What Factors Make a Chocolate Depositor Factory Suitable for Consistent Production

Choosing the right chocolate depositor factory is a practical decision that affects final texture, yield stability, and daily throughput. A well-matched production partner supplies equipment and processes that help maintain uniform portioning, reduce waste, and simplify cleaning routines. This article outlines the main considerations manufacturers and buyers should discuss before committing to a production line.

Hygienic construction and serviceability

A plant designed for food manufacture uses materials and finishes that withstand regular sanitation. Smooth, accessible surfaces and hygienic joins reduce places where residue can gather. Modular assemblies and tool-free access points shorten cleaning cycles and make routine inspections straightforward. Expect clear guidance on approved cleaning agents and checkpoints that help teams validate each sanitation event.

Accurate dosing and gentle handling

Consistent portioning starts with a deposit mechanism that meters product reliably while preserving structure. Machines that control speed, stroke, and fill volume minimize variation between portions and between batches. Gentle transfer paths and short residence times limit thermal stress and avoid overworking delicate formulations, which helps preserve mouthfeel and visual appearance.

Robust process control and data logging

Repeatable results depend on holding key variables within predefined windows. A control system that stores recipes, logs run parameters, and flags deviations supports repeatability. Integration with plant automation enables correlation between upstream mixing and downstream depositing, helping teams identify and correct sources of drift before they affect many cartons.

Clean-in-place options and downtime planning

Where possible, choose equipment that supports in-line sanitation to cut manual intervention and reduce production stops. When manual cleaning is required, clearly documented procedures and accessible components reduce the time equipment is offline. Suppliers should provide a maintenance schedule with estimated intervals so production planners can reserve capacity for preventive work rather than reactive repairs.

Spare parts strategy and wear monitoring

Portioning elements, seals, and bearings are subject to wear that can change fill accuracy. A clear spare parts list, recommended stocking levels, and predictable lead times help avoid extended stoppages. Some manufacturers offer starter kits for commissioning runs, which smooth the transition from trial to routine output.

Flexible recipe handling and rapid changeover

A factory that supports multiple formats and fillings reduces setup time when product lines change. Features such as quick-change nozzles, programmable recipes, and adaptable conveyors enable the same line to handle different shapes or viscosities with minimal adjustment. Fast changeovers improve utilization and lower the risk of cross-contamination.

Operator training and procedural documentation

Even well-engineered systems need competent operators. Comprehensive onboarding covering startup, shutdown, acceptable parameter ranges, and corrective actions reduces variability introduced by different shifts. Practical checklists and simple troubleshooting flowcharts help staff make consistent decisions under pressure.

Pilot testing and scale validation

Before full-scale rollout, trial runs using representative formulations give a realistic view of portioning behavior and downstream compatibility. Test reports that include visual checks, weight variation statistics, and sensory notes form the baseline for production acceptance criteria. Using those benchmarks during commissioning reduces guesswork and accelerates stable operation.

Integration with downstream processes

A depositor works as part of a broader line that may include enrobing, cooling, or packing. Compatibility with conveyor speeds, hopper refill systems, and packaging equipment is essential to avoid bottlenecks. Discuss how the machine will coordinate with adjacent stations and whether synchronization features or buffer solutions are recommended.

Quality assurance and sampling plans

Objective measures such as weight variance, portion geometry, and surface finish help teams track consistency. Suppliers can propose sampling frequencies, acceptance limits, and corrective workflows that align with internal quality programs or external audit requirements. Clear documentation of these routines supports traceability and continuous improvement.

After-sales support and remote assistance

Prompt technical help shortens recovery time when issues arise. Remote diagnostics, spare-part dispatch options, and scheduled service visits contribute to predictable uptime. Before purchase, agree on support channels, expected response times for different fault categories, and escalation paths so expectations are aligned.

Environmental and footprint considerations

Energy consumption, wastewater from cleaning activities, and physical footprint influence operating costs and layout decisions. A factory should present practical measures to minimize resource use and ease integration into existing facilities, including recommended utility connections and access points for maintenance.

Commercial clarity and acceptance testing

Transparent commercial terms, clear delivery milestones, and defined acceptance tests protect both parties. Acceptance criteria should be measurable and tied to pilot data or agreed sampling plans. Include commissioning activities, initial operator training, and a basic spare-parts kit in the contract to reduce surprises during start up.

How a Chocolate Depositor Factory Can Improve Efficiency in Your Production Line

A well-chosen depositor partner can make a measurable difference to throughput, yield, and labour use across a confectionery line. Rather than treating the portioning station as an isolated purchase, consider it as a node in a wider system where design, controls, sanitation, and support all affect daily output. The paragraphs below outline practical ways a chocolate depositor factory can help you streamline operations and reduce waste while keeping product quality consistent.

