The confectionery manufacturing industry continues to evolve with advanced technologies that optimize production processes, where storage tank systems play a pivotal role in maintaining product quality and operational efficiency. These specialized containers have become integral components in modern chocolate processing facilities, ensuring precise temperature control and consistent material handling throughout various production stages.

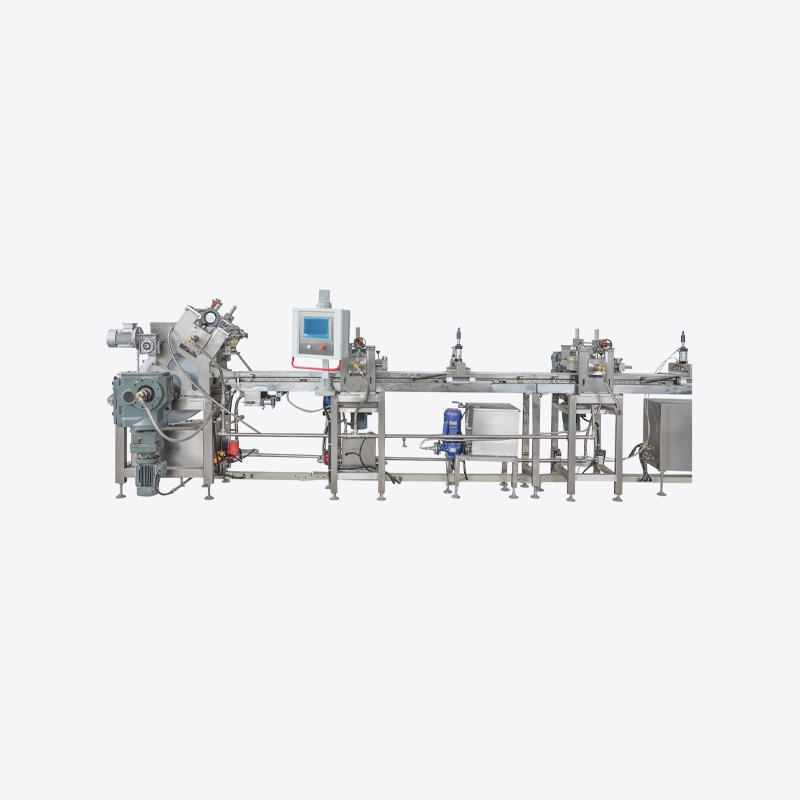

Modern storage solutions for chocolate processing incorporate sophisticated thermal regulation features that maintain ideal viscosity for different chocolate formulations. The tanks' insulated designs prevent temperature fluctuations that could compromise product texture or appearance, while integrated agitation systems ensure homogeneous mixing of ingredients. This technological approach supports continuous production flows while meeting stringent food safety requirements.

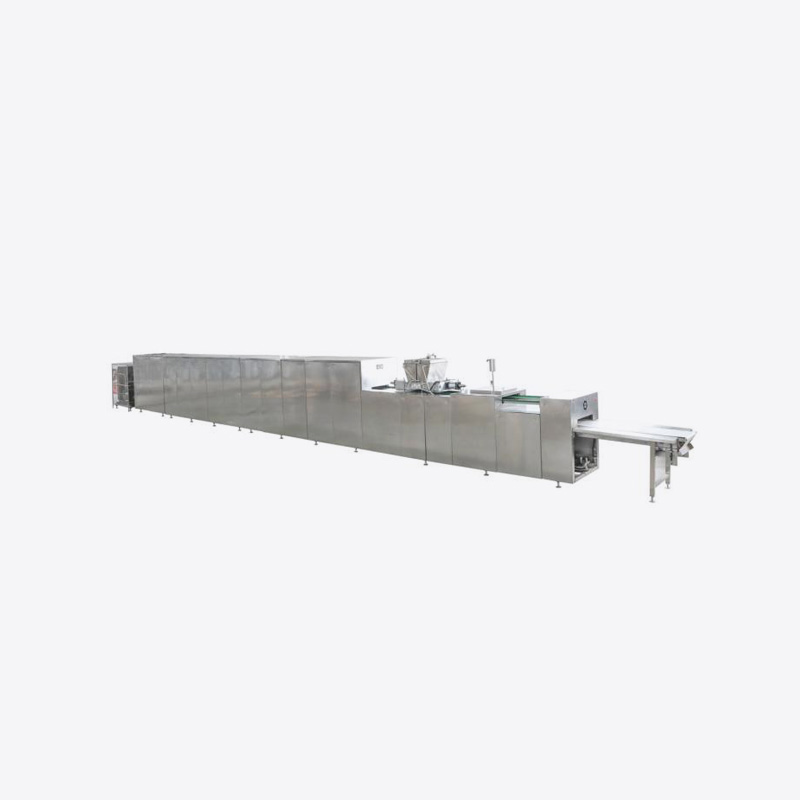

Material handling efficiency has significantly improved through the implementation of these specialized tanks in confectionery plants. Their capacity to store large quantities of tempered chocolate enables uninterrupted operation of enrobing and molding lines, reducing downtime between production batches. The seamless integration with pumping and piping systems allows for precise delivery to coating stations or depositors, maintaining product consistency across high-volume outputs.

Sanitary design principles guide the construction of contemporary storage tanks, featuring smooth surfaces and minimal joints that facilitate thorough cleaning. This design philosophy aligns with food safety protocols, reducing potential contamination risks during extended production runs. Advanced models incorporate automated cleaning systems that optimize hygiene maintenance while minimizing water and chemical usage.

Energy efficiency has become a key focus in recent storage tank developments. Innovative insulation materials and heat recovery systems help reduce power consumption during chocolate tempering and storage processes. These sustainable features support manufacturers' environmental initiatives while maintaining operational cost-effectiveness in competitive markets.

The versatility of modern storage systems allows adaptation to various chocolate formulations, from dark and milk varieties to specialized compound coatings. This flexibility enables manufacturers to efficiently switch between product lines without extensive reconfiguration, responding quickly to changing market demands and seasonal production requirements.

For confectionery businesses seeking to upgrade their production capabilities, professional guidance on storage system selection and integration can help optimize their manufacturing processes. Technical expertise ensures proper sizing and specification of equipment to match specific production volumes and product characteristics.

English

English Español

Español