Overview: What “commercial use” really means

When buyers ask whether a chocolate making machine can be used for commercial production, they usually mean three things: consistent output at scale, food-safe operation, and profitable unit economics. Commercial production ranges from a small artisan shop producing a few dozen kilograms per week to a mid-sized factory producing tons per month. The suitability of a specific machine depends on product type (bonbons, bars, enrobed items), target daily throughput, and integration with downstream packaging.

Types of chocolate machines and their commercial roles

Not every machine is built for the same role. Understanding function and capacity is the first practical step toward deciding whether a machine fits a commercial workflow.

Key machine categories

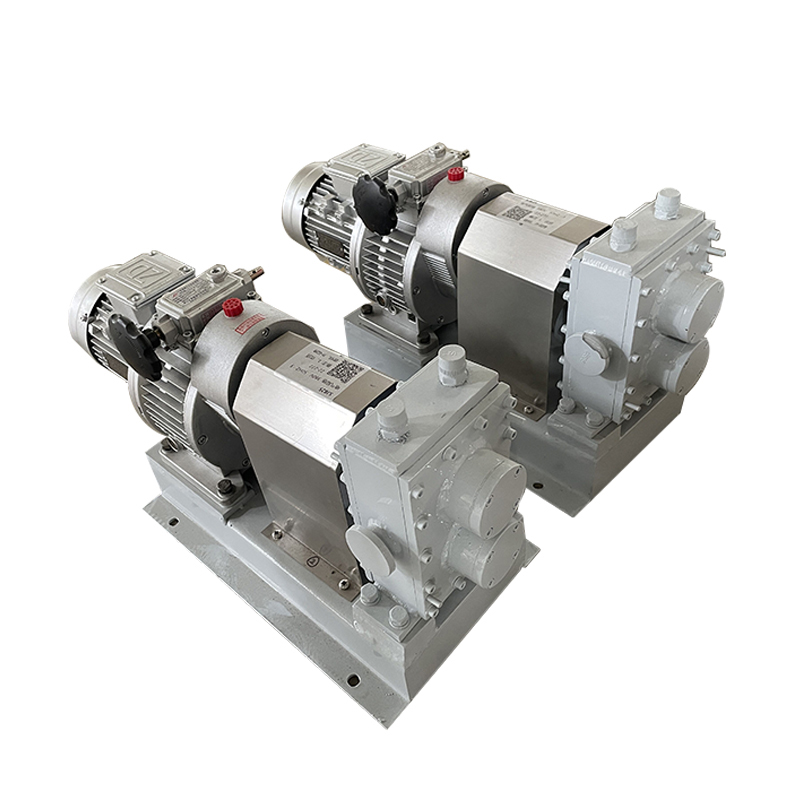

- Melters & tempering machines — control crystal formation and are essential for glossy, snap-ready chocolate.

- Conches & refiners — used for particle size and flavor development; larger units are needed for bulk production.

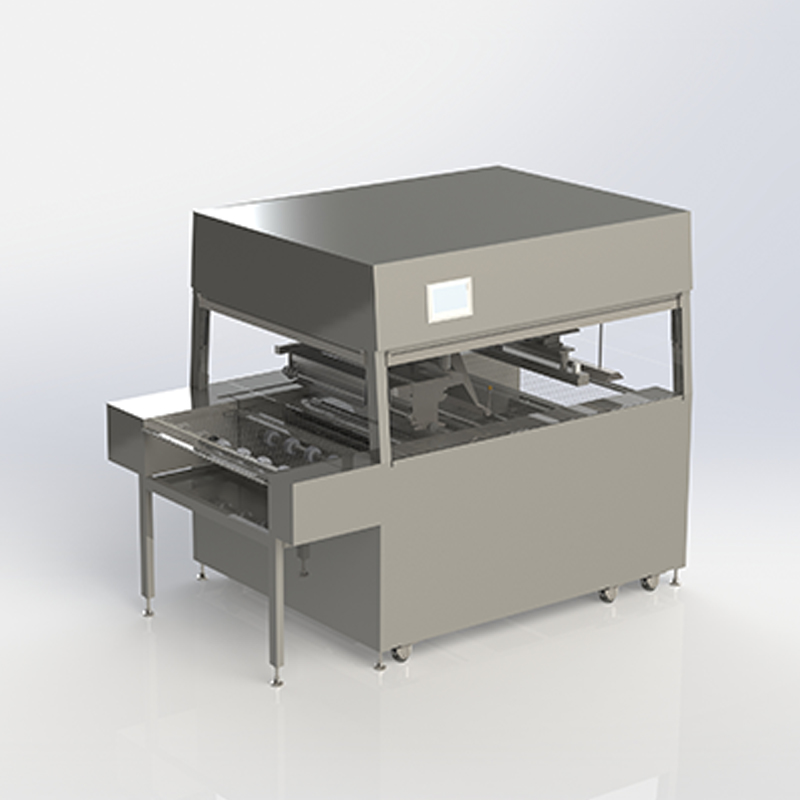

- Molding and depositor machines — fill molds or form bars quickly and consistently.