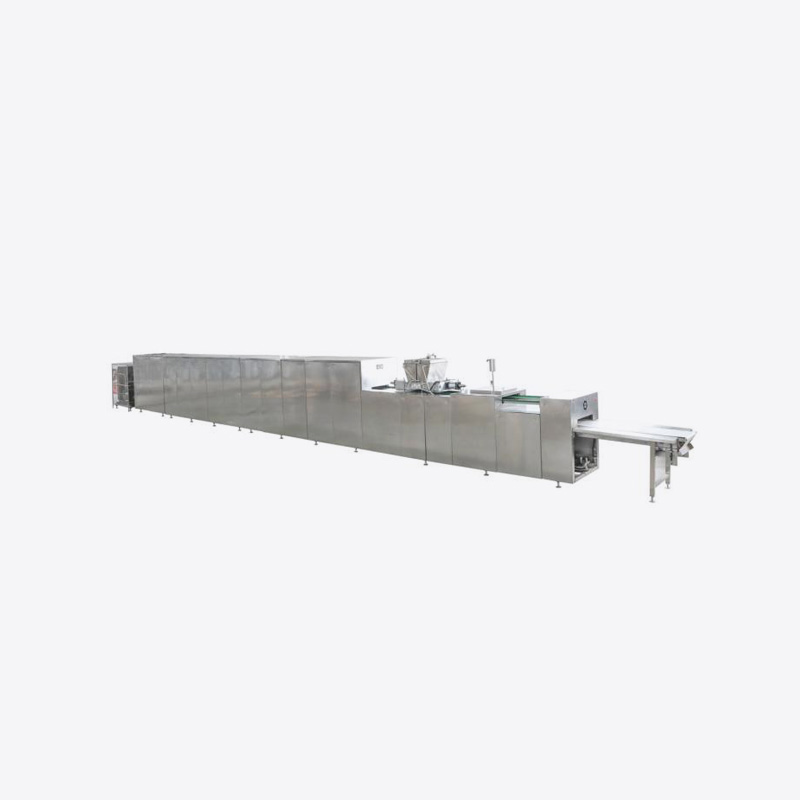

Streamlined line layout and material flow

Manufacturers that plan equipment layout with line flow in mind help avoid bottlenecks. Thoughtful positioning of hoppers, conveyors, and feed systems reduces unnecessary transfers and operator movement. When the depositing unit is configured to match upstream mixing and downstream cooling or packing, the whole line runs more smoothly and cycle times become more predictable.

Precise portioning to reduce rework and giveaway

Accurate metering and steady fill behaviour lower the incidence of overweight or underweight portions, which otherwise lead to trimming, rework, or product rejection. A depositor that maintains consistent deposit volume reduces material giveaway and makes quality checks more efficient, saving both ingredient cost and inspection time.

Faster changeovers and format flexibility

Production schedules often require frequent product changes. Equipment designed for rapid nozzle swaps, programmable recipes, and simple product transitions shortens changeover intervals. Less time spent resetting means more production hours available for running product, which directly improves line utilization.

Sanitation features that cut cleaning time

Cleaning routines account for a significant portion of planned downtime in food plants. Depositor designs that allow quick access to product-contact surfaces, or that support in-line cleaning, reduce the labour and time required for sanitation. Clear guidance on approved cleaning methods and strategic inspection points further speeds validation and restart.

Controls, automation, and data capture

Integration with factory automation enables synchronised operation across stations. When the depositor logs run parameters, conveyor speeds, and fault events, operators can spot trends that cause slowdowns. Recipe storage and automatic parameter recall remove operator guesswork and make each run more consistent, which lowers the frequency of corrective stoppages.

Operator ergonomics and training to limit human error

Human factors shape many everyday losses. Equipment designed with intuitive controls, reachable adjustment points, and clear status indicators helps operators perform tasks faster and with fewer mistakes. Suppliers that provide practical training, checklists, and troubleshooting flowcharts make it simpler for teams to respond to common issues without lengthy delays.

Spare parts strategy and preventive maintenance

Unexpected component failures are a frequent source of unscheduled downtime. A factory partner that supplies a spare-parts kit for commissioning and recommends a preventive maintenance program helps you avoid long waits for replacements. Predictable maintenance intervals and accessible parts lists make it easier to plan outages and keep the line running at steady capacity.

Pilot testing and acceptance criteria to reduce ramp-up time

Pilot trials using representative fillings and shapes create benchmarks that reduce trial-and-error during start up. Clear acceptance tests based on weight variation, visual checks, and cycle stability give both buyer and supplier a shared definition of readiness. Using these benchmarks during commissioning shortens the time to stable operation.

