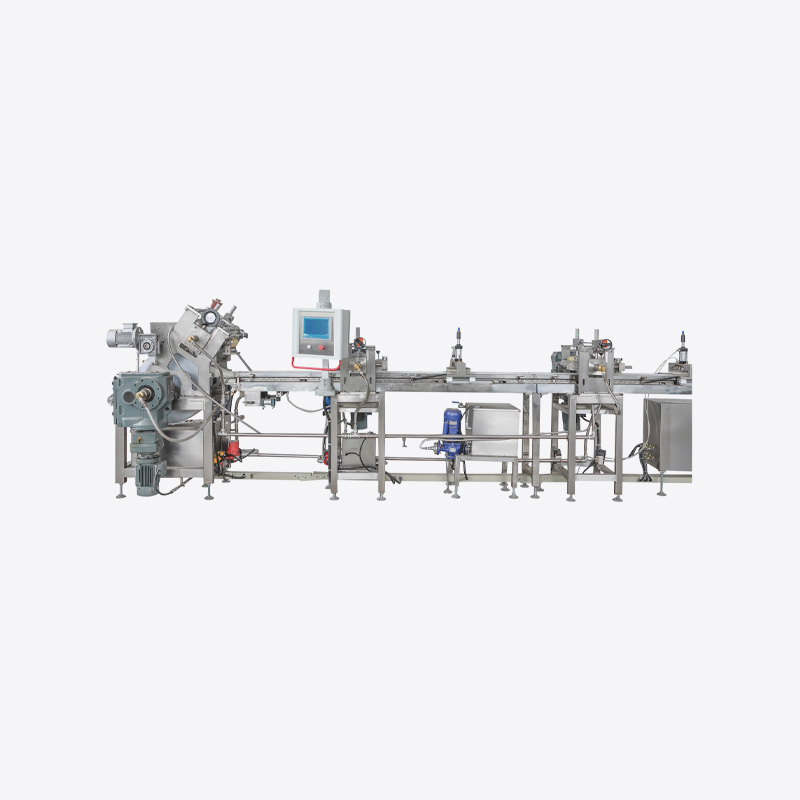

In modern confectionery manufacturing, efficiency and precision define how products move from concept to shelf. A well-designed Candy Bar Line brings together multiple processes that transform basic ingredients into consistent and appealing products. Whether a producer focuses on artisanal treats or large-scale confectionery, understanding how each part of the system functions helps ensure smooth operations and reliable results.

A complete production setup connects mixing, forming, enrobing, cooling, and packaging into a coordinated workflow. Each stage plays a role in achieving uniform texture, balanced flavor, and visually appealing presentation. By examining the workflow and comparing different production scales, manufacturers can align their equipment choices with long-term goals.

Key Components and Workflow of a Candy Bar Line

Mixing and Preparation

Every confection begins with ingredient blending. This initial phase ensures even distribution of components and a smooth base for shaping. Proper mixing influences texture, taste, and structural integrity. Depending on the recipe, various combinations of sugars, fats, and inclusions are prepared for the next phase.

