The Shift Toward Automation in Chocolate Manufacturing

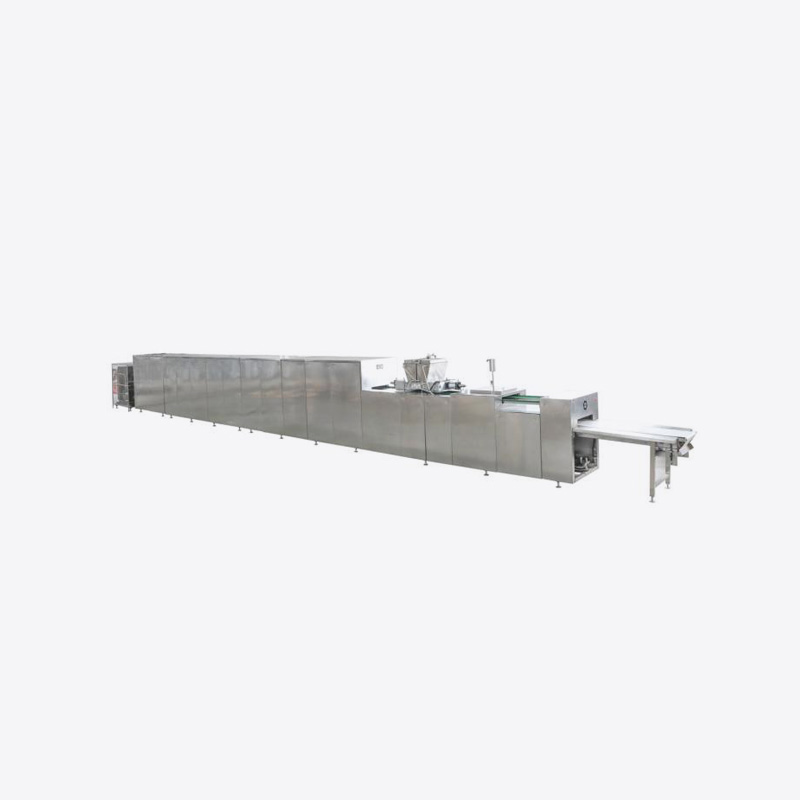

Chocolate production has historically relied on a mix of manual labor and semi-automated processes. However, rising demand, strict quality standards, and the need for cost efficiency are driving manufacturers to adopt fully automated production lines. Automation not only streamlines the chocolate-making process but also enhances consistency, hygiene, and overall output.

By integrating robotics, sensors, and computer-controlled machinery, chocolate factories can now achieve precise ingredient mixing, consistent molding, and uniform packaging at scale. This evolution reflects both technological advancements and growing consumer expectations for high-quality chocolate products.

Key Components of Automated Chocolate Production Lines

Automated chocolate production lines encompass several stages, each optimized for efficiency and precision. The integration of intelligent machinery allows manufacturers to monitor every step, from raw material handling to final packaging.

Raw Material Processing and Ingredient Control

- Automated grinders and melangers ensure consistent cocoa particle size.

- Precise weighing and dispensing systems control sugar, milk, and cocoa ratios.

- Temperature-controlled mixing tanks maintain optimal viscosity and texture.

Tempering and Molding Automation

Tempering is critical for chocolate quality, determining shine, snap, and mouthfeel. Automated tempering machines precisely control temperature cycles, ensuring uniform crystal formation. Mold filling robots then deposit exact amounts of chocolate into molds, reducing human error and waste.

Advanced vision systems can inspect each mold for defects, enabling real-time adjustments. This level of control improves the visual and textural quality of the finished product while minimizing the need for rework.

Efficiency and Scalability Benefits

Automation significantly increases throughput, allowing factories to meet growing market demands without proportional increases in labor costs. Machines operate continuously, maintaining steady production rates and minimizing downtime associated with manual processes.

Scaling production is also simpler with automated systems. Adding additional molding stations, packaging units, or conveyor modules can be done with minimal disruption, making it easier to respond to seasonal demand fluctuations or new product launches.

Quality Consistency and Waste Reduction

One of the primary motivations for automation is consistent product quality. Human operators, despite experience, introduce variability in mixing, molding, and tempering. Automated lines enforce strict adherence to process parameters, resulting in uniform taste, texture, and appearance.

Waste reduction is another significant advantage. Automated dosing, precise mold filling, and real-time quality checks reduce material loss during production. Less chocolate is discarded due to defects, improving cost efficiency and sustainability.

Key Automation Features for Quality Control

- Vision systems for mold and surface defect detection

- Sensors monitoring temperature, humidity, and viscosity

- Data logging for process traceability and compliance

Packaging and Logistics Integration

Automated chocolate production lines often include integrated packaging systems. Chocolate bars, truffles, and molded chocolates can be wrapped, boxed, and labeled with minimal manual intervention. Conveyor systems, robotic arms, and automated sealing machines optimize speed and accuracy.

Integration with inventory management systems allows real-time tracking of production volumes, packaging counts, and batch information. This connectivity improves supply chain visibility and reduces the risk of stockouts or overproduction.

Comparing Manual, Semi-Automated, and Fully Automated Lines

| Feature | Manual Line | Semi-Automated Line | Fully Automated Line |

| Labor Requirement | High | Moderate | Low |

| Output Consistency | Variable | Moderate | High |

| Waste Reduction | Low | Moderate | High |

Challenges and Considerations in Automation

Despite its advantages, automation requires significant investment and technical expertise. Initial setup costs for machinery, sensors, and robotics can be high. Additionally, maintenance, software updates, and operator training are essential for long-term reliability.

Factories must also consider flexibility. Fully automated systems may struggle with frequent recipe changes or small-batch artisanal products. Hybrid approaches that combine automation with manual processes can sometimes provide the best balance between efficiency and adaptability.

The Future of Automated Chocolate Production

As consumer demand for consistent, high-quality chocolate continues to grow, automation is expected to become the standard in both large-scale and mid-sized factories. Advances in robotics, AI, and process monitoring will further optimize production, reduce waste, and ensure product safety.

Ultimately, automated chocolate production lines enable manufacturers to meet market demands efficiently while maintaining the premium quality consumers expect. This technological evolution represents a strategic investment in productivity, consistency, and long-term competitiveness.

English

English Español

Español