Why Production Planning Is Becoming a Business Decision in Confectionery

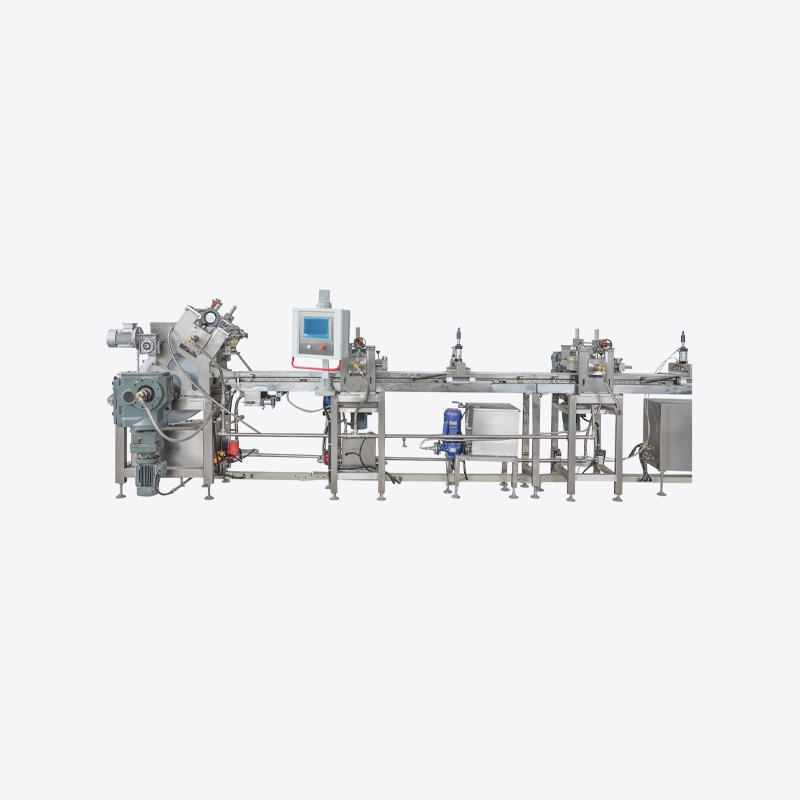

In recent years, the confectionery sector has shifted from a narrow focus on volume to a broader concern for consistent product quality and operational resilience. Many brands are treating production planning as part of their market strategy rather than a purely technical issue. This change is visible on factory floors, in procurement discussions, and in conversations between brand teams and equipment suppliers. Manufacturers increasingly refer to the Candy Bar Line as a central element of planning, reflecting how production setup influences market performance.

The bar confections segment has seen particular attention because the products are ubiquitous in retail and face strong visual competition on shelves. A well designed production setup can make the difference between meeting distribution expectations and struggling with returns, inconsistent batch results, or increased waste. For practical teams, the question is not only which machines to buy, but how to make daily operation predictable.

What Matters to Buyers Today

Real buyers—product managers, factory supervisors, and procurement leads—think in practical terms. When evaluating an equipment solution they look at daily operation: frequency of changeovers, ease of cleaning, consistency of portioning, and how the line handles different coatings or wrappers. These operational concerns often outweigh headline specifications.

Quality consistency is a frequent topic. Shoppers notice subtle differences in shape and surface finish; retailers have low tolerance for appearance variation. For many buyers the ability of a Candy Bar Line to maintain that consistency is a decisive factor during procurement. Beyond visible quality, buyers want systems that are easy to maintain and that include clear service pathways.

Flexibility is not a luxury; it is a requirement for many mid-size brands. Seasonal flavors, promotional runs, and co-packing orders demand systems that can switch between formats without long stoppages. The more adaptable a production arrangement, the faster a brand can try new products and respond to market feedback. In procurement meetings, teams increasingly ask about quick-change tooling and modular architectures rather than just maximum theoretical throughput.

Designing for Growth

A production solution that supports growth is designed with both current needs and future options in mind. In practical terms, the modularity of the Candy Bar Line often determines how quickly a factory can introduce new formats. Modularity also reduces the cost of future upgrades because it allows targeted additions rather than wholesale replacements.

Practical design choices include straightforward material paths, accessible service points, and compatible interfaces for control systems. These choices reduce the hidden costs of operation—time spent on adjustments, staff training, and troubleshooting. The right setup can reduce friction in day-to-day activity and free teams to focus on quality and innovation. For teams planning expansions, the emphasis should be on predictable integration rather than speculative performance claims.