Energy and resource efficiency

Optimised depositors minimise unnecessary heating, overfeeding, or idle running. Equipment that supports gentle handling and controlled transfers reduces waste caused by breakage or spoilage. Attention to utilities — for example, reasonable compressed air use or conservative power draw strategies — lowers operational cost per unit produced.

Quality assurance and inline sampling

Inline or frequent spot checks that are simple to perform reduce the time spent on lab analysis and corrective loops. Suppliers can recommend sampling plans and acceptance thresholds that align with your quality program, enabling faster corrective action and fewer stops for investigation.

Responsive technical support and remote diagnostics

When issues do arise, rapid troubleshooting is key to limiting lost production. Providers offering remote diagnostics, clear escalation procedures, and service networks reduce the mean time to repair. Agreed response times and documented support routes make it easier to manage disruptions and resume normal output sooner.

| Area | Practical effect |

|---|---|

| Layout & flow | Fewer bottlenecks, steadier cycle times |

| Portion accuracy | Less rework and ingredient waste |

| Changeover design | Shorter setup windows, higher uptime |

| Cleaning features | Reduced sanitation downtime |

| Automation & logging | Faster root-cause analysis, stable runs |

| Training & ergonomics | Fewer operator errors, quicker recovery |

| Spare parts plan | Reduced unscheduled stops |

| Pilot validation | Faster ramp-up to target throughput |

| Energy use | Lower operating cost per unit |

| Support | Shorter repair windows, predictable recovery |

Efficiency gains usually come from combining design detail with practical services. A chocolate depositor factory that works with you on layout, control strategies, sanitary practice, spare stocking, and staff readiness delivers more than a machine: it delivers a production asset that helps you run the line with fewer interruptions and lower waste. When procurement emphasizes measurable improvements and clear handover procedures, production teams can convert those gains into consistent daily output and steadier margins.

Which Features to Consider When Choosing a Chocolate Depositor Factory

Selecting the right partner for portioning and depositing equipment influences product consistency, line uptime, and overall operating cost. A thoughtful choice reduces rework, shortens changeovers, and helps production teams meet routine targets. Below are practical features and selection points to guide procurement and technical discussions. The phrase Chocolate Depositor Factory appears here to match search intent; related terms are used sparingly throughout the text.

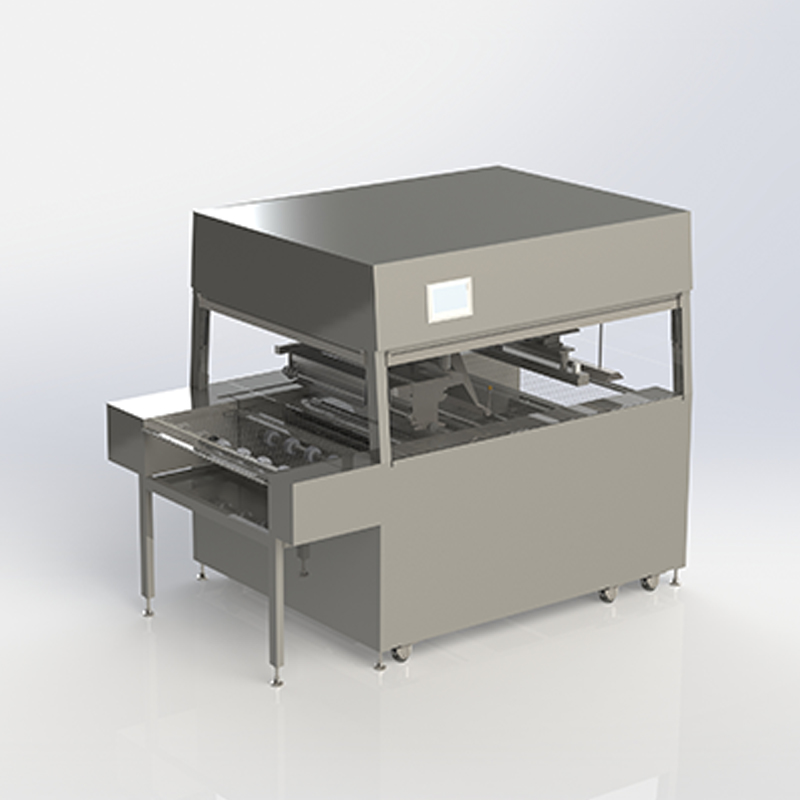

Design and hygienic construction

Hygienic design is non-negotiable for food production. Seek machines and assemblies with smooth finishes, sanitary joins, and minimal crevices where residue can collect. Access points that allow rapid inspection and tool-free removal of product-contact parts speed cleaning and lower contamination risk. Ask for written cleaning procedures and documentation of approved detergents or methods.