Forming and Shaping

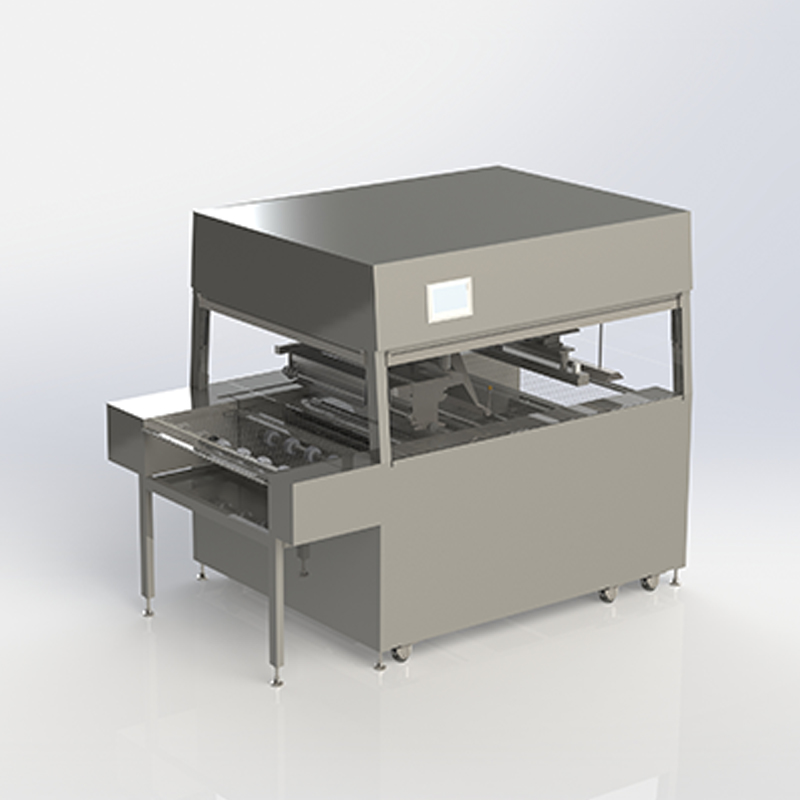

Once the mixture reaches the right consistency, it is formed into bars through extrusion, molding, or pressing. The forming section defines the final product’s size, shape, and density. Precision at this stage ensures uniformity across batches, which is important for both quality control and packaging compatibility.

Enrobing and Coating

Many candy bars are finished with coatings such as chocolate or glaze. The enrobing stage creates a balanced layer that enhances both taste and appearance. Controlling coating thickness and temperature contributes to a consistent finish, while maintaining proper flow prevents waste and irregular coverage.

Cooling and Stabilization

After coating, products move through a controlled cooling zone. This section helps coatings set properly, ensuring firmness and visual appeal. Gradual temperature transitions avoid surface flaws and preserve internal textures. The balance between cooling time and throughput determines production rhythm.

Wrapping and Packaging Integration

The final step brings automation and precision together. Packaging equipment is often synchronized with the upstream stages, allowing a continuous flow of finished products. Proper alignment between cooling and wrapping minimizes handling damage and maintains hygiene. Modern systems can accommodate various wrapping styles, supporting branding and shelf-life requirements.

Small-Batch vs Large-Scale Candy Bar Line Setups

Defining the Two Approaches

Small-batch operations usually emphasize flexibility, allowing frequent recipe changes and creative experimentation. Industrial-scale setups, by contrast, are built for consistent, continuous output and higher efficiency. Both serve unique business needs depending on production volume and product diversity.

Investment and Capacity Considerations

Smaller systems require less space and capital but involve higher labor interaction. Large installations call for greater initial investment yet deliver higher throughput over time. When deciding between the two, manufacturers often evaluate expected demand, available floor space, and utility infrastructure.

| Factor | Small-Batch Setup | Large-Scale Setup |

|---|---|---|

| Production Flexibility | High | Moderate |

| Space Requirement | Compact | Expansive |

| Labor Involvement | Manual & Semi-Automated | Highly Automated |

| Output Volume | Limited | Continuous |

| Upgrade Potential | Scalable | Long-Term Operation |

Suitability for Different Producers

Small-scale configurations are practical for startups, boutique confectioners, or seasonal producers exploring new flavors. Larger systems are better suited to established factories aiming for continuous, high-volume production. The choice depends not only on size but also on brand strategy and target market.

Operational and Staffing Factors

Labor availability, training requirements, and maintenance schedules all influence system selection. Smaller setups benefit from hands-on control and quick adjustments, while large-scale lines depend on automated consistency and technical oversight. Balancing human expertise with mechanical precision supports sustainable operation.

Transitioning to a Larger System

Growth in market demand or product range often leads to expansion. Upgrading to a larger setup involves evaluating process integration, floor layout, and automation compatibility. Planning ahead allows businesses to scale without disrupting existing production or compromising product quality.

Maintaining Process Harmony

Consistency in confectionery production depends on timing and temperature management. Each section of the line must be synchronized to maintain flow and prevent bottlenecks. A small variation in cooling speed or enrobing temperature can affect the final texture or coating finish. Continuous monitoring and preventive maintenance keep the system stable and efficient.

Energy management and hygiene are also important. Designing the line with easy-clean surfaces and efficient cooling systems supports long-term reliability while reducing downtime. Integration with digital control systems can further enhance traceability and operational insight.

Selecting and managing the right production system requires both technical understanding and practical planning. A Candy Bar Line represents more than machinery; it is a combination of timing, coordination, and craftsmanship. By understanding how each part interacts, and by choosing between small or large configurations wisely, confectionery manufacturers can achieve balance between flexibility and efficiency.

As consumer preferences evolve, adaptable equipment and thoughtful production strategies will continue to define successful confectionery operations—where creativity meets consistency, and every bar tells a story of precision and care.

English

English Español

Español