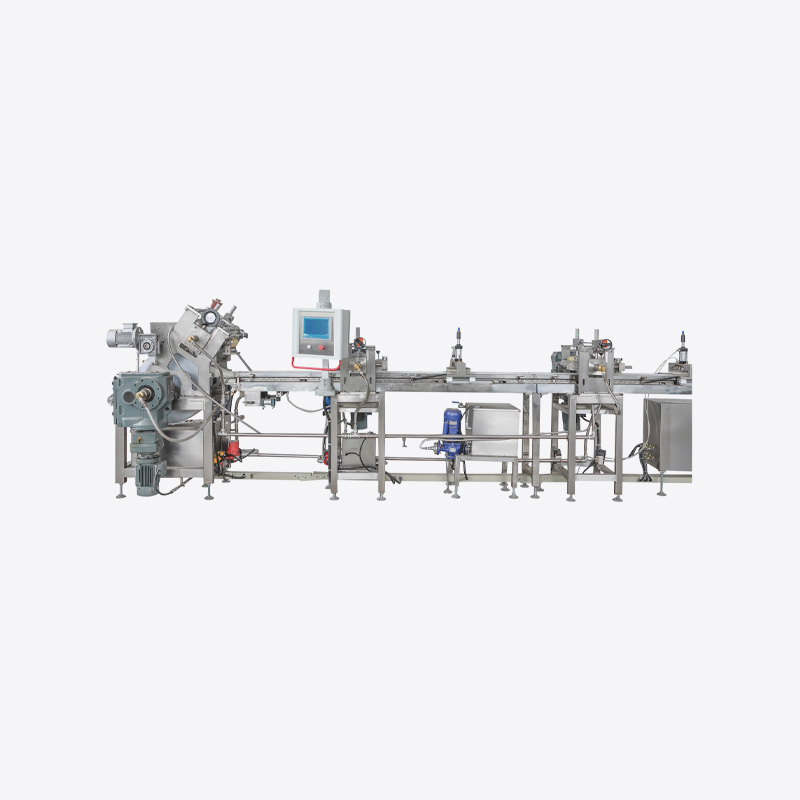

- Enrobing & cooling tunnels — used for coating centers and rapidly crystallizing chocolate at line speed.

- Packaging integrations — weighers, flow wrappers, and sealing machines for finished goods.

Practical capacity and throughput considerations

Commercial feasibility depends on realistic estimates of kilograms per hour and daily operating hours. A small tempering unit that handles 10–20 kg/hour may suit an artisan kitchen but won’t support high-volume retail demand. Evaluate machines by:

- Nominal throughput (kg/hour) under continuous operation.

- Duty cycle — many small machines overheat or require cooldowns when pushed continuously.

- Scalability — whether multiple identical units can be paralleled or a larger single unit is required.

Sanitation, food-safety and regulatory fit

Commercial production requires HACCP planning, sanitary design, and materials compliant with food contact regulations (e.g., stainless steel 304/316, food-grade seals). Machines intended for hobby use often lack the polish, weld quality, or accessible parts needed for proper cleaning and verification during audits.

Sanitary features to require

- Smooth welds and rounded internal corners to avoid chocolate traps.

- Removable parts for CIP (clean-in-place) or easy manual cleaning.

- Documented materials and certificates for regulatory compliance.

Quality control and product consistency

Commercial customers expect identical taste, texture, and appearance across batches. Look for machines that offer digital temperature control, programmable profiles, automated dosing, and consistent depositor accuracy. Manual tempering and hand-piping are sources of variation that erode brand reliability as volumes grow.

Economic assessment: cost, return, and lifecycle

A commercial decision is ultimately financial. Consider capital expense, operating costs (power, labor, maintenance), and yield losses (trimming, rejects). Small machines are cheaper but may increase labor costs and waste; industrial lines cost more up front but lower per-unit cost at scale.

| Machine Type | Typical Capacity | Commercial Fit |

| Small tempering unit | 10–25 kg/hr | Artisan / low volume |

| Continuous temperer/refiner | 100–500 kg/hr | Small factory / wholesale |

| Full enrobing line | 200–2000+ kg/hr | Large commercial / retail supply |

Operational tips for using a machine commercially

- Document standard operating procedures (SOPs) for each product and train staff on them.

- Implement batch tracking and raw material lot control for traceability.

- Schedule preventive maintenance and keep a spares kit for wear parts (seals, belts, thermocouples).

- Run pilot batches at expected line speed before committing to full production runs.

Common pitfalls and how to avoid them

Typical mistakes include underestimating labor to operate and clean machines, choosing hobby equipment for commercial use, and neglecting packaging speed. Avoid these by conducting a pilot scale test, verifying sanitary design, and calculating total cost per finished unit including waste and labor.

Conclusion: yes — with requirements

A chocolate making machine can be used for commercial production, but only if it matches the desired throughput, meets sanitary and regulatory standards, integrates with quality control and packaging, and makes sense economically. For small artisan brands, mid-range tempering and molding equipment can achieve commercial output. For wholesale or retail scale, invest in industrial lines designed for continuous operation. Always pilot, document, and budget for maintenance and compliance when scaling from hobby to commercial production.

English

English Español

Español