Portion accuracy and repeatability

Consistent fill weight and shape reduce giveaway and customer complaints. Look for depositors that offer programmable recipes, stable actuation, and gentle handling that preserve structure. Recipe recall and automatic parameter recall support repeatable runs between shifts and batches, cutting the need for frequent manual adjustments.

Changeover simplicity and format flexibility

Production schedules often demand frequent format shifts. Features such as quick-change nozzles, modular tooling, and recipe-based presets shorten setup time. A line that accommodates multiple sizes, fillings, or molds with limited manual intervention improves utilization and lowers labor cost per run.

Control, connectivity, and logging

Integrated controls that store recipes, log run data, and provide alarm records help production teams detect drift early. Ability to connect to plant automation allows synchronization with upstream and downstream stations, which reduces bottlenecks. Data logs also support traceability and simplify root-cause analysis when a deviation occurs.

Cleaning-in-place and serviceability

If the process allows, cleaning-in-place routines cut manual labor and reduce downtime for sanitation. Where CIP is impractical, designs that permit fast manual cleaning with clear step-by-step guides are valuable. Consider how easily seals, valves, and feed components can be inspected and replaced during scheduled maintenance windows.

Material handling and hopper design

Uniform feed into the depositor prevents air pockets and inconsistent portioning. Hopper geometry and gentle transfer paths reduce shear on sensitive fillings and avoid entrained air that causes weight variation. Features that minimize product stagnation also help when switching between formulations.

Wear management and spare parts support

Portioning equipment contains components that wear over time. A clear parts list, recommended spare inventory, and accessible service channels reduce the risk of extended outages. Ask about lead times for common wear items and whether a starter parts kit is provided at commissioning.

Operator ergonomics and safety

Controls should be intuitive, with clear status indicators and reachable adjustment points. Emergency stops, safe lockout procedures, and ergonomic access reduce the chance of accidents and speed routine tasks. Training materials and on-site instruction for operators and maintenance staff are important to maintain consistent handling practices.

Validation, trials, and acceptance testing

Before committing to volume production, pilot runs with representative formulations give realistic confirmation of deposit behavior and downstream compatibility. Insist on measurable acceptance criteria that reflect weight variance, visual checks, and cycle stability so both parties share a clear definition of satisfactory performance.

Integration with downstream equipment

A depositor is only one part of a line. Confirm compatibility with conveyors, cooling tunnels, enrobers, and packaging machines. Synchronization features or buffer solutions can reduce line stoppages and make throughput more predictable.

Energy and utility considerations

Understand the utility demands of the equipment and how they fit into your facility. Conservative designs that minimize idle running, unnecessary heating, or compressed air use lower operating costs and simplify integration with existing services.

Quality assurance and sampling plans

Suppliers that recommend practical sampling frequencies, acceptable tolerance bands, and corrective workflows help teams detect and address issues quickly. Documentation for these routines supports audit readiness and continuous improvement efforts.

After-sales service and remote assistance

Prompt access to technical help shortens repair time. Remote diagnostics, straightforward escalation procedures, and scheduled preventive visits reduce mean time to repair. Agree on support channels and expected response times before finalizing a purchase.

Commercial transparency and delivery terms

Clear pricing for spare parts, transparent maintenance estimates, and defined delivery milestones reduce surprises. Include commissioning, initial training, and a basic spare-parts kit in the contract to smooth the transition from installation to stable operation.

| Feature area | Why it matters |

|---|---|

| Hygienic design | Speeds cleaning and reduces contamination risk |

| Portion repeatability | Lowers giveaway and rework |

| Changeover design | Increases uptime and line flexibility |

| Controls & logging | Supports traceability and consistent runs |

| CIP/serviceability | Shortens sanitation downtime |

| Hopper design | Stabilizes feed and reduces air entrainment |

| Spare parts plan | Minimizes unscheduled stops |

| Ergonomics & safety | Reduces errors and improves response time |

| Pilot testing | Confirms performance before full rollout |

| Integration | Prevents downstream bottlenecks |

| Support & warranties | Ensures predictable after-sales care |

When evaluating a Chocolate Depositor Factory, balance written evidence against sales claims. Request pilot data, maintenance schedules, and sample run logs where possible. Prioritize features that reduce downtime, simplify sanitation, and preserve portion consistency across varied recipes. A clear set of acceptance tests and documented support commitments will make installation and ongoing operation more predictable and cost-effective.

English

English Español

Español