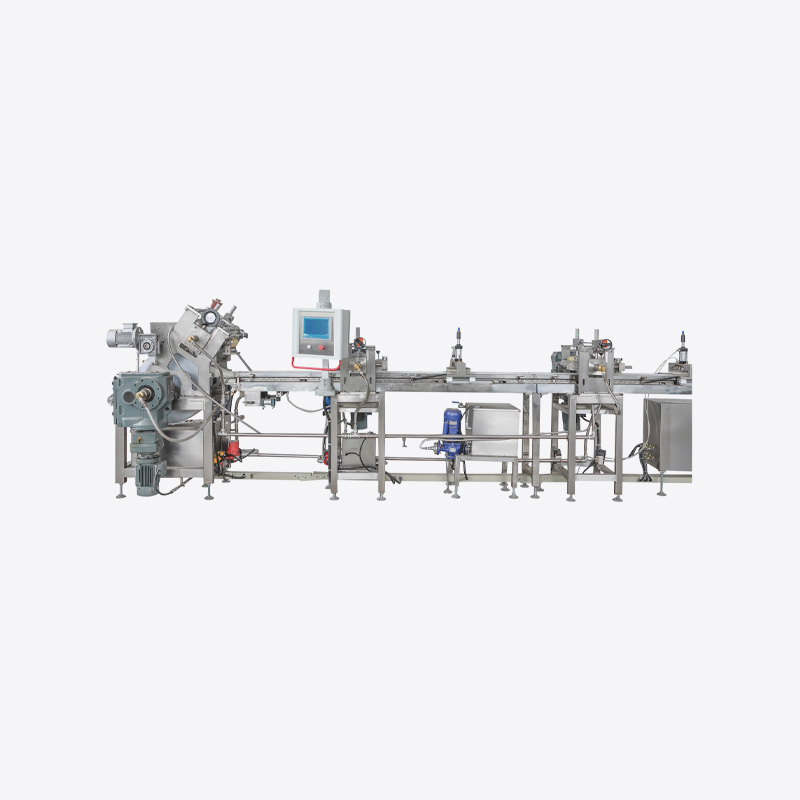

Understanding Chocolate Enrobers

Chocolate enrobers are essential machines in the confectionery industry, designed to provide consistent chocolate coating on products such as biscuits, nuts, candies, and chocolates. Using an enrobing machine ensures that each item receives a uniform layer of chocolate, improving both appearance and texture. Modern chocolate enrobers combine automation with precise control, making them indispensable for large-scale production and premium quality chocolate products.

Key Components of a Chocolate Enrober

A high-quality chocolate enrober consists of several critical components that work together to guarantee consistent chocolate coating:

- Chocolate melting and tempering system: Maintains chocolate at optimal viscosity and temperature for smooth and even coating.

- Chocolate curtain or waterfall: Provides continuous chocolate flow for uniform coverage on all product surfaces.

- Conveyor belt system: Transports products at controlled speeds to achieve precise coating thickness.

- Air knives: Remove excess chocolate to ensure a consistent layer and prevent waste.