Operational Improvements That Deliver Value

Small, steady changes in how a facility operates often produce the biggest gains. Optimizing the layout to match process flow, improving handover procedures between stages, and simplifying maintenance tasks are concrete steps teams can take.

Material handling is a common source of inefficiency. When ingredients and semi-finished items move through excessive distance or require repeated manual handling, errors and delays follow. A streamlined flow minimizes handling, reduces chance for contamination, and cuts cycle time.

Staff expertise is another significant factor. Skilled operators who understand the process and can make adjustments without disrupting output improve resilience. Investing in training, practical manuals, and collaborative troubleshooting sessions pays back through fewer quality incidents and more consistent output. In many factories, an extra hour of focused training yields better results than a costly equipment add-on.

Practical Tips for Efficiency

Start by mapping the actual flow rather than relying on ideal plans. When teams map real runs they can also evaluate whether the existing Candy Bar Line tooling supports quick changeovers or requires redesign. Walk the line during a full shift and note where materials pile up or where operators frequently intervene.

Use data to guide improvements. Track run times, reject rates, and downtime causes. Small dashboards or regular review meetings provide the discipline needed to make improvements that stick. When everyone sees the same numbers, it becomes easier to agree on priorities.

Work closely with equipment partners but own the specification. Suppliers bring know-how, yet the factory knows its constraints best. Clear specifications, realistic testing during factory acceptance tests, and staged commissioning reduce surprises during handover.

Balancing Cost and Capability

Cost discussions are inevitable, but they should include lifecycle thinking. The cheapest upfront option can become expensive through higher maintenance, more frequent part replacements, or inefficient operation. Conversely, high flexibility can come at a premium that is not necessary for every producer.

Decision-makers should weigh initial spend against expected product mix, projected growth, and the cost of downtime. Considerations like energy use, spare parts availability, and local technical support often sway the decision when two options offer similar capacity. A practical cost model includes average downtime cost per hour and spare part lead times, not just the purchase price.

Market Context and Practical Signals From the Floor

Across production sites, managers track a few simple signals that reveal whether the current setup is working. These include yield stability across shifts, frequency of tooling adjustments during runs, average time to clean and restart after a batch, and the proportion of product returns linked to surface or packaging defects. Tracking these indicators gives teams direct insight into where to prioritize improvements.

When a factory sees frequent short interruptions—minor jams, repeated reworks, or mismatched wrapper alignment—it points to process friction. Addressing those frictions often yields faster gains than chasing higher theoretical throughput. In practice, a small change in operator routines, or a clearer staging area, can improve effective output more than a larger equipment upgrade.

Operator Experience and Knowledge Transfer

Operators play a central role in turning machinery potential into everyday performance. A production line with high automation still depends on people who understand process variations and can react to unusual conditions. Encouraging operators to document ad hoc fixes, and to participate in improvement workshops, creates a culture where incremental changes stick.

A simple knowledge transfer routine—where evening shift operators brief the morning team on recent quirks—reduces repeated mistakes and speeds up troubleshooting. Many facilities find it useful to maintain a short, illustrated checklist for each production step; this helps new staff reach competence faster and reduces the chance of quality drift.

Tooling and Changeover Strategy

Tooling choices have an outsized impact on flexibility. Investing in quick-release fixtures, standardized connection points, and clear tool storage reduces changeover time. Some producers adopt a approach where all tools required for a format are kept together and checked before the change begins. This reduces search time and contributes to safer, more predictable transitions.

When planning changeovers, timing matters. Scheduling short format runs during less congested hours, or organizing promotional batches into blocks, reduces the need for repeated adjustments. The goal is to create predictable windows where the team can focus on a single objective, reducing error rates during complex transitions.

Testing and Pilot Runs

Pilots are valuable because they stress the production arrangement under realistic conditions. During pilot runs, use the same wrappers, fillings, and handling that will be used in the market—not simplified test materials. Real materials often expose problems that laboratory tests miss.

Collect detailed data during pilots: yield rates, defect types, and operator comments. These data points create a targeted action list and make acceptance criteria objective rather than subjective. The best pilots leave the team with clear next steps and a refined production checklist.

Maintenance and Spare Parts Management

A proactive spare parts policy reduces unexpected downtime. Identify items with short lead times and keep a stock that matches your run cadence. For slower-moving spare parts, invest in clear procurement plans so that replacements arrive before a failure becomes critical.

Routine maintenance should be scheduled around production requirements. Nightly or weekly checks that focus on wear-prone items prevent urgent breakdowns. A simple log of checks and results builds a useful history for planning part replacements and predicting potential failures.

