How Does a Chocolate Depositor Improve Portion Control in Production Lines

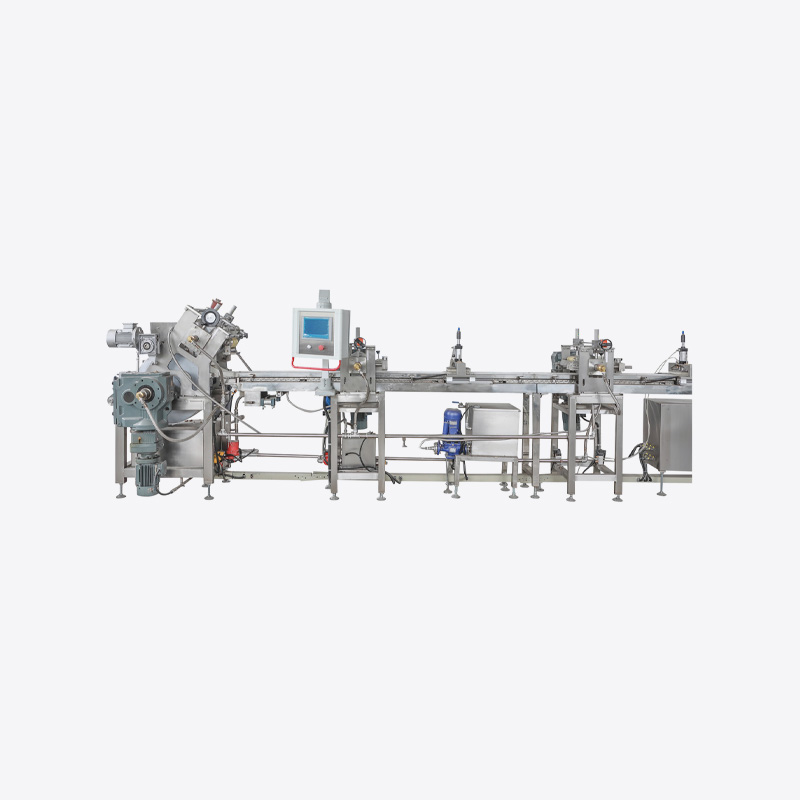

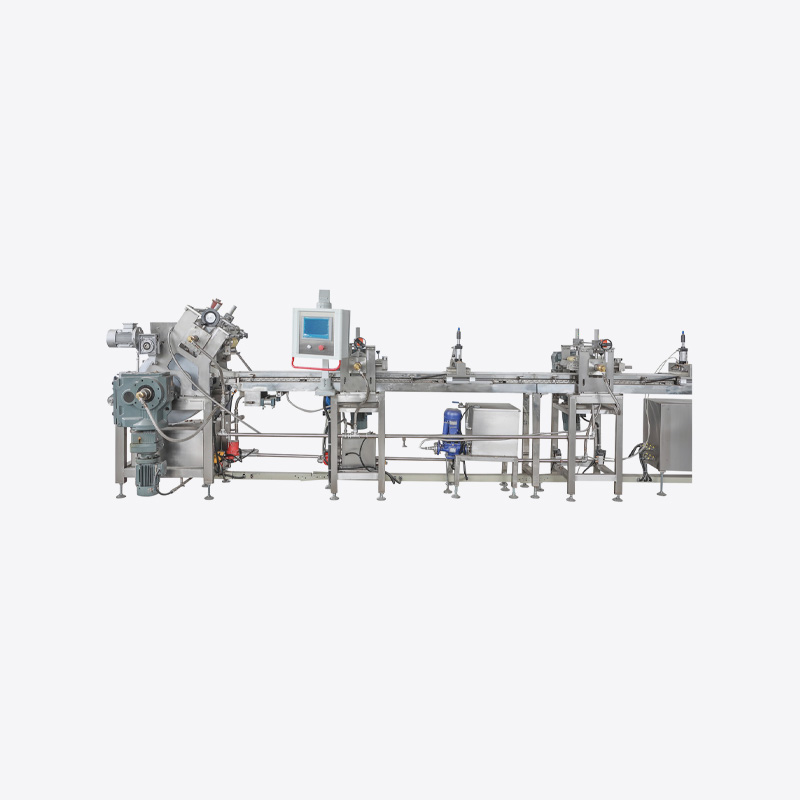

Chocolate Depositor devices play a direct role in achieving consistent portioning on confectionery production lines. By automating the dose-and-fill step, these systems remove much of the variability that comes with manual handling and simple mechanical dispensers, helping manufacturers meet weight tolerances, preserve recipe balance, and streamline downstream packing operations.

