How a Chocolate Depositor Changes Production Flow

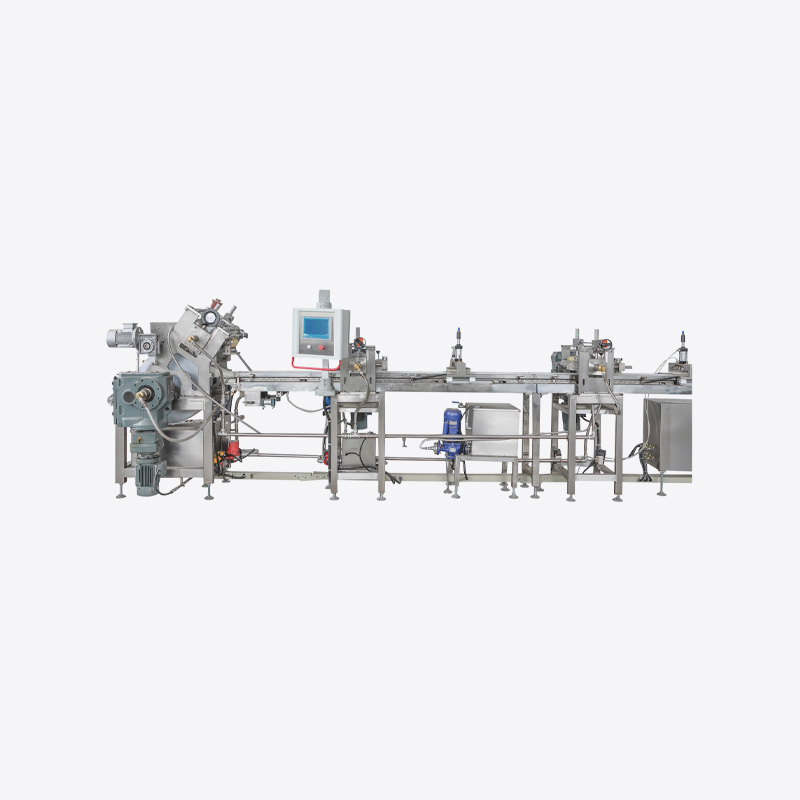

A chocolate depositor is not merely a piece of automation; it's a production node that changes throughput, consistency, and labor dynamics. In practical terms, a depositor replaces repetitive manual pouring or spooning with a controlled, repeatable process. This reduces cycle time per SKU, lowers variation in portion weight, and standardizes fill patterns (solid, shell, layered). For factories scaling from artisan batches to mid-volume runs (hundreds to thousands of pieces per hour), a depositor can transform a bottleneck operation into a continuous, predictable step in the production line.

Core Mechanisms That Deliver Efficiency

Understanding the mechanisms helps you evaluate whether a depositor will improve your operation. Key features that drive efficiency include:

- Metered Dispensing: precise volumetric or piston-based dosing eliminates overfill and reduces product giveaway.

- Multi-head Configuration: multiple deposit heads work in parallel to multiply output without increasing cycle time.

- Programmable Recipes: quick-change recipes save setup time when switching SKUs or modifying portion sizes.

- Integration with Tempering and Cooling: inline tempering + rapid cooling shortens total process time and stabilizes crystal structure.

- Synchronized Conveyors and Indexing: accurate timing reduces rejects and ensures each deposit lands exactly on target.

Measurable Gains: Throughput, Yield, and Labor

To justify investment, manufacturers look at three measurable gains: throughput (pieces/hour), yield (usable product vs. raw input), and labor hours saved. Typical improvements observed after installing a depositor:

- Throughput increases by 2–10x compared to manual depositor stations, depending on head count and cycle time.

- Yield improves because metered dosing reduces over-portioning and rejects from inconsistent fills.

- Labor reduction is commonly 30–70% on the depositing station, freeing staff for quality control and packaging tasks.

Choosing the Right Depositor: Types Compared

Not all depositors deliver the same benefits; selection should match your product mix, line speed goals, and sanitation standards. The table below summarizes common types and practical fit.

| Type | Best for | Key advantage |

| Piston / Volumetric | High-viscosity centers, creams | Very accurate portion control |

| Pump / Gear | Thin chocolate, quick cycles | High-speed multi-head operation |

| Rotor / Dreh | Chocolate shells, continuous enrobing | Smooth deposition for shells |

Practical Considerations for Installation and Operation

Installing a depositor requires planning beyond the machine footprint. Key practical items include: line layout (feeding from temperer and to cooling tunnel), electrical supply and controls, sanitary access for cleaning, spare parts inventory, and staff training for recipe management. Pay attention to the following specifics:

- Hose and pump routing: minimize dead zones to avoid chocolate settling or crystallization inside lines.

- Temperature stability: depositor hopper insulation and gentle agitation prevent air entrainment and ensure consistent dosing.

- Clean-in-place (CIP) compatibility: hygienic designs reduce downtime for cleaning between flavor or allergen changes.

Maintenance, Downtime, and Long-Term ROI

Efficiency gains can be negated by poor maintenance. A robust preventive maintenance schedule typically includes seal replacement, piston skirt checks, motor bearing inspection, and calibration of metering volumes. Track the following KPIs:

- Mean time between failures (MTBF) for critical components

- Average changeover time between SKUs

- Net product giveaway rate (grams per piece)

When manufacturers compute ROI, they should include labor reallocation value, reduced giveaway, higher throughput, and less scrap. Many small-to-medium operations see payback within 12–36 months, depending on utilization.

Operational Tips to Maximize Efficiency

To extract the maximum efficiency from a depositor:

- Standardize recipes and store them in the machine for instant recall.

- Use multi-head balancing to match flow rates across all columns and avoid starved heads.

- Implement real-time weight sampling at regular intervals to detect drift early.

- Train operators on gentle hopper refilling techniques to prevent air pockets.

Conclusion: When a Depositor Truly Improves Efficiency

A chocolate depositor will improve production efficiency when it is matched to product needs, integrated into a well-designed line, and maintained with disciplined procedures. The biggest gains come from reduced portion variability, increased throughput, and labor redeployment. However, to realize those gains you must select the correct depositor type, design for sanitary and thermal control, and measure KPIs post-installation. When these conditions are met, depositors not only speed production but also raise product quality and predictability—turning a manual bottleneck into a scalable, controllable step.

English

English Español

Español