Understanding Chocolate Enrobers in Confectionery Production

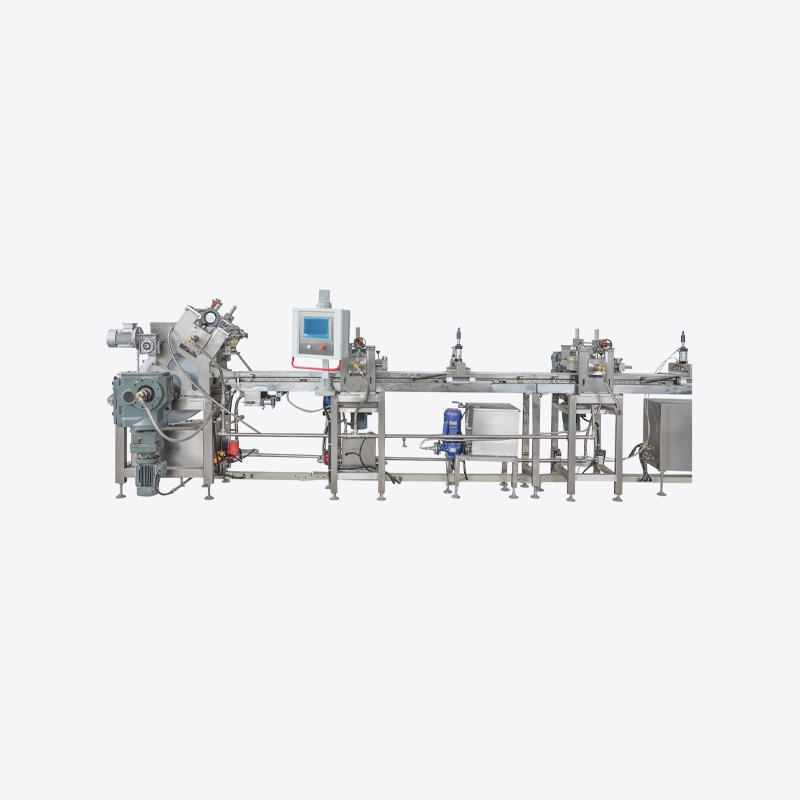

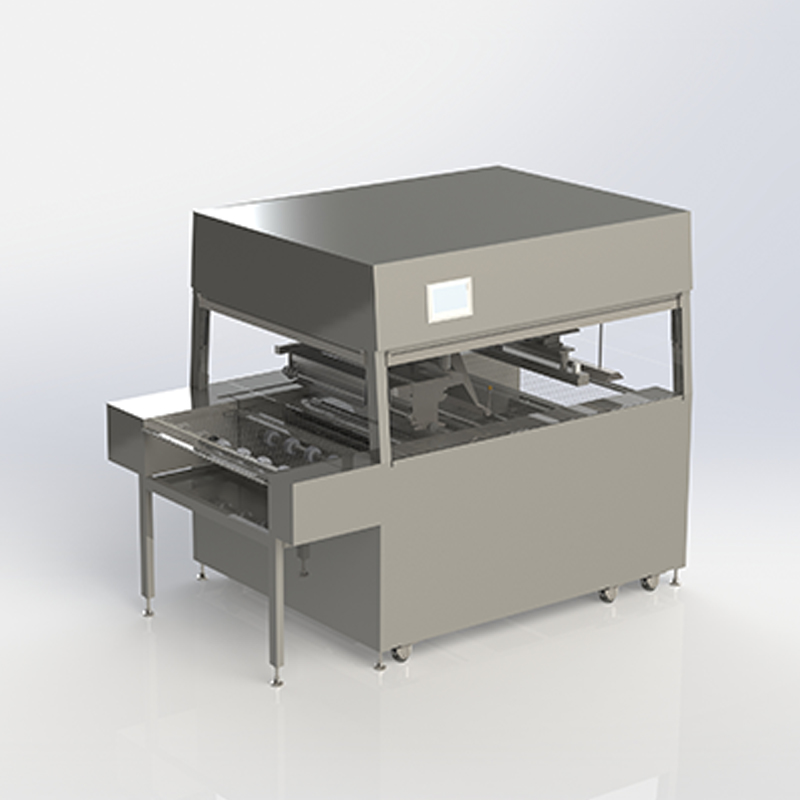

Chocolate enrobers are vital machinery in the confectionery industry, designed to coat products uniformly with chocolate or other coatings. They streamline production, reduce labor, and ensure consistent quality, which is crucial for meeting both consumer expectations and regulatory standards. From chocolate bars to pralines and biscuits, enrobers enable manufacturers to achieve precise coating thickness, even coverage, and glossy finishes without manual intervention.