Why portion accuracy matters

Accurate dosing affects several business and quality outcomes at once:

- Material cost control: Small overfills add up across thousands of units.

- Customer expectations: Consumers notice inconsistent sizes or weights.

- Packaging and labeling: Fixed weight or count requirements depend on uniform units.

- Process efficiency: Predictable parts allow downstream machines — coolers, enrobers, wrappers — to run smoothly.

- Regulatory compliance: Food weight and labeling rules demand traceable consistency.

Given these stakes, moving from hand scooping or coarse volumetric dispensers to a controlled deposition system can produce measurable improvements.

How automated deposition achieves consistent fills

Automated deposition systems improve portion control through several complementary principles:

Precise metering

Modern systems meter material using timed valves, piston shots, gear pumps, or adjustable pumps. The mechanism selected provides a repeatable volume per cycle, so each cavity or product receives a nearly identical amount of chocolate or filling.

Stable process conditions

Viscosity and flow are highly temperature dependent. Equipment that maintains a controlled thermal profile at the hopper, transfer lines, and nozzle reduces variation in flow rate. Stable flow yields more repeatable fills.

Repeatable motion and positioning

Robust mechanical design ensures the nozzle contacts the mold or substrate at the same position and height every cycle. Consistent physical positioning prevents splatter, uneven layering, or partial fills.

Recipe memory and fast recall

Operators can store process settings for different SKUs: dosing volume, cycle speed, nozzle selection and temperature setpoints. Saved recipes eliminate guesswork during changeovers and restore portioning accuracy quickly.

Closed-loop feedback

Integrated sensors — weight cells, optical checks, or camera systems — can verify fills in real time. When deviations occur, the control system adjusts dosing parameters or triggers an alarm before a large number of off-spec units are produced.

Multi-stage deposition for complex items

For layered or filled confections, depositors can place base layers, pause for partial set, then deposit centers or tops with controlled volumes. This staged approach ensures each element receives the correct share of material.

Practical benefits on the line

Switching to an automated depositor typically delivers advantages across operations:

- Lower scrap and rework: Fewer underfilled or overfilled units reduce waste and reduce time spent on correction.

- Higher first-pass yield: More units meet specification on the first run, improving throughput.

- Improved predictability: Downstream equipment runs at steady speeds because product geometry and weight are consistent.

- Reduced operator dependence: Staff supervise process performance instead of continuously adjusting hand fills.

Implementation tips to maximize portion control

Success depends on both equipment and procedures. Consider these practical steps:

- Standardize start-up checks: Create a pre-run checklist to ensure repeatable starting conditions.

- Perform trial fills and statistical sampling: Before full production, run test fills, weigh samples, and adjust settings in small increments. Record these profiles for future reference.

- Select the right nozzle geometry: Nozzle shape and orifice size influence fill behavior; match nozzle selection to cavity shape and product viscosity.

- Maintain temperature uniformity: Use segmented heating zones and regular temperature checks to keep viscosity stable from hopper to tip.

- Adopt in-line inspection: Cameras or weight sensors can catch drift early; set acceptable tolerance bands and automated responses.

- Train operators on changeovers: Well-documented recipes and hands-on training speed transitions and prevent operator-introduced variation.

- Keep a spare parts plan: Critical items such as seals and tips wear; stocking key spares avoids extended downtime that can disrupt process stability.

Quick comparison: common challenges and depositor responses

| Common portioning issue | How a depositor addresses it |

|---|---|

| Human inconsistency | Automated metering removes operator variability |

| Viscosity drift | Controlled heating and closed-loop adjustments stabilize flow |

| Nozzle misplacement | Precision motion systems ensure repeatable positioning |

| Slow changeovers | Saved recipes and modular tooling reduce set-up time |

| Over/under filling | Real-time checks and feedback correct deviations quickly |

Design and hygiene considerations that affect control

Portion accuracy is also influenced by hygienic design. Smooth internal surfaces, minimal dead zones, and easy-to-disassemble nozzles reduce buildup that can alter flow. Choosing equipment designed for quick cleaning and validated sanitation routines helps sustain dosing performance over extended runs.

For confectionery operations seeking better control of portion size and appearance, an automated depositor is a practical investment. By combining precise metering, stable thermal management, repeatable motion, recipe memory, and feedback mechanisms, these systems reduce material loss, increase yield, and make downstream processes more predictable. Success requires selecting equipment that fits product characteristics and pairing it with disciplined start-up, monitoring, and maintenance routines — steps that turn dosing control into a reliable component of production quality.

