manufacturing processes.

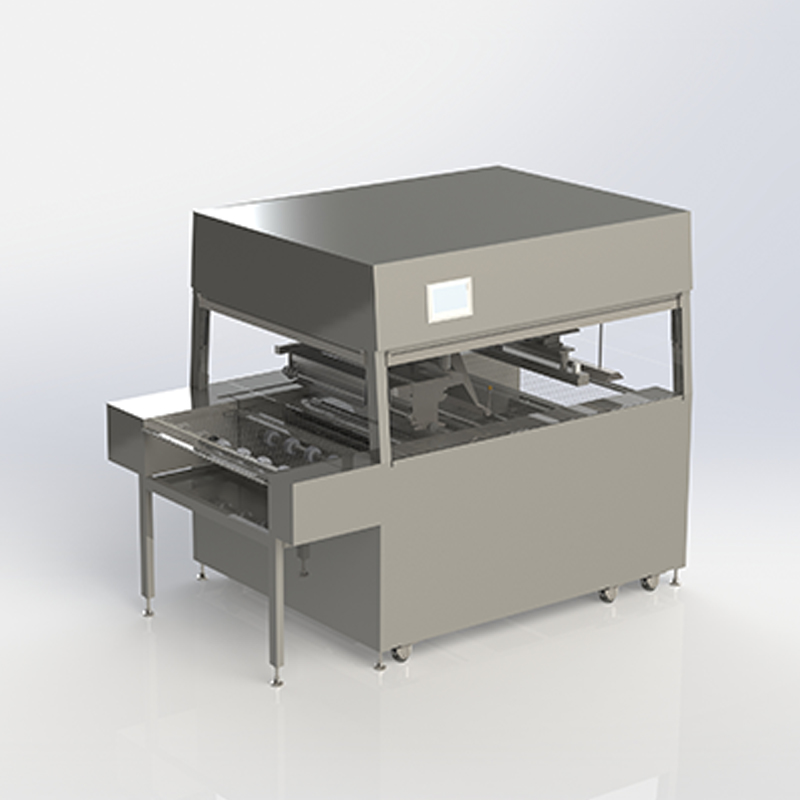

Engineering advances have resulted in improved automation designs that optimize production while ensuring reliable operation. These developments have proven especially valuable in applications where precision and repeatability are crucial.

Industry professionals note that recent design improvements have focused on energy efficiency, allowing better resource utilization and reduced operational costs. This enhanced efficiency has become increasingly important in facilities striving to achieve superior production standards.

Manufacturing facilities worldwide are embracing new-generation equipment that demonstrates improved stability and operational reliability. These systems feature advanced components that extend service intervals while maintaining consistent performance under demanding conditions.

Environmental considerations have influenced recent innovations, with designs focusing on sustainable operation and reduced resource consumption. This eco-conscious approach aligns with global manufacturing trends toward environmentally responsible production methods.

The integration of smart control systems enables operators to monitor and adjust parameters in real-time, ensuring optimal performance and preventing potential issues. This predictive capability has revolutionized maintenance scheduling and reduced unexpected downtime.

Safety features have evolved to include improved protection mechanisms and advanced monitoring systems, enhancing workplace safety and operational security. These advances have made manufacturing operations more reliable and secure.

Research continues in the development of innovative processing configurations that could further improve performance and versatility. These ongoing efforts suggest promising developments in manufacturing technology for future applications.

The technology's adoption in emerging markets has grown significantly, driven by increasing demand for efficient processing solutions. This global expansion has contributed to continuous refinement in design and functionality, benefiting manufacturers worldwide.

Maintenance procedures have been simplified through modular designs and improved access to critical components. This evolution in serviceability has reduced maintenance time and extended operational life spans.

Looking ahead, industry experts anticipate continued innovation focusing on enhanced automation capabilities and improved integration with Industry 4.0 systems. These developments are expected to further optimize production operations and improve efficiency.

The versatility of modern systems has expanded their application across different industries, from pharmaceutical processing to food production. This adaptability has made the technology essential in various manufacturing processes requiring precise control.

Control systems have seen significant advancement, with new technologies enabling improved process management. These improvements have contributed to increased reliability and reduced operational complications.

The integration of advanced materials has enabled more effective processing while maintaining product quality. This enhanced performance has become crucial in maintaining manufacturing standards across various applications.

The impact of these technological advances extends beyond immediate operational benefits, contributing to overall manufacturing excellence and product quality improvement. As the industry continues to evolve, these innovations remain crucial in modern production processes.

English

English Español

Español