Regulatory and Compliance Considerations

Food production is governed by hygiene and traceability standards. Integrating traceability data points into process control simplifies audits and reduces last-minute documentation work. Record keeping that aligns with production flow means quality teams spend less time combing through records when questions arise.

Begin acceptance criteria with regulatory checkpoints in mind. If a change in format requires additional hygiene steps, include these in the changeover plan. This avoids non-compliance during rapid product launches.

Operational Case Examples

Consider a mid-size brand that needed to introduce seasonal bars with different coatings and sizes. Their decision to invest in a flexible Candy Bar Line enabled smaller batch economics and reduced risk when testing the market. The company combined tooling changes with a focused operator training program and reduced promotional changeover time significantly.

Another manufacturer focused on reducing surface defects which were causing customer complaints. Improvements included adjusting forming stations, refining tempering profiles, and retraining operators on packing alignment. Over months, the defect rate fell and product returns decreased, improving retailer confidence and stabilizing orders.

A third site prioritized maintenance planning. By tracking component wear rates and stock levels, they avoided a series of emergency stops and cut unplanned downtime. The result was steadier throughput and improved line utilization without a large capital expense.

Buyer Checklist: Questions to Ask Before Purchasing

- What is the expected product mix and how often will formats change? Knowing realistic changeover frequency helps decide between fixed tooling and quick-change options.

- What are the primary causes of downtime in current operations? A supplier can often address specific failure modes if the buyer provides clear data.

- How available are critical spare parts and what are typical lead times? Local parts availability can be a bigger factor than theoretical lead time from the manufacturer.

- What training and documentation are included with delivery? Hands-on transfer of knowledge prevents missteps during the first months of operation.

- Can the supplier demonstrate similar installations and share non-sensitive outcomes? Seeing a comparable setup running under real conditions provides reassurance.

- What are the energy and utility requirements for the proposed solution? These ongoing costs affect total ownership and should be compared across options.

- What acceptance tests will be performed on site, and what metrics define a successful handover? Objective acceptance criteria protect both buyer and supplier during commissioning.

Measuring Success

Success is measured through a few clear metrics: yield consistency, reject rate, average downtime per week, and time taken for standard changeovers. Regular reviews of these indicators allow teams to prioritize improvements and justify further investments.

A Note on Communication

Clear communication during procurement, commissioning, and early operation is the single most important factor for success. Regularly scheduled check-ins, transparent reporting of issues, and a collaborative attitude between buyer and supplier shorten the time to stable operation.

Final Notes on Practical Leadership

Leadership that supports incremental change and listening to the floor encourages steady improvement. Rather than seeking a single transformative purchase, the most resilient sites balance equipment upgrades with process refinements, training, and stronger supplier relationships. This balanced approach delivers reliable outcomes and reduces the risk that a single decision will cause future bottlenecks.

Market Context and Practical Signals From the Floor

Across production sites, managers track a few simple signals that reveal whether the current setup is working. These include yield stability across shifts, frequency of tooling adjustments during runs, average time to clean and restart after a batch, and the proportion of product returns linked to surface or packaging defects. Tracking these indicators gives teams direct insight into where to prioritize improvements.

When a factory sees frequent short interruptions—minor jams, repeated reworks, or mismatched wrapper alignment—it points to process friction. Addressing those frictions often yields faster gains than chasing higher theoretical throughput. In practice, a small change in operator routines, or a clearer staging area, can improve effective output more than a larger equipment upgrade.

Bringing It Together in a Roadmap

Creating a practical roadmap helps teams move from assessment to action. Start with a short assessment of constraints, then pick three high-impact items for the next quarter. For many factories this might be: reduce changeover time, improve packaging alignment, and set up a simple downtime tracking dashboard.

Set clear metrics for each item and review progress at regular intervals. These small, measurable wins build momentum for larger investments. Over time, the factory becomes more predictable, launches are smoother, and teams spend less time firefighting.

Production Decisions That Support Market Goals

Production arrangements for bar confections are more than machinery; they are a core business tool. When teams treat operational design as part of strategy, the result is clearer: better product consistency, faster response to market changes, and a more controlled cost structure. Manufacturers and brands that build reliable, adaptable production setups—especially when the Candy Bar Line is planned as a strategic asset—strengthen their position in a crowded retail environment. The emphasis is on practical improvements—layout, data, training, and partner collaboration—rather than assuming a single piece of equipment will solve all challenges. With steady, informed steps, production becomes a platform for growth rather than an obstacle.

English

English Español

Español