Modern enrobers combine automation, precise temperature control, and adjustable conveyor systems to produce large quantities of coated products efficiently. Their reliability and versatility make them indispensable for both artisanal and industrial chocolate production.

How Chocolate Enrobers Ensure Coating Consistency

One of the primary functions of a chocolate enrober is to provide uniform coating thickness across all products. This is achieved through a combination of controlled chocolate flow, adjustable curtain settings, and conveyor speed regulation. By standardizing these parameters, enrobers eliminate human error and variations caused by manual dipping methods.

Consistent coating is essential for product appearance, taste, and shelf life. Uneven chocolate layers can lead to issues such as air pockets, uneven melting, or poor visual appeal, all of which can affect brand perception and consumer satisfaction.

Key Features That Maintain Uniform Coating

- Adjustable chocolate curtain height and flow for precise coverage

- Controlled conveyor speed for consistent exposure time

- Temperature-regulated chocolate tanks to maintain fluidity and viscosity

Efficiency Benefits for High-Volume Production

Chocolate enrobers significantly enhance production efficiency by automating the coating process. They reduce the need for manual labor, minimize product handling, and increase throughput. For high-volume manufacturers, this translates to faster production cycles and consistent output quality without sacrificing speed.

Automation also reduces waste by applying the exact amount of chocolate required for coating. Overuse or uneven application can result in excess chocolate consumption and rejected products, which enrobers help minimize through precise dosing and controlled flow.

Enhancing Product Appearance and Quality

Beyond consistency, chocolate enrobers improve the overall appearance and texture of confectionery products. Features like vibrating tables or rollers remove excess chocolate, creating a smooth, glossy finish. Proper tempering within enrobers ensures that chocolate sets correctly, providing the desired snap, shine, and mouthfeel.

The ability to maintain uniform temperature and controlled cooling prevents crystallization issues and fat bloom, which can compromise both visual appeal and product quality. This precision is particularly important for premium chocolates where aesthetics directly impact brand reputation.

Visual and Textural Quality Enhancements

- Vibrating or rolling mechanisms to remove excess coating

- Controlled tempering to maintain shine and texture

- Even cooling systems to prevent bloom or cracking

Types of Chocolate Enrobers and Their Applications

Chocolate enrobers are available in several types depending on production needs. Standard enrobers are suitable for small to medium batches, while high-capacity industrial enrobers handle large-scale operations with continuous flow. Specialized enrobers, such as those designed for enrobing bars, pralines, or filled chocolates, offer specific features tailored to product shape and complexity.

Choosing the right enrober ensures optimal coating quality, production speed, and minimal maintenance. Factors such as chocolate viscosity, product size, and desired coating thickness must be considered when selecting an enrober for specific applications.

Comparing Manual vs Automated Enrobing

| Feature | Manual Enrobing | Automated Enrobing |

| Consistency | Variable | Highly consistent |

| Production Speed | Slow | Fast, continuous |

| Labor Requirement | High | Low, automated |

Maintenance and Longevity Considerations

Maintaining chocolate enrobers is essential for consistent performance. Regular cleaning prevents chocolate buildup and contamination, while periodic inspection of belts, curtains, and pumps ensures smooth operation. Using high-quality chocolate and proper tempering minimizes wear on mechanical components and extends machine lifespan.

Preventive maintenance schedules, coupled with operator training, reduce downtime and maximize efficiency. A well-maintained enrober continues to deliver uniform coatings, consistent quality, and reliable output over years of production.

Conclusion: The Indispensable Role of Chocolate Enrobers

Chocolate enrobers are essential for ensuring consistent coating quality, improving efficiency, and enhancing product appearance in confectionery production. They minimize human error, reduce waste, and maintain uniformity across large batches, meeting both production and consumer standards.

By investing in high-quality enrobers and implementing proper maintenance, manufacturers can achieve operational efficiency, product excellence, and long-term reliability, making chocolate enrobers a cornerstone of modern chocolate manufacturing.

English

English Español

Español