What Factors Should Manufacturers Check Before Choosing a Chocolate Depositor

Selecting the right chocolate depositor is a strategic decision that affects yield, product quality, and line efficiency. Before committing to a purchase, operations teams should evaluate a set of practical criteria that reflect current needs and future plans. Below are the main areas to review, with actionable considerations to guide a confident choice.

Product compatibility and material handling

Not all formulations behave the same. Consider the types of chocolate and fillings you plan to run — for example, thin couverture, viscous ganache, or blends containing small solid inclusions. Ask whether the unit's hopper, feed and nozzle systems handle your materials without frequent intervention. Features that support gentle agitation, controlled recirculation, or a low-shear feed path are useful for maintaining homogenous mixes and preventing separation.

Dosing principle and control accuracy

Different dosing methods (timed valves, piston shots, gear pumps, volumetric screw systems) offer distinct advantages depending on application. Evaluate how precisely the system can dose small volumes and whether it offers fine adjustment. Machines with recipe memory and incremental control help operators reproduce settings across shifts. If in-line weighing or visual verification is available, that adds a layer of quality assurance.

Hygiene and cleanability

Food safety drives many equipment choices. Design elements that simplify sanitation — quick-release nozzles, smooth internal surfaces, and minimal dead zones — reduce cleaning time and contamination risk. Consider whether the depositor supports cleaning-in-place (CIP) or requires disassembly, and estimate the real-world downtime for sanitation between runs. Materials and surface finishes that meet regulatory guidance should be confirmed.

Throughput and cycle suitability

Match the depositor's realistic output capacity to your line plan. Assess cycle time under production conditions rather than ideal lab numbers. If your schedule includes long runs as well as small batch work, flexible speed control and modular head configurations help maintain portion accuracy across varying loads. Also consider how multiple machines or multiple heads would operate together in your production layout.

Changeover flexibility and tooling

Frequent product changes demand quick and reliable changeovers. Look for modular tooling, adjustable nozzle pitch, and straightforward mounting systems that let operators switch formats with minimal adjustment. Saved machine profiles that recall temperature, dosing and timing settings reduce setup time and lower the chance of human error during transitions.

Temperature and viscosity management

Accurate temperature control at hopper, transfer lines and nozzle tips is critical. The depositor should allow stable thermal management appropriate to your formulations. Segmented heating zones, local cooling options, or insulation where needed help preserve target viscosity and improve dosing repeatability.

Integration with upstream and downstream equipment

A depositor rarely stands alone. Verify mechanical and control compatibility with tempering systems, conveyors, indexing units and cooling tunnels. Communication interfaces ease synchronization and reduce manual handling. Consider how the depositor's footprint and connection points fit existing line geometry and service access areas.

Maintenance accessibility and spare parts

Evaluate how easy it is to reach wear parts, seals and drive elements for inspection or replacement. Machines that allow routine tasks to be performed without specialized tools shorten downtime. Check spare parts lead times from the supplier and the availability of local service, as these factors influence total uptime.

Operator ergonomics and control usability

Intuitive human-machine interfaces reduce training time and operational mistakes. Touchscreens with clear recipe management, simple alarms and graphical guidance help plant staff run the depositor consistently. Ergonomic placement of hoppers, valves and maintenance points also contributes to safe and efficient daily routines.

Safety features and compliance

Confirm that guarding, interlocks and safe-access design meet local safety regulations. Safety is not just about compliance — it also helps avoid unplanned stops and supports steady production by protecting both personnel and equipment.

Supplier support and documentation

A responsive supplier network matters. Look for vendors offering installation assistance, start-up tuning, operator training and diagnostic support. Clear documentation — wiring diagrams, parts lists, sanitation procedures and validated recipes — speeds adoption and supports traceability.

Total cost of ownership

Compare options on more than purchase price. Estimate lifetime costs including energy use, cleaning time, spare parts turnover, service visits and material waste. A unit that reduces scrap or shortens changeovers can yield savings that outweigh a higher initial investment.

Short comparison table

| Consideration | Practical question to ask |

|---|---|

| Material handling | Will the feed path suit viscous or particulate mixes? |

| Dosing control | Are recipes and fine adjustments supported? |

| Cleanability | Can sanitary areas be accessed quickly for cleaning? |

| Throughput | Does realistic cycle time meet shift output? |

| Integration | Can the unit communicate with existing PLC or conveyors? |

| Support | What warranty, training and spare parts are included? |

Choosing the appropriate depositor means balancing immediate production goals against longer term operational needs. Prioritize compatibility with your formulations, ease of sanitation, and reliable supplier support. When a unit fits both your products and your procedures, it becomes a predictable element of the line rather than a source of recurring adjustments. That predictability helps sustain quality, reduce waste, and keep schedules on track.