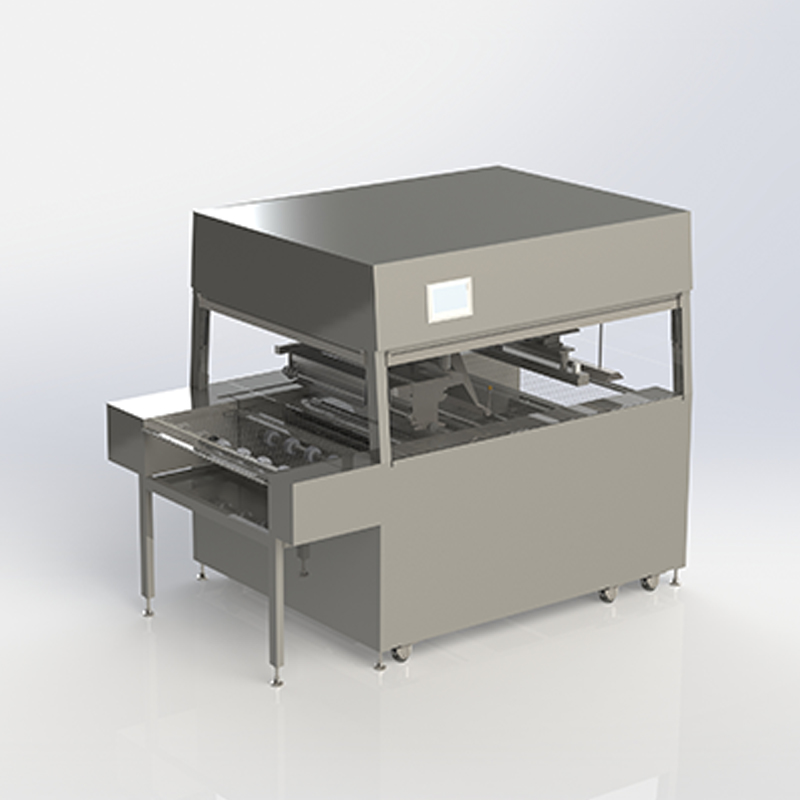

- Cooling tunnel: Quickly sets the chocolate, preserving shine, texture, and structural integrity.

How Chocolate Enrobers Improve Coating Consistency

Ensuring a consistent chocolate coating is critical for visual appeal, taste, and customer satisfaction. Chocolate enrobers enhance consistency through advanced technology and precise control:

Precise Temperature Control

Temperature affects chocolate viscosity and crystallization. A properly calibrated enrobing machine maintains chocolate at the ideal temperature, preventing issues such as bloom, streaks, or uneven gloss. This ensures every product receives a smooth, high-quality chocolate coating.

Uniform Chocolate Flow

The chocolate curtain in enrobers guarantees a consistent flow of chocolate over each product. Unlike manual dipping, which can produce uneven coating, automation ensures all pieces are coated uniformly, enhancing both appearance and texture.

Controlled Coating Thickness

Enrobers allow precise adjustment of conveyor speed and air knife pressure to control coating thickness. This prevents dripping, pooling, or overly thin layers, ensuring that each product receives the optimal chocolate layer for taste and visual quality.

Enhancing Product Quality Through Automation

Automating the chocolate coating process reduces variability and improves overall quality. Benefits of using chocolate enrobers include:

- Consistent appearance and thickness of chocolate coating across all products.

- Improved mouthfeel and texture due to even distribution of chocolate.

- Reduced contamination risk with minimal human contact.

- Faster production cycles without compromising quality.

Optimizing Enrobing Parameters for Best Results

To maximize efficiency and quality, operators must fine-tune key enrobing parameters:

Chocolate Viscosity

Chocolate viscosity determines flow and coating quality. Thinner chocolate flows easily over intricate shapes, while thicker chocolate provides robust layers for bars and tablets. Proper viscosity ensures smooth coverage without streaks or gaps.

Conveyor Speed

The conveyor speed affects coating thickness. Slower speeds allow more chocolate to adhere, creating thicker coatings, while faster speeds result in thinner layers. Finding the optimal speed ensures consistent chocolate coating while maintaining production efficiency.

Air Knife Pressure

Air knives remove excess chocolate, controlling layer thickness and preventing drips. Adjusting air pressure allows for precise coating on delicate or irregularly shaped products, ensuring a high-quality finish.

Practical Applications in Confectionery

Chocolate enrobers are versatile and widely used for various confectionery applications:

- Chocolate bars and tablets: Ensures even coverage and glossy appearance.

- Filled chocolates: Provides uniform shells around fillings.

- Nuts and dried fruits: Coats individual pieces without clumping.

- Baked goods: Applies chocolate layers to biscuits, cookies, and pastries.

- Seasonal or themed products: Supports high-volume production with consistent quality.

Troubleshooting Common Coating Issues

Even with automation, chocolate enrobers may face coating challenges. Common issues and solutions include:

| Issue | Possible Cause | Solution |

| Uneven coating | Improper chocolate viscosity or conveyor speed | Adjust temperature or conveyor speed |

| Chocolate bloom | Incorrect tempering or cooling rate | Calibrate tempering and cooling tunnel |

| Dripping chocolate | Low air knife pressure | Increase air knife pressure or reduce chocolate flow |

| Thin coating | Chocolate too thick or conveyor too fast | Adjust viscosity or slow conveyor speed |

Conclusion

Chocolate enrobers are essential for manufacturers seeking consistent chocolate coating and superior product quality. By combining automation, precise temperature control, uniform chocolate flow, and adjustable coating parameters, enrobers enhance production efficiency, reduce waste, and ensure visually appealing, high-quality chocolates. Optimizing the enrobing process guarantees that every product meets consumer expectations and maintains a competitive edge in the confectionery market.

English

English Español

Español