When Should Producers Upgrade to a More Automated Chocolate Depositor

As production environments evolve, many confectionery producers reach a point where existing equipment no longer matches operational demands. Moving toward a more automated chocolate depositor is not only about adding technology. It is about responding to real changes in volume, labor structure, quality expectations, and market pressure. Understanding the right timing helps manufacturers invest with purpose rather than react to problems after they appear.

Growing order volumes strain manual processes

One of the clearest signals for an upgrade is sustained growth in order volume. When daily output increases but equipment remains unchanged, operators often compensate with longer shifts, additional labor, or frequent adjustments. Over time, this approach introduces fatigue, inconsistency, and higher operating costs. Automated depositing systems help stabilize production flow by maintaining consistent output across extended runs without relying on constant manual input.

Increasing product variety requires faster changeovers

Modern confectionery lines rarely produce a single item all year. Seasonal shapes, private label requests, and limited editions are now common. Manual or semi-automatic systems often struggle with frequent changeovers, leading to downtime and setup errors. More automated solutions typically support recipe storage, quick nozzle replacement, and guided setup steps. When product variety becomes a routine part of the schedule, automation can reduce lost time between runs.

Labor availability becomes unpredictable

Many producers face challenges recruiting and retaining skilled operators. Training new staff to manually control portioning or timing takes time and introduces variability. Automation shifts the focus from manual handling to supervision and monitoring. When labor turnover rises or staffing becomes less predictable, upgrading equipment can help maintain stable output with fewer experienced hands required on each shift.

Quality consistency expectations rise

Retailers and brand owners increasingly expect uniform appearance and portion control across every batch. Small variations that once passed inspection may now result in rejected shipments or rework. Automated depositing systems support repeatable motion, timing, and dosing logic, helping producers meet tighter quality standards. If inspection rates or customer feedback indicate rising inconsistency, it may be time to consider automation.

Waste reduction becomes a priority

Ingredient costs and sustainability goals push manufacturers to reduce scrap and reprocessing. Manual systems can generate excess drips, overfilled cavities, or start-up losses that accumulate over time. Automated solutions often include controlled start and stop sequences, recovery features, and stable flow management. When waste tracking shows a persistent upward trend, upgrading equipment can support more efficient material use.

Line integration plans expand

As plants modernize, depositing equipment must communicate with upstream and downstream systems such as tempering units, conveyors, and cooling tunnels. Manual controls limit synchronization and slow down the entire line. Automated depositors with digital interfaces allow coordinated speed changes and smoother transitions. If expansion plans include higher levels of line integration, automation becomes a practical requirement rather than an option.

Compliance and documentation requirements increase

Food safety audits and traceability standards continue to evolve. Automated systems can record production data, recipe settings, and operational events. This information supports compliance reviews and internal process improvement. When documentation demands become more complex, relying solely on manual records may no longer be efficient or reliable.

Maintenance patterns indicate limits

Frequent stoppages, adjustments, or unplanned maintenance can signal that existing equipment is operating beyond its intended range. While maintenance can extend service life, it cannot always compensate for design limitations. Automated depositors often include diagnostics and predictive alerts that help maintenance teams plan interventions more effectively. When maintenance costs rise without improving stability, an upgrade may offer a more sustainable path.

Market positioning shifts toward scale

Producers supplying larger retail chains or export markets often face stricter delivery schedules and higher volume commitments. Manual systems may handle pilot runs well but struggle to support contract manufacturing or long-term supply agreements. Automation supports scalable growth, allowing producers to respond confidently to new opportunities without compromising reliability.

Financial planning aligns with long-term efficiency

Upgrading to automated equipment is a capital decision, but timing it correctly improves return on investment. When calculations show that labor costs, waste, downtime, and quality losses are approaching the cost of automation, the business case becomes clearer. Rather than waiting for a breakdown or missed delivery, proactive investment helps control expenses over the long term.

Signs that indicate it may be time to upgrade

- Production schedules regularly exceed planned shift hours

- Changeovers cause frequent delays or setup errors

- Skilled labor is difficult to retain or replace

- Quality checks reveal recurring variation issues

- Material waste is difficult to control consistently

- Expansion plans require closer line synchronization

Upgrading to a more automated chocolate depositor is rarely driven by a single issue. It is usually the result of several pressures building at the same time. Producers who monitor operational data, labor trends, and market expectations are better positioned to choose the right moment. Automation, when introduced at the appropriate stage, supports steady growth, controlled costs, and reliable quality without disrupting existing workflows.

English

English Español

Español